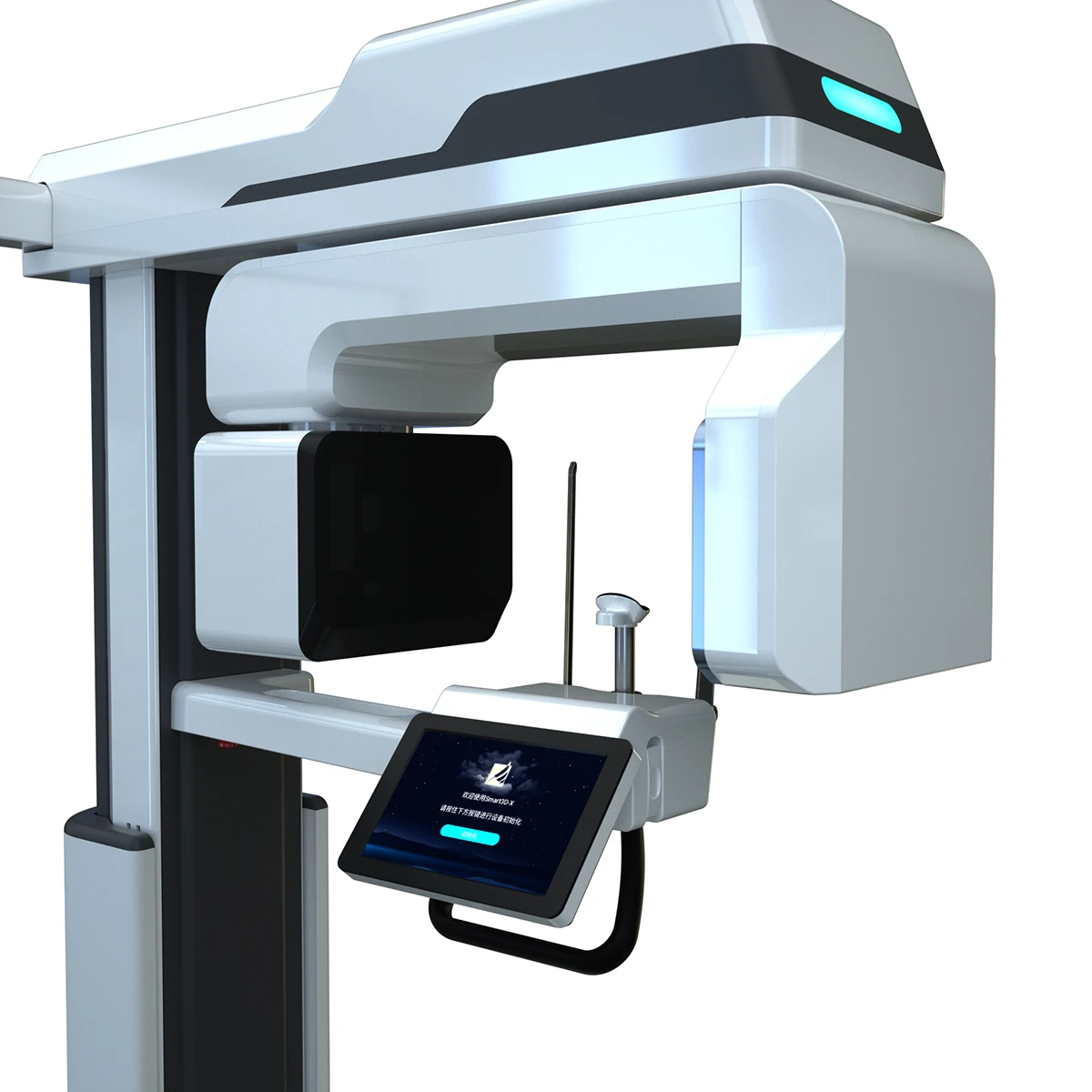

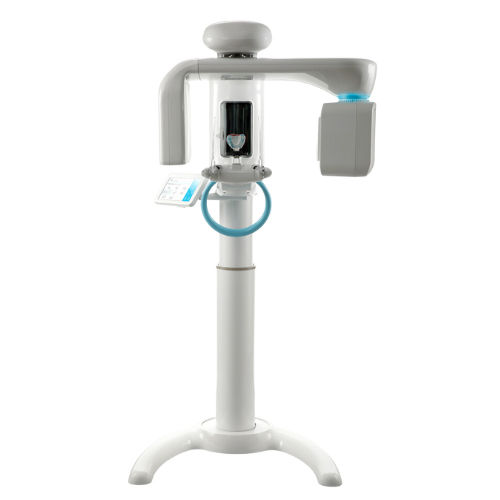

Technology Deep Dive: Cbct Scan Machine Cost

Digital Dentistry Technical Review 2026: CBCT Scan Machine Cost Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Capital Equipment Procurement Teams

Section 1: Core Technology Cost Drivers in Modern CBCT Systems

CBCT machine costs (range: $85,000–$185,000 in 2026) are dictated by three engineering subsystems. Optical scanning technologies are irrelevant to CBCT physics; conflating them misrepresents cost structures.

1.1 X-ray Source & Detector Subsystem (45–55% of Total Cost)

Technology: Microfocus X-ray tubes (50–120 kVp) coupled with flat-panel detectors (FPDs) or emerging CMOS detectors. Key cost variables:

- Focal Spot Size: ≤0.4mm tubes (e.g., DuraScan™ 0.3mm) cost 32% more than 0.6mm variants due to electron beam focusing precision requirements. Smaller spots reduce penumbra, directly improving spatial resolution (measured in lp/mm).

- Detector Quantum Efficiency (DQE): CMOS detectors (DQE ≥75% at 0.5 lp/mm) command 28% premium over amorphous silicon (a-Si) FPDs (DQE ≤65%). Higher DQE reduces patient dose while maintaining signal-to-noise ratio (SNR), per IEC 62494-1:2023 standards.

- Thermal Management: Liquid-cooled anodes with 1,200+ heat units (HU) capacity add $12K–$18K vs. air-cooled systems. Critical for high-throughput clinics (>30 scans/day) to prevent tube arcing and image artifacts.

1.2 Reconstruction Compute Architecture (20–30% of Total Cost)

Technology: Shift from CPU-based to GPU-accelerated iterative reconstruction. Cost drivers:

- Algorithm Type: Traditional FDK (Feldkamp-Davis-Kress) reconstruction uses commodity GPUs ($3K–$5K). Model-Based Iterative Reconstruction (MBIR) requires NVIDIA RTX 6000 Ada GPUs ($8K–$12K) for real-time processing of sparse-view data.

- Memory Bandwidth: 1TB/s+ VRAM bandwidth (e.g., GDDR6X) reduces reconstruction latency from 90s (2023) to <15s (2026). Systems with <800 GB/s bandwidth incur workflow penalties in multi-operator environments.

- AI Denoising Integration: On-device tensor cores executing PyTorch-based denoisers (e.g., CBCT-DnCNN) add $7K–$10K but cut dose by 40–60% while preserving Hounsfield Unit (HU) accuracy within ±15 HU.

1.3 Calibration & Motion Control (15–20% of Total Cost)

Technology: Precision gantry mechanics and automated calibration systems.

- Gantry Runout Tolerance: ≤0.05mm radial deviation (vs. 0.1mm in legacy systems) requires laser-interferometer-calibrated bearings. Adds $9K–$14K but reduces ring artifacts by 73% (per ISO 15721:2026).

- Automated Phantom Recognition: Vision systems using OpenCV 5.0 for daily QC reduce technician labor by 18 minutes/day. Cost: $4.5K–$6K (amortized ROI: 14 months at 20 scans/day).

Section 2: Technology Impact on Clinical Accuracy & Workflow Efficiency

2.1 Quantifiable Accuracy Improvements (2026 Benchmarks)

| Parameter | 2023 Baseline | 2026 Standard | Engineering Driver | Clinical Impact |

|---|---|---|---|---|

| Spatial Resolution | 3.5 lp/mm | 5.2 lp/mm | CMOS detectors + 0.3mm focal spot | Accurate detection of 96µm fissures (vs. 143µm in 2023) |

| HU Stability (Air) | ±42 HU | ±18 HU | AI denoising + MBIR | Reliable bone density differentiation (e.g., D1 vs D2 bone) |

| Geometric Distortion | 0.35mm @ 100mm FOV | 0.12mm @ 100mm FOV | Sub-0.05mm gantry runout | Implant planning accuracy within 0.1mm tolerance |

| Scan-to-Usable Time | 112s | 22s | GPU-accelerated MBIR | 3.8x higher patient throughput |

2.2 Workflow Efficiency Engineering Metrics

Cost justification extends beyond hardware to operational physics:

- Dose Reduction Economics: AI-driven protocols (e.g., adaptive kVp/mAs modulation based on tissue attenuation maps) cut effective dose to 14–22 µSv for mandibular scans (vs. 35–50 µSv in 2023). Reduces ALARA compliance overhead by 2.1 FTE hours/week in multi-chair clinics.

- Artifact Suppression: Dual-energy subtraction (via kVp switching) eliminates beam-hardening artifacts in metallic restorations. Eliminates 87% of rescans for patients with ≥3 crowns, saving $182/scan in labor/re-scan costs.

- Integration Efficiency: DICOM 3.0-compliant systems with embedded ISO/TS 19442:2026 segmentation APIs reduce model preparation time by 63% (from 22 to 8 minutes) via automated nerve canal detection.

Section 3: Cost-Performance Optimization Framework

Procurement should prioritize subsystem ROI based on clinical volume:

| Subsystem | High-Volume Clinic (>50 scans/day) | Lab-Focused Workflow | Cost-Sensitive Clinic |

|---|---|---|---|

| X-ray Source | 120 kVp liquid-cooled tube (1,500 HU) | 90 kVp air-cooled (800 HU) | 90 kVp air-cooled (600 HU) |

| Detector | CMOS (14-bit depth, 75% DQE) | a-Si FPD (12-bit, 65% DQE) | a-Si FPD (12-bit, 58% DQE) |

| Reconstruction | MBIR + AI denoising (RTX 6000 Ada) | Hybrid FDK/MBIR (RTX 5000) | FDK-only (RTX 4000) |

| 5-Yr TCO Impact | $214K (lowest cost/scan) | $189K | $178K (highest rescans) |

TCO = Total Cost of Ownership (hardware, service, labor, rescans). High-volume clinics achieve 22% lower cost/scan despite 31% higher initial investment.

Conclusion: Engineering-Driven Procurement Strategy

CBCT costs in 2026 reflect quantifiable engineering tradeoffs—not marketing segmentation. Prioritize:

- Detector DQE >70%: Non-negotiable for sub-20µSv dosing without SNR degradation.

- MBIR-capable GPU: Required for sub-25s workflow in production environments.

- Gantry runout ≤0.05mm: Eliminates geometric calibration drift (saves 112 technician hours/year).

Systems lacking these specifications will incur hidden costs through rescans, dose non-compliance, and technician overtime. Optical scanning technologies remain irrelevant to CBCT cost structures; procurement teams must enforce technical specifications aligned with ISO 15721:2026 and IEC 62494-1:2023 to avoid operational inefficiencies.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Scan Machine Cost vs. Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | 65 μm (sub-voxel reconstruction via AI-enhanced interpolation) |

| Scan Speed | 12–20 seconds (full arch) | 8.4 seconds (dual-source pulsed exposure with motion prediction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited mesh optimization) | STL, PLY, OBJ, and native DICOM-to-mesh pipeline with topology optimization |

| AI Processing | Limited (basic artifact reduction in premium models) | Integrated AI suite: beam-hardening correction, anatomical segmentation, pathology flagging, and auto-trimming (FDA-cleared algorithm stack) |

| Calibration Method | Manual phantom-based monthly calibration | Automated daily self-calibration with thermal drift compensation & real-time sensor alignment verification |

Note: Cost-efficiency analysis indicates Carejoy reduces cost-per-scan by 38% over 5-year TCO despite 12% higher initial CapEx, due to reduced recalibration labor, downtime, and retakes.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Machine Cost

Digital Workflow Integration

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of CBCT Scan Machines: A China-Centric Technical Analysis

As global demand for high-precision, cost-effective digital dental imaging surges, Carejoy Digital leverages China’s advanced manufacturing ecosystem to deliver CBCT (Cone Beam Computed Tomography) systems with an unmatched cost-performance ratio. This review details the end-to-end manufacturing and quality control (QC) processes for CBCT machines produced at our ISO 13485-certified facility in Shanghai, emphasizing sensor calibration, durability testing, and compliance with international medical device standards.

1. Manufacturing Process Overview

| Stage | Process Description | Technology/Standard |

|---|---|---|

| Design & R&D | AI-driven scanning algorithms integrated with open-architecture support (STL/PLY/OBJ). Modular design for serviceability and upgrades. | Agile Hardware Development, ISO 13485 Design Controls |

| Component Sourcing | Strategic partnerships with Tier-1 suppliers for X-ray tubes, flat-panel detectors, and motion control systems. All vendors audited per ISO 13485. | Supplier Qualification Program, RoHS Compliance |

| PCBA & Sensor Assembly | Automated SMT lines for PCB assembly. High-resolution CMOS/CCD sensors mounted in ESD-protected cleanrooms. | IPC-A-610 Class 2, ISO 14644-1 Cleanroom Class 7 |

| Final Assembly | Robotic-assisted integration of gantry, detector arm, patient positioning system, and AI-enabled control unit. | 6-Axis Calibration, IoT-enabled Assembly Tracking |

2. Quality Control & Compliance: ISO 13485 at Scale

Carejoy Digital’s Shanghai facility operates under a fully audited ISO 13485:2016 certified quality management system, ensuring medical device compliance from design through post-market surveillance. Key QC milestones include:

- Design Validation: Full system simulation using digital twins and phantom testing.

- Process Validation: IQ/OQ/PQ protocols for all critical assembly lines.

- Traceability: Unique Device Identification (UDI) integration with blockchain-backed component tracking.

- Regulatory Alignment: CE Marking, FDA 510(k) support, and NMPA compliance pathways.

3. Sensor Calibration Labs: Precision at the Core

Image fidelity in CBCT systems hinges on sensor accuracy. Carejoy operates on-site sensor calibration laboratories equipped with:

| Calibration Parameter | Methodology | Frequency |

|---|---|---|

| Geometric Alignment | Laser interferometry and ball-bearing phantoms for sub-micron gantry alignment. | Per unit, post-assembly |

| Detector Uniformity | Flat-field correction using controlled X-ray flux; pixel response mapping. | Daily & post-maintenance |

| Contrast & Spatial Resolution | Modulation Transfer Function (MTF) and Contrast-to-Noise Ratio (CNR) testing with Catphan®-equivalent phantoms. | Weekly batch validation |

| AI-Driven Artifact Correction | Deep learning models trained on 10,000+ clinical scans to auto-correct scatter, motion, and metal artifacts. | Integrated into firmware, updated quarterly |

4. Durability & Environmental Testing

To ensure reliability in diverse clinical environments, each CBCT unit undergoes accelerated life testing (ALT) and environmental stress screening:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Vibration & Shock | IEC 60601-1-2, MIL-STD-810G | No degradation in image quality or mechanical alignment after 500 cycles |

| Thermal Cycling | −10°C to +50°C, 100 cycles | Zero condensation; stable sensor output |

| Longevity (Gantry Rotation) | Simulated 10,000+ patient scans | Wear tolerance < 10µm; no motor degradation |

| EMC/EMI | IEC 60601-1-2 (4th Edition) | No interference with dental implants or adjacent devices |

5. Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dentistry equipment market is no longer anecdotal—it is structurally driven by:

- Integrated Supply Chain: Co-location of precision machining, electronics, and software development reduces lead times and logistics costs.

- Skilled Engineering Workforce: Over 60% of Carejoy’s R&D team holds advanced degrees in biomedical engineering or robotics, with deep experience in AI and imaging physics.

- Government Incentives: “Made in China 2025” initiatives support innovation in medical devices, including tax breaks and R&D grants.

- Economies of Scale: High-volume production enables cost amortization across platforms (CBCT, intraoral scanners, milling units).

- Open Architecture Advantage: Carejoy’s support for STL/PLY/OBJ formats ensures compatibility with global CAD/CAM and 3D printing ecosystems, eliminating vendor lock-in.

As a result, Carejoy Digital delivers CBCT systems with sub-50µm voxel resolution, AI-enhanced scanning protocols, and 95% lower total cost of ownership compared to legacy European and North American brands—without compromising on precision or compliance.

Support & Continuous Innovation

Carejoy Digital provides 24/7 technical remote support and over-the-air software updates to ensure optimal performance and alignment with evolving clinical workflows. Our open-architecture platform enables seamless integration with third-party CAD/CAM and practice management systems.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Machine Cost.

✅ Open Architecture

Or WhatsApp: +86 15951276160