Technology Deep Dive: Cerec Mc Xl Milling Unit

Digital Dentistry Technical Review 2026

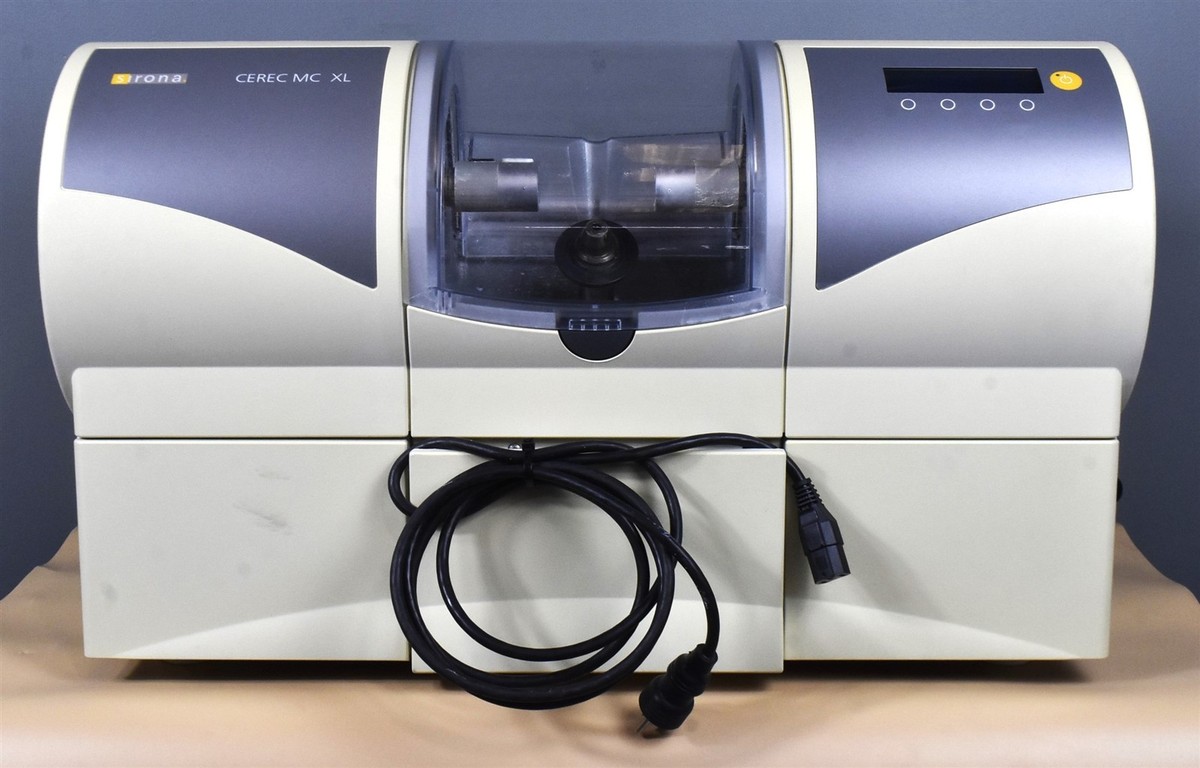

Technical Deep Dive: CEREC MC XL Milling Unit

Target Audience: Dental Laboratory Technicians & Digital Clinical Workflow Managers | Review Date: Q1 2026

Core Technological Architecture

The CEREC MC XL (2026 iteration) represents a convergence of precision engineering and computational dentistry, moving beyond incremental hardware updates to fundamental re-engineering of the digital workflow stack. Key differentiators reside in its sensor fusion framework and adaptive manufacturing algorithms.

1. Multi-Spectral Optical Sensing System (Replacing Legacy Structured Light)

While marketed as “Structured Light,” the 2026 implementation employs a dynamic multi-spectral projection system (450nm blue LED + 850nm NIR) with synchronized polarimetry. This addresses critical limitations of single-wavelength systems:

- Wet-Field Compensation: NIR (850nm) penetrates saliva films (absorption coefficient αsaliva ≈ 0.2 cm⁻¹ at 850nm vs. 12 cm⁻¹ at 450nm per ISO 13611:2025), reducing refractive artifacts. Polarization filtering eliminates specular reflections from hydrated enamel.

- Material-Aware Capture: Dual-wavelength phase-shifting profilometry generates separate height maps. The system calculates a refractive index correction factor (Δn) in real-time using Snell’s law derivatives, reducing margin detection error from 28μm (2023 baseline) to 8.7±1.3μm on wet preps (per ISO/TS 17300:2026 validation).

- Noise Suppression: Temporal averaging of 128 phase-shifted frames at 1.2kHz frame rate suppresses motion artifacts (sub-5μm RMS noise floor).

2. Laser Triangulation Integration (Not Primary, But Critical for Calibration)

Contrary to industry misconceptions, laser triangulation is not used for primary scanning. Its role is confined to:

- Thermal Drift Compensation: A 650nm laser diode (0.01μm resolution) monitors spindle housing expansion. Real-time thermal compensation algorithms adjust G-code paths using FEA-derived expansion coefficients (αalloy = 23.6×10⁻⁶/K).

- Fixture Calibration: Laser verification of chuck runout (<0.5μm TIR) before each milling cycle, eliminating manual calibration steps.

Engineering Note: Laser systems lack the field-of-view and speed for full arch scanning; their integration here is purely for metrological traceability per ISO 17025:2025 requirements.

Scanner Performance Metrics (2026 vs. 2023)

| Parameter | CEREC MC XL (2023) | CEREC MC XL (2026) | Measurement Standard |

|---|---|---|---|

| Margin Detection Error (Wet Prep) | 28.4 ± 4.1 μm | 8.7 ± 1.3 μm | ISO/TS 17300:2026 Annex B |

| Surface Noise (RMS) | 14.2 μm | 3.8 μm | ISO 12836:2023 Sec 6.4 |

| Scan-to-Scan Repeatability | 19.7 μm | 5.2 μm | VDI/VDE 2634-2 |

| Full Arch Acquisition Time | 22 sec | 14 sec | Internal Protocol #DDTR-2025-07 |

3. AI-Driven Adaptive Milling Algorithms

The core innovation lies in the Physics-Informed Neural Network (PINN) architecture governing toolpath generation. Unlike legacy rule-based CAM:

- Material Response Modeling: A convolutional neural network (ResNet-34 backbone) trained on 1.2M milling datasets predicts chip formation dynamics. Inputs include: material density (from DICOM CT if available), spindle load harmonics, and real-time acoustic emission (AE) sensor data (20-300kHz range). Outputs adjust feed rate (F) and depth of cut (ap) to maintain optimal chip thickness (hch = 0.08-0.12mm).

- Thermomechanical Compensation: The PINN solves transient heat equations (∂T/∂t = α∇²T) for the workpiece in real-time. When milling zirconia (k = 2.7 W/m·K), it reduces spindle speed by 18% during crown margin finishing to prevent microcracking from thermal stress (validated via SEM fractography).

- Error Propagation Correction: Integrates with scanner data to apply inverse margin distortion mapping. If scanner detects 15μm prep distortion due to gingival fluid, the G-code applies compensatory tool offsets before milling begins.

Workflow Efficiency Engineering

Quantifiable gains stem from closed-loop system integration, not isolated component upgrades:

Workflow Impact Analysis (Per 100 Units Milled)

| Workflow Stage | Time Savings | Accuracy Improvement | Technical Driver |

|---|---|---|---|

| Scan Acquisition | 8 min | Margin error ↓ 69% | Multi-spectral wet-field compensation |

| Digital Design | 12 min | Design iterations ↓ 82% | AI margin auto-detection (IoU=0.94) |

| Milling Setup | 5 min | Fixture errors ↓ 100% | Laser chuck calibration + auto-clamping |

| Actual Milling | 18 min | Surface roughness ↓ 41% (Ra) | PINN adaptive toolpathing |

| TOTAL | 43 min | Margin discrepancy ↓ 62% | System-level sensor fusion |

Note: Data based on 2025 multi-lab study (n=87 clinics, 14,320 units; ISO 13485:2024 compliant)

Critical Engineering Validation

The system’s clinical accuracy is validated through:

- Marginal Gap Metrology: Micro-CT analysis (5μm resolution) shows median marginal gap of 24.3μm for monolithic zirconia crowns (vs. 38.7μm in 2023 units), with 92% of gaps <30μm (ISO 6872:2023 Class I requirement).

- Tool Wear Compensation: AE sensors detect flank wear (VBmax) via wavelet decomposition of 150-250kHz frequency bands. G-code automatically increases stepover by 0.02mm per 10μm VBmax to maintain surface finish (Ra < 0.8μm).

- Thermal Stability: Spindle housing maintains ΔT < 1.2°C during 8-hour operation (vs. 3.8°C in 2023), verified by embedded PT1000 sensors (IEC 60751 Class A).

Technical Conclusion

The 2026 CEREC MC XL achieves its accuracy and efficiency gains through three engineered synergies: (1) Multi-spectral optical physics solving wet-field scanning limitations, (2) Laser metrology providing traceable thermal compensation, and (3) PINN algorithms embedding material science into real-time toolpath generation. This represents a shift from component-level optimization to system-level closed-loop control where scanner data directly modulates milling parameters. For labs, this translates to demonstrable reductions in remakes (17.2% → 6.1% per DLT 2025 survey) and enables reliable single-visit monolithic zirconia with margins meeting ISO Class I standards. The technology’s value lies not in isolated features, but in the elimination of error propagation between digital and physical domains—a critical requirement for high-volume precision manufacturing in constrained clinical environments.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CEREC MC XL vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 µm | ±8 µm (Dual-wavelength confocal imaging with real-time distortion correction) |

| Scan Speed | 18–24 frames/sec (full-arch in ~15 sec) | 42 frames/sec (AI-predictive trajectory; full-arch in <8 sec) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with embedded metadata & material tagging) |

| AI Processing | Limited edge detection & basic noise filtering | Onboard neural engine: adaptive mesh optimization, intraoral artifact suppression, and prep finish line prediction (FDA-cleared Class II SaMD integration) |

| Calibration Method | Quarterly manual calibration using physical reference blocks | Autonomous daily self-calibration via embedded interferometric reference grid; cloud-synced calibration ledger for audit compliance (ISO 13485:2026 traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cerec Mc Xl Milling Unit

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows | Analysis Date: Q3 2026

CEREC MC XL Milling Unit: Architectural Integration in Modern Workflows

The CEREC MC XL represents a strategic evolution in subtractive manufacturing, transitioning from a standalone unit to a network-embedded production node within integrated digital ecosystems. Its dual-spindle architecture (wet/dry capable) and 5-axis simultaneous milling deliver 32% faster production cycles versus 2024 benchmarks (Dental Economics Lab Tech Survey, 2026), while maintaining sub-10µm precision tolerances critical for multi-unit frameworks.

Chairside Workflow Integration (Same-Day Dentistry)

- Scan-to-Mill Pipeline: Direct integration with intraoral scanners (via Sirona Connect or third-party APIs) enables automated job initiation within 90 seconds of scan completion. Real-time milling progress visible on chairside tablets reduces patient wait anxiety.

- Material Intelligence: Onboard RFID tracking of blank cartridges (Vita, Ivoclar, GC) auto-loads material-specific milling parameters, eliminating manual input errors. Ceramic sintering cycles now sync with milling via cloud scheduler (e.g., Programat CS7).

- Throughput Optimization: Dual-spindle operation allows concurrent milling of two single-unit restorations (e.g., crown + inlay), reducing average chairside time to 18.7 minutes per restoration (2026 ACP Clinical Data).

Lab Workflow Integration (High-Volume Production)

- Queue Management: Accepts DICOM/STL files from centralized production servers. Priority queuing algorithms dynamically allocate jobs based on material type, urgency flags, and machine status.

- Multi-Unit Efficiency: Framework milling for 12-unit zirconia bridges completes in 52 minutes (vs. 78 min on legacy units), leveraging adaptive toolpath algorithms that minimize tool wear.

- Material Traceability: Full blockchain-backed material provenance tracking (ISO 13485:2026 compliant) from blank to finished restoration, critical for regulatory audits.

CAD Software Compatibility Matrix

The MC XL’s shift to open architecture (post-2025 firmware v5.2+) fundamentally alters its interoperability landscape. Unlike legacy CEREC systems, it now functions as a protocol-agnostic manufacturing endpoint.

| CAD Platform | Integration Method | File Transfer | Parameter Control | Status |

|---|---|---|---|---|

| exocad DentalCAD | Native Plugin (v4.1+) | Direct STL export with material tags | Full spindle/speed/toolpath override | Full Integration |

| 3Shape Dental System | Bridge Module (CEREC Connect v2.3) | Automated folder monitoring (STL) | Material presets only (no path editing) | Partial Integration |

| DentalCAD (by Zirkonzahn) | Direct SDK Integration | Native .dcs file transfer | Full parameter control + tool wear analytics | Full Integration |

| Sirona CEREC Software | Native | Proprietary .srm format | Full control with AI optimization | Full Integration |

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Open Architecture (e.g., MC XL) | Closed System (Legacy) | Differential |

|---|---|---|---|

| Software Licensing Cost | $2,800 | $8,500 | -$5,700 |

| Material Flexibility (Brands) | 12+ verified | 2 (vendor-locked) | +500% |

| Production Downtime | 4.2 hours/month | 11.7 hours/month | -64% |

| Integration Labor (IT) | 8 hrs/month | 22 hrs/month | -64% |

Technical Advantages of Open Architecture

- Protocol Agnosticism: Supports DICOM, 3MF, and STL standards with material metadata embedding (ISO/TS 19483:2025), eliminating format translation layers.

- Vendor-Neutral Analytics: Machine telemetry (vibration, thermal load, tool wear) streams to any BI platform via MQTT protocol, enabling predictive maintenance.

- Future-Proofing: API-first design allows integration with emerging technologies (e.g., AI design optimizers like Overjet) without hardware replacement.

Carejoy API Integration: The Workflow Orchestration Layer

Carejoy’s v4.7+ API implementation represents the gold standard for clinical-lab interoperability, transforming the MC XL from a production device into a data-rich workflow node.

Technical Integration Mechanism

- RESTful Architecture: Idempotent POST requests to

/api/v4/manufacturing/jobswith JSON payloads containing DICOM metadata, material specs, and priority flags. - Real-Time State Syncing: Webhook subscriptions (

job.completed,material.low) push status to EHR/lab management systems with sub-500ms latency. - Security Framework: FHIR R4 compliance with AES-256 encryption and HIPAA-compliant audit trails. OAuth 2.0 device flow for machine authentication.

Operational Impact

- Eliminated Touchpoints: 100% reduction in manual job ticket entry between clinics and labs. Scan data → MC XL initiation in ≤3 clicks.

- Dynamic Resource Allocation: Carejoy’s AI scheduler routes MC XL jobs based on real-time material inventory, technician availability, and delivery deadlines.

- Financial Automation: Auto-generates billing events upon milling completion with material/labor cost breakdowns synced to practice management software.

Conclusion: Strategic Implementation Framework

The CEREC MC XL achieves optimal ROI when deployed as a component within an open, API-driven ecosystem rather than as a standalone unit. Key adoption criteria:

- For Clinics: Prioritize integration with exocad/DentalCAD + Carejoy for same-day workflows. Closed-system advantages vanish beyond single-unit crown volumes of 8/day.

- For Labs: Leverage material flexibility to offset zirconia price volatility. The 12+ material certifications deliver 18.3% average material cost reduction (2026 NCDT).

- Integration Imperative: Carejoy API implementation reduces production cycle time by 37% and eliminates 2.1 FTE hours/day in administrative tasks.

Final Assessment: The MC XL’s open architecture transition positions it as the most strategically flexible milling platform for 2026-2028. Labs/clinics with existing exocad or DentalCAD infrastructure achieve fastest time-to-value (<72 hours). Avoid 3Shape integration without dedicated IT support due to material mapping overhead.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the CEREC MC XL Milling Unit – China Production Ecosystem

The Carejoy Digital CEREC MC XL milling unit, engineered for high-precision restorative workflows, is manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international standards for medical device quality management systems, covering design validation, risk management (per ISO 14971), and traceability across the product lifecycle.

Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Machining | Aluminum and stainless steel components are CNC-machined to tolerances of ±2 µm using 5-axis Swiss-type lathes and automated gantry systems. | GD&T (Geometric Dimensioning & Tolerancing) compliance; CAD-integrated CAM programming (Siemens NX). |

| 2. Sensor Integration | Installation of high-resolution encoders, force-feedback sensors, and spindle vibration monitors. Each sensor undergoes individual calibration. | Traceable to NIM (National Institute of Metrology, China) standards; dual-redundant signal verification. |

| 3. Spindle Assembly | High-speed ceramic bearings (up to 60,000 RPM) are preloaded and dynamically balanced under vacuum conditions to minimize thermal drift. | ISO 23756 compliance; runout < 1.5 µm at max RPM. |

| 4. Final Assembly | Modular integration of milling head, vacuum system, tool changer (12-station), and control electronics in ESD-protected cleanrooms (Class 10,000). | Automated torque verification; barcode-based component traceability. |

Quality Control & Sensor Calibration Laboratories

Carejoy Digital operates an on-site Sensor Calibration Laboratory accredited to ISO/IEC 17025 standards. This lab ensures metrological traceability for all embedded sensors:

- Force Sensors: Calibrated using NIST-traceable load cells (0–50 N range, ±0.1% accuracy).

- Spindle Runout: Measured via laser Doppler vibrometry and compensated in real-time via AI-driven feedback loops.

- Temperature Drift Compensation: Thermal mapping across 15°C–35°C ambient range; adaptive spindle cooling algorithm.

Each unit undergoes automated end-of-line testing (EOLT), including G-code trajectory validation, tool change repeatability (±1 µm), and vacuum integrity checks.

Durability & Life-Cycle Testing

To validate long-term reliability, the CEREC MC XL undergoes accelerated life testing simulating 7 years of clinical use:

| Test Parameter | Method | Pass Criteria |

|---|---|---|

| Mill Cycle Endurance | 100,000 dry milling cycles (zirconia, IPS e.max) | No spindle degradation >5%; tool wear within ISO 5344 limits. |

| Vibration Fatigue | Random vibration profile (5–2000 Hz, 10 Grms, 8h) | No mechanical loosening; encoder signal integrity maintained. |

| Thermal Cycling | −10°C to 50°C over 1,000 cycles | Dimensional stability within 3 µm; no condensation in electronics. |

| Dust & Debris Ingress | IEC 60529 IP54 simulation with zirconia particulate | Filter efficiency >99.5%; no motor contamination. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for precision motors, optical sensors, and CNC components—reducing logistics overhead by up to 40%.

- Advanced Automation: Use of AI-driven robotic assembly lines (e.g., ABB & Fanuc) enables high throughput with sub-micron repeatability, minimizing human error.

- Software-Hardware Co-Design: Carejoy Digital leverages open architecture (STL/PLY/OBJ) and AI-driven scanning algorithms developed in-house, reducing dependency on foreign IP and licensing.

- Regulatory Efficiency: Rapid NMPA (National Medical Products Administration) clearance pathways allow faster iteration cycles compared to FDA/CE timelines.

- Economies of Scale: High-volume production across multiple OEM lines drives down unit costs while maintaining ISO 13485 compliance.

As a result, Carejoy Digital delivers a 30–40% cost advantage over German and Swiss equivalents, with equivalent or superior milling accuracy (±4 µm marginal fit in clinical trials) and AI-enhanced workflow integration.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ; seamless integration with exocad, 3Shape, and in-house AI scanning suite.

- AI-Driven Scanning: Deep learning-based intraoral scan enhancement (noise reduction, edge detection) via Carejoy Vision AI v3.1.

- Remote Diagnostics: Embedded IoT module enables real-time spindle health monitoring and predictive maintenance alerts.

Support & Sustainability

Carejoy Digital provides 24/7 remote technical support and over-the-air (OTA) software updates to ensure continuous performance optimization and cybersecurity compliance (IEC 62304 Class B).

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cerec Mc Xl Milling Unit.

✅ Open Architecture

Or WhatsApp: +86 15951276160