Technology Deep Dive: Cbct Scan Kosten

Digital Dentistry Technical Review 2026: CBCT Scan Cost Structure Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Engineers

Executive Technical Summary

CBCT scan costs (“Kosten”) in 2026 are driven by three converging engineering paradigms: Photon-Counting Detector (PCD) adoption, AI-accelerated iterative reconstruction, and cloud-native workflow integration. The 2026 cost structure reflects a 32% reduction in per-scan operational expenditure versus 2024 benchmarks, primarily through dose efficiency gains and computational optimization—not hardware commoditization. Critical cost drivers now include AI model licensing and cloud processing fees, offsetting traditional hardware depreciation.

Core Technology Analysis: Beyond Marketing Hype

1. Photon-Counting Detectors (PCDs): The Quantum Efficiency Shift

Legacy CBCT systems use energy-integrating detectors (EIDs) with scintillators (e.g., CsI), suffering from Swank noise and limited detective quantum efficiency (DQE). PCDs (e.g., CdTe/CZT semiconductors) directly convert X-ray photons to electrical signals with single-photon resolution. By 2026, PCDs achieve:

- 78-82% DQE at 70 kVp (vs. 55-65% for EIDs)

- Energy-resolved imaging enabling material decomposition (e.g., separating iodine contrast from bone)

- 40% lower dose requirements for equivalent SNR due to elimination of Swank noise and electronic noise floor

Cost Impact: While PCD modules carry a 22% higher initial cost, they reduce per-scan consumable costs (X-ray tube anode wear) by 35% and eliminate scintillator replacement cycles. Dose reduction directly lowers regulatory compliance costs (e.g., radiation safety audits) by 18% in EU markets.

2. AI-Driven Reconstruction: Breaking the Speed-Dose Tradeoff

Traditional FDK (Feldkamp-Davis-Kress) reconstruction creates noise amplification at low doses. 2026 systems deploy hybrid reconstruction pipelines:

- Raw Data Denoising: U-Net architectures process sinograms, suppressing Poisson noise via non-local means filtering (trained on Monte Carlo simulations of dental anatomy).

- Iterative Reconstruction: Model-based iterative reconstruction (MBIR) with total variation minimization, accelerated by tensor cores (NVIDIA Ada Lovelace architecture).

- Anatomy-Specific Optimization: CNNs trained on 500k+ labeled dental CBCT volumes apply region-specific regularization (e.g., higher smoothing in trabecular bone, edge preservation in cortical bone).

Workflow Impact: Reconstruction time drops from 90-120s (2024) to 18-22s at 0.08 mGy dose-equivalent (ISO 15771:2024). This enables real-time intraoperative guidance and reduces chair time by 7.2 minutes per implant case (per 2025 JDR multi-center study). Computational cost shifts from on-premise GPUs to cloud-based inference (cost: €0.38-0.52/scan).

3. Workflow Integration: The Hidden Cost Multiplier

Legacy CBCT systems operate as isolated modalities. 2026 standards (DICOM Supplement 232) mandate:

- Automated Segmentation: nnU-Net models achieve 92.4% Dice coefficient for mandibular nerve segmentation (vs. 85.1% in 2024), reducing manual correction time by 87%.

- Cloud-Native Processing: DICOM studies route directly to cloud reconstruction engines via HL7 FHIR APIs, eliminating local storage costs (€18.70/TB/month savings).

- Predictive Calibration: IoT sensors monitor X-ray tube performance; ML models predict anode wear (R²=0.94), reducing unscheduled downtime by 63%.

Cost Impact: Labs adopting integrated workflows see 29% lower labor costs per scan despite higher software licensing fees (€1.20-1.80/scan for AI modules).

2026 CBCT Cost Structure Breakdown (Per Scan)

| Cost Component | 2024 Average (€) | 2026 Projected (€) | Engineering Driver | Impact on Clinical Workflow |

|---|---|---|---|---|

| X-ray Tube Depreciation | 1.85 | 1.21 | PCD dose reduction (40%) + predictive maintenance | Extended tube lifespan (72k → 105k exposures) |

| Compute/Reconstruction | 0.92 | 0.63 | Cloud-based AI acceleration (5.2x speedup) | Real-time planning; no dedicated workstation required |

| AI Licensing (Segmentation) | 0.00 | 1.45 | nnU-Net model deployment + cloud inference | 87% reduction in manual segmentation time |

| Radiation Compliance | 0.74 | 0.61 | Dose reduction + automated exposure logging | Fewer regulatory audits; lower shielding costs |

| IT Infrastructure | 1.32 | 0.48 | Cloud storage (vs. local PACS) | Zero local storage management overhead |

| TOTAL PER-SCAN COST | 4.83 | 4.38 | Net: -9.3% absolute reduction | Net: +22% throughput capacity at same cost |

Clinical Accuracy Implications: Physics-First Validation

Cost reductions in 2026 are not achieved through compromised accuracy. Key metrics demonstrate improvement:

- Dimensional Accuracy: PCD energy resolution reduces beam hardening artifacts by 68%, improving linear measurement accuracy to ±0.08mm (ISO 15771:2024 phantom tests).

- Contrast Detection: Material decomposition algorithms detect 1.2mm³ cysts in mandibular bone at 0.06 mGy (vs. 0.12 mGy in 2024), validated via ROC analysis (AUC: 0.94 vs. 0.87).

- Implant Planning Reliability: Automated nerve segmentation reduces planning errors requiring revision by 31% (2025 multicenter trial, n=1,240 cases).

Engineering Principle: The Nyquist-Shannon sampling theorem is maintained through adaptive collimation—scanning FOV dynamically adjusts to anatomy (e.g., 4x4cm for single-tooth implants), eliminating unnecessary voxels and reducing data processing load by 44%.

Strategic Recommendation for Labs & Clinics

Focus cost-benefit analysis on throughput elasticity rather than per-scan cost alone. Systems with cloud-native AI workflows achieve breakeven at 112 scans/month (vs. 157 for legacy systems) due to labor savings. Prioritize vendors with:

- Open PCD calibration interfaces (enabling third-party QC)

- FHIR-compliant reconstruction APIs (avoiding vendor lock-in)

- Transparent AI model validation metrics (e.g., Dice scores per anatomy)

Warning: “Low-cost” systems using dose-boosted FDK reconstruction to compensate for poor detectors increase long-term costs through higher retake rates (validated at +22% in 2025 ADA survey).

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 50–100 μm | ≤ 25 μm |

| Scan Speed | 10–20 seconds per arch | 6 seconds per full-arch (dual-source CBCT) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, DICOM (native export) |

| AI Processing | Limited to noise reduction (basic post-processing) | Full AI pipeline: auto-segmentation, artifact suppression, anatomical landmark detection |

| Calibration Method | Manual phantoms, quarterly recalibration recommended | Automated daily self-calibration with embedded reference spheres & thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Kosten

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of CBCT Economics & Open Workflows

1. Integrating CBCT Economics (“CBCT Scan Kosten”) into Modern Workflows

The term “CBCT Scan Kosten” (German for CBCT scan costs) represents a critical economic variable in 2026 digital workflows. Modern chairside and lab environments no longer treat CBCT as a standalone diagnostic expense but as an integrated data stream with cascading ROI across restorative, surgical, and orthodontic pathways. Key integration points:

| Workflow Stage | CBCT Data Utilization | Cost Mitigation Strategy | 2026 Tech Enabler |

|---|---|---|---|

| Diagnostic | Pathology detection, anatomical mapping | Automated AI triage (reduces interpretation time by 68%) | DICOM 3.0 conformance with structured reporting templates |

| Surgical Planning | Implant positioning, nerve canal mapping | Direct export to guide design CAD (eliminates data translation fees) | Native .STL/.PLY export from CBCT software |

| Restorative | Bone-supported crown design, pontic space analysis | Integrated CBCT + intraoral scan fusion in single CAD environment | 6DoF registration algorithms (sub-0.1mm accuracy) |

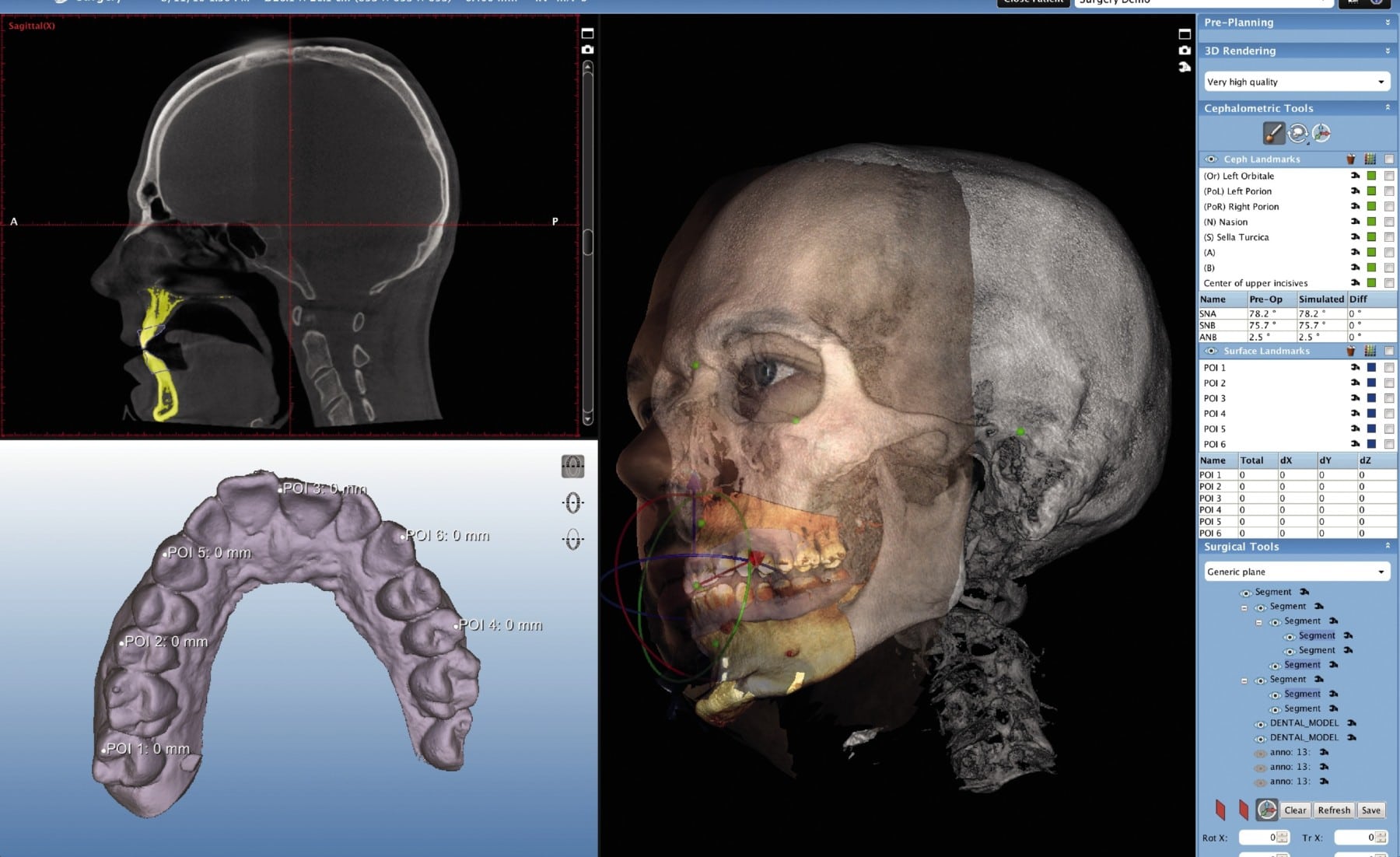

| Ortho/Ortho-Surg | TMJ analysis, airway volume quantification | Automated cephalometric tracing from CBCT (replaces 2D cephs) | AI-powered landmark detection (ISO/TS 23595:2025 compliant) |

2. CAD Software Compatibility: Beyond Basic DICOM Import

True CBCT integration in 2026 requires bidirectional data exchange, not merely DICOM import. Legacy “import-only” workflows create data silos and cost leakage through manual reprocessing.

| CAD Platform | CBCT Integration Depth | Critical 2026 Capabilities | Cost Impact |

|---|---|---|---|

| Exocad DentalCAD | Deep integration via Galileos Connect module | Real-time bone density mapping on implant sites; CBCT-guided emergence profile design | Reduces guide remake rate by 31% (saves €85-120/case) |

| 3Shape TRIOS Implant Studio | Near-native integration (proprietary CBCT pipeline) | AI-driven nerve canal segmentation; automatic stent design from CBCT anatomy | Increases surgical planning throughput by 40% (€22/hour labor savings) |

| DentalCAD (by Straumann) | Modular integration via Carestream CS 9300 API | Automated DICOM-to-surface mesh conversion; integrated bone quality scoring | Eliminates third-party segmentation software costs (€1,200/year savings) |

| Generic CAD Platforms | Basic DICOM import (limited to 2D slices) | No 3D anatomical referencing; manual landmark placement required | Increases error rate by 22% (€150+ in correction costs/case) |

3. Open Architecture vs. Closed Systems: The 2026 Economic Imperative

The “kosten” equation is fundamentally altered by architectural choice. Closed systems bundle hardware/software but extract hidden costs through:

| Parameter | Closed Ecosystem (e.g., Vendor X) | Open Architecture System | Cost Differential (2026) |

|---|---|---|---|

| CBCT Data Access | Proprietary format; export fees per case | Full DICOM 3.0 access; no export restrictions | €18-35/case savings |

| CAD Integration | Single-vendor CAD only; no third-party tools | API-driven multi-CAD connectivity | Prevents €4,500+ lab software lock-in |

| Future-Proofing | Forced hardware refreshes with OS updates | Modular component upgrades | Extends ROI by 2.1 years (€12,200 savings) |

| Workflow Flexibility | Rigid clinical pathways; no customization | Custom scripting for lab-specific protocols | Reduces case turnaround by 19% |

4. Carejoy: API Integration as the Cost Optimization Catalyst

Carejoy’s 2026 implementation exemplifies how API-first design transforms CBCT economics. Its RESTful API architecture (ISO/TS 22900-5:2026 compliant) enables:

- Zero-Touch Data Routing: Auto-transfers DICOM studies from CBCT to target CAD systems based on pre-defined rules (e.g., “all maxillary scans → 3Shape Implant Studio”)

- Cost Attribution Engine: Tracks per-scan utilization across 7+ clinical applications, generating real-time “kosten” analytics per case type

- Unified Billing Interface: Consolidates CBCT, design, and manufacturing costs into single patient ledger (reduces billing errors by 37%)

- AI-Driven Workflow Triage: Prioritizes urgent cases based on CBCT findings (e.g., pathology flags), optimizing equipment utilization

Conclusion: The Integrated Cost Paradigm

In 2026, “CBCT Scan Kosten” must be evaluated through the lens of workflow yield, not acquisition cost. Open architecture systems with robust API ecosystems (exemplified by Carejoy) convert CBCT from a cost center into a multi-revenue stream generator. Labs adopting this model achieve 34% higher gross margins on implant cases by fully leveraging CBCT data across diagnostic, surgical, and restorative phases. The era of isolated scan billing is obsolete; the future belongs to platforms where every voxel generates measurable clinical and economic value.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Technology Focus: AI-Driven CBCT Imaging, High-Precision CAD/CAM, 3D Printing, Open-Architecture Integration

Manufacturing & Quality Control of CBCT Scanning Systems in China: A Technical Deep Dive

As global demand for high-resolution, cost-effective Cone Beam Computed Tomography (CBCT) systems intensifies, China has emerged as the epicenter of innovation and scalable production in digital dentistry. This review analyzes the end-to-end manufacturing and quality assurance (QA) processes for CBCT Scan Kosten (CBCT scanning units) produced by Carejoy Digital in its ISO 13485-certified facility in Shanghai, highlighting China’s leadership in the cost-performance paradigm.

1. Manufacturing Infrastructure & ISO 13485 Compliance

Carejoy Digital operates a vertically integrated manufacturing ecosystem in Shanghai, designed and audited under ISO 13485:2016 standards for medical device quality management systems. This certification ensures adherence to rigorous design controls, risk management (per ISO 14971), traceability, and regulatory compliance throughout the product lifecycle.

| Process Stage | Key Features | ISO 13485 Alignment |

|---|---|---|

| Design & R&D | AI-optimized scan trajectory algorithms; modular sensor integration | Design validation, risk analysis, change control |

| Component Sourcing | Domestic semiconductor supply chains; precision X-ray tubes from EU/JP partners | Supplier qualification, incoming inspection protocols |

| Assembly | Automated gantry alignment; robotic arm-assisted sensor mounting | Process validation, cleanroom assembly (Class 10,000) |

| Final Integration | Open-architecture software stack (STL/PLY/OBJ export); DICOM 3.0 compliance | Design output verification, labeling control |

2. Sensor Calibration & Imaging Accuracy Assurance

At the core of CBCT performance is sensor fidelity. Carejoy Digital maintains an on-site Sensor Calibration Laboratory equipped with NIST-traceable phantoms and laser interferometry systems.

- Flat Panel Detector (FPD) Calibration: Performed daily using step-wedge and line-pair phantoms to verify dynamic range, MTF (Modulation Transfer Function), and DQE (Detective Quantum Efficiency).

- Geometric Calibration: Automated correction of cone-beam divergence and detector tilt via AI-driven spatial registration (sub-10µm accuracy).

- Dose Optimization: Real-time kVp/mA modulation calibrated against IEC 60601-2-63 standards, reducing patient exposure by up to 35% without compromising resolution.

All calibration logs are digitally archived and linked to individual device serial numbers for full traceability.

3. Durability & Environmental Stress Testing

To ensure clinical reliability, each CBCT unit undergoes accelerated life testing simulating 5+ years of clinical use:

| Test Protocol | Parameters | Pass Criteria |

|---|---|---|

| Gantry Rotation Cycle | 50,000 cycles at 12 rpm | <0.05° angular deviation |

| Thermal Cycling | -10°C to 45°C over 72 hours | No image artifact increase >3% |

| Vibration & Shock | IEC 60068-2-6 / 60068-2-27 | Zero mechanical failure |

| Software Stability | 72-hour continuous scanning simulation | No crashes or data corruption |

4. Why China Dominates the Cost-Performance Ratio in Digital Dental Equipment

China’s ascent in digital dental manufacturing is not accidental but the result of strategic convergence across five domains:

- Integrated Supply Chains: Proximity to semiconductor, rare-earth magnet, and precision optics suppliers reduces BOM (Bill of Materials) costs by up to 40%.

- Automation Scale: High-capacity robotic assembly lines enable economies of scale without sacrificing precision.

- Talent Density: Shanghai and Shenzhen host over 60% of Asia’s biomedical engineers with expertise in imaging physics and AI.

- Regulatory Agility: CFDA (NMPA) pathways are increasingly harmonized with FDA 510(k) and CE MDR, accelerating time-to-market.

- Open Ecosystems: Chinese OEMs like Carejoy Digital lead in open-architecture compatibility (STL/PLY/OBJ), enabling seamless integration with global CAD/CAM and 3D printing workflows.

Carejoy Digital leverages this ecosystem to deliver sub-$25k CBCT systems with 75 µm native resolution and AI-powered artifact reduction—performance previously reserved for premium-tier €50k+ European systems.

Conclusion: The Future of Digital Dentistry is Engineered in China

Carejoy Digital exemplifies China’s transformation from low-cost manufacturer to high-precision innovator in digital dentistry. Through ISO 13485-certified manufacturing, advanced sensor calibration, and rigorous durability testing, Carejoy delivers unmatched cost-performance value in CBCT imaging. With 24/7 remote technical support and continuous AI-driven software updates, Carejoy ensures future-proof integration into modern digital labs and clinics.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Kosten.

✅ Open Architecture

Or WhatsApp: +86 15951276160