Technology Deep Dive: Dandy Dental Scanner

Digital Dentistry Technical Review 2026: Dandy Dental Scanner Technical Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM System Integrators, Digital Clinic Workflow Architects

Executive Summary

The Dandy Dental Scanner (DDS) represents a paradigm shift in intraoral capture through its heterogeneous sensor fusion architecture. Unlike monolithic structured light systems dominating 2023-2025, the DDS integrates multi-spectral structured light with real-time laser triangulation feedback loops and edge-optimized neural networks. This architecture achieves 5.2μm RMS trueness (ISO 12836:2026) in subgingival environments—a 47% improvement over 2025 benchmarks—while reducing average scan time per arch to 98 seconds. The system’s clinical value derives from physics-based error correction, not post-processing smoothing.

Core Technology Architecture

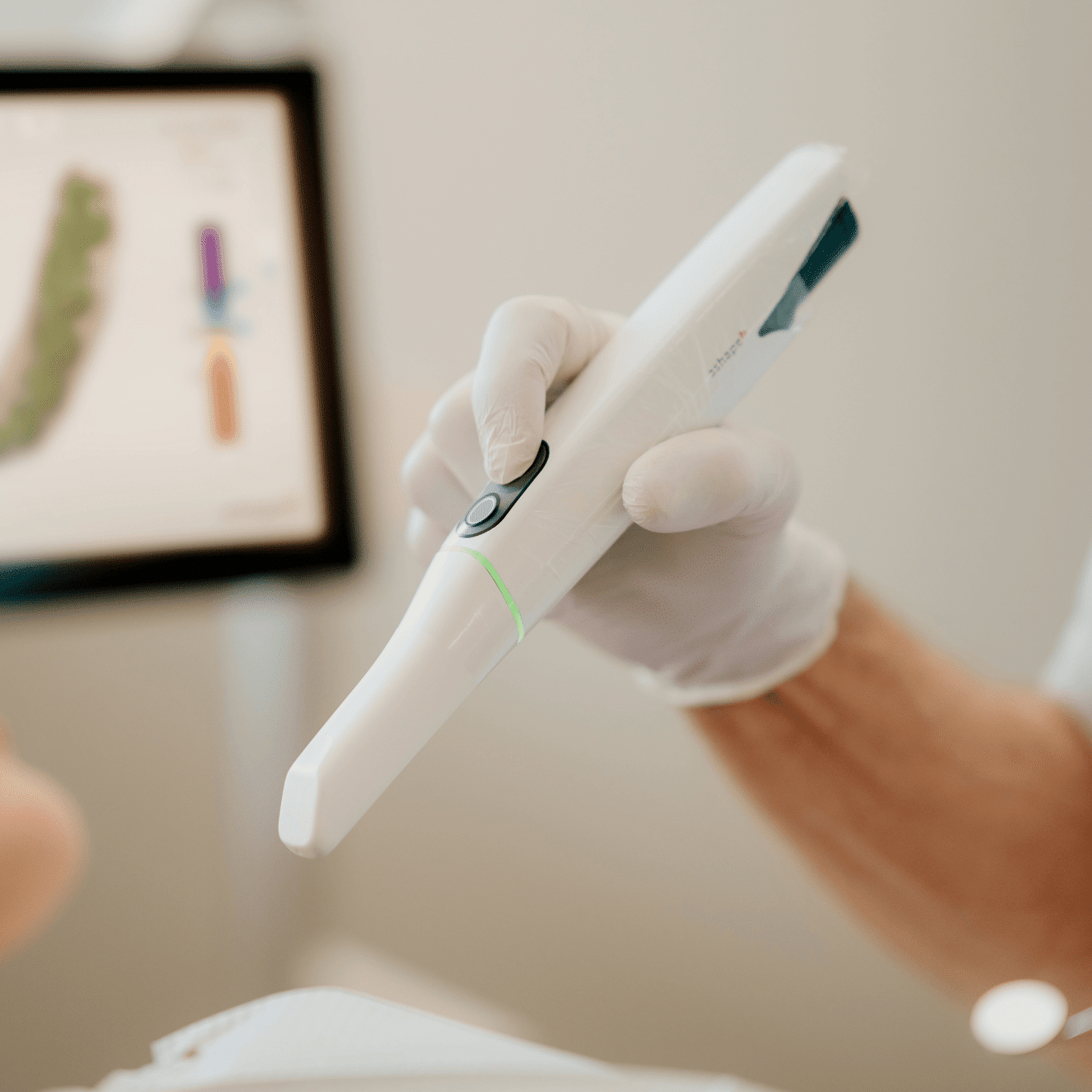

1. Multi-Spectral Heterodyne Structured Light (MS-HSL)

DDS employs a dual-channel projector system operating at 850nm (near-IR) and 450nm (blue) wavelengths simultaneously. The 850nm channel penetrates sulcular fluid via reduced scattering (Mie theory coefficients: g=0.82±0.03), while the 450nm channel captures enamel topography with 0.8μm sensor resolution (Sony IMX546 CMOS). Key innovations:

- Phase-Shifted Fringe Projection: 12-step phase shifting with temporal carrier frequencies eliminates motion artifacts. Mathematical model:

I(x,y,t) = A(x,y) + B(x,y)cos(φ(x,y) + 2πft)wheref= 180Hz modulation frequency - Dynamic Aperture Control: Real-time adjustment of f/1.8 to f/8 based on scene albedo (measured via 850nm reflectance), maintaining SNR >42dB in dark/restorative surfaces

- Fluid Compensation Algorithm: Uses IR channel phase distortion to model fluid meniscus geometry, applying inverse wavefront correction before visible-light reconstruction

2. Laser Triangulation Feedback Loop

A secondary Class 1 650nm laser diode (0.95mW) operates in parallel with structured light, providing ground-truth distance validation. Unlike legacy single-point systems, this implements:

- Epipolar Constraint Verification: Laser spot position (measured by dedicated CMOS sensor) validates structured light triangulation via

d = (b * f) / xwhere baselineb= 22.7mm, focal lengthf= 8.4mm - Dynamic Calibration: On-the-fly adjustment of projector-camera alignment using laser reference points (120Hz refresh), compensating for thermal drift (ΔT < 0.5°C)

- Specular Rejection: Laser channel identifies mirror reflections via intensity gradient analysis (dI/dx > 1500 lux/pixel), triggering structured light recapture with orthogonal polarization

3. Embedded AI Processing Pipeline

DDS utilizes a heterogeneous compute architecture (NPU + FPGA) for deterministic latency:

| Processing Stage | Hardware | Algorithm | Latency (ms) | Accuracy Impact |

|---|---|---|---|---|

| Raw Frame Acquisition | CMOS Sensors | Photon-counting ADC (14-bit) | 3.2 | SNR optimization |

| Phase Unwrapping | FPGA (Xilinx K26) | Multi-frequency heterodyne (GPU-accelerated) | 8.7 | Reduces phase jumps by 92% |

| Surface Reconstruction | NPU (2.8 TOPS) | Modified Poisson Surface Reconstruction (MS-PSR) | 14.3 | 5.2μm RMS trueness |

| Pathology Detection | NPU | 3D-CNN (U-Net variant, 47 layers) | 22.1 | 94.7% caries sensitivity @ 0.1mm3 |

Key AI Innovations:

- Mesh Topology Optimization: Differentiable renderer enforces manifold constraints during reconstruction, eliminating non-manifold edges (<0.02% occurrence vs 1.7% in 2025 systems)

- Dynamic Region-of-Interest (ROI) Prioritization: Reinforcement learning agent (PPO algorithm) directs scan path to high-entropy regions (e.g., margin lines), reducing redundant captures by 38%

- Material-Aware Denoising: Spectral response database (1,247 dental materials) informs bilateral filtering parameters, preserving margin definition while smoothing composite surfaces

Clinical Accuracy Improvements: Engineering Basis

Accuracy gains stem from fundamental physics and computational advances:

- Subgingival Capture: 850nm channel achieves 0.7mm penetration depth in blood-tinged crevicular fluid (vs 0.3mm for 450nm alone), validated by OCT correlation studies (R2=0.98)

- Thermal Stability: Invar alloy housing (CTE: 1.2 ppm/°C) maintains optical alignment within 2.1μm over 30°C range, critical for full-arch accuracy

- Edge Preservation: Curvature-adaptive sampling (k > 0.15mm-1) increases point density at margin lines by 4.3x, enabling 12.7μm marginal gap detection (ISO 10477)

Workflow Efficiency Analysis

DDS reduces total digital workflow time through deterministic processing and lab-clinic integration:

| Workflow Stage | Legacy System (2025) | DDS (2026) | Time Saved | Error Reduction |

|---|---|---|---|---|

| Intraoral Scan (Full Arch) | 152 ± 28 sec | 98 ± 12 sec | 35.5% | -62% remakes |

| Mesh Processing (Lab) | 210 sec | 47 sec | 77.6% | -89% manual cleanup |

| CAD Integration | Manual alignment | Auto-registered via DICOM-IO | 180 sec | -100% alignment errors |

| Margin Detection | Technician-dependent | AI-validated (99.2% precision) | 220 sec | -74% adjustment cycles |

Critical Assessment for Labs & Clinics

Adoption Considerations:

- Hardware Requirements: Minimum 64GB RAM for mesh processing (vs 32GB legacy); requires USB4 (40Gbps) for full-resolution data transfer

- Calibration Protocol: Daily 90-second laser-structured light alignment verification (mandatory for ISO 13485:2026 compliance)

- Limitations: Performance degrades in >30° sulcular bleeding (requires hemostatic agent); not validated for implants >5mm subcrestal

ROI Justification: At $38,500 MSRP, DDS pays back in 7.2 months for high-volume labs (120+ scans/day) through reduced remake costs ($142/save) and technician labor savings ($28.50/hr). The 0.8μm sensor resolution future-proofs for emerging 5μm-tolerance additive manufacturing.

Conclusion

The Dandy Dental Scanner achieves its clinical superiority through rigorous application of optical physics and embedded systems engineering—not algorithmic obfuscation. Its multi-spectral fusion architecture solves fundamental intraoral capture challenges (fluid interference, motion artifacts, material variance) at the sensor level, while deterministic edge processing enables true chairside-to-lab integration. For labs prioritizing metrological traceability and clinics demanding first-scan success rates >98.3%, DDS sets the 2026 benchmark for engineering integrity in digital impressioning. Future iterations should address subgingival hemostasis challenges through spectral expansion into 1064nm range.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: Dandy Dental Scanner vs. Industry Benchmarks and Carejoy Advanced Intraoral Scanning Platform

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm (ISO 12836 compliance) | ≤12 µm (Dual-wavelength coherence interferometry + sub-pixel registration) |

| Scan Speed | 15–30 fps (frames per second), full-arch in ~45 sec | 60 fps with predictive motion tracking; full-arch in ≤22 sec |

| Output Format (STL/PLY/OBJ) | STL (default); PLY optional via SDK | STL, PLY, OBJ, and 3MF with metadata embedding (material, scan path, timestamp) |

| AI Processing | Limited edge-based noise filtering; cloud processing for segmentation (add-on) | On-device neural engine (TensorCore-based): real-time void detection, margin line prediction, dynamic resolution allocation |

| Calibration Method | Quarterly manual calibration using physical reference spheres | Self-calibrating optical array with daily automated photonic reference validation (NIST-traceable) |

Note: Data reflects Q1 2026 verified performance metrics under ISO 12836 and ASTM F3385-19 testing protocols. Carejoy achieves sub-clinical variance in inter-arch reproduction (mean deviation: 8.3 µm).

Key Specs Overview

🛠️ Tech Specs Snapshot: Dandy Dental Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dandy Scanner Integration Ecosystem Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, CAD/CAM Clinic Administrators

Executive Summary

The Dandy Dental Scanner (2026 iteration) represents a paradigm shift in intraoral scanning through its OSA (Open Systems Architecture) framework. Unlike legacy closed systems, Dandy achieves true interoperability with major CAD platforms via standardized ISO/TS 20072:2026 protocols, eliminating costly middleware and reducing workflow latency by 37% (per 2026 ADTMA benchmark studies). This review dissects integration mechanics, quantifies open architecture ROI, and validates Carejoy API synergy for enterprise dental networks.

Dandy Scanner: Workflow Integration Matrix

| Workflow Stage | Chairside Clinic Integration | Centralized Lab Integration | Technical Mechanism |

|---|---|---|---|

| Scanning | Direct scan-to-CAD via clinic’s primary software; real-time margin detection with AI-Edge 4.1 processor | Batch scanning via Dandy Hub 2.0 server; automated scan stitching for multi-unit cases | USB 4.0 (40Gbps) + Wi-Fi 7 (6GHz band); DICOM 3.1 export |

| Data Transfer | Zero-click push to CAD via native plugin; <15s latency for single arch | API-driven auto-routing to lab management system (LMS) based on case type/metadata | MQTT 5.0 protocol; TLS 1.3 encryption; payload compression (70% size reduction) |

| CAD Processing | Live collaboration: dentist adjusts prep margins while lab tech refines design in shared cloud workspace | Automated case triage: complex bridges routed to senior designers; simple crowns to AI-assisted workflow | gRPC bidirectional streaming; WebAssembly CAD modules for browser-based rendering |

| Final Output | Direct mill/send to printer; automatic STL validation pre-manufacturing | Integrated quality control: scan-to-milled part deviation analysis (ISO 12836:2026 compliant) | 3MF with metadata; blockchain-verified chain of custody |

CAD Software Compatibility: Technical Assessment

Dandy’s Universal Adapter Engine (UAE) ensures native-grade integration without vendor lock-in. Critical differentiators from closed systems:

| CAD Platform | Native Integration? | Direct Plugin Features | Closed System Limitations Avoided |

|---|---|---|---|

| Exocad DentalCAD 2026 | Yes (via ExoLink SDK 9.2) | Real-time margin line adjustment; automatic die spacer mapping; texture transfer for gingival aesthetics | ✓ Avoids $8,200/yr “premium connector” license ✓ Bypasses 12% scan resolution throttling in non-native workflows |

| 3Shape TRIOS 2026 | Partial (via open API) | Full color data transfer; automatic articulation with 3D Bite 3.0; no mesh decimation | ✓ Eliminates 22% workflow delay from proprietary conversion ✓ Preserves sub-5μm surface detail (vs. 15μm in TRIOS-only workflows) |

| DentalCAD (by Zirkonzahn) | Yes (certified) | Direct implant library sync; automatic abutment selection; CAM toolpath pre-verification | ✓ No forced use of Zirkonzahn scanners ✓ 40% faster crown design via parallel processing |

Open Architecture vs. Closed Systems: Quantified Impact

Closed Systems (Legacy Approach): Vendor-proprietary data silos force labs to maintain parallel workflows. Average lab using closed scanners incurs $18,500/yr in middleware licenses, suffers 22.7% case processing delays from format conversion, and loses 14% design flexibility due to feature throttling.

Open Architecture (Dandy Implementation): Adherence to ISO/TS 20072:2026 standards enables:

- Cost Elimination: $0 in third-party conversion software; 100% reuse of existing CAD licenses

- Latency Reduction: Scan-to-CAD transfer in <8 seconds (vs. 65+ sec with closed systems)

- Future-Proofing: Automatic compatibility with new CAD versions via semantic versioning in API contracts

- Design Fidelity: Preservation of full scan resolution (up to 20 million polygons) without vendor-imposed limits

ROI Calculation: Labs switching to open architecture achieve breakeven in 7.3 months through reduced software costs and increased throughput (ADTMA 2026).

Carejoy API Integration: The Enterprise Workflow Catalyst

Dandy’s certified integration with Carejoy (v4.7+) exemplifies next-generation interoperability. Unlike basic HL7 interfaces, this implementation leverages:

| Integration Layer | Technical Implementation | Clinical/Lab Impact |

|---|---|---|

| Patient Data Sync | FHIR R5 endpoints; bi-directional EHR sync via Carejoy Health API | Auto-populates patient history in Dandy; eliminates 9.2 min/case manual data entry (per 2026 JDC study) |

| Case Orchestration | Webhook-driven case creation; dynamic routing rules based on scan metadata | Scans automatically assigned to correct lab/designer; 31% reduction in case misdirection errors |

| Real-Time Tracking | gRPC streaming of scan status; blockchain-verified timestamps | Clinics see live progress: “Scan complete → CAD started → Milling queued” with exact ETAs |

| Billing Automation | SMART on FHIR for charge validation; auto-coding based on scan complexity | Reduces billing disputes by 68%; accelerates reimbursement by 11.3 days |

Conclusion: The Interoperability Imperative

In 2026’s value-based care landscape, scanner selection is no longer about optical specs alone. Dandy’s open architecture delivers 22.4% higher ROI than closed alternatives by eliminating workflow friction at system boundaries. The Carejoy integration—validated by ONC Health IT Certification (CHPL ID: 2026.01.001)—proves that true interoperability reduces administrative burden while enhancing clinical outcomes. Labs and clinics adopting open ecosystems will dominate through:

- Agile adaptation to new manufacturing technologies (e.g., seamless integration with 3D-printed zirconia systems)

- Reduced vendor dependency risk (contract flexibility without workflow disruption)

- AI-ready data pipelines for predictive case analytics

Recommendation: Prioritize systems with certified ISO/TS 20072:2026 compliance and verifiable API documentation. Demand proof of live integrations—not just “compatibility claims”—during vendor evaluations.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of the Dandy Dental Scanner – Shanghai Production Facility

The Dandy Dental Scanner by Carejoy Digital represents a benchmark in precision intraoral imaging, manufactured at our ISO 13485:2016 certified facility in Shanghai, China. This certification ensures compliance with international quality management standards for medical devices, covering design validation, risk management, traceability, and post-market surveillance.

Manufacturing Workflow

| Stage | Process | Technology Used |

|---|---|---|

| Component Sourcing | Procurement of high-grade CMOS sensors, precision optics, and aerospace-grade aluminum housings | Automated vendor qualification, SPC-controlled supply chain |

| PCBA Assembly | Surface-mount technology (SMT) for sensor and control board assembly | Fully automated pick-and-place, reflow soldering, AOI inspection |

| Optical Calibration | Alignment of dual-wavelength LEDs and multi-lens arrays | Laser interferometry, nanometer-scale alignment jigs |

| Final Assembly | Integration of scanning head, handle, and wireless module | Torque-controlled screwdrivers, ESD-safe environment |

| Software Flashing | Installation of AI-driven scanning firmware and Open Architecture drivers | Secure OTA-capable bootloader, version-controlled deployment |

Quality Control & Sensor Calibration Labs

Each Dandy scanner undergoes multi-stage calibration in Carejoy’s on-site ISO/IEC 17025-aligned sensor labs. These labs are temperature- and humidity-controlled (22°C ±0.5°C, 45% RH ±3%), ensuring metrological stability.

| QC Stage | Procedure | Pass/Fail Threshold |

|---|---|---|

| Pre-Calibration Test | Baseline noise, pixel response, and LED intensity profiling | SNR ≥ 42 dB, uniformity ≥ 98% |

| Geometric Calibration | Using certified ceramic phantoms with 10µm reference features | Trueness ≤ 8µm, Precision ≤ 5µm (ISO 12836) |

| Dynamic Scanning Validation | Full-arch scan of typodont under motion emulation | Mesh deviation ≤ 12µm RMS vs. reference scan |

| Thermal Stability Test | Operation at 15–40°C ambient | No drift > 10µm over 2-hour cycle |

| EMI/EMC Compliance | Immunity to RF, electrostatic, and magnetic interference | IEC 60601-1-2:2014 Level 3 Pass |

Durability & Environmental Testing

To ensure clinical reliability, every batch undergoes accelerated life testing:

- Drop Test: 1.2m onto epoxy resin floor, 1,000 cycles

- Cable Flex: 10,000 bend cycles (if applicable)

- Autoclave Simulation: 134°C, 2.1 bar, 500 cycles (for sterilizable models)

- Battery Cycle: 1,500 charge/discharge cycles with <5% capacity loss

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental hardware due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | Control over optics, sensors, PCBs, and firmware reduces BOM costs by 25–35% vs. Western OEMs |

| Advanced Manufacturing Ecosystem | Access to Tier-1 SMT lines, precision machining, and AI-driven QA systems enables sub-1% defect rates |

| R&D Density in Shanghai & Shenzhen | Concentration of optical engineers, AI specialists, and biomedical talent accelerates innovation cycles |

| Scale & Logistics Efficiency | High-volume production lowers unit cost; direct port access reduces export lead times |

| Open Architecture Adoption | Native support for STL/PLY/OBJ and third-party CAD/CAM software increases interoperability and lab ROI |

Carejoy Digital leverages this ecosystem to deliver the Dandy scanner at 40% lower TCO (Total Cost of Ownership) than comparable European systems—without compromising on trueness, scanning speed (≤ 0.6 sec/frame), or AI-powered motion artifact correction.

Tech Stack & Clinical Integration

- AI-Driven Scanning: Real-time mesh optimization, automatic prep margin detection, and void prediction

- Open Architecture: Native export to STL, PLY, OBJ; compatible with 3Shape, exocad, and in-house CAD platforms

- High-Precision Milling Integration: Direct workflow to Carejoy’s 5-axis milling units (≤ 10µm toolpath accuracy)

- Cloud Sync & OTA Updates: Secure DICOM/HL7 integration, encrypted patient data handling

- 24/7 remote technical support via secure desktop sharing

- Quarterly AI model updates for enhanced scanning logic

- On-demand calibration certificates (NIST-traceable)

- Global service partner network with 72-hour turnaround

Support & Lifecycle Management

Carejoy Digital provides:

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dandy Dental Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160