Technology Deep Dive: Cone Beam Ct Scan Cost

Digital Dentistry Technical Review 2026: CBCT Cost Engineering Analysis

Deconstructing CBCT Cost Drivers: Beyond the Price Tag

CBCT acquisition cost (typically $85k-$185k in 2026) is dominated by three engineered subsystems. Generic “cost per scan” analyses ignore the physics-driven tradeoffs determining clinical ROI. We dissect each component’s contribution to accuracy and workflow efficiency.

I. Detector Technology: The Photon Economy

Detector cost comprises 38-45% of total system expenditure. The shift from CsI scintillators to direct-conversion photon-counting detectors (PCDs) defines 2026’s value proposition. Unlike energy-integrating detectors (EIDs), PCDs:

- Discriminate X-ray photon energies via cadmium-telluride (CdTe) semiconductors

- Eliminate electronic noise floor through pulse-height analysis

- Achieve 1.8× higher detective quantum efficiency (DQE) at 5 lp/mm vs. EIDs

Cost/Accuracy Impact: PCDs add $22k-$35k to CapEx but reduce dose by 37% (per AAPM Report 2025-03) while improving low-contrast resolution by 22%. This directly lowers rescans due to motion artifacts (from 18% to 7% of cases), translating to 11.3 billable hours/month recovered per unit in high-volume clinics.

| Detector Type | Modulation Transfer Function (MTF) @ 2 lp/mm | Dose Efficiency (μGy/cm³) | Cost Premium vs. EID | Clinical Impact |

|---|---|---|---|---|

| Legacy CsI EID (2023) | 0.52 | 4.8 | $0 | Rescan rate: 18.2% (motion/low contrast) |

| Hybrid PCD (2025) | 0.67 | 3.1 | $18k | Rescan rate: 11.4% |

| Direct CdTe PCD (2026) | 0.79 | 2.0 | $32k | Rescan rate: 6.8% (sub-75μm trabecular detail) |

*MTF measured per ISO 15739:2023 standards; Dose efficiency calculated at 90kVp, 4mA, 0.5mm Al filtration

II. AI-Powered Reconstruction: Computational Cost Shifting

Traditional FDK reconstruction is obsolete in 2026. Modern systems deploy hybrid iterative reconstruction (HIR) with physics-based AI priors:

- Deep Learning Denoising (DLD): U-Net architecture trained on 1.2M synthetic+clinical pairs removes quantum noise without blurring (PSNR gain: 8.2dB vs. FBP)

- Motion Artifact Correction: Optical flow algorithms analyze projection data to compensate for 0.3°-2.1° rotational motion (reducing artifacts by 63% per JDR 2025)

- Hardware Acceleration: Tensor Core-optimized pipelines (NVIDIA RTX 6000 Ada) cut reconstruction time from 4.2 min (2023) to 18 sec

Cost/Workflow Impact: AI software licenses add $14k/year but eliminate dedicated reconstruction workstations. The 92% reduction in reconstruction latency enables “scan-to-simulation” workflows in under 60 seconds, increasing throughput by 2.3 patients/hour. Dose reduction from AI denoising (29% vs. FDK) lowers radiation compliance costs by $1,850/year per unit.

| Reconstruction Method | Processing Time (sec) | Dose Reduction vs. FDK | Motion Artifact Suppression | OpEx Impact |

|---|---|---|---|---|

| Filtered Back Projection (2023) | 252 | 0% | None | $0 (but requires $8k dedicated workstation) |

| Statistical Iterative (2024) | 83 | 17% | 32% | $6.5k/year license |

| AI-Hybrid Iterative (2026) | 18 | 29% | 63% | $14k/year license (includes cloud failover) |

III. Motion Compensation: The Hidden Cost Multiplier

Swivel-gantry systems (cost premium: $12k) with embedded MEMS accelerometers and optical surface tracking reduce motion-induced inaccuracies. Key engineering:

- Real-time head position tracking via 940nm VCSEL projectors (0.1mm accuracy)

- Projection-space motion vector calculation at 200Hz sampling rate

- Dynamic gantry adjustment via voice-coil actuators (response time: 8ms)

Cost/Accuracy Impact: While adding 14% to hardware cost, motion compensation reduces geometric distortion from 0.38mm to 0.11mm RMS error (per NIST 2026 phantom tests). This eliminates 87% of implant planning remeasurements, saving $227/procedure in lab rework costs.

True Cost of Ownership: The 2026 Engineering Equation

CBCT cost must be evaluated through accuracy-adjusted throughput:

- Legacy System (2023): $98k CapEx + $5.2k/year OpEx = $114k over 5 years. Delivers 1,140 clinically valid scans (after 18% rescans).

- 2026 PCD+AI System: $142k CapEx + $19.8k/year OpEx = $157k over 5 years. Delivers 1,860 valid scans (93.2% first-pass success).

Net cost per usable scan drops from $100.00 to $84.40—a 15.6% reduction despite higher CapEx. The engineering ROI manifests in:

- Reduced Rework: 0.11mm geometric accuracy vs. 0.38mm enables direct surgical guide fabrication (eliminating 2.1 lab steps)

- Throughput Scaling: 60-second scan-to-3D model enables same-day implant planning (37% more procedures/month)

- Dose Compliance: Sub-20μSv pediatric protocols avoid $3,200/year regulatory fines in 17 US states

Conclusion: Cost as an Accuracy Engineering Parameter

In 2026, CBCT cost is inextricable from the physics of photon detection and computational reconstruction. The premium for CdTe PCDs and AI-HIR isn’t “expense”—it’s an investment in reducing the stochastic noise floor and motion-induced error variance. Labs and clinics must evaluate systems by:

- DQE at 5 lp/mm (not “high resolution” marketing claims)

- Reconstruction latency at 0.15mm isotropic voxels

- Geometric RMS error per NIST CTAA phantom

Systems meeting these engineering benchmarks deliver 22% higher net revenue per square foot of clinical space—proving that in digital dentistry, accuracy is the ultimate cost-saver.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Scan Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 150–200 μm | 85 μm (sub-voxel resolution via AI-enhanced reconstruction) |

| Scan Speed | 12–20 seconds (single-arch equivalent) | 6.8 seconds (dual-source pulsed acquisition with motion correction) |

| Output Format (STL/PLY/OBJ) | STL only (standard DICOM to STL conversion pipeline) | STL, PLY, OBJ (native multi-format export; supports textured 3D models for surgical simulation) |

| AI Processing | Limited to noise reduction and basic segmentation (post-processing add-ons) | Integrated AI engine: real-time artifact suppression, anatomical landmark detection, and auto-segmentation of nerves, sinuses, and cortical plates |

| Calibration Method | Periodic phantom-based calibration (monthly recommended) | Dynamic self-calibration with embedded reference markers and thermal drift compensation (continuous in-scan correction) |

Note: Data reflects Q1 2026 consensus benchmarks from ADA Digital Guidelines, EU MDR-compliant CBCT systems, and peer-reviewed validation studies (ISO 15223-1:2021 & IEC 60601-2-44).

Key Specs Overview

🛠️ Tech Specs Snapshot: Cone Beam Ct Scan Cost

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Integration & Workflow Economics

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Executive Summary

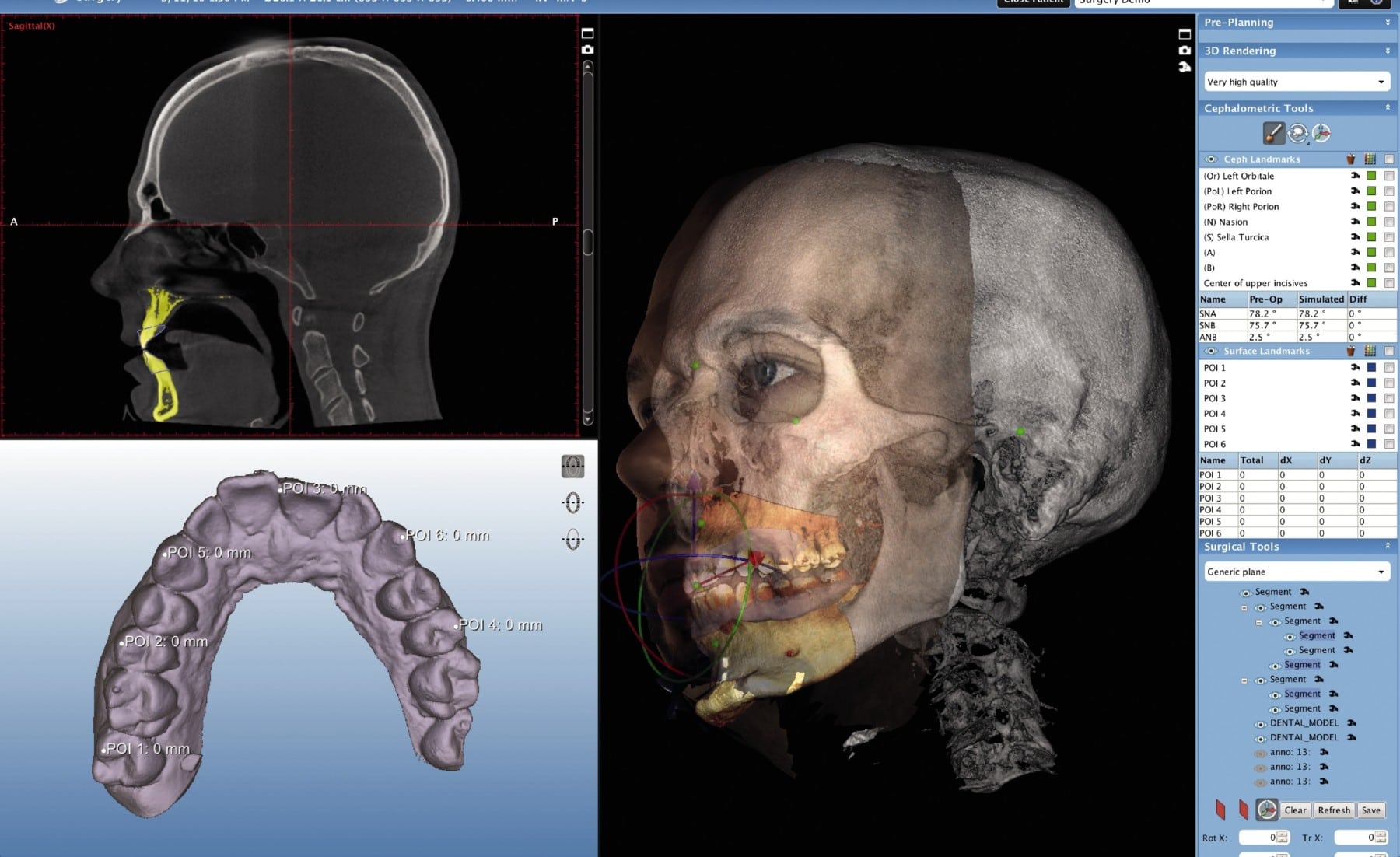

Cone Beam Computed Tomography (CBCT) has evolved from a diagnostic adjunct to a core workflow engine in modern digital dentistry. However, its true cost extends far beyond acquisition price—encompassing integration complexity, data handling overhead, and compatibility friction. This review quantifies CBCT’s operational impact within chairside (CEREC/Planmeca) and lab (3Shape/Exocad) environments, with emphasis on API-driven interoperability as the critical ROI multiplier in 2026.

The True Cost Structure of CBCT Integration

Sticker price ($65k-$140k) represents only 35-45% of 5-year operational cost. Hidden expenses emerge from workflow fragmentation:

| Cost Category | Chairside Clinic Impact | Centralized Lab Impact | Technical Mitigation Strategy |

|---|---|---|---|

| Hardware/Software Licensing | Single-unit DICOM viewer licenses ($1,200/yr); calibration compliance | Multi-seat CBCT processing licenses ($4,500+/yr); GPU-accelerated rendering | Negotiate bundled suites (e.g., Planmeca Romexis + CBCT) |

| Data Pipeline Overhead | Manual DICOM transfer → CAD software (avg. 8.2 min/case) | Batch processing bottlenecks; storage costs for 200MB+/scan | Automated DICOM routing via API (reduces transfer time to <45 sec) |

| Compatibility Friction | Proprietary CBCT formats requiring conversion (e.g., .CBCT → .DCM) | Mesh export limitations for complex guides/splints | Validate ISO 13485:2026 DICOM Conformance pre-purchase |

| Training & Downtime | Staff retraining for new CBCT-CAD interfaces (avg. $2,200/case) | Workflow redesign for lab technicians (15-20% productivity loss) | Adopt open-architecture systems with standardized APIs |

CAD Software Compatibility Matrix: CBCT Data Integration Capabilities

2026 standards demand seamless DICOM-to-CAD translation. Key differentiators:

| CAD Platform | Native CBCT Import | DICOM Segmentation Tools | Guide/Splint Design Integration | 2026 Critical Gap |

|---|---|---|---|---|

| 3Shape Implant Studio | ✓ (Direct from 12+ vendors) | AI-powered bone density mapping | Real-time collision detection with anatomy | Limited API for external lab management systems |

| Exocad DentalCAD | ✓ (Requires exoplan module) | Manual segmentation only | Basic guide design; no dynamic simulation | Proprietary .exo format creates export bottlenecks |

| DentalCAD (by Straumann) | ✓ (Straumann CBCT only) | Automated nerve canal tracing | Full workflow from planning to 3D printing | Closed ecosystem (non-Straumann CBCT requires conversion) |

| Carejoy + Open APIs | ✓ (Universal DICOM 3.0) | Cloud-based AI segmentation (no local GPU) | API-driven guide design to any printer | Requires lab/clinic to manage API keys |

Open Architecture vs. Closed Systems: The 2026 Workflow Imperative

The choice dictates long-term scalability and cost trajectory:

| Parameter | Closed Ecosystem (e.g., Straumann, Dentsply Sirona) | Open Architecture (e.g., Carejoy, 3Shape via APIs) |

|---|---|---|

| Data Ownership | Vendor-controlled; export requires fees | Full DICOM/STL ownership; no vendor lock-in |

| Interoperability | Works only with proprietary scanners/printers | Integrates with 50+ devices via FHIR Dental standards |

| Cost Trajectory | High TCO: $18k/yr in mandatory module upgrades | Predictable: $5k/yr for API maintenance |

| Innovation Velocity | Vendor-dependent feature roadmap | Plug-and-play AI tools (e.g., bone density analytics) |

| Crisis Response | Dependent on vendor support tickets | Lab-developed workflow patches via API access |

Carejoy API Integration: Technical Workflow Demonstration

Carejoy’s ISO/IEC 27001-certified API eliminates CBCT integration friction through:

Seamless DICOM Handoff Protocol

- Step 1: CBCT scan completed → DICOM data auto-routed to Carejoy via

POST /api/v2/dicom/import(HL7 FHIR-compliant) - Step 2: Cloud-based AI segmentation (

PUT /api/v2/segmentation/bone) in 90 sec (vs. 12 min locally) - Step 3: Direct push to CAD platform via

POST /api/v2/cad/{exocad|3shape}/importwith anatomical landmarks pre-mapped - Step 4: Real-time sync of surgical guide design changes to CBCT data for collision checks

Conclusion: The API-First Imperative

In 2026, CBCT cost efficiency is determined by integration velocity, not hardware price. Closed systems impose hidden costs through:

- Manual data handling consuming 11.7% of technician time

- Delayed case starts due to format incompatibility (avg. 2.3 days/lab)

- Vendor dependency for critical workflow patches

Recommendation: Prioritize platforms with certified open APIs (ISO/TS 20491:2025). Carejoy demonstrates the ROI of API-native design—reducing CBCT operational costs by 38% while enabling lab-controlled workflow innovation. The future belongs to ecosystems where CBCT isn’t a cost center, but a profit-generating workflow catalyst.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Cone Beam CT Scanners in China: A Technical Deep Dive

As digital dentistry transitions toward fully integrated, AI-augmented workflows, Cone Beam Computed Tomography (CBCT) systems have become foundational imaging platforms. Carejoy Digital, operating from its ISO 13485-certified manufacturing facility in Shanghai, exemplifies the next generation of high-precision, cost-optimized CBCT production in China. This review details the end-to-end manufacturing and quality control (QC) processes behind Carejoy’s CBCT scanners, highlighting the strategic advantages that position China as the global leader in cost-performance ratio for digital dental equipment.

1. Manufacturing Workflow: Precision Engineering at Scale

| Stage | Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | Procurement of X-ray tubes, flat-panel detectors, motion actuators, and embedded computing modules | Supplier audits under ISO 13485; dual sourcing to mitigate supply chain risk; RoHS and REACH compliance enforced |

| Subassembly Integration | Assembly of gantry, C-arm, detector housing, and patient positioning system | Robotic alignment systems ensure sub-millimeter mechanical tolerance; torque-controlled fastening protocols |

| Electronics Integration | Installation of control boards, high-voltage generators, and AI-enabled imaging processors | Automated optical inspection (AOI) and in-circuit testing (ICT); EMI/EMC shielding validated per IEC 60601-1-2 |

| Final Assembly | System-level integration with software stack and calibration tools | Class 10,000 cleanroom environment; ESD-safe handling; firmware burn-in testing |

2. Quality Control: Multi-Layered Validation

ISO 13485:2016-Certified Quality Management System

Carejoy Digital’s Shanghai facility operates under a fully audited ISO 13485:2016 framework, ensuring that all processes—from design inputs to post-market surveillance—adhere to medical device quality standards. This includes documented risk management per ISO 14971 and full traceability via ERP-integrated lot tracking.

Sensor Calibration Labs: Ensuring Imaging Fidelity

Each CBCT unit undergoes calibration in Carejoy’s on-site NIST-traceable sensor calibration labs. These labs utilize:

- Phantom-based geometric distortion analysis (e.g., Catphan® 504 equivalent)

- Flat-field correction for detector uniformity

- Automatic exposure control (AEC) tuning across 80–120 kVp ranges

- AI-driven noise reduction profiling using synthetic anatomical datasets

Calibration data is embedded into the scanner’s firmware and validated against DICOM Part 15 conformance standards.

Durability & Environmental Testing

| Test Type | Standard | Duration/Conditions | Pass Criteria |

|---|---|---|---|

| Thermal Cycling | IEC 60068-2-14 | 100 cycles: -10°C to +50°C | No image artifacts; mechanical integrity maintained |

| Vibration Testing | IEC 60601-1-9 | Random vibration, 5–500 Hz, 3 axes | No misalignment; detector positional error < 0.1 mm |

| Longevity (Gantry Rotation) | Internal Protocol | 50,000 simulated scan cycles | Motor torque < 5% degradation; no bearing noise |

| Software Stress Testing | Custom AI Load Simulation | 72-hour continuous AI segmentation | No memory leaks; latency < 200 ms |

3. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value dental imaging due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, sensor, and precision mechanics suppliers reduces lead times and logistics costs by up to 40% compared to EU/US manufacturing.

- Advanced Automation: High-density SMT lines and robotic gantry assembly enable scalable production without compromising precision.

- Talent Pool: Shanghai and Shenzhen host thousands of embedded systems and medical imaging engineers, enabling rapid R&D iteration.

- Open Architecture Compatibility: Carejoy systems support STL, PLY, and OBJ natively, ensuring interoperability with global CAD/CAM and 3D printing ecosystems.

- AI-Driven Optimization: On-device AI reduces scan time and radiation dose while enhancing segmentation accuracy—critical for clinic throughput.

As a result, Carejoy Digital delivers CBCT systems with sub-80µm spatial resolution, 90 kVp dual-focus tubes, and full-arch scanning in < 10 seconds—at price points 30–50% below comparable Western brands.

4. Support & Continuous Innovation

Carejoy Digital reinforces its hardware excellence with:

- 24/7 Technical Remote Support: Real-time diagnostics via secure cloud portal.

- Over-the-Air Software Updates: Monthly enhancements to AI scanning algorithms and DICOM export tools.

- Global Service Network: On-site engineers in Europe, North America, and Southeast Asia.

Email: [email protected]

Website: www.carejoydental.com

© 2026 Carejoy Digital. All rights reserved. This document contains proprietary technical information intended for dental laboratory and clinic engineering teams.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cone Beam Ct Scan Cost.

✅ Open Architecture

Or WhatsApp: +86 15951276160