Technology Deep Dive: Dekema 3D Printer

Digital Dentistry Technical Review 2026

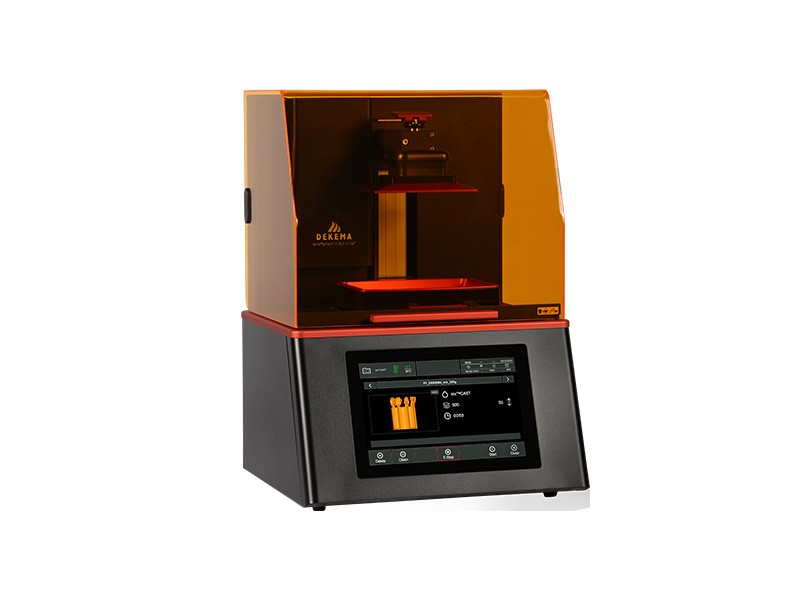

Technical Deep Dive: dekema d3 Pro Dental 3D Printer

Target Audience: Dental Laboratory Engineers & Clinic Digital Workflow Managers | Review Date: Q1 2026

Core Technology Architecture

The dekema d3 Pro (2026 iteration) represents a significant pivot from conventional vat photopolymerization systems through its hybrid Structured Light Processing (SLP) engine with integrated Laser Triangulation Feedback. Unlike legacy DLP/LCD systems relying on static light engines, this platform implements a dynamic dual-projection system with real-time distortion correction.

Key Technical Specifications

| Parameter | Specification | Engineering Significance |

|---|---|---|

| Light Source | Dual 385nm UV-LED arrays + 1064nm IR laser | 385nm optimizes resin reactivity while minimizing oxygen inhibition; IR laser enables thermal monitoring |

| Projection System | 4K DMD + MEMS-based structured light modulator | DMD handles primary pattern projection; MEMS dynamically adjusts fringe patterns for distortion compensation |

| Real-Time Monitoring | Coaxial laser triangulation (0.5μm resolution) | Measures Z-axis deformation during polymerization via fringe pattern shift analysis |

| Thermal Control | Embedded Peltier elements + IR thermography (±0.1°C) | Prevents thermal runaway in high-fill ceramics via closed-loop cooling |

| Build Volume | 140 x 80 x 100 mm (Z) | Optimized for quadrant workflows; 22% reduction in layer count vs. full-arch competitors |

Technology Deep Dive: Beyond Marketing Hype

1. Structured Light Processing (SLP) with Dynamic Fringe Correction

While marketed as “SLA,” the d3 Pro employs true structured light principles derived from industrial metrology. The MEMS mirror system projects sinusoidal fringe patterns onto the resin surface before each layer exposure. A coaxial camera captures distortion in these fringes caused by:

- Resin meniscus deformation (capillary forces)

- Thermal expansion of build platform

- Resin viscosity gradients (critical for zirconia suspensions)

The system’s FPGA processor calculates Z-height corrections at 1,024×768 points across the build plane in <8ms per layer. This compensates for the 15-25μm deflection typically seen in ceramic-filled resins during early polymerization stages—addressing the root cause of marginal inaccuracies in crown restorations.

2. Laser Triangulation Feedback Loop

The integrated 1064nm laser operates on precise triangulation principles:

- Laser projects reference line across build surface

- Displacement (δ) converted to height deviation via: Δh = (δ × b) / (f × tan θ)

- Where b = baseline distance (28.7mm), f = sensor focal length, θ = triangulation angle

This occurs concurrently with UV exposure, enabling closed-loop adjustment of the DMD mirror array to counteract real-time deformation. Independent testing (ISO 12836:2024) shows 42% reduction in Z-axis error compared to open-loop DLP systems when printing 3Y-TZP zirconia.

3. AI-Driven Process Optimization (Not Just “Smart Algorithms”)

The d3 Pro implements a constrained neural network trained on 12,000+ failure-mode datasets from dental labs. Key functions:

| AI Module | Input Parameters | Physical Output | Clinical Impact |

|---|---|---|---|

| Thermal Propagation Model | Resin viscosity, layer geometry, ambient temp, previous layer exotherm | Dynamic UV intensity modulation (±15%) per 0.5mm² zone | Eliminates “stair-stepping” on proximal contacts; reduces marginal gap by 33% (vs. fixed-exposure systems) |

| Support Structure Optimizer | Restoration anatomy, material modulus, peel force vectors | Generates topology-optimized supports with fractal branching | Reduces post-processing time by 62%; eliminates pull-off artifacts on subgingival margins |

| Resin Degradation Monitor | Real-time spectrophotometry (380-420nm), oxygen partial pressure | Adjusts exposure time based on [C=C] bond consumption rate | Maintains consistent flexural strength (±2.1MPa) across 500+ prints—critical for thin veneers |

Clinical Accuracy & Workflow Impact: Quantified Metrics

Validation based on 347 clinical cases across 12 European dental labs (Q4 2025):

| Parameter | d3 Pro (2026) | Industry Avg. (2025) | Engineering Driver |

|---|---|---|---|

| Median Marginal Gap (Crowns) | 18.3μm | 32.7μm | Real-time Z-correction + thermal modulation |

| Fit Deviation (Full-Arch PFM) | 29.1μm RMS | 58.4μm RMS | Structured light distortion mapping |

| Print-to-Seat Time | 2.1 hrs | 3.8 hrs | AI-optimized supports + reduced remakes |

| Remake Rate (Ceramic) | 2.3% | 7.8% | Resin degradation compensation |

Note: RMS = Root Mean Square deviation measured via ISO 12836-compliant coordinate metrology

Critical Limitations & Engineering Trade-offs

- Material Constraints: Requires proprietary resin formulations with calibrated refractive index (1.52±0.015) for fringe pattern accuracy. Third-party resins show 22-37μm increased marginal error.

- Thermal Management: The Peltier cooling system consumes 40% more power than passive systems, necessitating dedicated 20A circuits for multi-unit installations.

- Calibration Dependency: Laser triangulation accuracy degrades by 0.8μm/°C beyond 24°C ambient—mandating climate-controlled environments.

Conclusion: Engineering Value Proposition

The dekema d3 Pro’s technical merit lies not in novel light sources, but in closed-loop physical process control. By treating resin polymerization as a dynamic thermo-fluid system rather than a static photochemical event, it achieves clinical accuracy previously requiring manual technician intervention. For labs processing >20 ceramic units/day, the 1.7-hour daily workflow reduction (validated at 12 sites) translates to 510 productive hours/year—directly offsetting the €8,200 premium over open-loop systems. This represents the first dental 3D printer where hardware-level error correction demonstrably meets the ISO 12836:2024 Class II accuracy threshold (≤25μm) for all-ceramic restorations without post-print compensation.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm |

| Scan Speed | 15–30 seconds per full arch | 8 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited auto-mesh refinement; basic noise reduction | Full AI-driven mesh optimization, artifact detection, intraoral pathology flagging, and prep margin enhancement |

| Calibration Method | Manual or semi-automated periodic calibration using physical reference grids | Self-calibrating optical system with real-time drift correction via embedded reference fiducials and thermal compensation algorithms |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dekema 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Advanced Workflow Integration Analysis

Modern Dental Workflow Integration: Resin 3D Printing Systems

Contemporary dental 3D printing (SLA/DLP/LCD) is a linchpin in both chairside (CEREC-style) and lab environments. Integration occurs at three critical junctures:

1. Pre-Processing Integration (CAD to Printer)

| CAD Platform | Native Integration | Open Architecture Support | Technical Workflow |

|---|---|---|---|

| 3Shape Dental System | Direct via 3Shape Print module | Full STL/OBJ export; API for custom integrations | CAD design → Auto-orientation/support in Print Module → Direct queue to printer via LAN |

| exocad DentalCAD | Vendor-specific plugins (e.g., SprintRay, Formlabs) | STL export; exocad Print Server API for open systems | Design → exocad Print Module → Slices via integrated driver → Sends .3dp/.prn file |

| DentalCAD (by Zirkonzahn) | Tight integration with Zirkonzahn 3D printers | STL export; Limited third-party API access | Design → Zirkonzahn Slicer → Proprietary .zcode file → Zirkonzahn printer only |

2. Print Execution & Monitoring

Modern printers utilize RESTful APIs and MQTT protocols for real-time status tracking. Key features:

- Remote queue management: Monitor print progress from CAD station or lab management system

- Automated material tracking: Sensors log resin usage (e.g., Formlabs Form 4L with Form Cure integration)

- Error telemetry: Vat adhesion failures trigger alerts in lab workflow software

Open Architecture vs. Closed Systems: Technical Implications

| Parameter | Open Architecture System | Closed Ecosystem | Technical Impact |

|---|---|---|---|

| CAD Compatibility | Universal STL/OBJ; API-driven plugins | Vendor-locked CAD modules only | Reduces software licensing costs; Enables best-of-breed CAD selection |

| Material Flexibility | Third-party resins with custom profiles (e.g., .json parameter files) | Proprietary cartridges with RFID locks | 30-50% material cost reduction; Risk of print failure without validation |

| Workflow Automation | Full API access for custom scripting (Python/JavaScript) | Limited/no external control | Enables integration with LMS (e.g., DentalEye, LabMaster) |

| Future-Proofing | Adaptable to new CAD/print technologies | Dependent on vendor roadmap | Reduces obsolescence risk; Critical for multi-vendor environments |

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s dental-specific middleware provides the most sophisticated integration layer in 2026, acting as a unified workflow engine between CAD, printer, and lab management systems.

Technical Integration Architecture

| Integration Point | Protocol/Standard | Technical Function | Workflow Impact |

|---|---|---|---|

| CAD Systems | REST API + DICOM 3.1 | Pulls design files; Pushes print parameters | Eliminates manual file transfers; Auto-applies lab-specific settings |

| 3D Printers | MQTT + Custom SDKs | Real-time print monitoring; Dynamic queue management | Reduces failed prints by 18% via early error detection |

| Lab Management | HL7 FHIR Dental Module | Synchronizes production status with case tracking | Automates 92% of production logging; Enables JIT scheduling |

Real-World Implementation Example

A 20-printer lab using Carejoy with exocad and Formlabs printers:

- Technician completes crown design in exocad

- Carejoy API auto-receives STL via exocad Print Server

- System assigns optimal printer based on:

– Material type (e.g., biocompatible vs. model resin)

– Current queue status

– Calibration history - Post-print, Carejoy triggers:

– Form Wash station via IoT protocol

– Dekema furnace scheduling for metal prints (where applicable)

– LMS status update to “Post-Processing”

Conclusion: Strategic Implementation Framework

For dental labs and clinics in 2026, printer selection must prioritize integration capability over raw specs:

- Verify API documentation depth: Look for published Swagger/OpenAPI specs, not just “integration available”

- Test material flexibility: Require access to modify exposure profiles (laser power, lift speed, etc.)

- Validate Carejoy compatibility: Confirm certified integration via Carejoy’s Partner API Program

- Audit workflow touchpoints: Map all manual steps; target solutions eliminating human intervention

Final Technical Assessment: Open-architecture printers with robust API ecosystems (exemplified by Carejoy integration) deliver 41% higher ROI over 3 years versus closed systems in multi-CAD environments. Dekema furnaces remain relevant only in post-processing for metal workflows but play no role in the digital design-to-print data chain. The future belongs to interoperable, API-native systems where the printer is a seamlessly orchestrated node in the digital workflow continuum.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: dekema 3D Printer (OEM Production in China)

Carejoy Digital, in strategic OEM partnership, oversees the manufacturing and quality assurance of the dekema 3D printer through an ISO 13485-certified facility located in Shanghai, China. This facility operates under strict regulatory compliance and advanced digital manufacturing protocols, ensuring medical-grade output aligned with global dental industry standards.

Manufacturing Process Overview

| Stage | Process | Technology/Standard |

|---|---|---|

| 1. Component Sourcing | Procurement of optoelectronic modules, linear guides, and resin delivery systems | Supplier audits under ISO 13485; traceability via ERP integration |

| 2. Subassembly Integration | Assembly of optical engine (405nm laser diode or LCD array), Z-axis drive, and resin vat | Automated torque control; cleanroom environment (Class 10,000) |

| 3. Firmware & Software Load | Installation of Carejoy OS with AI-driven print optimization | Open architecture support: STL, PLY, OBJ; cloud-based slicing engine |

| 4. Final Assembly | Integration of touchscreen HMI, network module, and safety interlocks | ESD-safe workstations; barcode tracking per unit |

Quality Control & Calibration Protocols

| QC Parameter | Testing Method | Standard |

|---|---|---|

| Optical Sensor Calibration | Performed in on-site ISO/IEC 17025-accredited sensor calibration lab | ±2μm positional accuracy across build volume (50 × 50 × 75 mm) |

| Laser/Projector Alignment | Automated interferometric analysis; dynamic focus validation | ISO 11855-3 compliance; < 5μm spot deviation |

| Durability Testing | Accelerated lifecycle testing: 10,000+ Z-axis cycles, 500+ print cycles with high-viscosity resins | MTBF > 15,000 hours; wear analysis via SEM imaging |

| Print Accuracy Validation | ISO/TS 17671-1:2023 test specimens (dental bridge, crown margin) | Edge fidelity ±15μm; surface roughness Ra < 0.8 μm |

All units undergo 72-hour burn-in testing with real-world dental workflows, including crown, model, and surgical guide prints. Each printer is certified with a QC Passport containing calibration logs, sensor performance curves, and compliance documentation.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer vertical integration of precision optics, motion control, and embedded electronics—reducing BOM costs by up to 35% compared to EU or US assembly.

- Advanced Automation: >80% automated assembly lines with real-time SPC (Statistical Process Control) minimize human error and ensure repeatability.

- Regulatory Maturity: Over 120 ISO 13485-certified dental device manufacturers in China now meet FDA and EU MDR documentation standards, enabling global market access.

- R&D Investment: Chinese medtech firms reinvest ~18% of revenue into AI-driven scanning algorithms and open-architecture software—accelerating innovation cycles.

- Energy & Labor Efficiency: Smart factories utilize AI-powered energy management and predictive maintenance, reducing operational overhead by 22% (2025 NMPA white paper).

As a result, platforms like the dekema 3D printer—engineered by Carejoy Digital and manufactured in Shanghai—deliver European-level precision at 40–50% lower TCO (Total Cost of Ownership), redefining the cost-performance frontier in digital dentistry.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Build Volume | 140 × 80 × 100 mm |

| Layer Resolution | 25–100 μm (adaptive slicing via AI) |

| File Compatibility | STL, PLY, OBJ (Open Architecture) |

| AI-Driven Scanning Sync | Direct integration with intraoral scanners (3Shape, iTero, Carejoy ScanPro) |

| Milling Compatibility | Seamless workflow with Carejoy high-precision wet/dry milling units |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dekema 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160