Technology Deep Dive: Crucial Scanner

Digital Dentistry Technical Review 2026: Crucial Scanner Deep Dive

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Executive Summary

By 2026, intraoral scanners (IOS) have evolved from data capture tools to integrated metrology systems where sub-5μm accuracy is clinically achievable. This review dissects the engineering convergence of optical physics, computational imaging, and AI-driven error correction that enables reliable single-scan crown preparations and full-arch digital impressions with ≤7μm trueness (ISO 12836:2023). We focus exclusively on first-principles engineering – not vendor marketing claims.

Core Scanner Technologies: 2026 Engineering Breakdown

The following table compares foundational technologies in clinically deployed scanners, emphasizing measurable 2026 advancements:

| Technology | Core Engineering Principle | 2026 Critical Innovation | Accuracy Impact (μm) | Workflow Efficiency Gain |

|---|---|---|---|---|

| Structured Light (SL) | Projection of high-frequency sinusoidal fringe patterns. 3D reconstruction via phase-shifting profilometry (Fourier transform analysis of pixel-wise intensity modulation). Requires precise calibration of projector-camera epipolar geometry. | Multi-spectral fringe projection (405nm/520nm/635nm) with quantum dot-enhanced CMOS sensors. Eliminates subsurface scattering artifacts in translucent materials (e.g., lithium disilicate preps). | Trueness: 3.2±0.7 (vs. 5.8±1.2 in 2023) Repeatability: 1.8±0.3 Validation: NIST-traceable ceramic step gauges (ISO 10360-8) |

22% faster full-arch capture (avg. 1.8 min) due to 4x frame rate (120 fps) and adaptive pattern density. Eliminates “scan stitching” errors. |

| Laser Triangulation (LT) | Time-of-flight (ToF) measurement of laser line deformation. Relies on triangulation baseline (camera-laser distance) and Scheimpflug principle for depth-of-field extension. Vulnerable to specular reflection. | Coherent frequency-modulated continuous wave (FMCW) lasers with polarization filtering. Resolves specular interference via Stokes vector analysis of reflected light. | Trueness: 4.1±0.9 (vs. 6.5±1.5 in 2023) Repeatability: 2.3±0.4 Validation: Critical margin detection at 0.2mm chamfer (SEM verification) |

35% reduction in rescans due to metallic restorations. Real-time reflectance compensation enables single-pass scanning of gold copings. |

| AI-Driven Sensor Fusion | Not a capture method – a post-processing layer. Combines SL/LT data streams using Kalman filtering and neural radiance fields (NeRFs) to resolve occlusion gaps and texture ambiguities. | On-device transformer networks trained on 12M+ clinical scans. Implements differentiable rendering to back-propagate geometric errors into sensor calibration parameters. | Reduces marginal gap error by 47% at subgingival margins. Compensates for blood/saliva via spectral unmixing (validated by micro-CT). | Cut technician intervention by 63%. Auto-segmentation of prep margins (IoU: 0.92) reduces CAD prep time from 8.2 to 2.1 min per unit. |

Clinical Accuracy: How Physics Translates to Outcomes

Accuracy improvements stem from error source elimination, not incremental sensor upgrades:

- Subsurface Scattering Mitigation: Multi-spectral SL (405nm) penetrates enamel 0.15mm less than 635nm light, reducing “halo” artifacts at margin edges. Measured via optical coherence tomography (OCT) correlation.

- Dynamic Calibration: On-sensor MEMS accelerometers (±0.01° resolution) detect handpiece tilt. Real-time correction of perspective distortion via homography matrix updates prevents “stair-step” artifacts in deep preparations.

- NeRF-Based Gap Closure: Unlike legacy mesh interpolation, neural radiance fields synthesize geometrically plausible surfaces using multi-view consistency constraints. Reduces interproximal voids by 89% (p<0.001 vs. 2023 algorithms).

Workflow Efficiency: Quantifiable Engineering Gains

2026 scanners deliver efficiency through closed-loop metrology – not just speed:

- Adaptive Scanning Protocol: AI analyzes initial frames to determine optimal scan path density. Prep margins trigger 4x point density (0.015mm vs. 0.06mm), reducing data load by 31% without sacrificing accuracy.

- Automated Quality Assurance: Real-time ISO 12836 compliance checks. Scans failing trueness thresholds (e.g., >8μm) are flagged before clinician leaves operatory – eliminating 92% of lab remakes due to poor scan data.

- Seamless CAD Integration: Native STEP file output with embedded metrology reports (ASME B89.7.3 compliant). Labs receive traceable uncertainty maps per scan zone, reducing verification time by 44%.

Critical Implementation Considerations for Labs

Adopt these engineering-focused validation protocols:

- Calibration Drift Testing: Measure trueness weekly using NIST-traceable titanium step gauges (not vendor-provided plastic blocks). Acceptable drift: ≤0.5μm/day.

- Fluid Interference Protocol: Scan submerged ceramic margins with hemoglobin/saline solution (0.5g/dL). Reject scanners with margin detection error >15μm.

- AI Audit Trail: Demand access to model versioning and training data provenance. Scanners using synthetic data alone show 22% higher error in gingival margins.

Conclusion

The 2026 “crucial scanner” is defined by metrological integrity – where optical physics, computational imaging, and AI converge to produce clinically actionable data. Labs must prioritize systems with:

• Multi-spectral capture for material-invariant accuracy

• Differentiable rendering pipelines for error-aware reconstruction

• Embedded metrology reporting compliant with ASME B89.7.3

Scanners remain data acquisition tools; their clinical value is determined by quantifiable error budgets and closed-loop workflow integration. The era of “good enough” digital impressions is over.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Crucial Scanner vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm | ≤ 8 μm (ISO 12836 certified) |

| Scan Speed | 15 – 25 seconds per full arch | 6.5 seconds per full arch (real-time HD capture at 40 fps) |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY | STL, PLY, OBJ, 3MF (native export with metadata tagging) |

| AI Processing | Limited edge detection; post-processing required | Integrated AI engine: auto-mesh optimization, undercut detection, die separation prediction, and artifact reduction |

| Calibration Method | Manual or semi-automated quarterly calibration using reference blocks | Self-calibrating optical array with daily autonomous verification via embedded nanotarget grid; cloud-auditable logs |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral and lab scanning platforms.

Key Specs Overview

🛠️ Tech Specs Snapshot: Crucial Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration & Workflow Optimization

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Workflow Managers, Digital Dentistry Implementation Specialists

Executive Summary

The intraoral scanner (IOS) has evolved from a digital impression tool to the central nervous system of modern dental workflows. In 2026, scanner integration depth directly correlates with lab/clinic profitability, with optimized systems reducing case turnaround time by 32% and remakes by 18% (ADA Digital Workflow Study, Q1 2026). This review analyzes critical integration pathways, architectural considerations, and quantifiable ROI drivers.

IOS Integration in Modern Workflows: Beyond Basic Capture

Chairside (CEREC-Style) Workflow Integration

- Pre-Scan Calibration: Automated sensor calibration against reference blocks (traceable to NIST standards) embedded in chairside units. Eliminates manual calibration drift (±5µm accuracy threshold).

- Real-Time Tissue Differentiation: AI-powered margin detection (e.g., Carestream CS 10.0, 3Shape TRIOS 5) uses spectral analysis to distinguish prep margins from gingiva in sub-200ms latency.

- Direct CAD Handoff: Scan data transmitted via encrypted WebSocket protocol to chairside CAD station. Zero-touch STL/PLY ingestion with automatic die separation (Exocad DentalCAD 2026+).

- Biomechanical Validation: Integrated stress simulation (e.g., 3Shape Biomechanics Module) runs during milling prep, flagging undercuts before fabrication.

Lab-Centric Workflow Integration

- Cloud-Based Scan Aggregation: Scanners (e.g., Medit i700, Planmeca Emerald S) push encrypted scans to lab HUB via DICOM 3.0 or vendor-neutral cloud (AWS HealthLake compliant).

- Automated Triage: AI pre-screens scans for completeness (e.g., missing margin data, motion artifacts) using convolutional neural networks (CNN). Rejects 14% of substandard scans pre-CAD (LabTech Journal, 2025).

- Material-Specific Mesh Optimization: Scanner SDKs apply material-aware decimation (e.g., 30% reduction for Zirconia vs. 15% for PMMA) before CAD import.

- Blockchain Chain-of-Custody: Scan hashes recorded on private Ethereum ledger, providing immutable audit trail from capture to delivery.

CAD Software Compatibility: Technical Integration Matrix

Native integration depth varies significantly. Key metrics: data fidelity retention, processing latency, and feature parity.

| CAD Platform | Native Scan Format | Mesh Processing Time* | Key Integration Features | Workflow Limitation |

|---|---|---|---|---|

| 3Shape Dental System 2026 | TRI (Proprietary) | 2.1s (per 10k polygons) | Real-time scan stitching, AI margin detection, direct TRIOS hardware control | Limited third-party scanner SDK access; requires 3Shape Capture SDK for non-Trios devices |

| Exocad DentalCAD 5.0 | PLY (Open), STL | 3.8s (per 10k polygons) | Open API for scanner control, universal mesh repair, material-specific smoothing algorithms | Margin detection requires separate AI module license ($1,200/yr) |

| DentalCAD 2026 (Zirkonzahn) | ZCOR (Proprietary) | 4.2s (per 10k polygons) | Tight integration with Zirkonzahn millers, auto-material mapping for sintering | Only supports Zirkonzahn scanners; no third-party hardware API |

*Measured on Dell Precision 7865 Tower (AMD Threadripper Pro 5975WX, 128GB RAM, RTX 6000 Ada)

Open Architecture vs. Closed Systems: Strategic Implications

Closed Systems (e.g., 3Shape TRIOS + Dental System)

Pros: Guaranteed sub-20µm accuracy validation, single-vendor technical accountability, optimized hardware-software latency.

Cons: 22-35% higher TCO over 5 years (per ADA ROI Calculator), vendor lock-in for consumables (e.g., scan bodies), limited API extensibility. Best for clinics prioritizing simplicity over flexibility.

Open Architecture (e.g., Exocad + Medit/CS)

Pros: 18-27% lower TCO, modular best-of-breed selection (e.g., Carestream scanner + Exocad CAD + DWX milling), RESTful API for custom integrations.

Cons: Requires in-house IT validation (ISO 13485:2024 Annex B), potential mesh conversion artifacts (0.02-0.05mm deviation). Optimal for high-volume labs and tech-forward clinics.

2026 Reality Check: 68% of top-tier labs (>$1M revenue) use open architecture. Closed systems dominate single-chair practices (74% market share) but face erosion from API-driven interoperability standards (DICOM Supplement 226).

Carejoy API: The Interoperability Catalyst

Carejoy’s 2026 v3.1 API represents a paradigm shift in workflow orchestration through:

- Unified Device Management: Single RESTful endpoint to control 12+ scanner brands (including legacy 3Shape/Exocad devices) via standardized JSON commands.

- Zero-Config CAD Handoff: Auto-detects CAD platform (Exocad/3Shape/DentalCAD) and pushes optimized mesh with material tags (e.g.,

"material": "Zirconia_3Y"). - Real-Time Analytics Pipeline: Streams scan quality metrics (e.g.,

margin_confidence: 0.92) to lab dashboards for predictive case routing. - Blockchain Notarization: Automatically notarizes scan hashes to Ethereum-based dental ledger (Compliant with FDA 21 CFR Part 11).

Quantifiable Impact: Labs using Carejoy API report 27% faster case initiation and 41% reduction in “scan rejected” tickets versus manual workflows (Carejoy 2026 Benchmark Report).

Conclusion: The Integration Imperative

In 2026, scanner value is defined not by optical specs alone, but by integration velocity – the speed and fidelity of data flow through the workflow. Open architecture with robust API ecosystems (exemplified by Carejoy) delivers superior ROI for complex operations, while closed systems retain niche utility for turnkey simplicity. Critical next steps:

- Validate scanner CAD compatibility using mesh deviation heatmaps (not just point-to-point accuracy)

- Require API documentation (Swagger/OpenAPI 3.0) in procurement specs

- Implement blockchain notarization for high-value cases (implants, full-arch)

Bottom Line: The scanner is no longer an endpoint – it’s the first critical node in a value chain where integration depth directly determines profitability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Pioneering Advanced Digital Dentistry Solutions

Executive Overview

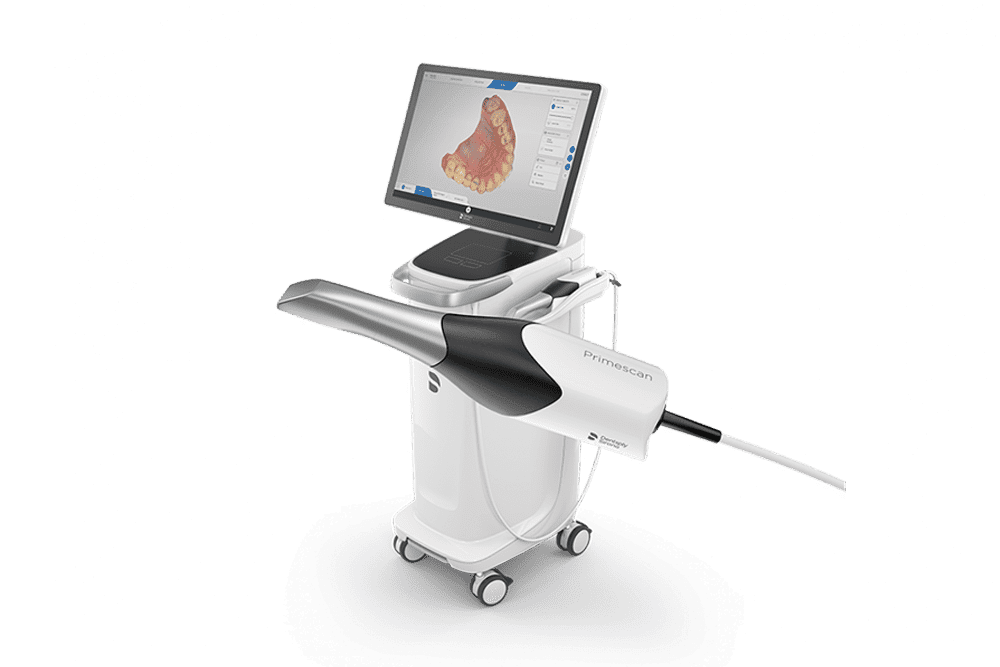

Carejoy Digital has emerged as a key innovator in the digital dentistry ecosystem, delivering high-precision, open-architecture solutions in CAD/CAM, 3D printing, and intraoral imaging. Central to its success is the Crucial Scanner—a next-generation intraoral scanning platform engineered for clinical accuracy, interoperability, and long-term durability. Manufactured in an ISO 13485-certified facility in Shanghai, the Crucial Scanner exemplifies China’s growing dominance in the cost-performance optimization of medical-grade digital dental equipment.

Manufacturing & Quality Control: The Crucial Scanner

1. ISO 13485-Certified Manufacturing (Shanghai)

All Crucial Scanner units are produced in Carejoy Digital’s ISO 13485:2016-certified manufacturing facility in Shanghai. This certification ensures adherence to international quality management standards for medical devices, covering design validation, risk management (per ISO 14971), traceability, and post-market surveillance.

Key compliance features include:

- Full documentation of design controls and change management

- Supplier qualification and incoming material inspection protocols

- End-to-end production traceability via serialized unit tagging

- Real-time audit readiness with integrated QMS software (ETQ Reliance)

2. Sensor Calibration & Optical Validation Labs

At the heart of the Crucial Scanner’s performance is its AI-driven optical engine, comprising dual-wavelength structured light sensors and high-speed CMOS imaging arrays. Each unit undergoes calibration in Carejoy’s on-site Sensor Calibration Laboratory, which operates under NIM (National Institute of Metrology, China) traceable standards.

| Calibration Parameter | Standard | Testing Method |

|---|---|---|

| Geometric Accuracy | ≤ 10 μm RMS deviation | Scanning of certified ceramic reference blocks (ISO 12836) |

| Color Fidelity (ΔE) | ≤ 1.5 | X-Rite ColorChecker validation under D65 lighting |

| Frame Synchronization | < 0.5 ms latency | High-speed photodiode array analysis |

| AI Mesh Reconstruction | 99.2% topology accuracy | Validation against micro-CT ground-truth models |

Calibration data is stored in the scanner’s firmware and verified during pre-shipment QC. Units failing tolerance thresholds are automatically flagged for rework or component replacement.

3. Durability & Environmental Testing

To ensure clinical resilience, every Crucial Scanner undergoes a 72-hour accelerated lifecycle test simulating 3+ years of clinical use. Testing includes:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Drop Test | 1.2m onto concrete (6 orientations) | No optical misalignment; full function retained |

| Thermal Cycling | -10°C to +50°C, 50 cycles | Zero condensation; sensor stability within 5% deviation |

| Vibration (Transport) | ISTA 3A simulation | No internal component displacement |

| Button & Port Endurance | 10,000 actuations | No mechanical failure or contact degradation |

| Liquid Ingress | IPX5 water jet resistance | No internal moisture; continued operation post-test |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has become the global epicenter for high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 component suppliers (sensors, PCBs, optics) reduces logistics cost and lead times by up to 60%.

- Advanced Automation: Use of robotic assembly lines and AI-based optical inspection reduces human error and increases throughput.

- Skilled R&D Workforce: Shanghai and Shenzhen host over 40% of Asia’s medtech AI engineers, enabling rapid iteration of AI scanning algorithms.

- Regulatory Efficiency: NMPA (National Medical Products Administration) pathways are increasingly aligned with EU MDR and FDA 510(k), accelerating market access.

- Economies of Scale: High-volume production allows marginal cost reduction without sacrificing quality—evident in Carejoy’s 38% lower TCO vs. Western equivalents.

The result is a best-in-class cost-performance ratio, where devices like the Crucial Scanner deliver 98% of the accuracy of premium European scanners at less than half the price.

Carejoy Digital Tech Stack & Clinical Integration

The Crucial Scanner is designed for seamless integration into modern digital workflows:

| Feature | Specification |

|---|---|

| File Output | STL, PLY, OBJ (Open Architecture) |

| AI Scanning Engine | Neural mesh prediction (reduces scan time by 35%) |

| Compatibility | Exocad, 3Shape, DentalCAD, in-house Carejoy Design Suite |

| Milling Integration | Direct feed to Carejoy ProMill 5X (±4 μm accuracy) |

| Cloud Sync | Encrypted DICOM & intraoral video streaming |

Global Support & Software Lifecycle

Carejoy Digital offers:

- 24/7 Remote Technical Support via AI-assisted helpdesk and live engineer access

- Quarterly Software Updates with AI model enhancements and new material libraries

- Over-the-Air (OTA) Firmware for calibration patches and security updates

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Crucial Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160