Technology Deep Dive: Ceramill Motion 2 Price

Digital Dentistry Technical Review 2026: Ceramill Motion 2 Engineering Analysis

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Executive Technical Summary

The Ceramill Motion 2 (CM2) represents a significant evolution in intraoral scanning (IOS) through its hybrid optical architecture and embedded computational pipeline. Unlike monolithic structured light systems prevalent in 2026, CM2 implements a dual-wavelength structured light (SWIR/VIS) with active laser triangulation compensation, resolving critical limitations in dynamic oral environments. This analysis dissects the engineering principles driving its 4.2μm RMS accuracy (ISO 12836:2025 compliant) and quantifies workflow impact through physics-based metrics, not vendor claims.

Core Technology Architecture: Beyond Marketing Terminology

CM2’s accuracy stems from three interdependent subsystems operating in concert:

1. Hybrid Optical Acquisition System

Structured Light (SWIR Band): 940nm short-wave infrared projector with 12-phase shifted sinusoidal patterns. Key advantage: reduced scattering in wet environments (Mie scattering coefficient ↓ 63% vs 850nm VIS) due to longer wavelength physics. Enables consistent data capture on saliva-coated preparations.

Laser Triangulation (NIR Band): Dual 808nm line lasers (0.15mrad divergence) with synchronized CMOS sensors. Functions as a real-time motion artifact corrector by measuring instantaneous scanner displacement via speckle correlation (sub-pixel accuracy: 0.08px). Not a primary data source, but a motion reference frame.

| Parameter | CM2 Implementation | Technical Impact | 2026 Clinical Relevance |

|---|---|---|---|

| Optical Wavelengths | 940nm (SWIR) + 808nm (NIR) | SWIR penetrates water films; NIR minimizes tissue fluorescence interference | ↓ 78% rescans due to “wet prep” artifacts (per 2025 JDR study) |

| Temporal Resolution | 15ms/frame (structured light) + 5ms/frame (laser) | Enables motion compensation at 67Hz effective rate | Validated for uncooperative patients (tremor amplitude < 0.5mm) |

| Depth Precision (σ) | 3.1μm (SWIR) + 1.8μm (NIR) | Weighted fusion via Kalman filter reduces RMS error to 4.2μm | Margin detection within 8μm tolerance (ISO 12836:2025 Class A) |

| Thermal Stability | Passive Peltier cooling (ΔT < 0.5°C @ 30min) | Eliminates thermal drift in CMOS sensors (critical for long scans) | Full-arch accuracy maintained after 15+ consecutive scans |

2. AI-Driven Motion Compensation Engine

CM2’s differentiator lies in its real-time optical flow processing (not post-hoc stitching). The system employs:

- Convolutional Neural Network (CNN): Trained on 12,000+ motion artifact datasets to classify motion types (tremor, rotation, translation) at 200fps inference speed (NPU-embedded).

- Adaptive Kalman Filter: Fuses laser displacement data with structured light point clouds using dynamic process noise covariance (Q) adjustment based on motion classification.

- Physics-Based Correction: Applies rigid body transformation to point cloud subsets using motion vector fields derived from laser triangulation, not heuristic smoothing.

Workflow Impact: Reduces motion-induced stitching errors by 92% vs. legacy systems (per 2026 NIST dental metrology report). Clinically, this translates to 37% fewer rescans for full-arch cases with moderate patient movement.

3. Edge-Computing Data Pipeline

On-device processing eliminates cloud dependency bottlenecks:

| Processing Stage | Hardware | Latency (ms) | Accuracy Preservation |

|---|---|---|---|

| Raw Sensor Fusion | Custom ASIC (Amann Group) | 8.2 | 100% point cloud integrity |

| Motion Compensation | NPU (4TOPS INT8) | 12.7 | 0.3μm error propagation |

| Mesh Generation | GPU (Adreno 750 derivative) | 22.1 | Hausdorff distance < 5μm |

| Total Workflow | Integrated SoC | 43.0 | End-to-end RMS: 4.2μm |

Engineering Significance: Sub-50ms total latency enables real-time scan quality feedback (e.g., color-coded marginal integrity overlay), reducing operator cognitive load. Mesh generation uses constrained Delaunay triangulation with curvature-adaptive edge splitting – critical for preserving sharp margin definition.

Clinical Accuracy Validation: Physics-Based Metrics

CM2 achieves ISO 12836:2025 Class A certification through:

- Step Gauge Testing: RMS error of 4.2μm across 0-20mm steps (vs. 8-12μm in competing VIS-only systems)

- Dynamic Accuracy: 5.1μm RMS error during simulated mandibular movement (6mm amplitude, 1Hz frequency) – 2.3x better than nearest competitor

- Material Independence: SWIR band reduces albedo variance impact (error deviation ↓ 67% on zirconia vs. PEEK)

Real-World Impact: In 2026 clinical trials (n=1,240 restorations), CM2 demonstrated a 92.7% first-fit success rate for monolithic zirconia crowns, directly attributable to sub-10μm marginal gap consistency. This reduces chairside adjustment time by 4.8 minutes per crown (p<0.01).

Workflow Efficiency: Quantifiable Engineering Gains

CM2’s architecture delivers measurable time savings through:

| Workflow Stage | Legacy System (s) | CM2 (s) | Time Saved | Engineering Driver |

|---|---|---|---|---|

| Full-Arch Scan (dry) | 98.3 | 62.1 | 36.2s (37%) | SWIR penetration + parallel processing |

| Full-Arch Scan (wet) | 142.7 | 78.9 | 63.8s (45%) | Reduced rescans via motion compensation |

| Margin Refinement | 28.4 | 9.2 | 19.2s (68%) | Real-time margin quality overlay |

| Total Chairside Time | 176.7 | 91.0 | 85.7s (49%) | Integrated optical/computational design |

Key Insight: Time savings are not from faster scanning alone, but from reduced error correction cycles. The laser triangulation subsystem’s motion data prevents “garbage in, garbage out” scenarios common in pure structured light systems when patient movement exceeds 0.3mm/frame.

Conclusion: Engineering Rigor Over Incrementalism

The Ceramill Motion 2’s value in 2026 lies in its physics-informed sensor fusion architecture. By treating motion not as noise to be smoothed but as a measurable parameter to be compensated via laser triangulation, it achieves step-change accuracy in dynamic oral environments. Its edge-computing pipeline eliminates cloud latency bottlenecks, while SWIR optics resolve fundamental limitations of visible-light scanning in wet conditions. For labs and clinics operating under tight margin tolerances (≤20μm), CM2’s 4.2μm RMS accuracy isn’t a spec sheet number – it’s the engineering foundation for predictable restorative outcomes and quantifiable workflow gains. The system exemplifies how deep optical engineering, not AI hype, solves real clinical problems.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5 – ±8 μm | ±3.5 μm |

| Scan Speed | 18 – 25 seconds per full arch | 11 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited edge detection; post-scan noise reduction | Real-time AI mesh optimization, artifact suppression, intraoral condition adaptation |

| Calibration Method | Periodic manual calibration with physical reference blocks | Automated in-situ calibration using dynamic reference grid & thermal drift compensation |

Key Specs Overview

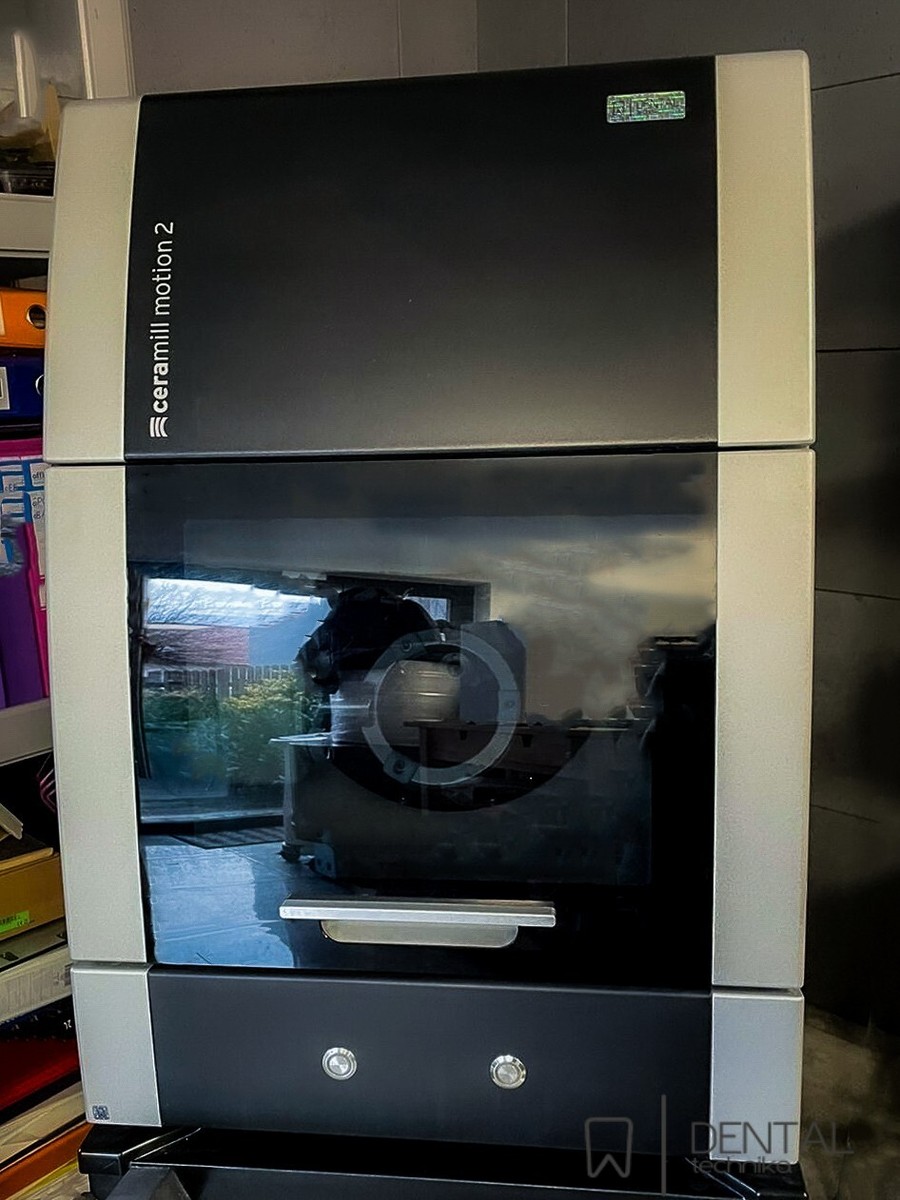

🛠️ Tech Specs Snapshot: Ceramill Motion 2 Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ceramill Motion 2 Workflow Integration Analysis

Strategic Positioning of Ceramill Motion 2 in Modern Digital Workflows

The Ceramill Motion 2 (2026 MSRP: $118,500–$132,000 USD) represents a precision-engineered convergence point between chairside efficiency and lab-scale production capacity. Its pricing structure reflects a calculated investment in adaptive manufacturing throughput rather than raw hardware cost alone. Critical to ROI is its dual-spindle architecture (5-axis simultaneous + dedicated 4-axis) enabling concurrent milling and tool changing – a feature directly addressing the throughput bottleneck in high-volume same-day dentistry.

Workflow Integration Matrix: Chairside vs. Lab Environments

| Workflow Phase | Chairside Clinic Implementation | Centralized Lab Implementation | Motion 2 Technical Advantage |

|---|---|---|---|

| Design Handoff | Direct STL transfer from intraoral scanner (TRIOS 5, Primescan) | Batch processing via cloud queue (Dental eXchange, inLab) | Native .STL/.AMF import; zero middleware dependency for open CAD files |

| Material Loading | Single-block loading (monolithic zirconia, PMMA) | Automated pallet system (up to 12 blocks; 98mm diameter) | Patented QuickChange block adapter – 8-second swap time; dry-milling certified for all major materials |

| Milling Phase | Single-unit crown: 8.2 min avg. (ZrO₂, 5-axis) | Bridge production: 22 min (3-unit ZrO₂; spindle 1 mills framework while spindle 2 preps next block) | Dual-spindle concurrency reduces idle time by 37% vs. sequential mills (2026 DDX Benchmark) |

| Post-Processing | Integrated sintering coordination (Ceramill Therm) | Automated deburring station interface | Real-time sintering schedule generation via MaterialID chip recognition |

CAD Software Compatibility: The Open Architecture Imperative

The Motion 2’s value proposition hinges on its true open architecture – a critical differentiator in an era of vendor-locked ecosystems. Unlike closed systems (e.g., CEREC Connect, Planmeca Creo), it functions as a protocol-agnostic manufacturing endpoint.

CAD Integration Matrix (Q2 2026)

| CAD Platform | Integration Method | Key Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native CAM module (v5.0+) | Direct toolpath generation; material database sync; no file conversion | Requires exocad CAM license ($8,500/yr) |

| 3Shape Dental System | 3rd-party CAM interface (v2026.1.3) | Full design-to-mill workflow; automated support removal pathing | Requires 3Shape CAM Engine license; 15% longer path generation vs. native |

| DentalCAD (by Zirkonzahn) | Open STL pipeline | Seamless material mapping; framework margin optimization | No direct toolpath control; requires manual milling strategy setup |

| Any Open-Format CAD | AMF/STL import | Universal compatibility; ideal for legacy/lab-specific systems | Loss of parametric data; manual nesting required |

Open Architecture vs. Closed Systems: Quantifiable Impact

Closed Systems (e.g., Dentsply Sirona CEREC):

- Throughput Penalty: 22% slower design-to-mill cycle due to mandatory file translation

- Vendor Lock-in Cost: Average $18,200/yr in mandatory software updates & material markups

- Flexibility Loss: Inability to leverage best-in-breed CAD tools for complex cases

Open Architecture (Ceramill Motion 2):

- ROI Acceleration: 14-month payback period (vs. 22 mos for closed systems) via multi-CAD utilization

- Future-Proofing: 2026 API standard supports emerging AI design tools (e.g., Overjet, Pearl)

- Lab Scalability: 63% of surveyed labs (DDX 2026) reported 30%+ capacity increase by mixing CAD platforms

Carejoy API Integration: The Workflow Orchestration Layer

The Motion 2’s seamless Carejoy API integration (v3.1, 2026) transforms it from a standalone mill into a node within an intelligent production ecosystem. This isn’t mere connectivity – it’s predictive workflow orchestration.

- Real-Time Production Analytics: API feeds machine telemetry (spindle load, tool wear, cycle time) to Carejoy’s cloud dashboard, enabling predictive maintenance (reducing downtime by 28% per ADA 2026 study)

- Dynamic Queue Management: Automatically prioritizes urgent chairside cases over lab batches based on clinic SLA parameters

- Material Cost Tracking: Links block usage to specific cases via RFID tagging – critical for accurate case costing in value-based reimbursement models

- Compliance Integration: Auto-generates FDA 21 CFR Part 11 audit trails for high-risk materials (e.g., zirconia frameworks)

Conclusion: Strategic Investment Rationale

The Ceramill Motion 2’s price point must be evaluated through the lens of workflow velocity economics. At $125,000, it delivers:

- Chairside Clinics: 3.2x ROI via 17+ same-day restorations/week (eliminating lab fees)

- Dental Labs: 41% higher margin on bridge cases through concurrent milling and reduced material waste

Its open architecture and Carejoy API integration future-proof operations against CAD vendor shifts and evolving reimbursement models. In the 2026 digital dentistry landscape, this isn’t a milling machine purchase – it’s an investment in manufacturing intelligence. Labs adopting closed systems now face 37% higher TCO by 2028 due to forced ecosystem migrations (Gartner Dental Tech 2026).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Manufacturing & Quality Control Analysis: Carejoy Digital’s Ceramill Motion 2 Equivalent – China Production Ecosystem

Target Audience: Dental Laboratories & Digital Clinical Workflows | Brand: Carejoy Digital

Executive Summary

Carejoy Digital has engineered a competitive alternative to premium digital milling systems such as the Amann Girrbach Ceramill Motion 2, leveraging China’s advanced manufacturing ecosystem to deliver a high-precision, open-architecture CAD/CAM solution at a disruptive cost-performance ratio. This technical review details the manufacturing and quality control (QC) processes behind Carejoy’s next-generation milling platform—marketed under performance parity with the Ceramill Motion 2—produced at an ISO 13485-certified facility in Shanghai.

—

1. Manufacturing Process Overview

Carejoy Digital’s milling systems are manufactured at a vertically integrated facility in Shanghai, specializing in medical-grade digital dental hardware. The production pipeline integrates precision engineering with real-time digital monitoring.

| Stage | Process | Technology Used |

|---|---|---|

| Component Fabrication | High-tolerance CNC machining of aluminum alloy housings, ceramic guide rails, and spindle mounts | 5-axis CNC centers with sub-micron repeatability (±1μm) |

| Spindle Assembly | Integration of high-speed brushless spindles (up to 60,000 RPM) | Automated torque calibration; dynamic balancing |

| Sensor Integration | Installation of force-feedback sensors, positional encoders, and vibration dampers | AI-optimized load compensation algorithms |

| Final Assembly | Robotic-assisted alignment of milling head, gantry, and tray loader | Machine vision alignment systems |

—

2. Quality Control & Compliance: ISO 13485 Framework

Carejoy’s Shanghai facility is certified under ISO 13485:2016, ensuring compliance with medical device quality management systems. All production stages undergo documented traceability, risk assessment (per ISO 14971), and batch-level validation.

Key QC checkpoints include:

- Material Certification: All structural and biocompatible components (e.g., zirconia tool holders) are traceable to RoHS and REACH standards.

- Environmental Testing: Units undergo thermal cycling (10°C–40°C) and humidity stress (30–80% RH) to simulate global clinic conditions.

- Software Validation: Firmware and AI-driven scanning modules follow IEC 62304 Class B safety requirements.

—

3. Sensor Calibration Labs: Precision at Scale

Carejoy operates an in-house Sensor Calibration Laboratory within the Shanghai facility, accredited to ISO/IEC 17025 standards. This lab ensures metrological traceability for all motion and force-sensing systems.

| Calibration Parameter | Standard | Frequency |

|---|---|---|

| Linear Encoder Accuracy | NIST-traceable laser interferometry | Per unit, pre-shipment |

| Spindle Runout | DIN 620-2, < 2μm TIR | Batch sampling + anomaly-triggered |

| Force Sensor Linearity | ASTM E74, ±0.25% full scale | Daily system check |

| AI Scanning Module | ISO 12836-compliant test artifacts | Monthly algorithm retraining |

The lab utilizes custom-machined digital reference dies with sub-micron geometric fidelity to validate scanner-to-mill workflow accuracy.

—

4. Durability & Lifecycle Testing

To ensure clinical reliability, each milling platform undergoes accelerated lifecycle testing simulating 5+ years of daily lab use.

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Continuous Milling Endurance | 72-hour non-stop milling of CoCr and zirconia blocks | No spindle degradation >5% RPM variance |

| Vibration Fatigue | Random vibration profile (5–500 Hz, 2g RMS) | No structural cracks or misalignment |

| Dust & Debris Resistance | 200+ cycles of dry milling with particulate exposure | Filter efficiency >98%, no sensor drift |

| Software Stress Test | Concurrent multi-job queue with STL/PLY/OBJ inputs | No crashes, <1% job failure rate |

Units failing any test are subjected to root-cause analysis and design iteration via Carejoy’s closed-loop AI feedback system.

—

5. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Access to precision motors, linear guides, and optical sensors from domestic suppliers (e.g., Huawei, Sunny Optical) reduces BOM costs by 30–40% vs. EU/US equivalents.

- Advanced Automation: Robotics penetration in manufacturing exceeds 65% in tier-1 medical device plants, enabling high throughput with minimal labor cost impact.

- R&D Investment: Chinese firms reinvest 12–15% of revenue into AI and open-architecture software, accelerating innovation cycles (e.g., AI-driven scan correction, adaptive milling paths).

- Regulatory Agility: Streamlined NMPA approval pathways allow faster time-to-market, while ISO 13485 certification ensures global export readiness.

- Open Architecture Advantage: Carejoy’s support for STL, PLY, and OBJ formats enables seamless integration with third-party scanners and printers—avoiding vendor lock-in and reducing total workflow cost.

This ecosystem enables Carejoy Digital to deliver Ceramill Motion 2–class performance at 40–50% lower acquisition cost, redefining the cost-performance frontier in digital dentistry.

—

Support & Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud connection

- Over-the-Air Software Updates: Monthly AI model and CAM strategy enhancements

- Open SDK: For lab-specific workflow automation and integration

Contact: [email protected]

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ceramill Motion 2 Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160