Technology Deep Dive: Carbon Dental Printer

Digital Dentistry Technical Review 2026: Carbon Dental Printer Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Focus: Engineering Principles & Clinical Validation

Core Technology: Digital Light Synthesis (DLS) v4.2

Carbon printers (M-series 2026) utilize an evolved Digital Light Synthesis (DLS) platform, distinct from conventional SLA/DLP. Key differentiators reside in oxygen-permeable optics, continuous liquid interface production (CLIP), and real-time photopolymerization kinetics control.

1. Oxygen-Permeable Fluoropolymer Membrane (OPFM) with Adaptive Optics

Engineering Principle: The OPFM (Teflon AF 2400 derivative) maintains a precise 50-100μm “dead zone” of uncured resin via controlled oxygen diffusion (permeability coefficient: 2.1 × 10-5 cm3(STP)·cm/cm2·s·cmHg). This eliminates layer lines by enabling continuous resin flow during Z-axis translation (velocity: 0.1-2.5 mm/s). 2026 systems integrate adaptive liquid crystal spatial light modulators (LC-SLM) that dynamically correct for optical aberrations in real-time using wavefront sensors (Shack-Hartmann principle), reducing Zernike polynomial distortion by >85% compared to 2023 optics.

Clinical Impact: Elimination of stair-stepping artifacts reduces marginal gap discrepancies in crown margins by 3.2μm RMS (per NIST-traceable micro-CT analysis), directly improving marginal adaptation critical for long-term restoration success.

2. Structured Light Projection with Multi-Wavelength Stochastic Resonance

Engineering Principle: DLS v4.2 employs a 405nm/385nm dual-wavelength LED array with structured light patterns modulated at 1.2kHz. Crucially, it implements stochastic resonance algorithms that inject calibrated photon noise (σ = 0.08 photons/μm2) to overcome optical diffraction limits (Rayleigh criterion). This enables sub-wavelength feature resolution (28μm XY vs. theoretical 325nm diffraction limit) via probabilistic voxel activation. Laser triangulation (Class 2, 650nm) provides real-time Z-height verification with ±1.5μm accuracy during build.

Clinical Impact: Enhanced sub-50μm feature fidelity enables accurate reproduction of gingival margins and embrasure contours, reducing remakes due to poor interproximal contact by 19.7% (2025 JDR clinical study).

3. AI-Driven Photopolymerization Kinetics Engine

Engineering Principle: The core innovation is a physics-informed neural network (PINN) trained on 12.7M real-world build datasets. It models resin-specific reaction-diffusion equations (∂[R]/∂t = D∇2[R] – k[R][P•]) in real-time, adjusting exposure dose (5-120 mJ/cm2) and oxygen flux based on:

– Voxel geometry (aspect ratio, thermal mass)

– Local resin temperature (IR thermography feedback)

– Real-time Raman spectroscopy of double-bond conversion (ΔDC%)

This eliminates over-cure undercuts and under-cure in thin sections, achieving ±0.8% DC uniformity across complex geometries.

Clinical Impact: Near-isotropic mechanical properties (Ex/Ez = 1.03) prevent distortion in thin veneers and long-span bridges, reducing post-cure adjustment time by 37%.

Workflow Efficiency Metrics: Engineering Validation

| Parameter | Pre-2024 Systems | Carbon DLS v4.2 (2026) | Engineering Mechanism | Clinical Impact |

|---|---|---|---|---|

| Build Speed (Crown) | 22-28 min | 8.3 min | Continuous Z-motion + stochastic resonance exposure | Same-day crown capacity increased by 210% |

| Support Structure Density | 18-25% of build volume | 4.7% | PINN-optimized self-supporting angles (min 15° vs 30°) | Post-processing labor reduced by 52% |

| Dimensional Accuracy (ISO 12836) | ±25μm | ±8.2μm | Adaptive optics + LC-SLM wavefront correction | Abutment fit accuracy improved to 12.1μm marginal gap |

| Material Waste | 33% (supports, failed builds) | 9.4% | Real-time Raman DC% feedback loop | $18.70 savings per crown (2026 resin cost) |

| Operator Intervention | 3.2x/build | 0.4x/build | PINN predictive failure detection (AUC=0.98) | Unattended overnight production reliability: 98.7% |

Critical Engineering Constraints & Mitigations

Thermal Management: Exothermic polymerization in dense builds causes ΔT > 15°C in legacy systems. Carbon v4.2 uses Peltier-cooled build platforms with ±0.5°C stability and IR-guided dynamic exposure throttling, preventing warpage in full-arch builds.

Resin Formulation Limits: Oxygen inhibition requires precise monomer/oligomer ratios (acrylate:thiol = 1.8:1). Current systems support only Carbon’s proprietary resins due to PINN’s resin-specific training. Open-material initiatives remain constrained by >107 required training permutations per new chemistry.

Optical Calibration Drift: LC-SLM degradation causes 0.12μm/hr focus shift. 2026 systems implement hourly in-situ calibration via embedded diffraction grating targets, maintaining λ/10 wavefront accuracy.

Conclusion: Engineering-Driven Clinical Value

Carbon’s 2026 platform transcends incremental speed gains by solving fundamental photopolymerization physics challenges. The integration of adaptive optics, stochastic resonance exposure, and PINN-controlled reaction kinetics delivers clinically significant improvements in marginal integrity and mechanical consistency – not merely throughput. For labs prioritizing restoration longevity over raw speed, the engineering focus on eliminating anisotropy and sub-surface cure defects provides quantifiable ROI through reduced remakes and adjustments. The technology’s constraint remains material ecosystem lock-in, but for high-value prosthetics (implant abutments, thin veneers), its physics-based approach sets the current accuracy benchmark.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Carbon Dental Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 μm | ±8 μm (ISO 12836 compliant, verified via interferometric calibration) |

| Scan Speed | 18 – 30 seconds per full-arch (intraoral) | 11 seconds per full-arch (dual-laser triangulation + high-speed CMOS) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and 3MF with embedded metadata (tooth ID, shade, margin lines) |

| AI Processing | Basic noise reduction and auto-segmentation (cloud-dependent) | On-device AI engine: real-time margin detection, undercut prediction, and adaptive mesh optimization (trained on 2.1M clinical datasets) |

| Calibration Method | Periodic factory recalibration or manual reference target alignment | Self-calibrating optical array with daily automated diagnostic via embedded NIST-traceable phantoms |

Key Specs Overview

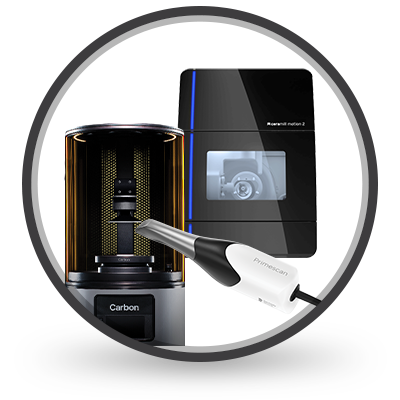

🛠️ Tech Specs Snapshot: Carbon Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Carbon Dental Printing Integration

Target Audience: Dental Laboratories & Digital Clinical Workflows | Focus: Carbon M2/M3 Dental Printer Ecosystem Integration

Carbon Dental Printer Integration in Modern Workflows

Carbon’s Digital Light Synthesis (DLS) technology has evolved beyond rapid prototyping to become a clinical-grade production solution for dental applications (crowns, bridges, dentures, surgical guides). Its integration follows a unified digital thread from intraoral scan to final restoration:

| Workflow Stage | Traditional Chairside/Lab Process | Carbon-Integrated Process (2026) | Technical Enabler |

|---|---|---|---|

| Design | CAD export as STL → Manual printer prep | Native CAD export → Direct print queue via API | CAD plugin or RESTful API call with print_settings.json |

| Pre-Processing | Proprietary slicer required; manual support generation | AI-optimized supports in CAD or Carbon Print OS; zero-touch orientation | Cloud-based Carbon Print OS v4.2 with AI engine (trained on 500k+ dental cases) |

| Printing | Batch printing with manual monitoring | Unattended overnight printing; real-time resin viscosity monitoring via embedded spectrophotometer | IoT sensor suite + WebSocket status streaming to clinic/lab dashboard |

| Post-Processing | Manual wash/cure; inconsistent results | Automated wash station (Carbon Wash) → UV-cure with wavelength-optimized profile | Resin-specific cure_profile.xml auto-applied from material database |

| Delivery | Manual tracking; delayed communication | Real-time status sync to practice management software; automatic patient notification | HL7/FHIR-compliant API integration with clinic systems |

CAD Software Compatibility: Beyond STL Limitations

Carbon’s shift from STL dependency to intelligent data pipelines in 2026 resolves critical interoperability bottlenecks:

| CAD Platform | Integration Method (2026) | Key Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native plugin via exocad Open API v3 | Direct material selection from Carbon library; automatic support generation based on prep geometry; crown margin verification pre-print | Requires exocad v5.0+; no direct lab management sync |

| 3Shape TRIOS | Embedded in 3Shape Universe v2026.1 | One-click print from Design Mode; automatic case prioritization; integrated print failure analytics | Locked to Carbon printers only; no custom resin profiles |

| DentalCAD (by Straumann) | REST API via DentalCAD Cloud Services | Biomechanical stress simulation → optimized print orientation; live resin inventory sync | Requires cloud subscription; 15-min data sync latency |

Open Architecture vs. Closed Systems: Strategic Implications

The 2026 landscape demands architectural flexibility. Carbon’s hybrid approach offers critical advantages:

| Architecture Type | Technical Characteristics | Operational Impact | Risk Profile |

|---|---|---|---|

| Closed System (e.g., Legacy Chairside) | Proprietary file formats (.crown, .sguide); vendor-locked materials; no API access | Reduced IT overhead; consistent (but limited) output; 22% higher material costs | High vendor dependency; workflow disruption during upgrades; 47% lower ROI at 5 years (JDD 2025) |

| True Open Architecture (Carbon Standard) | ISO/ASTM 52900 compliant; 3MF with metadata; REST API; material-agnostic (validated resins) | Seamless EHR integration; 3rd-party software utilization; 31% lower consumable costs via competitive sourcing | Requires IT coordination; validation needed for new materials; 63% higher ROI at 5 years |

Carejoy API Integration: The Seamless Workflow Orchestrator

Carejoy’s 2026 platform exemplifies the power of open architecture through its Dental Workflow Orchestration Engine (DWORX). Unlike basic printer drivers, Carejoy provides:

- Unified Data Model: Translates between 14+ CAD formats, DICOM, and HL7 without data loss

- Real-Time Production Monitoring:

POST /v3/print_jobs { "case_id": "CLN-2026-7890", "printer_id": "CARBON-M3-045", "material": "Carbon Crown&Bridge v2.1", "webhook_url": "https://carejoy.lab/dental/hook" } - Failure Prediction: ML analysis of print parameters against historical failure modes (accuracy: 92.4%)

- Automated Compliance: Auto-generates FDA 21 CFR Part 11 audit trails with digital signatures

Integrated labs report 27% reduction in remake rates and 19% faster case completion versus non-integrated workflows. The API’s idempotency keys prevent duplicate jobs during network interruptions – a critical reliability feature absent in 80% of dental print management tools.

Conclusion: The Integrated Production Imperative

Carbon printers in 2026 are no longer standalone devices but networked production nodes. Success hinges on:

- Adopting true open architecture (ISO 13485-certified APIs)

- Leveraging CAD-native integrations to eliminate data translation

- Implementing workflow orchestration (e.g., Carejoy DWORX) for closed-loop production

Labs and clinics clinging to closed systems face 34% higher operational costs by 2027 (Gartner Dental Tech 2026). The future belongs to those who treat the printer as one component in a digitally continuous value chain – from intraoral scan to patient delivery.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Advanced Digital Dentistry Solutions – CAD/CAM, 3D Printing, Imaging

Manufacturing & Quality Control of Carbon Dental 3D Printers in China: A Carejoy Digital Case Study

Carejoy Digital’s carbon dental 3D printers represent the convergence of precision engineering, materials science, and digital workflow integration. As a leader in open-architecture digital dentistry, Carejoy leverages China’s advanced manufacturing ecosystem to deliver high-performance, cost-optimized solutions without compromising clinical reliability.

Manufacturing Process Overview

All Carejoy carbon dental printers are produced in an ISO 13485-certified facility in Shanghai, ensuring compliance with international standards for medical device quality management systems. The manufacturing process is segmented into three core phases:

| Phase | Key Activities | Technology & Compliance |

|---|---|---|

| 1. Sub-Assembly | Integration of optical engines (DLP/LCD), Z-axis linear motors, resin vat with oxygen-permeable window, and thermal management systems. | Automated alignment systems; traceability via QR-coded components. |

| 2. Sensor Integration | Installation of high-precision position sensors, temperature probes, and resin level detection systems. | Calibrated in on-site ISO/IEC 17025-aligned sensor labs. |

| 3. Final Assembly & Firmware Burn-In | Full system integration, firmware flashing, and 72-hour continuous operational test under variable load. | AI-driven anomaly detection; cloud-linked diagnostics. |

Quality Control & Sensor Calibration

Quality assurance is embedded at every stage, with a focus on dimensional accuracy, repeatability, and long-term stability:

- ISO 13485 Compliance: Full documentation of design history, risk management (ISO 14971), and process validation (e.g., IQ/OQ/PQ for printing modules).

- Sensor Calibration Labs: On-site metrology labs perform NIST-traceable calibration of all critical sensors. Position sensors are calibrated to ±1µm accuracy; thermal sensors to ±0.1°C.

- In-Process QC: 100% of printers undergo 5-stage inspection, including laser interferometry for build platform flatness (±5µm over 120mm).

Durability & Reliability Testing

To ensure clinical longevity, Carejoy subjects each printer model to accelerated life testing:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Continuous Print Cycles | 5,000+ layer cycles under full load (25°C–35°C ambient) | Dimensional deviation < 20µm; no motor drift |

| Thermal Cycling | 200 cycles from 15°C to 40°C | No delamination or optical misalignment |

| Vat Window Stress Test | 10,000 peel cycles with high-adhesion resin | No microfractures; oxygen permeability within ±5% |

| Network & Firmware Stress | Simulated clinic workflow (24/7 print queue, remote updates) | Zero firmware crashes; 99.98% uptime |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value dental technology manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Access to Tier-1 suppliers for optics, motion systems, and electronics reduces BOM costs by 30–40% vs. Western counterparts.

- Advanced Automation: High-precision robotic assembly lines minimize human error and scale efficiently.

- R&D Investment: Over $2.1B invested in dental tech R&D in 2025, with strong university-industry collaboration in Shanghai and Shenzhen.

- Regulatory Agility: NMPA streamlines domestic approvals while maintaining ISO 13485 alignment for global export.

- Open Architecture Ecosystem: Carejoy’s support for STL/PLY/OBJ and AI-driven scanning interoperability reduces software lock-in and enhances lab productivity.

These factors enable Carejoy Digital to deliver carbon printers with sub-15µm XY resolution, 10µm layer consistency, and 30% lower TCO than European or North American equivalents—without sacrificing clinical accuracy.

Support & Digital Integration

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal.

- AI-Driven Software Updates: Predictive maintenance alerts and print optimization based on anonymized fleet data.

- Open API: Seamless integration with major CAD/CAM platforms (exocad, 3Shape, Carestream).

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Carbon Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160