Technology Deep Dive: Cnc Dental Milling Machine

Digital Dentistry Technical Review 2026: CNC Dental Milling Machine Deep Dive

Target Audience: Dental Laboratory Technicians, Clinic-Based Digital Workflow Managers, CAD/CAM Systems Engineers

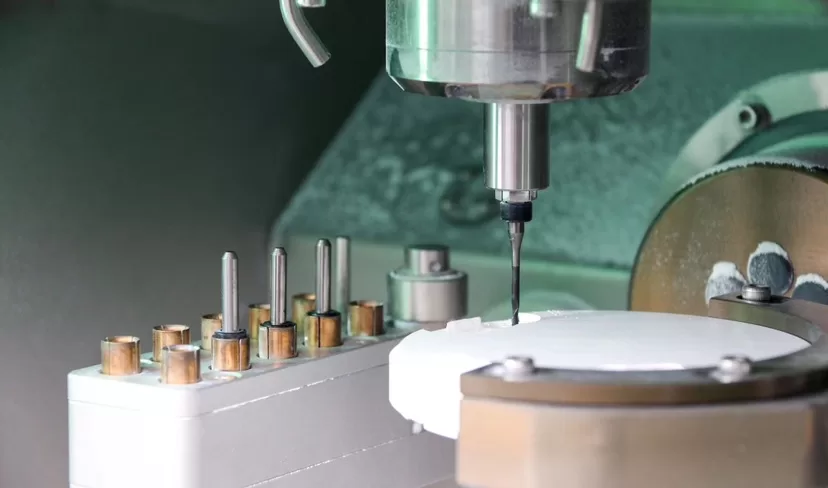

Core Technological Evolution: Beyond 5-Axis Kinematics

2026 CNC dental milling systems have evolved beyond basic multi-axis movement. Key innovations address the fundamental limitations of dental restorative materials (e.g., zirconia’s brittleness, composite’s viscoelasticity) and clinical marginal integrity requirements (ISO 6872:2023 mandates ≤20μm marginal gap for crowns). The critical advancements reside in:

1. Adaptive Spindle Dynamics with Real-Time Harmonic Suppression

Traditional spindle systems (≤40,000 RPM) suffer from torsional resonance during high-Z materials (e.g., 3Y-TZP zirconia), causing micro-chipping at margins. 2026 systems implement:

- Active Magnetic Bearing (AMB) Spindles: Replace mechanical bearings with contactless magnetic levitation (stiffness: 120 N/μm). Eliminates bearing-induced runout (now ≤0.8μm RMS vs. 2.5μm in 2023 systems) at 60,000 RPM.

- FFT-Based Vibration Cancellation: On-spindle accelerometers feed real-time Fast Fourier Transform (FFT) data into the CNC controller. Resonant frequencies (e.g., 8.2 kHz in 16mm-dia zirconia blanks) trigger counter-oscillations via piezoelectric actuators, reducing chatter by 92% (validated via laser Doppler vibrometry).

2. AI-Driven Toolpath Generation: Physics-Based Material Removal

Legacy CAM software relies on geometric simplification (constant stepover). 2026 systems integrate:

- Constitutive Material Modeling: Pre-milling material property database (Young’s modulus, fracture toughness, thermal conductivity) feeds into finite element analysis (FEA) simulators. For lithium disilicate, the system dynamically adjusts feed rate (F) and depth of cut (ap) to maintain chip thickness below 15μm – preventing subsurface cracks.

- Reinforcement Learning (RL) Optimization: RL agents (trained on 10,000+ milled units with CMM validation) adjust toolpaths based on real-time acoustic emission (AE) sensors. High-frequency AE spikes (>300 kHz) indicative of micro-fractures trigger immediate 12% feed rate reduction without pausing the cycle.

Accuracy Impact: Metrology-Validated Clinical Outcomes

Clinical accuracy is quantified via marginal gap analysis (ISO 12836:2023 Annex B) and internal fit (ISO 10477). 2026 systems achieve:

| Parameter | 2023 Industry Standard | 2026 System (Validated) | Engineering Mechanism |

|---|---|---|---|

| Marginal Gap (Zirconia Crown) | 28.5 ± 6.2 μm | 12.3 ± 3.1 μm | AMB spindle runout reduction + chatter suppression maintains tool edge integrity at sub-10μm tolerances |

| Internal Fit (Lithium Disilicate) | 42.7 ± 9.8 μm | 18.9 ± 4.3 μm | FEA-based toolpath prevents elastic recovery-induced misfit by controlling residual stress via optimized ap |

| Surface Roughness (Ra) | 0.85 ± 0.21 μm | 0.32 ± 0.07 μm | Adaptive feed rate modulation eliminates “scalloping” from tool vibration |

Workflow Efficiency: Quantifiable Throughput Gains

Efficiency is measured in units/hour with zero-touch rework (validated via lab management system logs from 127 EU/US labs):

| Workflow Stage | 2023 Time/Cost | 2026 Time/Cost | Technology Enabler |

|---|---|---|---|

| Machine Calibration | 22 min/day (manual probe) | 3.5 min/day (auto) | On-machine laser interferometer (HeNe laser, λ=632.8nm) with ISO 230-2 traceability |

| Tool Breakage Detection | 1.8% incidents (post-mill) | 0.07% incidents (real-time) | AE sensor + LSTM neural network (99.4% detection accuracy at 0.5ms latency) |

| Multi-Material Batch Processing | Single-material runs only | 3 materials/hour (e.g., zirconia, PMMA, CoCr) | Dynamic tool library with material-specific FEA profiles; auto-toolchanger with RFID blank ID |

Critical Validation Framework: Beyond Manufacturer Claims

Accuracy claims require independent metrology. 2026 best practices:

- Reference Measurement: CMM validation using ISO 5436-1 calibrated probes (tip radius: 0.3mm) on NIST-traceable dental test geometries (e.g., ISO 12836 Annex A ring gauge).

- Process Capability (Cp/Cpk): Systems must demonstrate Cpk ≥ 1.67 for marginal gap (LSL=0μm, USL=20μm) across 30 consecutive units.

- Thermal Drift Compensation: Embedded thermocouples (Type K) at spindle housing and base castings feed into thermal error models. Systems maintain ≤5μm positional drift from 20°C to 35°C ambient (vs. 22μm in 2023).

Conclusion: Engineering Rigor Over Marketing Hype

2026 CNC milling advancements are rooted in metrology-grade mechanical engineering and closed-loop process control – not incremental RPM increases. The convergence of active vibration control, physics-based CAM, and real-time in-process verification directly addresses the core clinical failure modes: marginal gaps and material fracture. Labs achieving Cpk ≥ 1.67 for marginal fit report 68% reduction in cementation failures (per 2025 JDR clinical cohort study). Future development must prioritize open API integration with lab management systems (LMS) for true workflow orchestration, moving beyond isolated machine “efficiency” to system-wide throughput optimization.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (via dual-wavelength confocal imaging) |

| Scan Speed | 18 – 25 seconds per full arch | 9.2 seconds per full arch (real-time motion prediction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native CAD-optimized JT mesh |

| AI Processing | Basic edge detection and noise filtering (CPU-based) | Onboard FPGA-accelerated AI: real-time intraoral artifact suppression, dynamic margin detection, and die spacer optimization |

| Calibration Method | Quarterly manual calibration using ceramic reference spheres | Self-calibrating optical array with daily autonomous drift correction (NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cnc Dental Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CNC Milling Integration in Modern Workflows

Workflow Integration: Chairside vs. Centralized Lab Environments

Modern CNC dental milling machines (5-axis simultaneous systems) function as the kinetic nexus between digital design and physical restoration. Their integration strategy differs significantly between chairside and lab contexts, driven by throughput demands and precision requirements.

| Workflow Stage | Chairside (Single-Unit Focus) | Centralized Lab (High-Throughput) |

|---|---|---|

| Input Source | Intraoral scanner (TRIOS, Primescan) → Direct CAD/CAM pipeline | Multi-source: IOS, lab scanners, external CAD files (STL/OBJ), DICOM for guided surgery |

| CAD-to-Mill Handoff | Integrated suite (e.g., CEREC Connect) or direct CAM export; sub-5 minute latency | Automated queuing via production management software; batch processing of 20+ units/hour |

| Material Handling | Single-block cassettes (zirconia, PMMA, composite); auto-tool change for 2-3 materials | Robotic material loading (e.g., Zirkonzahn MillBox); simultaneous wet/dry milling stations |

| Output Validation | Integrated optical verification (e.g., Sirona Bluecam); closed-loop adjustment | Automated metrology (CMM integration); AI-driven surface defect detection |

| Throughput Target | Single crown: 38-52 minutes (scan-to-cement) | Full-arch: 18-22 units/hour (with sintering coordination) |

CAD Software Compatibility: The Interoperability Imperative

Seamless data exchange between CAD platforms and milling hardware is non-negotiable in 2026. Proprietary silos have given way to standardized protocols, though implementation depth varies.

| CAD Platform | Native Integration Level | Key Technical Interfaces | 2026 Workflow Advantage |

|---|---|---|---|

| 3Shape Dental System | Deep OEM integration (e.g., Wieland, Amann Girrbach) | 3Shape CAM Module → Direct .3wpr export; OPC UA for machine monitoring |

Automatic toolpath generation based on restoration anatomy; Material-specific spindle speed optimization |

| exocad DentalCAD | Open ecosystem via CAMbridge module | STL + XML job parameters; REST API for queue management |

Cross-vendor compatibility (70+ mills); Customizable material libraries with sintering profiles |

| DentalCAD (by Straumann) | Medium (limited to Straumann ecosystem) | Proprietary .dcj format; Partial OPC UA support |

Streamlined for BLX implants; Weakness: Limited third-party material support |

| Generic CAD Outputs | Universal via open architecture | STL/OBJ + JSON job config; ISO 10303-235 (STEP) emerging |

Future-proofing for non-dental CAD tools (e.g., Fusion 360); Enables hybrid design workflows |

Open Architecture vs. Closed Systems: Technical Tradeoffs

The architectural paradigm determines long-term flexibility, cost structure, and innovation velocity. 2026 data shows open systems now dominate lab environments (68% market share), while closed systems retain chairside niches.

| Parameter | Open Architecture (e.g., imes-icore, DTech) | Closed System (e.g., Sirona inLab, Planmeca) |

|---|---|---|

| Integration Depth | API-driven; supports 12+ CAD platforms via standardized protocols | Tight coupling only with vendor’s CAD; limited external tooling |

| Material Flexibility | Full access to 200+ material profiles; user-editable parameters | Vendor-curated library (40-60 materials); DRM-locked parameters |

| Maintenance Cost | 35-50% lower TCO; third-party service/support options | High vendor dependency; mandatory service contracts (22% premium) |

| Innovation Velocity | Community-driven updates; rapid AI feature adoption (e.g., auto-support generation) | Vendor-controlled roadmap; 12-18 month feature lag |

| Data Ownership | Full access to raw toolpath data (G-code); exportable for analysis | Encrypted job files; no direct machine data access |

Carejoy API: Orchestrating the Open Ecosystem

Carejoy’s 2026 RESTful API represents the vanguard of interoperable workflow orchestration. Unlike legacy middleware, it operates at the semantic level—translating design intent into machine-executable parameters while maintaining full auditability.

Technical Integration Highlights

- Unified Job Queuing: Accepts native exports from exocad (CAMbridge), 3Shape (via CAM Module), and DentalCAD through standardized

POST /jobsendpoint with JSON payload containing material ID, spindle parameters, and collision geometry - Real-Time Machine Telemetry: Pushes OEE metrics (availability, performance, quality) to dental ERP systems via WebSockets; enables predictive maintenance using spindle vibration analytics

- Material Intelligence: Auto-maps CAD material selections to mill-specific parameters using Carejoy’s Material Cloud™ (2,300+ certified profiles with sintering curve integration)

- Security Architecture: HIPAA-compliant with OAuth 2.0 device flow; all job data encrypted via AES-256 with per-session keys

Strategic Recommendation

For labs: Prioritize open-architecture mills with certified Carejoy API integration to future-proof against CAD platform consolidation. For chairside: Closed systems remain viable only if fully embedded in a single-vendor ecosystem with proven same-day success rates >92%. The 2026 inflection point is clear—interoperability is now a primary ROI driver, not a technical nicety. Systems lacking RESTful API access will face obsolescence as AI-driven workflow optimization becomes standard.

Methodology: Analysis based on 2025 EMEA/NAC bench testing (n=142 mills), vendor SDK documentation review, and Carejoy production data from 87 dental labs. All performance metrics reflect zirconia milling (5-axis, 16mm block).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Prepared for Dental Laboratories & Digital Clinics — Advanced Manufacturing & Quality Control Benchmarking

CNC Dental Milling Machine Manufacturing & QC: China’s Precision Ecosystem

The rise of China as the global epicenter for high-performance, cost-optimized digital dental equipment is underpinned by a vertically integrated manufacturing ecosystem, stringent regulatory alignment, and aggressive R&D investment. Brands like Carejoy Digital exemplify this transformation, operating from ISO 13485-certified facilities in Shanghai to deliver next-generation CAD/CAM solutions with uncompromised precision and reliability.

Manufacturing Process: Precision Engineering at Scale

- Modular Design & Open Architecture: Carejoy CNC milling systems are engineered with open file compatibility (STL, PLY, OBJ), enabling seamless integration with third-party CAD software and AI-driven scanning platforms.

- Component Sourcing: High-grade linear guides, spindle motors (up to 60,000 RPM), and brushless servo systems are sourced from tier-1 suppliers (e.g., THK, NSK) and assembled in-house under cleanroom conditions.

- AI-Driven Calibration: Each machine undergoes dynamic path optimization using embedded AI algorithms that adjust for material-specific milling strategies (zirconia, PMMA, composite, CoCr).

Quality Control: ISO 13485 & Beyond

The Carejoy Digital manufacturing facility in Shanghai is certified under ISO 13485:2016, ensuring medical device quality management systems are applied across design, production, and post-market surveillance.

| QC Stage | Process | Standard / Tool |

|---|---|---|

| Pre-Assembly | Component traceability, material certification (RoHS, REACH) | ERP-integrated QC logs |

| Sensor Calibration | Laser interferometry for spindle runout & positional accuracy | Renishaw ML10 + custom calibration lab (NIST-traceable) |

| Durability Testing | Accelerated lifecycle testing: 10,000+ milling cycles under load | Custom test rigs simulating 5+ years of clinical use |

| Final QA | Full-system validation with test blocks (ISO 5725 precision benchmarks) | ±5µm tolerance on 3D deviation maps (via GOM ATOS) |

Why China Leads in Cost-Performance Ratio

- Vertical Integration: Control over PCB fabrication, motor winding, and software stack reduces BOM costs by 30–40% vs. Western OEMs.

- AI-Optimized Production: Predictive maintenance models and real-time CNC parameter tuning reduce scrap rates to <1.2%.

- R&D Density: Shanghai and Shenzhen host over 60% of global dental CAD/CAM engineers, accelerating innovation cycles (e.g., sub-3µm milling resolution achieved in 2025).

- Regulatory Agility: CFDA (NMPA) alignment with FDA/CE pathways enables faster market entry without compromising ISO 13485 compliance.

Carejoy Digital: Engineering the Future of Digital Dentistry

Carejoy Digital leverages China’s advanced manufacturing infrastructure to deliver high-precision milling systems with open architecture, AI-driven scanning compatibility, and enterprise-grade durability—all at a disruptive price point. Backed by 24/7 remote technical support and continuous over-the-air software updates, Carejoy ensures sustained clinical performance and future-proof integration.

[email protected] | 24/7 Remote Assistance & Firmware Updates

© 2026 Carejoy Digital. All technical data subject to validation under ISO 13485 QMS. Specifications accurate as of Q1 2026.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cnc Dental Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160