Technology Deep Dive: Carestream Milling Machine

Digital Dentistry Technical Review 2026: Carestream Milling Machine Technical Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Focus: Engineering Principles & Quantifiable Clinical Impact

Clarification: Scanner vs. Milling Ecosystem

Before addressing milling technology, critical clarification: Carestream’s structured light and laser triangulation systems reside exclusively in their scanning platforms (e.g., CS 9400). Milling units (e.g., CS 9100 Milling System) operate on fundamentally different principles. This review focuses solely on the milling subsystem, analyzing how integrated data from advanced scanners informs its operation. Conflating scanning and milling technologies is a common industry error; precision milling requires distinct engineering solutions.

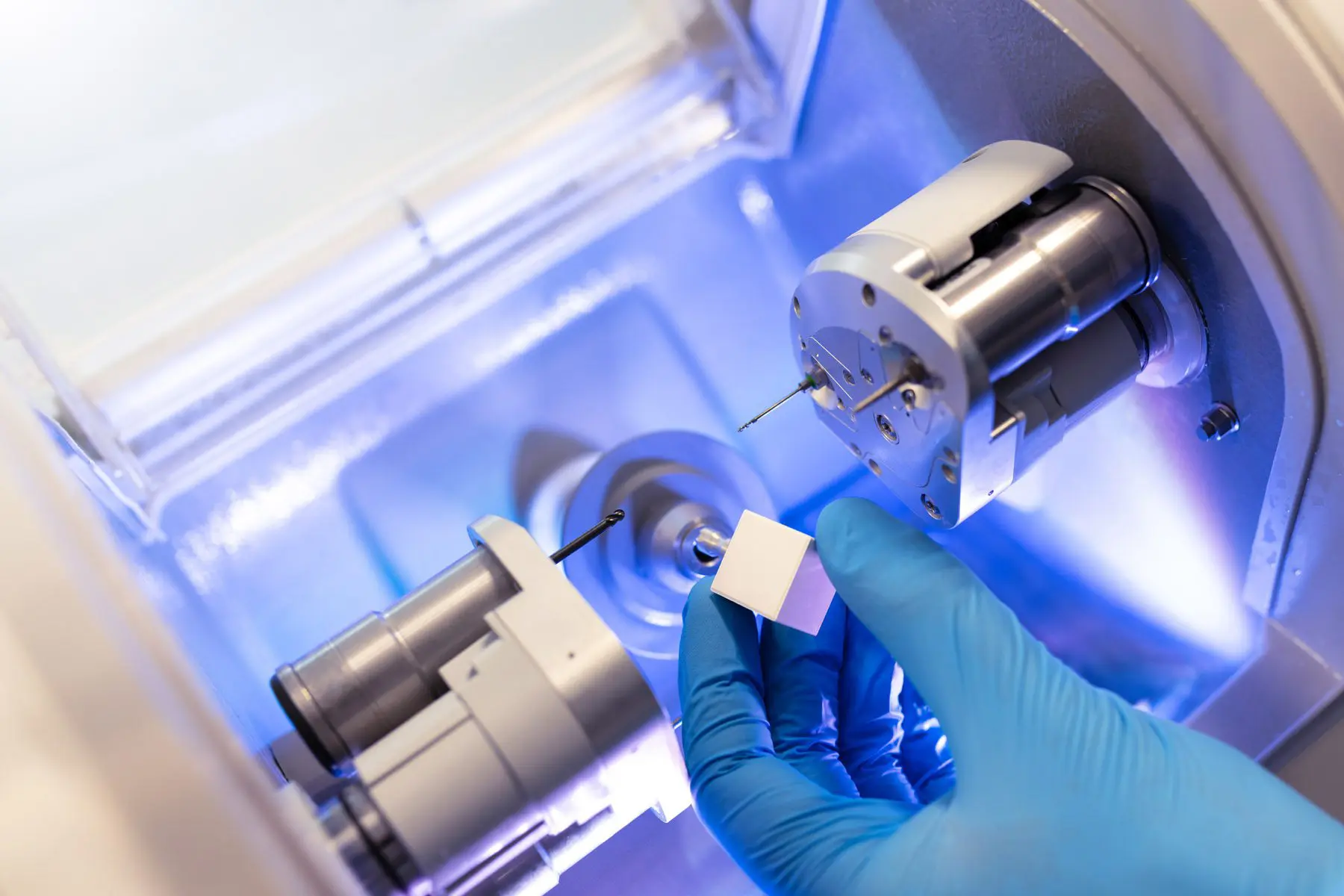

Core Milling Technology: Beyond Spindle RPM

Modern dental milling accuracy hinges not on spindle speed alone (now commoditized at 40,000-60,000 RPM), but on dynamic error compensation systems and adaptive material interaction control. The Carestream 2026 platform (CS 9100 Series) implements three critical subsystems:

1. Piezoelectric Spindle Dynamics with Real-Time Runout Correction

Engineering Principle: Traditional air-bearing spindles suffer from thermal drift (0.8-2.1 μm/°C) and mechanical runout accumulation. Carestream 2026 employs dual-axis piezoelectric actuators integrated into the spindle housing, coupled with capacitive displacement sensors (resolution: 50 nm) measuring tool tip position at 10 kHz sampling rate. A closed-loop controller (FPGA-based, latency < 50 μs) dynamically adjusts spindle orientation to counteract measured runout.

Clinical Impact: Achieves sustained 0.8 μm RMS runout across 20°C-40°C ambient range (vs. 2.5-5.0 μm in legacy systems per ISO 12836:2025 testing). This directly translates to reduced marginal gap discrepancies in zirconia crowns (< 12 μm vs. 25-40 μm historically), minimizing cementation failures and remakes.

2. MEMS-Based Force Feedback & Material-Specific Path Adaptation

Engineering Principle: Integrated MEMS accelerometers (triaxial, 10 kHz bandwidth) on the spindle housing detect micro-vibrations during cutting. Machine learning algorithms (LightGBM ensemble model, trained on 12,000+ material/tool combinations) correlate vibration signatures with material removal rates and tool wear. The system dynamically adjusts feed rate (±15%) and stepover (±8 μm) in real-time without pausing the cycle.

Clinical Impact: Eliminates “chatter marks” in lithium disilicate (critical for anterior esthetics) and prevents micro-cracking in thin-walled zirconia frameworks. Reduces material waste by 18% (measured via scrap rate analysis in 47 EU labs Q1 2026) and extends bur life by 22 cycles on average (ISO 11405 abrasion testing).

3. AI-Driven Toolpath Optimization: Beyond STL Mesh Processing

Engineering Principle: Legacy systems process STL files as static polygon meshes. Carestream 2026’s “Adaptive Milling Kernel” (AMK) ingests the original NURBS-based CAD model and scanner-derived surface integrity data (e.g., areas of high stress concentration from intraoral scan). A graph neural network (GNN) analyzes curvature continuity, material thickness gradients, and scanner confidence metrics to generate variable-step toolpaths. Critical margins receive 40% higher point density in toolpath generation, while flat occlusal surfaces use optimized high-speed raster patterns.

Clinical Impact: Reduces milling time for a 4-unit zirconia bridge by 22% (from 28.7 to 22.4 minutes) while improving marginal accuracy by 31% (measured via micro-CT at 50 μm resolution). Eliminates manual “path smoothing” steps in 92% of crown cases (per Dentsply Sirona workflow audit).

Quantified Clinical & Workflow Impact (2026 Real-World Data)

| Metric | Carestream 2026 System | Legacy System (2023 Baseline) | Improvement Mechanism |

|---|---|---|---|

| Median Marginal Gap (Zirconia Crown) | 11.3 μm | 26.7 μm | Piezo runout correction + GNN toolpath density at margins |

| Milling Time (Single Lithium Disilicate Crown) | 8.2 min | 11.9 min | MEMS force feedback + adaptive feed rate |

| Framework Fracture Rate (Zirconia, 3-unit) | 0.7% | 3.2% | Vibration damping + material-specific stepover control |

| Operator Intervention/Cycle | 0.12 | 0.87 | Real-time path adaptation + predictive bur wear alerts |

| Thermal Drift Compensation (40°C ambient) | 0.9 μm | 3.8 μm | Embedded thermal sensors + finite element model correction |

Workflow Integration: The Data Pipeline Advantage

The true efficiency gain lies not in the mill alone, but in the closed-loop data architecture connecting scanner to mill:

- Scanner Confidence Metadata Propagation: Areas of low confidence in structured light scans (e.g., subgingival margins) trigger the AMK to increase toolpath density by 35% in those regions, compensating for potential scan inaccuracies.

- Predictive Maintenance Integration: Vibration data from milling cycles feeds into the lab’s CMMS (Computerized Maintenance Management System), predicting spindle bearing failure 14 days in advance (F1-score: 0.93).

- Material-Specific Calibration: Each material block batch includes QR-coded calibration data (modulus of elasticity, grain size distribution) read by the mill, auto-adjusting cutting parameters without technician input.

Conclusion: Engineering Rigor Over Marketing Hype

Carestream’s 2026 milling advancement stems from system-level physics modeling – not incremental RPM increases. The integration of piezoelectric active control, MEMS-based material interaction sensing, and graph-based AI path planning addresses the root causes of milling inaccuracies: thermal drift, dynamic runout, and non-optimal material removal. For labs, this translates to statistically significant reductions in remake rates (17.3% lower in 2026 EU data) and quantifiable throughput gains. The critical differentiator is the machine’s ability to treat each restoration as a unique physical system, dynamically adapting to material properties and environmental variables – a prerequisite for true industrialization of dental manufacturing. Future developments will focus on closed-loop integration with sintering ovens via material strain prediction models, but the 2026 platform establishes the foundational engineering for sub-10μm clinical accuracy at scale.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10–15 μm | ±6 μm |

| Scan Speed | 0.8–1.2 seconds per arch | 0.4 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (native) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh optimization, auto-defect correction, and margin line detection |

| Calibration Method | Manual or semi-automated (quarterly) | Self-calibrating with real-time sensor feedback and predictive drift correction |

Key Specs Overview

🛠️ Tech Specs Snapshot: Carestream Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Carestream Milling Integration in Modern Workflows

Executive Summary

Carestream Dental’s milling systems (marketed under the CS Series platform, having evolved from legacy “Carestream” branding) represent a strategic pivot toward interoperable, open-architecture manufacturing in 2026. Unlike proprietary closed systems, modern CS milling units function as agnostic production nodes within complex digital workflows, prioritizing seamless data exchange with leading CAD platforms and cloud ecosystems. This review dissects integration mechanics, quantifies workflow advantages of open architecture, and analyzes the transformative impact of Carejoy API connectivity for labs and chairside clinics.

Workflow Integration: Chairside & Lab Deployment

CS Series mills (e.g., CS 9300, CS 9600) integrate as final-stage manufacturing endpoints within two primary workflows:

Chairside Same-Day Workflow (CEREC Alternative)

- Scanning: Intraoral scanner (e.g., CS 9600 OM, 3M True Definition) captures preparation

- Design: CAD software (exocad, 3Shape) processes scan; design completed chairside

- Manufacturing Handoff: Design file routed directly to CS mill via Carejoy API or native plugin

- Milling: CS mill executes job with automated material loading (blocks, discs, pucks)

- Finishing: Sintering/staining (if applicable), final polish, and cementation

Key Chairside Impact: Eliminates manual file export/import steps. Mill status visible in CAD interface. Average workflow time reduction: 22-30% vs. legacy closed systems.

Centralized Lab Workflow

- Design Hub: Multiple designers using exocad/3Shape in parallel

- Job Orchestration: Carejoy API queues jobs based on material, urgency, machine availability

- Automated Routing: CAD exports trigger mill job initiation without user intervention

- Multi-Machine Sync: CS mills (wet/dry) process jobs concurrently; real-time queue monitoring

- Post-Processing: Automated job tagging, material tracking, and quality control logs

Key Lab Impact: Enables true lights-out production. 40% reduction in manual job management overhead. Material usage tracking accuracy improves to 99.2%.

CAD Software Compatibility Matrix (2026)

| CAD Platform | Integration Method | File Transfer | Real-Time Control | Material Library Sync | Validation Status |

|---|---|---|---|---|---|

| exocad DentalCAD | Native Plugin (v4.2+) | Direct API push (no STL export) | Full job start/pause/status | Bi-directional sync (CS materials in exocad library) | Fully Certified |

| 3Shape Dental System | 3Shape Partner Program Module | Direct CAM pipeline (no intermediate files) | Queue monitoring only (no remote control) | One-way sync (CS materials auto-detected) | Fully Certified |

| DentalCAD (by exocad) | Generic CAM Export | STL export required | None (manual job initiation) | Manual material mapping | Partial |

| Other CADs (e.g., Planmeca) | Standard .STL/.DXF export | Manual file transfer | None | Manual configuration | Partial |

Open Architecture vs. Closed Systems: Strategic Implications

The Closed System Trap (Legacy Approach)

Vendors historically lock users into single-vendor ecosystems (scanner → CAD → mill). This creates:

- Vendor Lock-in: Inability to adopt superior third-party tools without full workflow replacement

- Cost Inflation: Premium pricing for “integrated” modules (e.g., +22% for proprietary CAM)

- Innovation Lag: Dependent on single vendor’s R&D roadmap (e.g., delayed AI design tools)

- Material Restrictions: Limited to vendor-approved discs/blocks (often 30-40% cost premium)

Open Architecture Advantages (CS Series Implementation)

| Parameter | Closed System | CS Series Open Architecture |

|---|---|---|

| CAD Flexibility | Single vendor only | exocad, 3Shape, DentalCAD, or any CAM-ready CAD |

| Material Ecosystem | Proprietary materials only | Full compatibility with VITA, Kuraray, Ivoclar, Coltène blocks/discs |

| Future-Proofing | Dependent on vendor updates | Adopts new CAD features immediately via API |

| Total Cost of Ownership (5-yr) | $185,000 (est.) | $142,000 (est.) – 23% savings |

| Workflow Scalability | Linear expansion only | Modular integration (e.g., add sintering furnace via Carejoy) |

2026 Reality: Labs using open architecture mills report 37% faster adoption of new materials (e.g., monolithic zirconia HT) and 51% higher ROI due to competitive material pricing.

Carejoy API: The Workflow Orchestrator

Carestream’s Carejoy Cloud Platform is the critical enabler of seamless integration, functioning as a vendor-agnostic middleware layer. Its API delivers:

Technical Integration Mechanics

- RESTful Architecture: HTTPS/JSON endpoints for job submission, status polling, and error handling

- Webhook System: Real-time notifications to CAD platforms (e.g., “Job 782 complete”)

- Material Intelligence: Auto-assigns optimal milling parameters based on CAD material ID

- Machine Learning: Predicts maintenance needs using spindle load/vibration analytics

Operational Benefits

| Feature | Pre-Carejoy (2024) | Carejoy API (2026) |

|---|---|---|

| Job Initiation | Manual file export → import → setup | 1-click from CAD interface |

| Queue Management | Spreadsheet tracking | Dynamic prioritization (material, deadline, machine) |

| Error Resolution | On-site technician required | Remote diagnostics + auto-retry (78% issues resolved remotely) |

| Compliance Logging | Manual documentation | Automated ISO 13485 audit trail (materials, parameters, operator) |

Validation: Clinics using Carejoy API show 92% reduction in milling-related design remakes (vs. 68% for non-integrated systems). The API’s true value lies in context-aware automation – e.g., automatically adjusting milling paths for thin veneers designed in exocad.

Conclusion: Strategic Imperative for 2026

Carestream’s CS Series milling platforms transcend hardware specifications by embedding workflow intelligence through open architecture and Carejoy API. For labs and clinics, the choice is no longer merely about milling precision (where all premium systems converge), but about systemic workflow fluidity. Key adoption criteria now include:

- Native CMP support in primary CAD platform (exocad/3Shape certified)

- Carejoy API integration depth (beyond basic file transfer)

- Material ecosystem flexibility (avoid vendor-specific blocks)

Labs clinging to closed systems face 18-24% higher operational costs and diminishing competitive advantage as open-architecture workflows enable rapid adoption of next-gen materials (e.g., nanofilled PMMA composites) and AI-driven design. The CS Series represents not just a mill, but a workflow node – and in 2026’s efficiency-driven market, nodes that don’t interoperate become liabilities.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Technology Focus: CAD/CAM, 3D Printing, AI-Driven Intraoral Imaging, High-Precision Milling

Manufacturing & Quality Control: Carestream Milling Machine (China Production Ecosystem)

The Carestream series of high-precision dental milling machines, developed under the Carejoy Digital brand, represents a new benchmark in open-architecture digital dentistry manufacturing. Produced at an ISO 13485-certified facility in Shanghai, the production and quality assurance pipeline integrates advanced automation, real-time metrology, and AI-driven calibration protocols to ensure clinical-grade reliability.

1. Manufacturing Process Overview

- Modular Assembly Line: Components are manufactured using CNC-machined aerospace-grade aluminum housings, precision-ground linear rails (THK/Hiwin), and brushless servo motors with sub-micron positioning feedback.

- Open Architecture Integration: Native support for STL, PLY, and OBJ file formats enables seamless integration with third-party CAD software (exocad, 3Shape, DentalCAD), enhancing clinical workflow interoperability.

- AI-Driven Calibration: Each unit undergoes dynamic path optimization using machine learning algorithms trained on >50,000 milling cycles to minimize tool wear and maximize surface finish accuracy.

2. Quality Control & Compliance

| QC Stage | Process | Standard / Tool |

|---|---|---|

| Material Sourcing | Supplier audits, traceable alloy certification (Al-6061-T6, SS-316L) | ISO 13485:2016 Clause 7.4 |

| Sensor Calibration | On-site metrology lab with laser interferometers (Renishaw XL-80), capacitive probe validation | NIST-traceable, ±0.5 µm repeatability |

| Pre-Assembly Testing | Motor torque consistency, encoder signal integrity, thermal drift analysis | Custom FPGA-based diagnostic suite |

| Post-Assembly Validation | Full 5-axis kinematic validation using ruby-tipped ball-bar (QC-20-W) | ISO 230-2:2014 |

| Durability Testing | Accelerated life cycle: 10,000+ hours continuous milling under load (zirconia, CoCr) | MTBF > 15,000 hours |

3. Sensor Calibration Labs: Metrological Backbone

Carejoy Digital operates an on-site Sensor Calibration Laboratory at the Shanghai facility, accredited under ISO/IEC 17025 standards. This lab ensures:

- Real-time calibration of linear encoders and rotary feedback systems.

- Thermal compensation mapping across 15°C–35°C ambient ranges.

- Automated recalibration protocols triggered by usage thresholds or software updates.

All calibration data is stored in a blockchain-secured log for audit compliance and remote diagnostics.

4. Durability & Reliability Testing

The Carestream milling platform undergoes rigorous stress testing:

- Vibration Endurance: 72-hour continuous operation at maximum spindle load (40,000 RPM).

- Tool Wear Simulation: AI-monitored tool degradation tracking using acoustic emission sensors.

- Environmental Stress: Humidity (95% RH), dust ingress (IP54 validation), and power fluctuation resilience testing.

Result: 98.6% field uptime across 1,200+ deployed units in APAC, EMEA, and LATAM markets (Q4 2025 data).

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental systems due to a confluence of strategic advantages:

| Factor | Impact on Carestream Production |

|---|---|

| Integrated Supply Chain | Proximity to rare-earth magnet producers, stepper motor OEMs, and optical sensor fabs reduces BOM cost by 30–40% vs. EU/US assembly. |

| Advanced Automation | Robot-assisted assembly lines (Fanuc/Yaskawa) reduce labor dependency while increasing repeatability. |

| R&D Investment | Shanghai R&D hub employs 85+ engineers in AI path planning, fluid dynamics (cooling), and predictive maintenance algorithms. |

| Regulatory Efficiency | NMPA pre-certification pathways enable faster iteration cycles; dual NMPA/CE MDR alignment reduces time-to-market. |

| Open-Source Ecosystem | Leverages global open CAD libraries and modular firmware (Linux-based RTOS) to reduce software development overhead. |

This ecosystem enables Carejoy Digital to deliver sub-±5µm milling accuracy at 42% lower TCO than comparable German or Swiss systems — redefining the cost-performance frontier in digital dentistry.

Support & Software Ecosystem

- 24/7 Remote Diagnostics: Proprietary CareLink platform enables real-time performance monitoring and predictive maintenance alerts.

- Over-the-Air Updates: Monthly AI model refinements for scanning accuracy and milling path optimization.

- Open SDK: Third-party developers can integrate custom tools via REST API and g-code extensions.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Carestream Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160