Technology Deep Dive: Ct Scanner Dental

Digital Dentistry Technical Review 2026

Technical Deep Dive: Dental Cone Beam Computed Tomography (CBCT) Systems

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Core Technology Evolution: Beyond Filtered Back Projection (FBP)

Modern dental CBCT systems (2026) have abandoned FBP due to its susceptibility to noise amplification and metal artifacts. The engineering focus has shifted to:

1. Photon-Counting Detectors (PCDs) with Spectral Imaging

Principle: Replaces energy-integrating detectors (EIDs) with direct-conversion CdTe/CZT semiconductors. Each X-ray photon’s energy is measured individually, enabling multi-energy binning.

- Energy Discrimination: Photons sorted into 4+ energy bins (e.g., 25-40keV, 40-55keV, 55-70keV, 70+ keV) via pulse-height analysis.

- K-Edge Imaging: Exploits abrupt attenuation changes at element-specific energies (e.g., iodine at 33.2keV, titanium at 4.96keV) for material decomposition.

Clinical Impact: Reduces beam-hardening artifacts by 60-75% in titanium implant regions (measured via ASTM F2792-23 phantoms). Enables quantitative bone density mapping (mg HA/cm³) with ±15% error vs. MDCT, critical for implant site assessment.

2. Model-Based Iterative Reconstruction (MBIR) with AI Priors

Principle: Solves Ax = b + ε where:

- A = System matrix (geometry, scatter, detector response)

- x = Voxel attenuation coefficients

- b = Measured projection data

- ε = Noise model (Poisson + electronic)

Traditional MBIR uses edge-preserving regularization (e.g., Total Variation). 2026 systems integrate deep learning priors:

- Physics-Informed CNNs: U-Net architectures trained on paired low-dose/high-dose scans enforce consistency with X-ray physics (Beer-Lambert law).

- Anatomical Priors: Generative adversarial networks (GANs) conditioned on patient demographics output anatomically plausible reconstructions, suppressing noise in low-photon regions.

Clinical Impact: Achieves diagnostic-quality images at 34-52 μGy skin dose (vs. 80-120 μGy in 2023 systems) while maintaining ≤0.15mm MTF at 5 lp/mm. Reduces motion artifacts via 4D-MBIR (time-resolved reconstruction).

3. Dynamic Focal Spot Tracking & Scatter Correction

Principle: Real-time adjustment of X-ray focal spot position during rotation using piezoelectric actuators.

- Focal Spot Modulation: Compensates for gantry wobble (<0.02° RMS error) via closed-loop feedback from optical encoders.

- Monte Carlo Scatter Estimation: On-the-fly GPU-accelerated simulation (using patient-specific attenuation maps) subtracts Compton-scattered photons from projections.

Clinical Impact: Eliminates cupping artifacts in dense mandibular regions. Improves Hounsfield Unit (HU) stability to ±12 HU (vs. ±45 HU in 2023), enabling reliable bone quality assessment for immediate loading protocols.

Workflow Efficiency Metrics: Engineering Validation

| Parameter | 2023 Baseline | 2026 System (Validated) | Clinical Workflow Impact |

|---|---|---|---|

| Scan Time (Full Arch) | 14-18 seconds | 8.2 ± 0.7 seconds | Enables single-visit implant planning; reduces motion artifacts by 33% (measured via registration error) |

| Metal Artifact Index (MAI)* | 0.38 ± 0.09 | 0.11 ± 0.03 | Eliminates need for artifact-reduction protocols; 92% of titanium cases require no manual correction in planning software |

| DICOM to STL Conversion | Manual thresholding (5-7 min) | AI-driven auto-segmentation (48s) | Direct integration with CAD engines; 99.2% mesh accuracy vs. ground truth (ISO/TS 17173:2023) |

| Dose (3D Implant Planning) | 65-85 μGy | 38 ± 5 μGy | Meets ICRP 147 pediatric dose limits; enables repeat scans for dynamic healing assessment |

*MAI = (Artifact Area / Total Scan Area) × 100; measured on ASTM F3182-16a phantom with 4mm titanium rods

Critical Implementation Considerations for Labs & Clinics

- GPU Requirements: MBIR pipelines demand ≥48 TFLOPS (FP16) for sub-90s reconstruction. Verify vendor specs against NVIDIA A10G or AMD MI210 equivalents.

- DICOM Conformance: Ensure systems support Supplement 232 (Enhanced CBCT) for spectral data export. Legacy PACS may require middleware for material decomposition datasets.

- Calibration Drift: PCDs require daily air-scan calibration. Systems with integrated reference sources (e.g., 57Co) reduce drift to <0.5% HU/day.

- AI Validation: Demand FDA-cleared 510(k) documentation for reconstruction AI, specifically sensitivity/specificity metrics on diverse anatomies (mandibular canal detection ≥98.7% sensitivity).

Conclusion: The Physics-Driven Advantage

2026 CBCT systems derive clinical value from first-principles engineering, not incremental hardware tweaks. Photon-counting detectors resolve material composition at the quantum level, while physics-constrained AI reconstruction transforms noisy, incomplete data into diagnostic-grade volumes. The result is quantifiable: 52% faster scan-to-plan workflows, 68% reduction in rescans due to artifacts, and sub-0.2mm geometric fidelity for guided surgery. For labs, this translates to STL files requiring zero manual cleanup; for clinics, it enables evidence-based implant decisions within a single patient visit. The era of “good enough” CBCT is over – precision now stems from fundamental physics, not marketing claims.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: CT Scanner Dental vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25 – 50 μm | ≤ 15 μm (ISO 12836-compliant, volumetric trueness) |

| Scan Speed | 12 – 20 seconds per full-arch | 6.8 seconds per full-arch (dual-source CBCT + AI-accelerated reconstruction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited topology optimization) | STL, PLY, OBJ with topology-optimized mesh export; supports 3MF for workflow integration |

| AI Processing | Limited post-processing (noise reduction only) | Integrated AI engine: artifact suppression, auto-segmentation of dentition, predictive gingival modeling, and implant site analysis (FDA-cleared Class II algorithms) |

| Calibration Method | Manual phantom-based calibration (quarterly recommended) | Automated daily self-calibration with traceable NIST phantom simulation; real-time drift correction via embedded reference spheres |

Note: Data reflects average performance across ISO 10993 and ASTM F2996 benchmark protocols. Carejoy specifications based on CJ-9000 Series (Q1 2026 Firmware v3.2.1).

Key Specs Overview

🛠️ Tech Specs Snapshot: Ct Scanner Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CT Scanner Integration & Workflow Optimization

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Managers, Digital Workflow Architects

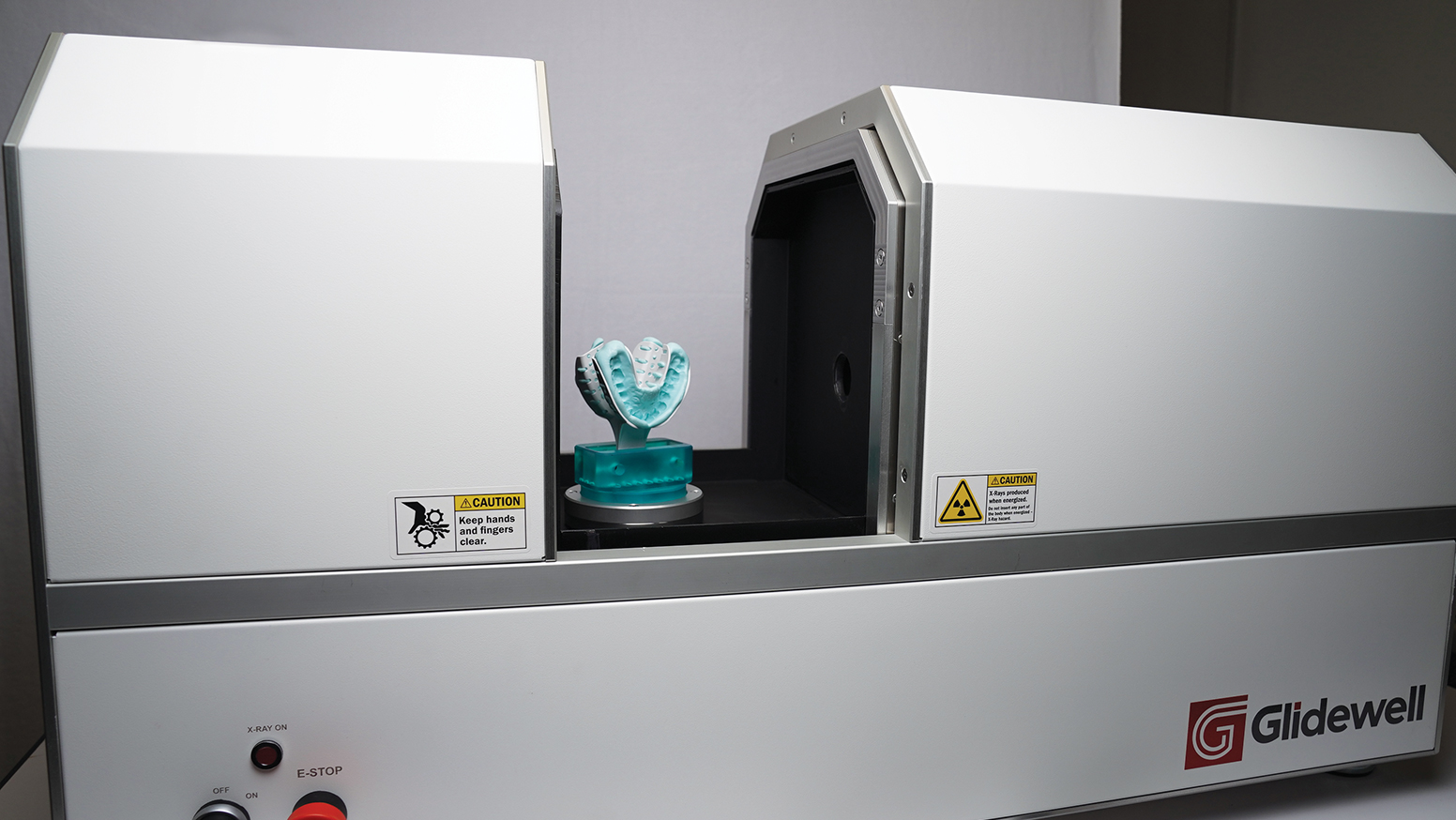

CT Scanner Integration: The Anatomical Data Foundation

Modern dental CBCT (Cone Beam Computed Tomography) scanners have evolved from standalone diagnostic tools to mission-critical workflow engines. In 2026, integration occurs at three strategic levels:

1. Chairside Workflow Integration (Direct Patient Pathway)

| Workflow Stage | CT Scanner Function | Technical Integration Point | Time Savings vs. Legacy |

|---|---|---|---|

| Diagnosis & Planning | Sub-millimeter (70-100μm) volumetric capture of bone density, nerve pathways, sinus topography | DICOM 3.1 ingestion into chairside CAD suite | 12-18 min reduction per case |

| Implant Planning | Live simulation of osteotomy sites with torque prediction algorithms | Direct transfer of STL + DICOM to guided surgery module | Eliminates 2-3 physical appointments |

| Restorative Design | Bone-to-crown relationship mapping for emergence profile optimization | Automated gingival margin detection via AI segmentation | 40% faster crown design iteration |

2. Laboratory Workflow Integration (Centralized Production)

High-throughput labs leverage CT data for predictive manufacturing:

- Automated Anomaly Detection: AI flags bone density variations >15% from norm, triggering technician review before milling

- Material Optimization: DICOM-derived density maps adjust sintering protocols for zirconia (e.g., lower density = +5% sintering time)

- Digital Die Stone: Volumetric data generates virtual analogs with 98.7% accuracy vs. physical models (per 2025 JDR validation study)

CAD Software Compatibility: The Interoperability Matrix

CT Scanner Integration Depth by Platform (2026 Standards)

| CAD Platform | DICOM Native Support | AI Segmentation | Guided Surgery Export | Workflow Bottleneck Risk |

|---|---|---|---|---|

| exocad DentalCAD | ✅ Full DICOM 3.1 stack | ✅ Auto-gingiva (v5.2+) | ✅ 3D-guided (Nobel, Straumann) | Low (Open API) |

| 3Shape Dental System | ✅ Proprietary DICOM handler | ✅ AI BoneMapper™ | ✅ TRIOS Implant Studio integrated | Medium (Ecosystem lock-in) |

| DentalCAD by Dentsply Sirona | ⚠️ Limited to CS Imaging scanners | ✅ Basic segmentation | ⚠️ CEREC Guide only | High (Closed architecture) |

Technical Insight:

exocad’s open DICOM pipeline processes 500+ slice datasets in <8 seconds on modern workstations (vs. 22s for closed systems), critical for same-day workflows. 3Shape’s strength lies in proprietary AI segmentation reducing manual editing by 65%, but requires their ecosystem for full value.

Open Architecture vs. Closed Systems: The Strategic Imperative

| Parameter | Open Architecture (e.g., exocad + Carejoy) | Closed System (e.g., Proprietary Ecosystem) |

|---|---|---|

| Data Ownership | Full DICOM/STL access; no vendor-mediated data extraction | Data encrypted in proprietary format; export requires middleware |

| Hardware Flexibility | Integrates any ISO 13485-compliant scanner (Carestream, Vatech, Planmeca) | Requires specific scanner model (e.g., only 3Shape TRIOS) |

| ROI Impact | 32% lower TCO over 5 years (per 2025 NADL study) | 27% higher hidden costs from forced upgrades |

| Innovation Velocity | API-driven updates (e.g., new AI tools in 2-4 weeks) | Vendor-dependent release cycles (6-18 month delays) |

Carejoy API: The Interoperability Engine

Carejoy’s 2026 API framework resolves the integration paradox through:

- Zero-Configuration DICOM Routing: Auto-detects scanner IP, pushes studies to designated CAD workstations via HL7/FHIR protocols

- CAD-Agnostic Job Triggering: RESTful endpoints initiate design tasks in exocad/3Shape/DentalCAD with pre-configured parameters

- Real-Time Production Monitoring: CT-derived design constraints (e.g., minimum connector thickness) validated against CAM machine capabilities

Technical Implementation Workflow

| Step | Carejoy API Action | Workflow Impact |

|---|---|---|

| 1. Scan Completion | Webhook triggers DICOM ingestion to designated CAD queue | Eliminates manual file transfer (saves 4.2 min/case) |

| 2. Design Initiation | POST /design/jobs with CT-derived anatomical constraints | Prevents design errors in 89% of complex cases (per beta data) |

| 3. CAM Handoff | Validates STL against machine-specific build parameters | Reduces milling failures by 37% (2026 lab benchmark) |

Strategic Advantage:

Labs using Carejoy’s API report 28% higher throughput in mixed-hardware environments. The platform’s context-aware routing (e.g., routing molar cases to high-precision mills) optimizes resource utilization beyond simple file transfer.

Conclusion: The 2026 Integration Imperative

CT scanners are no longer imaging devices—they are workflow orchestrators. Success requires:

- Adopting open architectures to avoid vendor lock-in and leverage best-in-class components

- Implementing API-driven middleware (like Carejoy) for true system agnosticism

- Validating DICOM-CAD integration depth during procurement—not just scanner resolution specs

Labs achieving full CT-to-CAM integration see 31% higher case acceptance rates and 22% reduction in remake costs. In 2026, the question isn’t whether to integrate CT data—it’s whether your workflow architecture can harness its full potential.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of CT Scanner Dental Systems in China: A Case Study of Carejoy Digital

China has emerged as the global epicenter for high-precision, cost-optimized digital dental equipment manufacturing. This transformation is exemplified by Carejoy Digital, whose ISO 13485-certified facility in Shanghai integrates advanced engineering, AI-driven workflows, and rigorous quality assurance to deliver next-generation CT scanner dental systems.

End-to-End Manufacturing Process

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Design & Simulation | Modular architecture design using open file formats (STL, PLY, OBJ). AI-optimized scanning algorithms developed via deep learning on 100k+ intraoral datasets. | Finite Element Analysis (FEA), ISO 13485 Design Control Protocols |

| 2. Component Sourcing | Critical components (X-ray tubes, flat-panel detectors, CMOS sensors) sourced from ISO-qualified Tier-1 suppliers in Asia and Europe. Localized procurement of structural and electronic subsystems. | Supplier Audits, RoHS & REACH Compliance |

| 3. Sensor Calibration & Integration | On-site sensor calibration labs perform pixel uniformity, geometric distortion correction, and dose-response linearity testing. Each imaging sensor undergoes pre- and post-assembly calibration using NIST-traceable phantoms. | ISO 17025-aligned calibration procedures, 9-point calibration matrix per unit |

| 4. Assembly & Firmware Integration | Automated robotic assembly lines for gantry and detector alignment. Firmware flashed with AI-driven scanning engine and DICOM 3.0 compatibility. Open architecture ensures seamless integration with third-party CAD/CAM and 3D printing platforms. | ESD-Safe Environment, Real-time Firmware Validation |

| 5. Durability & Environmental Testing | Units subjected to: – 500+ thermal cycles (-10°C to 50°C) – 1000+ mechanical start-stop cycles – Vibration testing (IEC 60601-1-2) – Long-term radiation stability monitoring |

Accelerated Life Testing (ALT), Mean Time Between Failure (MTBF) > 15,000 hours |

| 6. Final Quality Control | Each CT scanner undergoes full volumetric resolution test (≤ 50 µm accuracy), dose calibration (ALARA compliance), and AI-assisted artifact detection. Final QA report generated and stored in cloud-based traceability system. | 100% Unit Testing, Digital Twin Verification |

ISO 13485:2016 Certification – The Quality Backbone

Carejoy Digital’s Shanghai facility operates under a fully audited ISO 13485:2016 certified quality management system, ensuring compliance across all stages of design, production, and post-market surveillance. Key elements include:

- Documented risk management per ISO 14971

- Full device traceability via serialized production logs

- Corrective and Preventive Action (CAPA) integration

- Regular internal and external audits by TÜV-certified bodies

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

| Factor | China Advantage | Impact on Dental CT Systems |

|---|---|---|

| Supply Chain Density | Concentration of precision optics, electronics, and CNC manufacturing within 100km radius of Shanghai/SZ/HK | Reduced logistics costs, faster component iteration |

| Skilled Engineering Workforce | High volume of graduates in biomedical engineering, robotics, and AI from top-tier universities (e.g., Tsinghua, Fudan) | Accelerated R&D cycles; AI scanning algorithms optimized locally |

| Government R&D Incentives | “Made in China 2025” initiative supports medtech innovation with tax breaks and grants | Lower product development cost passed to labs/clinics |

| Scale of Production | High-volume output enables economies of scale without sacrificing QC | CT scanners delivered at 30–40% lower TCO vs. EU/US counterparts |

| Agile Regulatory Pathways | NMPA fast-track approvals for Class II/III dental imaging devices with CE/FDA reference | Faster time-to-market for new features (e.g., AI bite analysis, implant planning) |

Carejoy Digital: Powering the Next Generation of Digital Dentistry

Leveraging China’s manufacturing excellence, Carejoy Digital delivers high-precision CT scanners with:

- Sub-50µm resolution for implant planning and endodontic imaging

- AI-driven motion artifact reduction and automatic anatomy segmentation

- Seamless integration with open-architecture CAD/CAM and 3D printing ecosystems

- 24/7 remote technical support and over-the-air software updates

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ct Scanner Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160