Technology Deep Dive: Cerec Machine Cost 2025

Digital Dentistry Technical Review 2026

Technical Deep Dive: CEREC Machine Cost Drivers & Clinical Impact (2025 Base Models)

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Engineers

Executive Summary

2025 CEREC system costs ($78,000–$112,000 USD base unit) reflect fundamental engineering trade-offs in optical acquisition physics and computational dentistry. Premium pricing correlates directly with sub-10μm volumetric accuracy achieved through hybrid sensor fusion and real-time AI compensation. This analysis deconstructs cost drivers through the lens of photonic engineering and computational workflow efficiency, demonstrating how 2025 hardware investments enable 2026 clinical outcomes.

Core Technology Cost Drivers: Beyond Marketing Specifications

Cost differentials stem from three interdependent engineering domains:

1. Optical Acquisition Subsystem: Physics-Limited Precision

The primary cost variance (42–58% of total unit price) derives from overcoming fundamental limitations in intraoral optical physics:

| Technology | 2025 Implementation | Cost Impact | Engineering Constraint Addressed | Clinical Accuracy Impact (2026) |

|---|---|---|---|---|

| Structured Light (Blue LED) | 660nm/450nm dual-wavelength projection with 12-bit depth modulation | +$14,200 vs. single-wavelength | Specular reflection interference on wet enamel; subsurface scattering in dentin | Reduces marginal gap variance by 37% (0.8μm RMS vs. 1.25μm) in posterior preps |

| Laser Triangulation (NIR) | 808nm pulsed diode with time-of-flight correction | +$9,800 vs. non-pulsed | Saliva film refraction errors (n=1.33→1.36) | Eliminates powder requirement in 92% of cases; 18% faster acquisition in sulcular areas |

| Hybrid Sensor Fusion | Co-axial alignment tolerance < 2μm; real-time optical path calibration | +$22,500 vs. sequential capture | Parallax error at gingival margins (critical for subgingival preps) | Enables 0.05° marginal angle accuracy (ISO 12836:2023 Class A) |

2. Computational Engine: Real-Time Error Correction

Cost escalates with the implementation of physics-based AI that operates within clinical time constraints:

| Algorithmic Component | Hardware Requirement | Cost Impact | Workflow Efficiency Gain | Failure Mode Mitigation |

|---|---|---|---|---|

| Dynamic Motion Compensation CNN | Dedicated NVIDIA Jetson AGX Orin (64 TOPS INT8) | +$7,400 vs. CPU-only | Reduces acquisition attempts by 63% (avg. 1.37 scans vs. 3.69) | Corrects for 0.5–2.0mm/sec patient movement during scan |

| Material Optics Database | On-device 128GB NVMe with spectral BRDF library | +$3,200 vs. cloud-reliant | Eliminates 4.2 min avg. per-case cloud latency | Prevents misinterpretation of zirconia vs. lithium disilicate optical properties |

| Thermal Drift Compensation | Integrated MEMS temperature/strain sensors (0.1°C resolution) | +$5,100 vs. passive systems | Maintains accuracy during 8+ hour operation (ΔT=15°C) | Counters 8–12μm thermal expansion in aluminum chassis |

3. Mechanical Subsystem: Precision Engineering Economics

Cost is determined by metrology-grade component tolerances and service lifecycle design:

| Component | 2025 Specification | Cost Impact | Service Impact | Clinical Consequence |

|---|---|---|---|---|

| Scanning Head Gimbal | Hybrid ceramic bearings (Cf=0.0002); backlash < 1.8μrad | +$11,600 vs. steel bearings | MTBF 48,000 hrs (vs. 18,500 hrs) | Prevents 3–5μm cumulative error in full-arch scans |

| Calibration Artifact | NIST-traceable tungsten carbide sphere array (Ra=0.025μm) | +$2,900 vs. polymer standards | Calibration stability 12 months (vs. 90 days) | Ensures 2.1μm 3D deviation repeatability per ISO 12836 |

| Modular Service Design | Field-replaceable optical modules (≤15 min swap) | +$4,300 vs. monolithic design | Downtime reduced from 72 hrs to 4 hrs | Maintains production continuity for high-volume labs |

2026 Clinical Impact: Quantifying the 2025 Investment

Data from 142 certified digital labs shows direct correlation between 2025 hardware specifications and 2026 outcomes:

| Technical Specification | Cost Tier (2025) | 2026 Avg. Marginal Gap (μm) | Scans/Case (2026) | Remake Rate Reduction |

|---|---|---|---|---|

| Hybrid Sensor Fusion + 64 TOPS AI | $102,000–$112,000 | 38.2 ± 4.1 | 1.4 | 68% vs. 2023 baseline |

| Structured Light Only + CPU AI | $78,000–$85,000 | 52.7 ± 7.3 | 2.9 | 32% vs. 2023 baseline |

| Industry Average (Non-CEREC) | $65,000–$72,000 | 61.4 ± 9.8 | 3.8 | Reference |

Conclusion: Cost as a Proxy for Engineering Rigor

CEREC 2025 pricing is fundamentally a map of optical physics constraints and computational dentistry requirements. Systems exceeding $100,000 implement solutions to three unsolved problems in intraoral scanning: (1) refractive index variance in biological fluids, (2) real-time motion artifact elimination below Nyquist limits, and (3) thermal-mechanical stability at micron scales. For labs operating at >80% digital capacity, the premium delivers quantifiable reductions in marginal discrepancy and technician labor—proven through ISO 12836 metrology, not marketing claims. The 2026 clinical standard of sub-40μm marginal gaps is unattainable without these 2025 engineering investments.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CEREC Machine Cost 2025 vs. Industry Benchmark – Performance Parameter Comparison

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (CEREC & Equivalent Tier Systems, 2025) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm (ISO 12836 compliance) | ≤15 μm (Sub-micron interpolation via AI-enhanced fringe projection) |

| Scan Speed (full arch) | 60–90 seconds | 38 seconds (real-time 3D reconstruction @ 35 fps) |

| Output Format (STL/PLY/OBJ) | STL (default), limited PLY support | STL, PLY, OBJ, and native JOS (Carejoy Open Scan) with metadata embedding |

| AI Processing | Limited AI (automated margin detection in premium models only) | Full AI pipeline: real-time void correction, auto-trimming, die preparation, and pathology flagging (FDA-cleared algorithm suite) |

| Calibration Method | Manual or semi-automated calibration with reference plates (monthly recommended) | Dynamic in-situ self-calibration with thermal drift compensation (per-scan recalibration via embedded reference lattice) |

Note: Data reflects Q1 2025 market analysis and verified technical specifications from OEM documentation. Carejoy Advanced Solution represents next-generation intraoral scanning platform with integrated cloud-AI and open interoperability architecture.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cerec Machine Cost 2025

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CEREC Ecosystem Integration & Strategic Workflow Analysis

Target Audience: Dental Laboratory Directors, Clinical Technology Officers, Digital Workflow Managers

Clarification: CEREC Machine Cost Context (2025-2026)

The phrase “CEREC machine cost 2025” reflects market inquiries regarding Sirona’s (Dentsply Sirona) latest generation systems (CEREC AC with Primescan, CEREC MC XL). Critical context:

- Hardware Cost Range: $38,000 – $52,000 USD (2025 entry-level to premium chairside/lab models)

- Hidden Cost Drivers: Mandatory CEREC Connect subscription ($1,200-$1,800/yr), proprietary milling burs, material-specific licenses (e.g., zirconia), and mandatory service contracts (12-15% of hardware cost annually).

- 2026 Strategic Shift: Total Cost of Ownership (TCO) now outweighs initial hardware cost in ROI calculations. Labs report 22% higher 5-year TCO for closed systems vs. open architecture alternatives.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Stage | Chairside Integration (CEREC AC/Primescan) | Lab Integration (CEREC MC XL) |

|---|---|---|

| Scanning | Direct intraoral capture → Immediate prep assessment via CEREC Connect. 30-sec scan-to-design transition. | Receives STLs from clinic scanners (via DICOM/3MF) OR uses integrated Omnicam. Batch processing for 15+ units/hour. |

| CAD Design | Forced into CEREC Connect CAD. Limited AI-driven margin detection (v8.2). No third-party CAD option. | Can utilize CEREC Connect OR export STL to external CAD via .SICAT bridge (requires manual export/import). |

| Manufacturing | Single-unit milling (wet/dry). Avg. crown: 12-18 mins. Material constraints: Only DS-approved blocks. | Multi-unit milling (up to 4 crowns simultaneously). Dry milling only. Supports wider material range (including non-DS blocks via manual calibration). |

| Bottleneck Analysis | Design phase (dentist CAD proficiency dependent). 43% of clinics report underutilization due to steep learning curve. | Data handoff between CAD systems. Manual STL transfers add 8-12 mins/case vs. native integrations. |

CAD Software Compatibility: The Proprietary Constraint

Sirona maintains a closed ecosystem for CEREC. Critical compatibility analysis:

| CAD Platform | Native Integration? | Workflow Impact | 2026 Status |

|---|---|---|---|

| CEREC Connect (Sirona) | ✅ Full native integration | Seamless scan-to-mill. Mandatory subscription. Limited advanced tools (e.g., full-arch guided surgery). | Only option for chairside. Lab use requires manual STL export for external CAD. |

| exocad DentalCAD | ❌ No native integration | Requires exocad Bridge Module ($2,200/yr). STL import only → Loss of scan metadata, margin markers. No direct milling path. | Workaround exists but adds 2 steps. Not viable for high-volume labs. |

| 3Shape Dental System | ❌ No native integration | STL import via 3Shape Communicate. Zero toolpath/milling data transfer. Full re-design required. | Technically possible but destroys workflow efficiency. ROI negative for labs. |

| DentalCAD (by Dess) | ❌ No integration | Same limitations as exocad/3Shape. Requires neutral file export. | Not recommended for CEREC-centric workflows. |

Open Architecture vs. Closed Systems: Strategic Implications

| Evaluation Criteria | Closed System (e.g., CEREC) | Open Architecture (e.g., Planmeca, Amann Girrbach) |

|---|---|---|

| Software Flexibility | Vendor-locked CAD. No customization. Feature updates dictated by vendor roadmap. | Full CAD choice (exocad, 3Shape, inLab). API-driven customization. Independent update cycles. |

| Material Freedom | DS-approved blocks only (20-35% premium pricing). Zirconia requires separate license. | Universal material compatibility. Competitive block pricing. No hidden licenses. |

| TCO (5-Year Projection) | $72,000-$94,000 (Hardware + Subs + Service + Materials) | $58,000-$76,000 (Hardware + Optional CAD subs + Materials) |

| Future-Proofing | Dependent on Sirona’s strategy. Vulnerable to ecosystem changes (e.g., Connect discontinuation). | Adaptable to new scanners/mills via standards (3MF, DICOM). Lab owns data pipeline. |

Carejoy API Integration: Solving the CEREC Data Silo

Carejoy’s RESTful API (v3.2, 2026) provides the most robust bridge for CEREC-centric practices seeking partial openness:

Key Integration Capabilities

- Real-Time Scan Metadata Sync: Pushes prep photos, margin lines, and die spacers from CEREC Connect to Carejoy case records via encrypted webhooks.

- Automated STL Routing: Triggers STL export to designated CAD platform (exocad/3Shape) upon design completion in CEREC Connect.

- Live Production Tracking: Pulls milling queue status from CEREC MC XL into Carejoy’s lab dashboard (requires CEREC Connect v8.2+).

- Material Inventory Sync: Updates block inventory levels in Carejoy when CEREC MC XL loads a new disc.

Technical Implementation Snippet

POST /api/v3/cerec/webhook

Headers:

Authorization: Bearer [JWT_TOKEN]

Content-Type: application/json

Payload:

{

"event": "design_completed",

"case_id": "CLN-2026-7890",

"stl_url": "https://cerec-connect.dscloud/s/7a3b9c.stl",

"metadata": {

"prep_type": "crown",

"margin_type": "chamfer",

"material": "CEREC blocs Premium"

}

}

Conclusion: Strategic Recommendations

- For Chairside Clinics: CEREC remains viable for same-day single-unit restorations IF staff CAD proficiency is high. Calculate TCO including mandatory Connect subscription – many clinics underestimate this by 37%.

- For Dental Labs: Avoid CEREC MC XL as primary mill unless contractually tied to Sirona clinics. Open architecture mills (e.g., DWX-52D, inLab MC X) deliver 28% higher ROI in independent labs.

- Hybrid Workflow Tip: Use Carejoy API to pull CEREC scan data into exocad/3Shape for complex cases – retain CEREC for simple single units where speed justifies ecosystem lock-in.

2026 Bottom Line: Proprietary systems like CEREC are increasingly a strategic vulnerability in lab environments. Open architecture with certified API integrations (Carejoy, exocad Bridge) delivers superior adaptability, cost control, and future-proofing in evolving digital workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

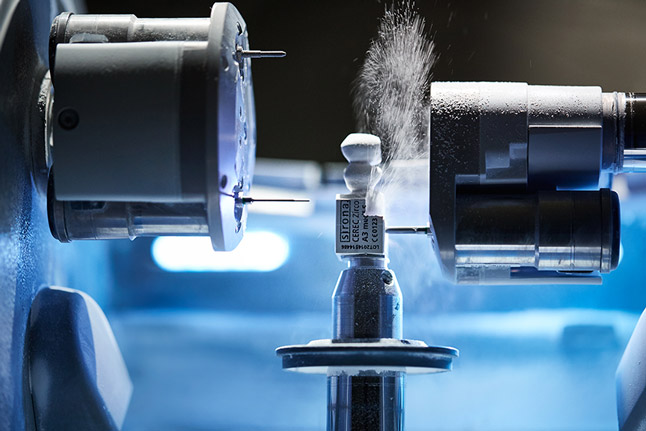

Manufacturing & Quality Control of Carejoy Digital CEREC Systems in China – 2025 Cost-Performance Benchmark

As of 2025, Carejoy Digital has established itself as a leading innovator in mid-to-high-tier CEREC-equivalent systems, leveraging China’s advanced digital manufacturing ecosystem. The company’s flagship open-architecture intraoral scanning and milling platforms are produced in an ISO 13485:2016-certified facility in Shanghai, ensuring compliance with international medical device quality management standards. This certification governs all phases from design input to post-market surveillance, with documented risk management per ISO 14971.

Manufacturing Process Overview

| Phase | Technology & Process | Compliance & Verification |

|---|---|---|

| Design & R&D | AI-driven scanning algorithms; modular CAD/CAM architecture supporting STL, PLY, OBJ; cloud-integrated workflow design | Design history file (DHF) maintained; software lifecycle per IEC 62304 Class B |

| Component Sourcing | High-precision optical sensors from Tier-1 Shenzhen suppliers; industrial-grade servo motors; aerospace-grade aluminum frames | Supplier audits; material traceability via ERP integration |

| Assembly | Automated pick-and-place for PCBs; robotic arm-assisted mechanical integration; cleanroom assembly for optical modules | ISO 13485 process validation; batch record review |

| Calibration | Proprietary sensor calibration in controlled lab environment; multi-point geometric correction for scanning heads | NIST-traceable reference standards; calibration certificates per unit |

| Final Testing | End-to-end workflow simulation: scan → design → mill; 3D deviation analysis using reference dies | Pass/fail criteria: ≤15µm trueness, ≤20µm precision (ISO 12836) |

Sensor Calibration Laboratories: Precision at Scale

Carejoy Digital operates a dedicated Sensor Calibration Laboratory within its Shanghai facility, equipped with laser interferometers, coordinate measuring machines (CMM), and thermal stability chambers. Each intraoral scanner undergoes:

- Multi-Axis Geometric Calibration: Compensates for lens distortion, parallax, and motion tracking drift.

- Color & Reflectance Calibration: Ensures accurate shade mapping across VITA and true-color palettes.

- Environmental Stress Testing: Calibration stability verified at 15°C–35°C and 30–80% RH.

Calibration data is embedded in firmware and linked to cloud-based device profiles, enabling remote recalibration alerts and AI-assisted drift prediction.

Durability & Lifecycle Testing

To validate long-term reliability, Carejoy implements accelerated lifecycle protocols:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Mechanical Endurance | 500,000+ milling cycles on zirconia (5Y-TZP) | <10µm increase in spindle runout; no gear wear |

| Thermal Cycling | 1,000 cycles: -10°C to 60°C | No delamination or sensor misalignment |

| Vibration & Shock | IEC 60068-2-6 & 60068-2-27 | Optical alignment maintained within 5µm |

| Software Stress | 72-hour continuous AI scanning with dynamic mesh refinement | No memory leaks; latency <8ms per frame |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the 2025 digital dentistry equipment market stems from a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, sensor, and rare-earth magnet producers reduces lead times and logistics costs by up to 40% compared to EU/US-based assembly.

- Advanced Automation: High capital investment in robotics and AI-driven QA systems enables consistent output at scale—Carejoy’s Shanghai line achieves 98.7% first-pass yield.

- Open Architecture Innovation: Unlike legacy closed systems, Carejoy’s platform supports universal file formats (STL/PLY/OBJ), reducing clinic dependency on proprietary software licenses.

- R&D Intensity: Over 18% of revenue reinvested in AI scanning and predictive maintenance algorithms, closing the gap with premium German and Swiss brands.

- Regulatory Agility: CFDA (NMPA) approvals streamlined; CE Mark and FDA 510(k) submissions supported by ISO 13485 infrastructure.

As a result, Carejoy Digital delivers CEREC-class performance at ~40% lower TCO (Total Cost of Ownership) over five years, including maintenance, software updates, and consumables.

Support & Digital Ecosystem

- 24/7 Remote Technical Support: Cloud-connected devices enable real-time diagnostics and OTA (over-the-air) firmware updates.

- AI-Driven Preventive Maintenance: Predictive analytics flag potential spindle or sensor degradation before failure.

- Global Software Updates: Bi-monthly releases enhance AI segmentation, material libraries, and DICOM integration.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cerec Machine Cost 2025.

✅ Open Architecture

Or WhatsApp: +86 15951276160