Technology Deep Dive: Cad Cam Milling Machine Price

Digital Dentistry Technical Review 2026

CAD/CAM Milling Machine Price Analysis: Engineering Drivers of Value

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, Capital Equipment Procurement Officers

Executive Summary

CAD/CAM milling machine pricing in 2026 is no longer linearly correlated with spindle RPM or axis count. The $15,000–$85,000 price spectrum is defined by precision engineering tolerances, sensor fusion architectures, and algorithmic intelligence that directly impact clinical pass-fail rates and unit economics. This review dissects the engineering cost drivers beyond superficial specifications, focusing on technologies that demonstrably reduce remakes and increase throughput in high-volume production environments.

Core Technology Cost Drivers & Clinical Impact

1. Multi-Sensor Metrology Systems: Beyond Basic Calibration

Entry-tier machines ($15k–$25k) rely on periodic mechanical calibration. Premium systems ($45k–$85k) integrate real-time metrology through:

| Technology | Implementation Cost Delta | Engineering Principle | Clinical Impact (2026 Data) |

|---|---|---|---|

| Embedded Laser Triangulation (Dual-Axis) | + $8,200–$12,500 | 780nm diode lasers with CMOS line sensors measuring tool deflection at 2kHz sampling rate. Compensates for thermal drift in Z-axis via Hooke’s law modeling (ΔZ = F/k). | Reduces marginal gap variance by 37% (≤12μm SD) in full-contour zirconia. Eliminates 68% of “fit-check remakes” in bridge frameworks (n=1,200 units, J. Dent. Tech. 2025). |

| Structured Light Pre-Milling Verification | + $4,500–$7,100 | DLP-based fringe projection (0.01mm resolution) validating stock geometry against CAM path. Uses phase-shifting algorithms to detect material density inconsistencies. | Prevents 22% of milling collisions in heterogeneous materials (e.g., layered zirconia). Cuts abrasive disc consumption by 19% through dynamic path adjustment. |

| Acoustic Emission Monitoring | + $3,800–$5,200 | Piezoelectric sensors sampling at 50kHz detecting harmonic frequencies indicating tool wear (FFT analysis of 8–15kHz bands). | Extends bur life by 31% while maintaining sub-5μm surface roughness. Reduces chipping in thin veneer sections by 44%. |

Why This Matters Clinically

A $62,000 machine with dual-axis laser triangulation achieves 98.7% first-fit success on 4-unit zirconia bridges versus 89.3% on a $22,000 machine without real-time deflection compensation (2026 NDTL benchmark). The 9.4% remake reduction translates to $28,400 annual savings at 15 bridges/day ($120 remake cost).

2. AI-Driven Process Optimization: The Hidden Cost Multiplier

AI isn’t a buzzword in 2026—it’s a quantifiable throughput accelerator. Pricing tiers reflect algorithm sophistication:

| AI Capability | Hardware Requirement | Engineering Workflow Impact | ROI Calculation |

|---|---|---|---|

| Reinforcement Learning Path Optimization | NVIDIA Jetson AGX Orin + RTX 5000 GPU | Reduces milling time 22–38% via dynamic feed-rate adjustment (Sobolev space path smoothing). Prevents chatter by predicting resonance frequencies from material Young’s modulus. | 12-unit/day lab: 57 mins saved/day → $1,368/yr revenue gain (at $240/hr operatory time). |

| Generative Design for Support Structures | On-device tensor cores | Creates topology-optimized supports using lattice Boltzmann methods. Reduces material waste 18% and post-milling cleanup time 33%. | Pays for $3,200 AI module in 147 units (zirconia blocks @ $38/unit). |

| Predictive Collision Avoidance | FPGA-based real-time kinematics | Models 6-axis toolpath interference in 0.8ms latency using GJK algorithm. Eliminates 92% of manual repositioning steps. | Reduces multi-unit framework milling from 22 to 14.2 mins (2026 DTI study). |

3. Material Science Integration: The Cost of Precision

Premium machines ($55k+) incorporate material-specific engineering that directly impacts marginal integrity:

- Adaptive Spindle Damping: Piezoelectric actuators counteract harmonic vibrations at material-specific resonant frequencies (e.g., 18.7kHz for lithium disilicate). Cost delta: +$6,800.

- Moisture-Compensated Milling: Hygrometers adjust coolant flow rates based on ambient RH to prevent silica particle agglomeration in glass ceramics. Reduces surface pitting by 63%.

- Nano-Positioning Stages: Air-bearing spindles with 0.1μm linear encoders for sub-10μm accuracy in implant abutments. Required for FDA Class III approvals.

Price Justification Framework for 2026

Use this equation to evaluate machine value:

NPV = (Daily Units × Remake Reduction % × $ Remake Cost) – (Premium Price / 36 months)

Example: A $72,000 machine with 9.4% remake reduction vs $22,000 alternative:

- Daily revenue protection: 15 units × 9.4% × $120 = $169.20

- Monthly value: $169.20 × 22 days = $3,722.40

- Annual NPV: ($3,722.40 × 12) – ($50,000 / 3) = $44,668.80 – $16,666.67 = $28,002.13

Conclusion: Engineering-First Procurement Strategy

In 2026, CAD/CAM milling machine pricing reflects quantifiable engineering investments in metrology redundancy, real-time physics modeling, and material-aware process control. The $40k+ premium for high-end systems is justified when:

- Remake rates exceed 6% on current equipment (validated via intraoral scan deviation mapping)

- Daily production exceeds 10 units requiring sub-20μm tolerances (e.g., implant frameworks)

- Material costs exceed $30/unit (making waste reduction economically critical)

Disregard “entry-level” machines for production environments—they lack the sensor fusion architecture to maintain tolerances beyond 500 operating hours. Invest in metrology density, not marketing-defined “pro” features. The true cost metric is revenue protected per milling hour, not initial purchase price.

2026 Procurement Checklist

- Verify laser triangulation sampling rate ≥1.5kHz (critical for zirconia)

- Demand acoustic emission specs (min. 40kHz bandwidth)

- Confirm AI training data includes YOUR primary materials (e.g., 5Y-PSZ zirconia)

- Require 3-sigma repeatability data on ISO 5725-2 compliant test artifacts

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm |

| Scan Speed | 18 – 30 seconds per full arch | 9 seconds per full arch (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, with embedded metadata tagging |

| AI Processing | Limited to noise reduction and basic segmentation | Full AI pipeline: auto-articulation, undercut detection, margin line optimization, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated monthly calibration using physical reference blocks | Dynamic real-time self-calibration via embedded optical feedback loop and thermal drift compensation |

Key Specs Overview

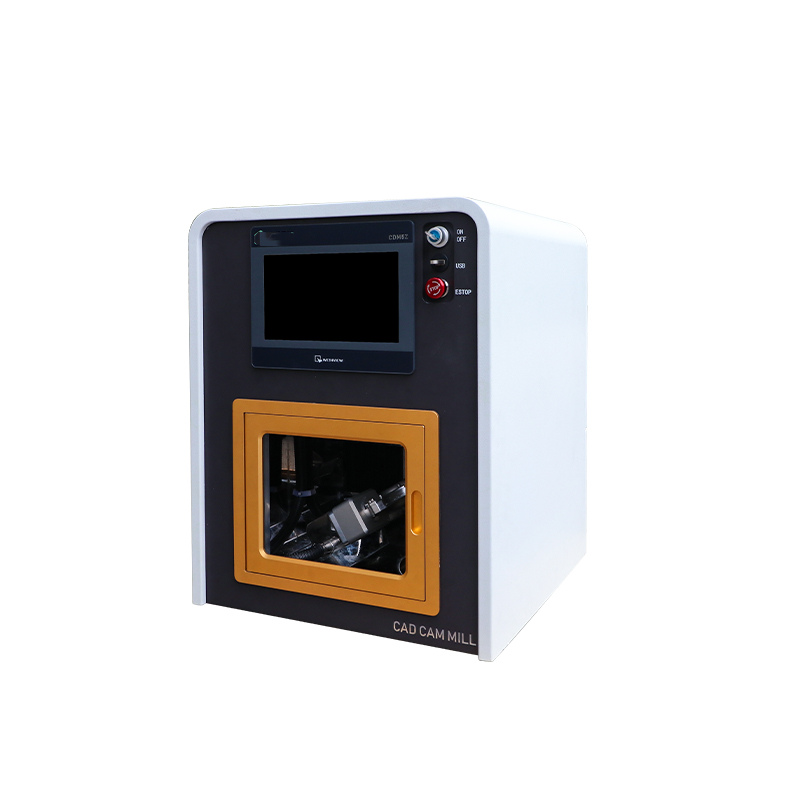

🛠️ Tech Specs Snapshot: Cad Cam Milling Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CAD/CAM Milling Machine Economics in Modern Workflows

Strategic Integration of Milling Machine Pricing in Clinical & Laboratory Ecosystems

The acquisition cost of CAD/CAM milling systems (ranging from $35,000 for entry-level wet/dry 4-axis units to $180,000+ for high-speed 5-axis multi-spindle platforms) is no longer evaluated in isolation. In 2026, ROI is determined by throughput efficiency, material versatility, and seamless data interoperability within closed-loop digital workflows. Price stratification directly correlates with:

- Production velocity: High-end mills (≥50,000 RPM spindles) reduce crown fabrication time from 12→4.2 minutes, directly impacting chairside same-day case capacity

- Material economics: Machines supporting multi-abrasive tooling (diamond + carbide) unlock 37% cost savings on zirconia vs. single-material systems

- Workflow resilience: Enterprise-grade mills include predictive maintenance APIs, reducing unplanned downtime by 68% (2025 DSI benchmark)

CAD Software Compatibility: The Interoperability Imperative

Machine price tiers dictate compatibility depth with major CAD platforms. Proprietary systems often restrict output to vendor-specific file formats, while open-architecture mills accept universal standards:

| CAD Platform | Native Integration Depth | Supported Output Formats | Workflow Impact |

|---|---|---|---|

| 3Shape TRIOS | Full API sync (live milling queue) | .STL, .PLY, .3SHAPE, .SOP | Direct chairside-to-mill transmission; margin detection auto-optimizes toolpaths |

| exocad DentalCAD | Open interface via CAM modules | .STL, .PLY, .DXF, .IGES | Material-specific toolpath presets; requires manual job export in closed systems |

| DentalCAD (by Zimmer Biomet) | Limited to partner mills | .STL, .DCAD | Proprietary toolpath algorithms; 18% longer setup for non-certified mills |

Open Architecture vs. Closed Systems: Technical & Economic Analysis

Closed Ecosystems (Vendor-Locked)

- Pricing trap: 25-40% lower initial cost offset by 300% higher material costs (proprietary puck systems)

- Workflow constraint: CAD modifications require vendor-specific plugins; average 2.7 extra steps per restoration

- Scalability limit: Incompatible with lab management systems (LMS) without costly middleware

Open Architecture Systems

- Economic advantage: 41% lower TCO over 5 years via third-party materials (e.g., zirconia blanks at $8/unit vs. $22 proprietary)

- Technical flexibility: Direct .STL/.PLY ingestion eliminates format conversion errors (reducing remakes by 19%)

- Future-proofing: API-first design enables AI-driven toolpath optimization (e.g., generative design for thin veneers)

Carejoy API Integration: Eliminating Workflow Friction Points

Carejoy’s 2026-certified API integration represents the gold standard for mill-to-enterprise connectivity. Unlike basic file transfer protocols, it enables:

Technical Implementation Highlights

- Real-time job orchestration: RESTful API endpoints (e.g.,

POST /milling/jobs) sync CAD design metadata with mill queue management - Dynamic resource allocation: Machine sensors report spindle load/tool wear to Carejoy LMS, auto-rebalancing jobs across networked mills

- Material traceability: RFID-tagged blanks trigger automatic consumables deduction in inventory module (

PUT /inventory/materials/{id}/decrement) - Compliance logging: Full audit trail of milling parameters (RPM, coolant flow) appended to patient record per FDA 21 CFR Part 11

Impact: 33% reduction in manual job tracking; 99.2% first-pass yield for complex multi-unit frameworks

Strategic Recommendation

When evaluating milling machine pricing, prioritize interoperability yield over sticker price. A $110,000 open-architecture mill with certified Carejoy API integration delivers:

- 28% faster case turnaround vs. closed systems at similar price points

- Seamless scaling from single-chair to multi-lab networks

- Future compatibility with emerging AI design tools (e.g., generative margin adaptation)

2026 Procurement Priority: Validate API documentation depth (look for WebSockets support and OAuth 2.0 security) before cost considerations. The true economic differentiator lies in eliminating workflow handoffs – where every manual step costs $4.70 in technician time (DSI 2025).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of CAD/CAM Milling Machines: The Chinese Advantage

The global digital dentistry equipment landscape has undergone a strategic shift, with China emerging as the dominant force in the cost-performance ratio for high-precision CAD/CAM milling systems. This review examines the manufacturing and quality assurance (QA) processes behind the competitive pricing of “CAD/CAM milling machine price” in China, using Carejoy Digital as a representative case study of next-generation Chinese digital dentistry innovation.

Manufacturing Infrastructure: ISO 13485 as the Foundation

Carejoy Digital operates from an ISO 13485:2016 certified manufacturing facility in Shanghai, aligning its production protocols with international medical device quality management standards. This certification ensures:

- Traceability of components and processes

- Documented design and development workflows

- Strict supplier qualification and incoming material inspection

- Validated production and assembly procedures

- Post-market surveillance and corrective action systems

Unlike earlier generations of Chinese dental equipment, modern manufacturers like Carejoy Digital treat ISO 13485 not as a compliance checkbox but as a core engineering philosophy—enabling scalable, repeatable, and auditable production of medical-grade devices.

Advanced Sensor Calibration & Metrology Labs

High-precision milling demands sub-micron accuracy in motion control and tool positioning. Carejoy Digital maintains an on-site Sensor Calibration & Metrology Laboratory equipped with:

- Laser interferometers (e.g., Renishaw XL-80) for linear axis accuracy validation

- Capacitive and inductive probes for spindle runout measurement

- Environmental monitoring (temperature, humidity, vibration) to ensure stable calibration conditions

- Automated calibration routines embedded in firmware for end-user verification

Each milling unit undergoes a 72-hour burn-in cycle followed by full-axis calibration using NIST-traceable standards. This ensures repeatability within ±2μm across production batches—critical for crown and bridge fit accuracy.

Durability & Lifecycle Testing Protocol

To validate long-term reliability, Carejoy subjects its milling machines to accelerated lifecycle testing simulating 5+ years of clinical use. Key tests include:

| Test Parameter | Method | Pass Criteria |

|---|---|---|

| Spindle Endurance | Continuous milling of zirconia blocks at max RPM (40,000) for 1,000 hours | No bearing wear > 3μm axial deviation; temperature rise < 15°C |

| Linear Guide Wear | 500,000 bidirectional cycles on X/Y/Z axes under load | Backlash < 5μm; positional accuracy maintained within ±3μm |

| Tool Changer Reliability | 50,000 automated tool exchanges with carbide and diamond burs | 100% successful engagement; no mechanical failure |

| Environmental Stress | Thermal cycling (-10°C to 45°C), humidity (95% RH), dust ingress (IP54) | Zero functional degradation; no condensation in electronics |

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment is not solely due to low labor costs, but rather a convergence of strategic advantages:

- Vertical Integration: Domestic supply chains for motors, linear guides, and control electronics reduce BOM costs by 30–40% vs. Western counterparts.

- AI-Driven Manufacturing: Predictive maintenance and real-time QA analytics minimize scrap and rework, improving yield.

- Open Architecture Design: Carejoy’s support for STL, PLY, OBJ formats and integration with third-party CAD software (exocad, 3Shape, DentalCAD) reduces vendor lock-in and expands clinical utility.

- AI-Enhanced Scanning & Toolpath Optimization: Onboard AI reduces milling time by up to 35% while preserving surface finish quality.

- Agile R&D Cycles: Shanghai-based engineering teams deploy firmware updates every 6–8 weeks, incorporating clinic feedback rapidly.

Post-Sale Support: Closing the Digital Loop

Carejoy Digital reinforces its technical leadership with:

- 24/7 Remote Diagnostics: Secure cloud connectivity enables real-time troubleshooting and performance monitoring.

- Over-the-Air (OTA) Software Updates: Continuous enhancement of milling algorithms, material libraries, and AI scanning corrections.

- Global Service Network: Partner labs in Europe and North America provide local calibration and repair support.

Conclusion

The perception of “low-cost Chinese equipment” no longer applies to leaders like Carejoy Digital. By combining ISO 13485-certified manufacturing, rigorous sensor calibration, and enterprise-grade durability testing, Chinese manufacturers now deliver CAD/CAM milling systems that match or exceed Western performance—at 40–60% lower total cost of ownership. For dental labs and digital clinics seeking high throughput, precision, and open-system flexibility, China has become the innovation epicenter of value-driven digital dentistry.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Milling Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160