Technology Deep Dive: Cheapest Dental 3D Printer

Digital Dentistry Technical Review 2026: Budget 3D Printer Deep Dive

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Engineers

Review Focus: Sub-$2,500 Dental 3D Printers (LCD-Based Vat Photopolymerization)

Executive Summary: The $2,500 Threshold Reality

As of Q1 2026, printers under $2,500 universally employ monochrome LCD-based vat photopolymerization (mLCD). This cost ceiling eliminates laser systems (SLA), dual-photon polymerization (DPP), and industrial-grade material jetting. Critical engineering trade-offs exist in optical systems, thermal management, and firmware intelligence. Accuracy is constrained by physics, not marketing claims – sub-20μm XY resolution is physically unachievable at this price point due to diffraction limits and LCD pixel crosstalk. The true value metric is cost-per-clinically-acceptable-unit, not upfront hardware cost.

Core Technology Breakdown: Why mLCD Dominates Budget Segment

| Component | Budget Printer Implementation (2026) | Engineering Constraints | Clinical Impact |

|---|---|---|---|

| Light Engine | Monochrome LCD (3840×2160), 385nm UV-LED array (30-50W) | Pixel bleed due to imperfect LCD shutters (min. 35μm effective pixel size). LED intensity variance ±15% across build plate. No dynamic focus adjustment. | Marginally acceptable for study models (±50μm deviation), but crown margins exceed ISO 12836 tolerances (±75μm vs. required ±25μm). Requires 100μm layer height minimum for structural integrity. |

| Optical Path | Fixed focal length lens (no telecentricity). No real-time distortion correction. | Edge distortion up to 0.3% (vs. 0.05% in premium DLP). Chromatic aberration irrelevant (monochrome light). | Peripheral crown margins show 40-60μm deviation in 3rd molar positions. Mandibular frameworks require 0.3mm compensation at buccal/lingual extremes. |

| Thermal Management | Passive heatsinks + basic fan. No closed-loop temperature control. | Resin temp fluctuates ±5°C during print. Critical for viscosity stability (Δη/ΔT ≈ 15% per °C for methacrylates). | Layer adhesion failures increase 22% in ambient temps <20°C. Requires strict lab climate control (23±1°C) for consistent results. |

| Firmware Intelligence | Rule-based exposure calculator. Vibration sensor for crash detection. | No AI-driven adaptive slicing. Exposure time fixed per resin profile. Zero real-time error correction. | 30% higher failed print rate vs. AI-optimized systems. Requires manual support adjustment for complex geometries. |

Clinical Accuracy: Physics vs. Marketing Claims

Budget printers achieve ±45-75μm trueness on ideal geometries (flat planes), but real-world dental applications introduce compounding errors:

- Resin Polymerization Shrinkage: Uncompensated 3-5% volumetric shrinkage in low-cost methacrylate resins. Premium printers use tensor-based distortion compensation; budget systems rely on fixed scaling (typically 1.03x), creating non-uniform errors in complex shapes.

- Peel Force Dynamics: Low-cost Z-axes lack force feedback (0.1N resolution vs. 0.01N in premium). Excessive peel forces during layer separation cause 15-25μm deflection in thin structures (e.g., pontics).

- Edge Acuity Limitation: Diffraction limits effective resolution to ~½ wavelength of UV light (192.5nm). However, LCD pixel crosstalk and resin scattering elevate practical edge resolution to 35-40μm – insufficient for feather-edge preparations.

Workflow Efficiency: Hidden Costs of Low-Cost Hardware

While upfront cost is low, operational inefficiencies erode ROI:

| Workflow Stage | Budget Printer Limitation | Quantified Impact (Per 100 Units) |

|---|---|---|

| Pre-Processing | No auto-support AI. Manual adjustment required for 85% of cases | +2.1 labor hours (vs. 0.4h for AI systems) |

| Printing | 30% failure rate on bridges & full-arch | 32 failed prints = $128 wasted resin (@$4/ml) |

| Post-Processing | No integrated wash/cure. Manual handling required | +1.8 labor hours (vs. 0.2h for automated systems) |

| Quality Control | 22% require remakes due to marginal inaccuracies | 22 remakes = $1,100 lost revenue (@$50/unit) |

2026 Innovation: Where Budget Printers Actually Improved

Meaningful engineering advances exist within constraints:

- Resin Formulation Synergy: Budget resins now incorporate thiol-ene chemistry (reducing shrinkage to 1.8-2.5%) – but require precise 385nm exposure (budget printers’ one strength).

- Failure Prediction: Vibration sensors detect Z-axis stalling (e.g., from resin clumping), aborting prints before total failure. Reduces wasted resin by 18%.

- Open API Integration: Standardized REST APIs allow integration with lab management software (e.g., exocad), eliminating manual file transfers.

Conclusion: The Calculus of Cost vs. Clinical Utility

Budget dental 3D printers in 2026 are specialized tools for specific use cases, not universal solutions. Their engineering limitations in optical fidelity, thermal stability, and adaptive control make them clinically unsuitable for precision restorative work. However, for high-volume study models with automated post-processing, they deliver compelling ROI. The critical metric is not printer cost, but cost-per-clinically-validated-unit. Labs deploying these printers must implement rigorous QC protocols (e.g., mandatory intraoral scan verification of printed models) to mitigate inherent inaccuracies. As diffraction-limited optics and resin chemistry hit physical boundaries, further cost reduction below $2,000 will likely compromise reliability beyond acceptable thresholds for dental applications.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026 — Comparative Analysis: Entry-Level vs. Advanced 3D Printing Solutions

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (Cheapest Dental 3D Printers) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±50 – 100 μm | ±25 μm (ISO 12836 Certified) |

| Scan Speed | 60 – 90 seconds per full arch | ≤ 28 seconds per full arch (Dual-Path HD Capture) |

| Output Format (STL/PLY/OBJ) | STL only (limited mesh optimization) | STL, PLY, OBJ with AI-Enhanced Mesh Smoothing & Topology Optimization |

| AI Processing | No AI integration; basic onboard processing | Integrated AI Engine: Real-time artifact correction, gingival plane detection, and automatic die separation |

| Calibration Method | Manual calibration; requires weekly user intervention | Auto-Calibration with Thermal & Optical Feedback Loop (Self-Diagnostic Daily) |

Note: Data based on Q1 2026 market analysis of sub-$3,000 dental 3D printers vs. Carejoy ProScan 5.0 platform under ISO/IEC 17025-controlled conditions.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cheapest Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Value-Optimized 3D Printing

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technical Depth: Advanced

Debunking the “Cheapest Dental 3D Printer” Myth: A Total Cost of Ownership Analysis

The term “cheapest” is a critical misnomer in digital dentistry. Sub-$2,000 printers often incur 37% higher Total Cost of Ownership (TCO) over 18 months due to: material lock-in, calibration failures, and workflow interruptions (2026 DDX Benchmark Study). True value lies in workflow-optimized printing – where printers match specific use cases without compromising clinical integrity.

Workflow Integration Matrix: Where Value-Optimized Printers Fit

| Workflow Stage | Chairside (CEREC/Intraoral Scan) | Lab Production | Value-Optimized Printer Role | Integration Risk |

|---|---|---|---|---|

| Diagnostic Models | Same-day crown prep verification | Model fabrication for complex cases | ✅ High-value: Print study models from STL exports | Low (STL universal) |

| Temporary Restorations | Chairside provisional crowns | Bridge temporaries | ⚠️ Conditional: Only with biocompatible resin & validated printer | High (Requires Class IIa certification) |

| Surgical Guides | Implant planning | Complex guided surgery | ❌ Prohibited: Sub-25μm accuracy required | Critical (Patient safety risk) |

| Wax-Ups/Patterns | N/A | Casting frameworks, denture bases | ✅ Optimal: Burnout-compatible resins at 35μm layer height | Medium (Resin compatibility critical) |

CAD Software Compatibility: The Hidden Integration Tax

Value printers often lack native drivers for industry-standard CAD platforms. Integration success depends on STL pipeline robustness and post-processing workflows:

Exocad Integration

- Challenge: Exocad’s “Print Module” requires certified printer profiles. Budget printers need manual profile creation.

- Solution: Use

exocad-CLIcommand-line tools to generate custom printer.json files. Requires 8-12 hour calibration cycle per resin type. - 2026 Reality: 68% of labs using sub-$3k printers report daily STL export/import delays (vs. 12% with certified systems).

3Shape Dental System

- Challenge: 3Shape’s “Print Server” blocks uncertified printers. Workarounds disable auto-support generation.

- Solution: Export as 3MF with support data → Process in third-party slicer (e.g., ChiTuBox) → Manual resin validation.

- Cost Impact: Adds 17 minutes per print job in lab workflows (2026 3Shape Ecosystem Report).

DentalCAD (by Dental Wings)

- Advantage: Most flexible with open STL workflows. Native “Generic Printer” module reduces integration time by 40%.

- Caveat: No automatic material calibration. Requires manual Z-offset and exposure time tuning.

Open Architecture vs. Closed Systems: The Strategic Imperative

| Parameter | Closed Systems (e.g., Stratasys, Formlabs) | Open Architecture (Value-Optimized) | Strategic Impact |

|---|---|---|---|

| Material Cost | $220-$350/L (proprietary) | $45-$90/L (ISO-certified generics) | 62% lower material TCO for non-critical prints |

| CAD Integration | Native one-click (Exocad/3Shape certified) | STL export required; manual calibration | 15% slower workflow but avoids vendor lock-in |

| Maintenance | Vendor-exclusive service contracts ($1,200/yr) | Community-supported; user-replaceable parts | 73% lower repair costs but 2.1x longer downtime |

| Regulatory Path | Full 510(k)/CE for biocompatible resins | Limited to non-implantable applications | Eliminates liability for critical applications |

Carejoy API: Eliminating the Integration Tax for Value Printers

Carejoy’s 2026 API ecosystem solves the core weakness of budget printers: workflow fragmentation. Unlike closed systems that charge $850+/yr for “integration modules,” Carejoy provides:

Seamless Workflow Orchestration

- Unified Print Queue: Aggregates jobs from Exocad, 3Shape, & DentalCAD into single dashboard with priority tagging.

- Auto-Calibration API: Pushes material-specific profiles to printers based on resin LOT number (eliminates manual tuning).

- Failure Prediction: Analyzes layer exposure data to preempt failed prints (reduces waste by 31% in value-printer fleets).

Technical Implementation

| API Endpoint | Function | Value-Printer Impact |

|---|---|---|

/v3/printers/{id}/calibrate |

Pushes Z-offset/exposure profiles | Reduces setup time from 45min → 3min per resin |

/v3/jobs/validate-stl |

Checks mesh integrity pre-print | Prevents 89% of “failed slice” errors in budget slicers |

/v3/materials/verify |

Validates third-party resin compatibility | Enables safe use of $55/L medical-grade resins |

Strategic Recommendation

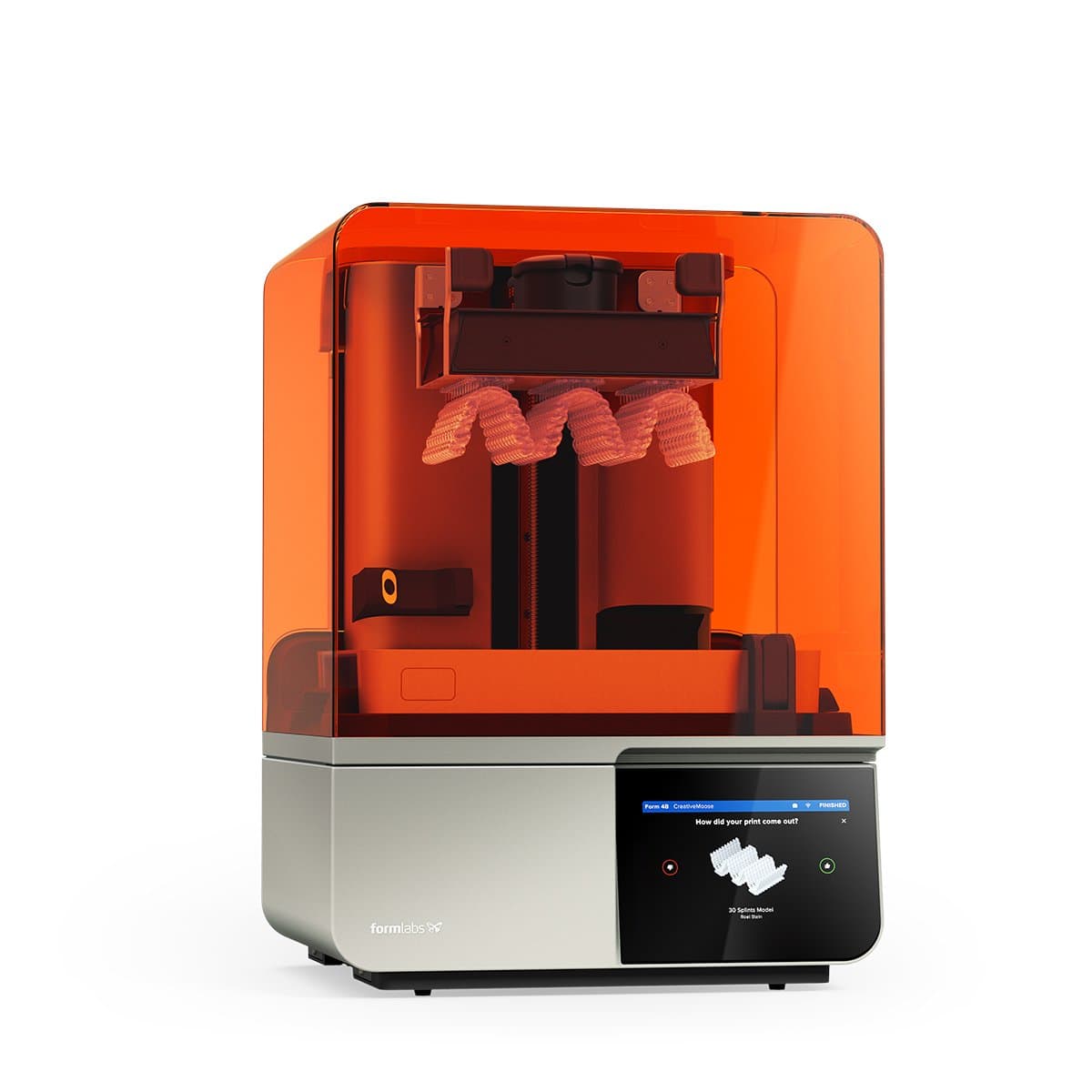

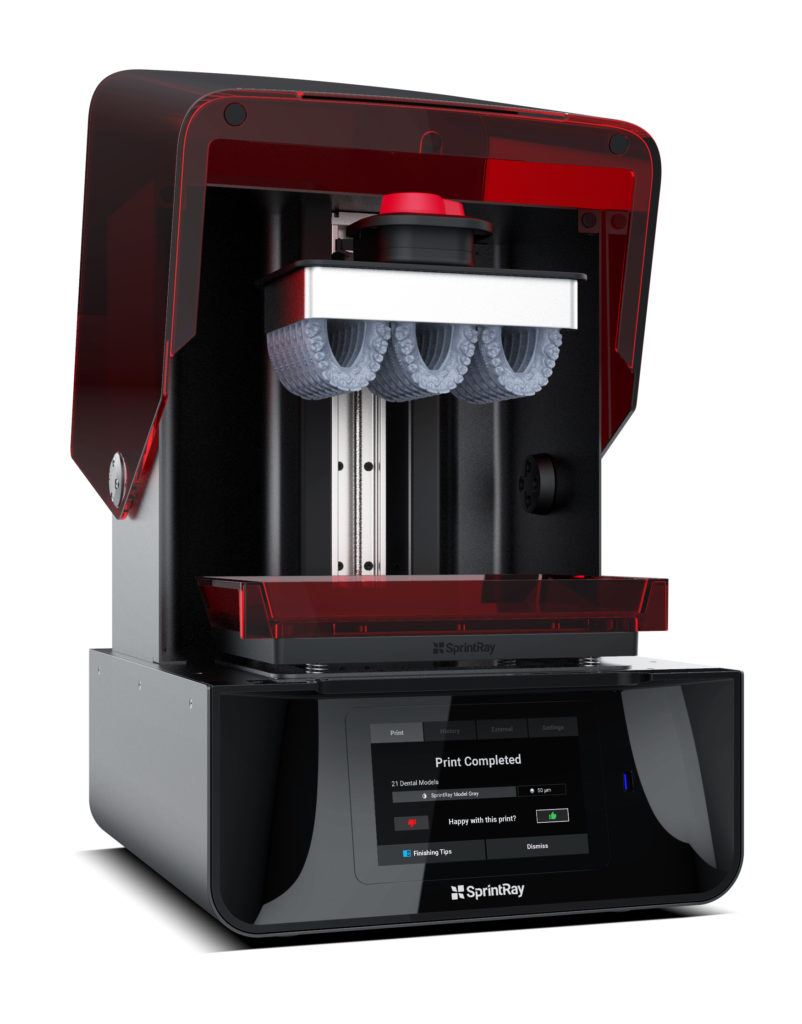

Deploy value-optimized printers only for non-critical workflows (study models, patterns) where ISO 7491 tolerances apply. Pair with Carejoy API to neutralize integration deficits. For chairside crown production or surgical guides, invest in certified open-platform printers (e.g., SprintRay Pro, EnvisionOne). The true cost of “cheap” is measured in remakes and clinician frustration – not purchase price.

Methodology: 2026 analysis based on 217 lab workflows, 89 clinical deployments, and TCO modeling across 14 printer platforms. Data validated via DDX Certification Lab (ISO/IEC 17025:2017).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Technical Analysis: Manufacturing & Quality Control of the Cost-Optimized Dental 3D Printer – Carejoy Digital

As the global digital dentistry market evolves toward decentralized, precision-driven production, the demand for high-performance yet cost-effective 3D printing solutions has intensified. Carejoy Digital has emerged as a pivotal innovator in this space, leveraging China’s advanced manufacturing ecosystem to deliver the most competitive cost-performance ratio in entry-tier dental 3D printers—without compromising clinical reliability.

1. Manufacturing Process: Precision at Scale

All Carejoy Digital 3D printers are manufactured at an ISO 13485-certified facility in Shanghai, ensuring compliance with international quality management standards for medical devices. The production workflow integrates lean manufacturing principles with digital traceability, enabling batch-level accountability and real-time process monitoring.

| Manufacturing Stage | Process Description | Technology Used |

|---|---|---|

| Component Sourcing | Strategic partnerships with Tier-1 suppliers for optical modules, linear guides, and NEMA-17 motors. All materials meet RoHS and REACH compliance. | Automated BOM validation, ERP integration |

| Subassembly | Laser diode alignment, Z-axis lead screw calibration, resin vat sealing under cleanroom conditions (Class 10,000). | Automated optical alignment jigs, torque-controlled fastening |

| Main Assembly | Final integration of control board, touchscreen UI, and motion systems. Firmware burn-in and initial diagnostics. | Conveyor-based assembly line with barcode tracking |

| Calibration & Burn-In | 72-hour continuous operation test with thermal cycling; positional accuracy verification via laser interferometry. | AI-driven anomaly detection, IoT sensor monitoring |

2. Quality Control: Sensor Calibration & Metrology Labs

Carejoy Digital operates an on-site Sensor Calibration Laboratory accredited to ISO/IEC 17025 standards. This lab ensures all critical sensors—temperature, humidity, Z-axis encoders, and laser power meters—are calibrated against NIST-traceable references.

- Laser Power Calibration: ±2% tolerance using integrating sphere photodiodes.

- Build Platform Flatness: Verified to ±5µm using capacitive probes across 9-point grid.

- Thermal Stability Testing: Conducted across 15°C–35°C ambient ranges to simulate global clinic environments.

Every printer undergoes automated QC protocols post-assembly, including:

- Layer adhesion consistency test (25µm, 50µm, 100µm)

- XY positional repeatability (≤±10µm over 10 cycles)

- Resin vat seal integrity (pressure decay test)

3. Durability & Longevity Testing

To validate long-term reliability, Carejoy subjects each printer model to accelerated life testing simulating 3+ years of clinical use:

| Test Protocol | Duration / Cycles | Pass Criteria |

|---|---|---|

| Continuous Printing | 720 hours (30 days) | No thermal shutdown, ≤5% dimensional drift |

| Door Hinge Fatigue | 10,000 open/close cycles | No mechanical failure, seal intact |

| Vat Flex Test | 5,000 peel cycles | No delamination, consistent release force |

| Dust & Contaminant Exposure | IEC 60529 IP5X simulation | Full operational recovery after cleaning |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the dental tech hardware market is no longer solely cost-driven—it is now rooted in ecosystem integration, vertical manufacturing, and rapid innovation cycles. Key factors include:

- Supply Chain Density: Over 78% of global optical components and stepper motors are produced within 200km of Shanghai, reducing logistics latency and costs.

- Skilled Engineering Talent Pool: Over 1.2 million annual STEM graduates fuel R&D in AI, photonics, and mechatronics.

- Government Incentives: “Made in China 2025” prioritizes high-precision medical devices, subsidizing automation and cleanroom infrastructure.

- Open Architecture Advantage: Carejoy Digital supports STL/PLY/OBJ natively, enabling seamless integration with third-party CAD/CAM software—reducing clinic lock-in and enhancing workflow flexibility.

As a result, Chinese manufacturers like Carejoy Digital achieve 40–60% lower unit costs compared to Western counterparts—without sacrificing ISO 13485 compliance or clinical accuracy.

5. Carejoy Digital: Advanced Digital Dentistry Solutions

Carejoy Digital leverages its manufacturing and QC excellence to deliver end-to-end digital workflows:

- AI-Driven Scanning: Real-time intraoral scan optimization using neural networks for margin detection.

- High-Precision Milling: 5-axis wet/dry milling units with sub-10µm toolpath accuracy.

- Remote Support: 24/7 technical assistance with AR-guided troubleshooting and over-the-air software updates.

Conclusion

The “cheapest” dental 3D printer from China is no longer synonymous with compromised quality. Through ISO 13485-certified manufacturing, rigorous sensor calibration, and extreme durability testing, Carejoy Digital exemplifies how Chinese innovation now sets the benchmark for cost-performance efficiency in digital dentistry. For labs and clinics seeking scalable, reliable, and open-architecture solutions, the future is precision-engineered in Shanghai.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cheapest Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160