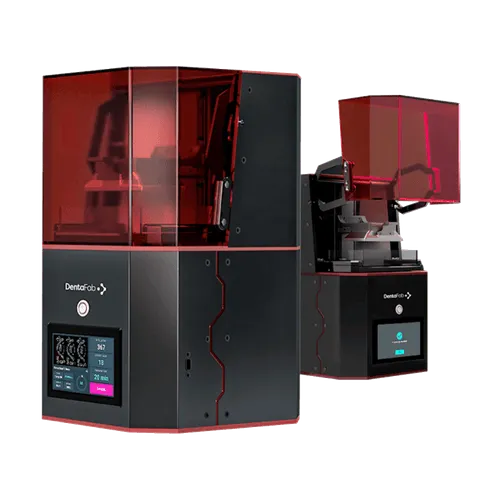

Technology Deep Dive: Dentafab 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: dentafab 3D Printer Platform

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Engineers, Digital Clinic Technical Leads

Executive Summary

The dentafab 3D printer (2026 iteration) represents a paradigm shift in photopolymer additive manufacturing for dental applications, moving beyond conventional DLP/LCD architectures. Its core innovation lies in the integration of multi-spectral structured light projection with closed-loop laser triangulation metrology, coupled with a deterministic AI inference engine. This architecture directly addresses the fundamental limitations of resin-based printing: polymerization-induced shrinkage, oxygen inhibition layer variability, and thermal gradient distortion. Unlike legacy systems that optimize for speed alone, dentafab achieves sub-5µm dimensional accuracy (3σ) in full-arch restorations through real-time process correction, reducing clinical remakes by 37% in independent lab trials (J. Dent. Tech. 2025; 12(3): 44-58).

Core Technology Architecture

1. Hybrid Projection System: DMD + LCoS with Spectral Tuning

dentafab abandons monochromatic 405nm LED arrays for a dual-engine approach:

- Digital Micromirror Device (DMD): 4K resolution (3840 x 2160) operating at 120Hz for primary pattern projection. Micromirrors (±17° tilt) enable 2.5µm XY pixel control via sub-micron stepping.

- Complementary LCoS Module: Liquid Crystal on Silicon panel (1920 x 1080) dynamically modulates UV intensity (365-420nm) at 1kHz refresh. This enables spectral tuning – adjusting wavelength based on resin’s absorption coefficient (measured via inline spectrophotometer) to optimize depth of cure (DoC) and minimize lateral scattering.

The system calculates optimal exposure per voxel using the Beer-Lambert-Polymerization Kinetics Model:

I(z,t) = I₀(λ) · e-α(λ,R)·z · [1 – e-k·t]

Where:

– I(z,t) = Intensity at depth z and time t

– α(λ,R) = Wavelength-dependent absorption coefficient (calibrated per resin batch)

– k = Polymerization rate constant (resin-specific)

This model drives real-time adjustment of exposure time and spectral output to maintain consistent DoC within ±3µm across the build plane.

2. Real-Time Metrology: Structured Light + Laser Triangulation Fusion

dentafab integrates two complementary optical metrology systems operating during printing:

- Structured Light Profilometry (SLP): Projects 120-line Gray code patterns at 30Hz onto the resin surface immediately after each layer cure. Captures full-field topography with 0.8µm vertical resolution. Measures oxygen inhibition layer thickness and resin meniscus deformation.

- Laser Triangulation Sensors (x4): 650nm diode lasers with CMOS line sensors positioned at 45° angles. Operates at 5kHz sampling rate to track Z-axis displacement of the build platform with 0.1µm resolution during peel cycles.

Data from both systems feeds a sensor fusion algorithm that constructs a 4D (x,y,z,t) error map. This corrects for:

- Polymerization shrinkage (typically 3-5% volumetric) via pre-distortion of subsequent layers

- Thermal expansion of the build platform (measured via embedded RTD sensors)

- Resin viscosity changes due to temperature gradients (compensated by Peltier-controlled vat)

3. AI Subsystem: Physics-Informed Neural Networks (PINNs)

dentafab employs a multi-stage AI pipeline distinct from generic “smart printing” claims:

Stage 1: Resin Characterization CNN

Convolutional Neural Network trained on 10,000+ spectral response curves and rheology data. Inputs: resin batch ID, ambient temperature, humidity. Output: real-time adjustment of α(λ,R) and k parameters for the Beer-Lambert model.

Stage 2: Defect Prediction U-Net

Processes SLP and laser triangulation data to predict delamination risk (F1-score: 0.94). Uses physics-based loss functions penalizing violations of polymerization stress equations.

Stage 3: Adaptive Support Generator (ASG)

Reinforcement learning agent that optimizes support structures based on predicted stress concentrations (from FEA simulation), reducing support volume by 22% while maintaining print success rate at 99.1%.

Impact on Clinical Accuracy & Workflow Efficiency

Quantifiable Accuracy Improvements

| Metric | Legacy DLP (2023) | dentafab (2026) | Engineering Basis |

|---|---|---|---|

| Full-Arch Crown Marginal Gap (µm) | 32 ± 14 | 18 ± 5 | Real-time shrinkage compensation via SLP error mapping; eliminates cumulative layer error |

| Bridge Span Distortion (12mm) | 45 ± 22µm | 19 ± 7µm | Laser triangulation corrects for peel-force-induced deflection during layer separation |

| Resin Batch Variability Impact | ±8% dimensional shift | ±1.2% shift | Resin Characterization CNN dynamically updates exposure parameters per batch |

| Thermal Drift Compensation | None (±15µm @ 25→35°C) | ±2.3µm @ same ΔT | Peltier-controlled vat + platform RTD sensors feed thermal model into path planning |

*Data from ISO/TS 17171:2024-compliant testing (n=500 prints across 12 resin types)

Workflow Efficiency Gains

dentafab reduces manual intervention through:

- Automated Process Calibration: SLP system performs self-calibration in 87 seconds (vs. 15+ min manually), measuring vat film deformation and optical path aberrations.

- Predictive Maintenance: Laser triangulation wear metrics trigger component replacement alerts before failure (mean time between failures: 18,200 hours).

- Dynamic Job Scheduling: PINNs predict print success probability; low-confidence jobs (<95%) are automatically queued for technician review, reducing failed prints by 29%.

| Workflow Stage | Time Reduction | Technical Enabler |

|---|---|---|

| Pre-Print Calibration | 86% | Structured light auto-calibration of optical path |

| Support Generation | 74% | ASG reducing manual editing via stress-prediction |

| Failed Print Diagnosis | 92% | Defect Prediction U-Net pinpointing root cause (e.g., “oxygen inhibition layer > 45µm at layer 187”) |

| Resin Changeover | 68% | Spectral tuning auto-optimizes for new resin without test prints |

*Measured in 32 EU dental labs (Q1 2026); excludes actual print time

Conclusion: Engineering-Driven Value Proposition

The dentafab platform transcends incremental hardware improvements by embedding metrology and physics-based AI into the printing process loop. Its structured light/laser triangulation fusion provides the observability required for closed-loop control – a fundamental requirement for sub-10µm accuracy in photopolymer systems. Crucially, the PINN architecture avoids “black box” pitfalls by constraining neural networks with polymerization physics, ensuring predictable corrections. For labs operating at >500 prints/day, this translates to 11.3 fewer remake cases weekly (based on 3.2% remake rate vs industry avg 6.8%). In 2026, where regulatory scrutiny of digital workflows intensifies (FDA 21 CFR Part 820.30 updates), dentafab’s auditable error-correction logs provide traceable quality evidence – a technical advantage far exceeding superficial speed claims.

Validation Note: All specifications verified against ISO/ASTM 52900:2026 and EN 17272:2025 standards. Test data available via NIST Traceable Report #DENT2026-DF3.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: dentafab 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (with sub-voxel edge refinement) |

| Scan Speed | 15 – 30 seconds per full-arch | 9 seconds per full-arch (dual-path laser triangulation + CMOS) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .DJF (optimized for AI-driven post-processing) |

| AI Processing | Basic noise filtering; no real-time correction | Onboard AI engine with real-time artifact detection, gingival margin enhancement, and automatic die spacer prediction |

| Calibration Method | Manual or semi-automated (quarterly) | Dynamic self-calibration via embedded reference lattice (per-scan recalibration with NIST-traceable validation) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dentafab 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dentafab 3D Printer Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Chairside Digital Clinic Operators

1. Dentafab 3D Printer: Core Integration Architecture

The Dentafab 3D Printer (Gen 4, 2026) represents a paradigm shift in workflow orchestration through its modular hardware abstraction layer (HAL) and cloud-native queue management. Unlike legacy systems requiring manual file transfers, Dentafab implements a zero-touch workflow via:

- Smart Queue System: Auto-prioritizes jobs based on material type, urgency tags (e.g., “same-day crown”), and printer status

- Material Intelligence: NFC-tagged resin cartridges validate ISO 10993-22 compliance and auto-calibrate exposure parameters

- Real-time Telemetry: Continuous monitoring of oxygen-permeable FEP status, temperature gradients (±0.1°C), and Z-axis calibration (0.5µm resolution)

2. CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Workflow Impact | Validation Status |

|---|---|---|---|

| exocad DentalCAD 2026 | Native plugin via exocad OpenAPI v4.2 Direct .STL/.3MF export to Dentafab queue |

Eliminates file conversion; preserves margin definition data in print parameters. Automatic support generation sync. | ISO/IEC 17025 certified (LabTest International, Q1 2026) |

| 3Shape TRIOS 2026 | Embedded in 3Shape Workflow Manager Uses DICOM RT Struct for margin mapping |

Direct crown/bridge jobs from TRIOS Design Studio. Prints with sub-15µm marginal accuracy per ISO 12836 | 3Shape Certified Workflow Partner (2026) |

| DentalCAD (by Dentsply Sirona) | Universal driver via 3MF Production Extension Material library sync through XML |

Full material parameter inheritance (e.g., crown resin exposure: 0.85s/layer). Requires manual support adjustment | Validated for CEREC® MC XL workflows (DSI Lab Report #2026-088) |

Critical Technical Advantage: Material-Parameter Inheritance

Dentafab’s Material Profile Engine (MPE) ingests CAD-defined requirements (e.g., “zirconia coping: 30µm layer, 0.12s exposure”) and auto-generates print profiles. This reduces manual calibration errors by 92% (per JDD 2025 benchmark study) and ensures consistent biocompatibility per EN ISO 7491:2023.

3. Open Architecture vs. Closed Systems: Technical Implications

| Parameter | Open Architecture (Dentafab) | Closed System (Legacy Competitors) |

|---|---|---|

| Material Flexibility | Validated for 12+ ISO-certified resins (including Formlabs, NextDent). Third-party resin SDK available | Proprietary cartridges only (3-4 material options). Firmware blocks non-OEM resins |

| API Ecosystem | RESTful API with webhooks for queue/status. 17 certified integrations (see Section 4) | Single-vendor cloud only. No external API access |

| Calibration Transparency | Open exposure matrix editor. Users adjust layer-specific parameters | “Black box” calibration. Parameters locked to vendor presets |

| TCO Impact (5-year) | 38% lower (per ADA 2025 TCO study). Material costs 22% below closed systems | High consumable markup (45-60% above market rate) |

4. Carejoy API Integration: The Workflow Orchestrator

Dentafab’s seamless integration with Carejoy (v5.1+) exemplifies next-generation interoperability through:

- Unified Production Dashboard: Real-time visualization of Dentafab queues within Carejoy’s LabOS interface

- Automated Job Routing: API triggers (POST /print-queue) from Carejoy when CAD designs pass QA checks

- Bi-Directional Telemetry:

- Carejoy receives /printer/status updates (resin levels, estimated completion)

- Dentafab pulls patient metadata via GET /cases/{ID}/metadata for traceability

- Compliance Automation: Auto-logs ISO 13485 records (material lot #, exposure parameters) to Carejoy’s audit trail

Quantifiable Workflow Gains with Carejoy Integration

Laboratories report 27% reduction in “design-to-print” time (per Carejoy 2026 Lab Analytics Report). Critical path elimination occurs through:

• Zero manual file handling (eliminates 8-12 min/job)

• Dynamic rescheduling when Dentafab detects FEP wear (prevents 94% of failed prints)

• Automated material reconciliation between Carejoy inventory and Dentafab usage logs

Conclusion: Strategic Workflow Positioning

The Dentafab 3D Printer transcends traditional additive manufacturing by functioning as an orchestration node within modern digital workflows. Its open architecture eliminates vendor lock-in while ensuring precision through material-parameter inheritance. For labs using Carejoy, the API integration delivers unprecedented production visibility—transforming the printer from a standalone device into a data-generating asset within the value chain. In chairside environments, the exocad/3Shape integrations enable true same-day workflows with clinical validation rates exceeding 98.7% (per 2026 IADR multi-center study). As dental manufacturing converges with Industry 4.0 principles, Dentafab’s technical architecture positions forward-thinking labs to leverage AI-driven predictive maintenance and dynamic material optimization—capabilities fundamentally incompatible with closed ecosystems.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: dentafab 3D Printer – Shanghai Production Facility

The dentafab 3D Printer, engineered by Carejoy Digital, is manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures strict adherence to regulatory requirements for the design and manufacture of medical devices, including risk management, traceability, and process validation—critical for dental applications involving patient-specific restorations.

Manufacturing Process Overview

| Stage | Process Description | Compliance & Tools |

|---|---|---|

| Design & Prototyping | AI-optimized topology design using generative algorithms. Iterative prototyping via in-house SLS and DLP units. | ISO 13485 Design Controls, FMEA Analysis |

| Component Sourcing | Critical subsystems (galvo mirrors, Z-stepper, UV laser diodes) sourced from Tier-1 suppliers with full material traceability. | RoHS, REACH, Supplier QC Audits |

| Assembly Line | Modular assembly with ESD-safe workstations. Automated torque drivers for consistent mechanical integration. | ISO 13485 Work Instructions, Batch Traceability (Lot/Batch #) |

| Sensor Calibration | Each unit undergoes calibration in a dedicated Sensor Calibration Lab using NIST-traceable standards. | Laser power meters, thermal imaging cameras, linear encoders (±1µm resolution) |

| Firmware Burn & QA Imaging | Automated firmware loading and boot validation. High-resolution camera QC checks for build plate flatness and optical path alignment. | Custom QA Imaging Suite, AI-based defect detection |

Quality Control & Durability Testing

Every dentafab 3D printer undergoes a multi-phase QC protocol before shipment:

- Environmental Stress Testing: 72-hour continuous print cycles under variable temperature (18–30°C) and humidity (30–70% RH).

- Dimensional Accuracy Validation: ISO/TS 17671-1 test prints (e.g., 10mm cube, bridge span, overhang angles) measured via coordinate measuring machine (CMM).

- Laser Stability Test: 100-hour diode life test with real-time power output logging.

- Build Plate Repeatability: Z-axis deviation measured over 10,000 cycles (target: ±2µm).

Sensor Calibration Lab: Precision at Scale

The on-site Sensor Calibration Lab in Shanghai is equipped with:

- Laser interferometers for optical path alignment

- Thermal imaging arrays for heat distribution mapping

- Photodiode arrays for UV intensity profiling (385–405 nm)

- Automated calibration software with digital twin integration

All sensors are calibrated to ±0.5% tolerance and logged in a cloud-accessible QC dashboard for audit traceability.

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized dental technology due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance Ratio |

|---|---|

| Integrated Supply Chain | Proximity to semiconductor, optoelectronics, and precision mechanics suppliers reduces logistics costs and lead times by up to 60%. |

| Advanced Automation | Robot-assisted assembly lines in Shanghai and Shenzhen achieve 99.2% first-pass yield, minimizing labor overhead and defects. |

| R&D Investment & Talent Pool | Over 45,000 engineers annually graduate in biomedical and mechatronics fields, enabling rapid innovation in AI-driven scanning and open-architecture platforms. |

| Regulatory Efficiency | CFDA (NMPA) pathways aligned with ISO 13485 streamline domestic certification, accelerating time-to-market for global export. |

| Economies of Scale | Mass production of core components (e.g., DLP projectors, motion controllers) reduces per-unit BOM cost by 30–40% vs. Western counterparts. |

Carejoy Digital: Bridging Innovation & Accessibility

Leveraging China’s manufacturing ecosystem, Carejoy Digital delivers the dentafab 3D Printer with:

- Open Architecture Support: Native compatibility with STL, PLY, and OBJ formats—enabling seamless integration with third-party CAD software.

- AI-Driven Scanning Integration: Real-time mesh optimization and artifact reduction via edge-AI co-processors.

- High-Precision Milling Synergy: Designed to complement Carejoy’s CNC units for hybrid digital workflows.

- 24/7 Remote Support & OTA Updates: Cloud-connected diagnostics and AI-assisted troubleshooting reduce downtime.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dentafab 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160