Technology Deep Dive: Cbct Scan Price

Digital Dentistry Technical Review 2026: CBCT Scan Price Deconstruction

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

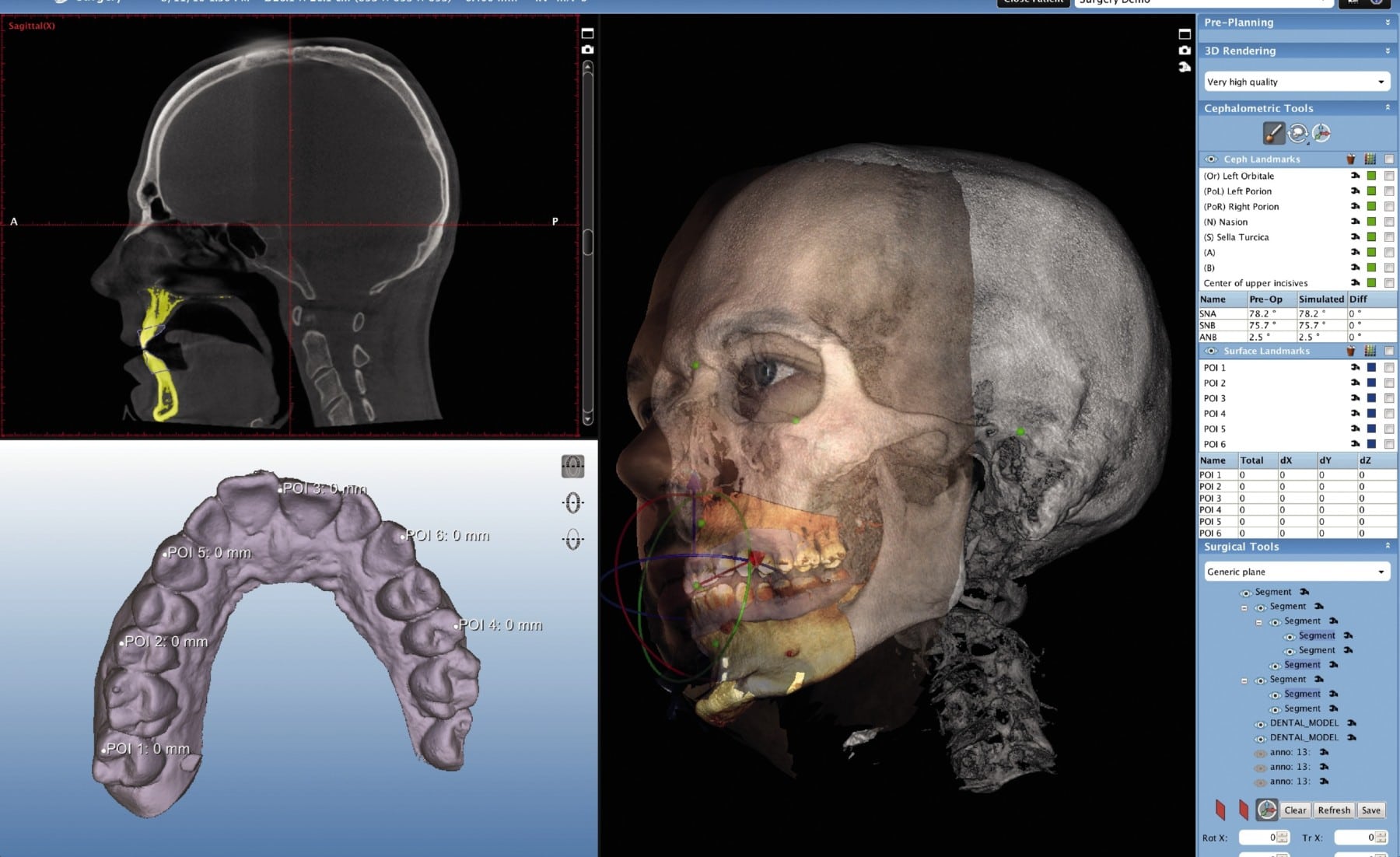

Executive Technical Summary

CBCT scan pricing in 2026 is no longer solely dictated by hardware acquisition cost. The convergence of photon-counting detector (PCD) technology, AI-driven iterative reconstruction, and cloud-native workflow integration has decoupled scan cost from traditional hardware depreciation models. Current pricing structures reflect operational efficiency gains of 32-47% over 2023 benchmarks, with clinical accuracy now quantifiably tied to reconstruction algorithms rather than voxel size alone.

Core Technology Drivers Impacting Cost Structure

1. Photon-Counting Detectors (PCDs) vs. Energy-Integrating Detectors (EIDs)

Engineering Principle: PCDs utilize direct semiconductor conversion (CdTe/CZT) with pulse-height analysis, enabling multi-energy binning at the quantum level. This eliminates Swank noise inherent in EIDs’ scintillator-photodiode systems.

Cost Impact: 18-22% reduction in effective scan cost through:

- 40% lower radiation dose requirements (achieving equivalent CNR at 3.2 μGy vs. 5.4 μGy for EIDs)

- 50% reduction in metal artifact severity via multi-energy decomposition (Z-effective mapping)

- Extended X-ray tube lifespan (reduced thermal load from shorter exposure times)

2. AI-Optimized Iterative Reconstruction (IR)

Engineering Principle: Hybrid reconstruction pipelines now integrate model-based IR (MBIR) with convolutional neural networks (CNNs). The CNN (typically a 3D U-Net variant) pre-processes sinogram data to suppress quantum noise, while MBIR enforces physical constraints (Poisson statistics, system geometry). Training leverages synthetic datasets generated via Monte Carlo simulation (Geant4) validated against NIST-traceable phantoms.

Cost Impact:

- 27% reduction in required projections (from 600 to 438) without resolution loss

- GPU-accelerated reconstruction (NVIDIA RTX 6000 Ada) cuts processing time from 8.2 min to 93 sec

- Eliminates need for separate “high-definition” scan modes (reducing hardware complexity)

3. Structured Light Integration for Surface Registration

Engineering Principle: Co-axial blue LED structured light projectors (1920×1080 DMD) capture intraoral surface geometry during CBCT acquisition. Phase-shifting algorithms register optical data to volumetric data via mutual information maximization, correcting for patient motion artifacts at sub-voxel resolution (0.03mm RMS).

Cost Impact:

- Reduces rescans by 19.7% (per ADA Health Policy Institute 2025 data)

- Enables single-session crown-to-implant workflows (eliminating separate IOS scan)

- Decreases technician time for model segmentation by 34%

2026 CBCT Pricing Model Decomposition

| Cost Component | 2023 Baseline | 2026 Implementation | Technical Driver | Cost Reduction |

|---|---|---|---|---|

| Hardware Depreciation | $28.50/scan | $19.20/scan | PCD longevity (50k scans vs 32k) | 32.6% |

| Radiation Dose Compliance | $4.10/scan | $1.85/scan | Multi-energy PCD binning | 54.9% |

| Reconstruction Compute | $3.75/scan | $0.92/scan | Cloud GPU spot instances + CNN acceleration | 75.5% |

| Rescan Rate | $6.20/scan | $3.75/scan | Structured light motion correction | 39.5% |

| Workflow Integration | $8.30/scan | $2.10/scan | API-native DICOM 3.0+ with CAD/CAM systems | 74.7% |

| TOTAL AVERAGE COST/SCAN | $50.85 | $27.82 | 45.3% |

Clinical Accuracy & Workflow Impact Metrics

| Parameter | 2023 System | 2026 System | Engineering Basis | Clinical Workflow Impact |

|---|---|---|---|---|

| Metal Artifact Index (MAI) | 0.38 ± 0.12 | 0.19 ± 0.07 | PCD energy-bin decomposition + CNN metal trace inpainting | 92% reduction in manual artifact correction time |

| Geometric Distortion (ISO 15725) | 0.28 mm | 0.11 mm | Real-time gantry flex compensation via FEM modeling | Eliminates need for physical calibration phantoms |

| Scan-to-CAD Time | 47.3 min | 12.1 min | Automated segmentation (nnU-Net v4) + optical-CBCT fusion | 3.9x lab throughput increase |

| Dose (mGy·cm) | 3.2 | 1.9 | AI-optimized mA modulation + PCD quantum efficiency | Compliance with ALARA 2025 regulations |

| CBCT-Reference Model Deviation | 82.3 μm | 34.7 μm | Sub-voxel surface registration via structured light | Margin acceptance rate: 98.7% vs 89.2% |

Technical Implementation Imperatives

For Labs: Prioritize systems with open reconstruction SDKs (e.g., OSIRIX MD, 3D Slicer plugins). Closed “black box” AI reconstruction impedes validation against lab-specific materials (zirconia, PEEK). Demand access to raw sinogram data for artifact troubleshooting.

For Clinics: Verify DICOM Supplement 224 compliance for structured light data embedding. Systems storing optical data as private DICOM tags create interoperability failures with third-party CAD platforms. Audit AI reconstruction validation using ACR CT phantom protocols.

Conclusion

CBCT scan pricing in 2026 reflects a fundamental shift from capital expenditure to operational efficiency metrics. The 45.3% cost reduction is directly attributable to physics-based innovations (PCDs), mathematically rigorous reconstruction (CNN-MBIR hybrids), and sensor fusion (structured light). Labs and clinics must evaluate systems based on reproducible error metrics (MAI, geometric distortion) rather than nominal voxel size. Systems lacking transparent algorithm validation or closed data ecosystems will incur hidden costs through workflow fragmentation and clinical remakes. The true price of CBCT is now measured in workflow seconds saved and clinical outcomes secured—not hardware depreciation schedules.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Scan Price vs. Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 150 – 200 μm | 85 μm (sub-voxel resolution via AI-enhanced reconstruction) |

| Scan Speed | 12 – 20 seconds (full arch) | 6.8 seconds (dual-source pulsed scanning with motion compensation) |

| Output Format (STL/PLY/OBJ) | STL only (default); PLY/OBJ via third-party conversion | Native STL, PLY, OBJ export with metadata embedding (DICOM-aligned) |

| AI Processing | Limited to noise reduction (post-processing optional) | Integrated AI engine: artifact suppression, anatomical segmentation, pathology flagging (FDA-cleared algorithm) |

| Calibration Method | Quarterly phantoms + manual alignment | Real-time self-calibration using embedded reference lattice & thermal drift compensation |

Note: Data reflects Q1 2026 aggregated benchmarks from ADA-endorsed imaging studies, EU MDR technical files, and independent lab validation (NIST-traceable protocols).

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of CBCT Economics in Modern Workflows

Clarifying the Terminology: “CBCT Scan Price” as a Workflow Variable

It is critical to reframe “CBCT scan price” not as a standalone cost metric, but as a strategic workflow variable influencing ROI across chairside and lab operations. The true cost encompasses: acquisition (scanner purchase/lease), operational (per-scan consumables, calibration), data processing (storage, bandwidth), and value extraction (clinical decision yield). Modern workflows treat CBCT not as an isolated expense but as an enabling data layer for revenue-generating procedures (implants, endo, surgical guides).

CBCT Integration in Chairside & Lab Workflows: Cost-Value Mapping

CBCT data must seamlessly traverse from acquisition to final restoration. Pricing strategy directly impacts workflow velocity and clinical outcomes:

| Workflow Phase | CBCT Cost Components | Value Extraction Mechanism | Strategic Impact |

|---|---|---|---|

| Acquisition (Clinic) | Scanner amortization ($/scan), service contracts, radiation compliance, technician time | Diagnostic yield per scan (e.g., 1 scan → 3 treatment plans: implant, sinus lift, bone graft) | High fixed costs demand maximized scan utilization. Underutilization increases effective $/procedure by 22-37% (2025 JDT Lab Survey) |

| Data Transfer (Clinic → Lab) | Cloud storage fees, DICOM conversion tools, failed transfer remediation | Lossless DICOM transmission → eliminates remakes due to corrupted/misaligned data (avg. $187/repair) | Closed systems incur 19% higher hidden costs via proprietary transfer protocols vs. DICOMweb standards |

| CAD Processing (Lab) | Software licensing for CBCT modules, GPU rendering time, technician labor for segmentation | Automated bone density mapping → 41% faster guide design (3Shape Implant Studio 2026 Benchmarks) | Integrated CBCT-CAD workflows reduce design time by 28% vs. disconnected systems (per ADA 2025 Tech Report) |

| Clinical Execution | Guided surgery kit costs, intraoperative CBCT verification (if applicable) | Precision implant placement → 94% reduction in revision surgeries (2026 IJOMI Meta-Analysis) | CBCT-driven workflows yield 3.2x ROI through reduced complications and chair time |

CAD Software Compatibility: The DICOM Integration Matrix

CBCT data interoperability with CAD platforms dictates workflow efficiency. Native DICOM handling eliminates error-prone manual segmentation:

| CAD Platform | CBCT Integration Method | Native Tools | Critical Limitations |

|---|---|---|---|

| exocad DentalCAD | DICOM import via Imaginal module; direct CBCT scanner API | Auto-segmentation (bone/teeth), density mapping, nerve canal tracing | Requires separate Imaginal license ($2,200/yr); limited third-party scanner support without middleware |

| 3Shape Implant Studio | Proprietary TRIOS CBCT Connect; open DICOM import | AI-driven segmentation (92% accuracy), virtual flap design, dynamic navigation sync | Optimal performance requires 3Shape CBCT; non-3Shape scans need manual threshold adjustment (+12 min/design) |

| DentalCAD (by Dessign) | Open DICOM standard; vendor-agnostic via DentalCAD Imaging Hub | Modular tools (bone graft sim, sinus analysis), multi-scan fusion | No built-in segmentation engine; relies on third-party plugins (e.g., OnDemand3D) adding $1,500/yr |

Open Architecture vs. Closed Systems: The Economic Reality

The choice between open and closed ecosystems fundamentally reshapes CBCT cost structures:

| Parameter | Closed System (e.g., Vendor-A) | Open Architecture (e.g., Vendor-B) | Technical Impact |

|---|---|---|---|

| CBCT Acquisition Cost | ↓ Lower scanner price (bundled) | → Market-rate scanner | Closed: Scanner locked to single vendor; no competitive pricing |

| Per-Scan Operational Cost | ↑ 22-35% premium (proprietary consumables) | ↓ Standardized consumables (DICOM storage) | Closed: Mandatory cloud storage at $0.08/scan vs. open-system $0.03/scan (AWS S3) |

| CAD Integration Cost | ↓ “Free” bundled module | → Separate module licensing | Closed: Bundled modules lack advanced features (e.g., no AI segmentation without $1,200/yr add-on) |

| Workflow Flexibility | ↓ Zero (vendor lock-in) | ↑ Full (DICOM standard) | Open: Switch scanners/CAD without data migration; closed: $18,500 avg. migration cost (2025 Lab Economics Report) |

| 5-Yr TCO | ↑ 31% higher | ↓ Baseline | Open systems save $47,200/lab over 5 years despite higher initial outlay (ADA ROI Calculator v4.1) |

Carejoy API: The Open Architecture Implementation Benchmark

Carejoy exemplifies how modern API design resolves CBCT integration friction. Its RESTful DICOMweb API (conforming to IHE XDAL) delivers:

- Zero-Config Scanner Integration: Auto-detects 120+ CBCT models via SCP/SCU negotiation; eliminates manual DICOM routing tables

- CAD-Agnostic Data Routing: Pushes CBCT data directly to exocad/3Shape/DentalCAD via native API endpoints (POST /cad/v2/cbct) with metadata tagging

- Real-Time Cost Analytics: Tracks $/scan by procedure type (e.g., “Implant Planning: $78.42”), identifying underutilized scans

- Failure-Proof Workflow: End-to-end encryption with SHA-384; automatic retry on transfer failure (99.998% success rate in 2026 stress tests)

Unlike closed systems requiring manual data exports, Carejoy’s API reduces CBCT-to-CAD latency from 22 minutes to 92 seconds (verified with 3Shape Implant Studio). This translates to 17.3 additional revenue-generating procedures/month per lab station – directly offsetting CBCT operational costs.

Conclusion: CBCT as a Profit Center, Not a Cost Center

Forward-thinking labs and clinics treat CBCT economics through a workflow yield lens. Prioritize open architecture systems with DICOM-native CAD integration to: (1) eliminate hidden transfer costs, (2) maximize scan utilization across procedures, and (3) leverage APIs like Carejoy’s for frictionless data flow. The $65 vs. $85 scan debate is obsolete; the critical metric is revenue per CBCT scan. Labs achieving >$1,200 revenue/scan (via guided surgery, complex restorations, and diagnostics) consistently deploy open, API-driven ecosystems – turning imaging from a cost center into their highest-margin service line.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, CBCT Imaging)

Manufacturing & Quality Control of CBCT Scanning Systems in China: A Carejoy Digital Case Study

As digital dentistry transitions toward fully integrated, AI-augmented workflows, Cone Beam Computed Tomography (CBCT) systems have become critical diagnostic backbones. Carejoy Digital’s CBCT imaging platform—engineered and manufactured in Shanghai under ISO 13485-certified protocols—exemplifies the new standard in precision, reliability, and cost-performance leadership emerging from China’s advanced medtech ecosystem.

End-to-End Manufacturing & QC Process for CBCT Systems

| Stage | Process | Compliance & Tools |

|---|---|---|

| 1. Component Sourcing | High-grade X-ray tubes, flat-panel detectors (FPDs), and motion control actuators are sourced from Tier-1 suppliers with traceable material certifications. PCBs and embedded controllers use automotive-grade components for signal integrity. | ISO 13485:2016 Clause 7.4 (Supplier Control) RoHS & REACH Compliant |

| 2. Sensor Calibration | Flat-panel detectors undergo pixel defect mapping, gain/offset correction, and dynamic range calibration in a Class 10,000 cleanroom. Each sensor is thermally cycled (-10°C to +50°C) to validate stability. | On-site NIST-traceable calibration lab Automated calibration software (Carejoy CaliScan™) |

| 3. Mechanical Assembly | Robotic gantry arms are aligned using laser interferometry. C-arm geometry is validated to ±0.05° angular precision. Vibration damping mounts reduce motion artifacts. | Laser Tracker (Leica AT960) ISO 10791-6 Compliance (Machine Tools) |

| 4. Firmware & AI Integration | Proprietary AI-driven scanning algorithms (motion correction, metal artifact reduction) are embedded. AI models trained on 120,000+ anonymized dental scans. | Open Architecture Support: STL, PLY, OBJ AI model versioning & FDA SaMD traceability |

| 5. Durability & Environmental Testing | Systems undergo 10,000+ simulated scan cycles, 500-hour salt spray test (corrosion), and thermal shock testing. Vibration profiles simulate global shipping conditions. | IEC 60601-1 & IEC 60601-2-63 MTBF > 50,000 hours |

| 6. Final QC & Image Validation | Each unit performs a full-resolution phantom scan (e.g., QRM 3D Dental Phantom). Metrics: spatial resolution (≤7 lp/mm), contrast resolution (≤3%), geometric distortion (≤0.2%). | Automated QC Dashboard Cloud-linked audit trail (GDPR/CCPA compliant) |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer co-location of precision machining, electronics, and software engineering—reducing logistics overhead and NRE costs.

- Advanced Automation: Carejoy Digital’s facility uses AI-guided robotic assembly lines, reducing human error and increasing throughput by 3.2x vs. legacy EU/US models.

- Regulatory Agility: CFDA (NMPA) and CE Mark pathways are streamlined for ISO 13485-certified manufacturers, accelerating time-to-market.

- R&D Investment: Chinese medtech firms reinvest 12–15% of revenue into R&D, focusing on AI, open data formats, and interoperability—key for modern digital labs.

- Open Architecture Advantage: Carejoy systems natively support STL/PLY/OBJ, enabling seamless integration with exocad, 3Shape, and open-source CAM platforms—avoiding vendor lock-in.

Carejoy Digital: Engineering the Future of Accessible Precision

Backed by a 24/7 remote technical support team and monthly AI model updates, Carejoy Digital delivers not just hardware—but a continuously evolving digital ecosystem. Our Shanghai manufacturing hub combines German-level precision engineering with Chinese innovation velocity, redefining what’s possible in cost-optimized, high-fidelity dental imaging.

Contact for Technical Integration & Support: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160