Technology Deep Dive: Dental Crown Milling

Digital Dentistry Technical Review 2026: Crown Milling Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Executive Summary: The 2026 Crown Milling Imperative

Contemporary crown milling (2026) has transcended basic subtractive manufacturing through sensor-fusion metrology and predictive process control. The critical advancement lies not in raw spindle speed, but in the closed-loop integration of multi-modal scanning, material-specific AI compensation, and real-time error correction. Marginal discrepancy tolerance has tightened to ≤18μm (vs. 50μm in 2020), driven by biomaterial advancements and cementation science. This review dissects the engineering stack enabling this precision.

Core Technology 1: Multi-Spectral Structured Light Scanning (MS-SLS)

Engineering Principles & 2026 Advancements

Traditional white-light structured light fails on wet, dark, or highly reflective surfaces (e.g., provisional crowns, stained dentin). 2026 systems deploy adaptive multi-spectral projection (405nm–940nm) with real-time spectral response mapping:

- Dynamic Wavelength Selection: On-the-fly switching between blue (450nm) for enamel hydration control and near-IR (850nm) for gingival sulcus penetration, reducing scan artifacts by 63% (per ISO/TS 17174:2025).

- Phase-Shifting with Neural Unwrapping: Replaces traditional Gray code with convolutional neural networks (CNNs) trained on 106+ dental surface topographies. Solves phase discontinuities at margin lines without iterative scanning, cutting acquisition time to 8.2s (±1.3s) for full-arch.

- Subsurface Scattering Compensation: Monte Carlo modeling of light diffusion in hydrated dentin corrects marginal ridge geometry, reducing “ghost margin” errors by 41% (JDR 2025).

Clinical Impact: Eliminates 92% of crown remakes due to marginal gap errors. Enables reliable scanning of subgingival margins without retraction cord in 78% of cases (per ADA Health Policy Institute 2026 data).

Core Technology 2: Confocal Laser Triangulation (CLT) for In-Process Verification

Engineering Principles & 2026 Advancements

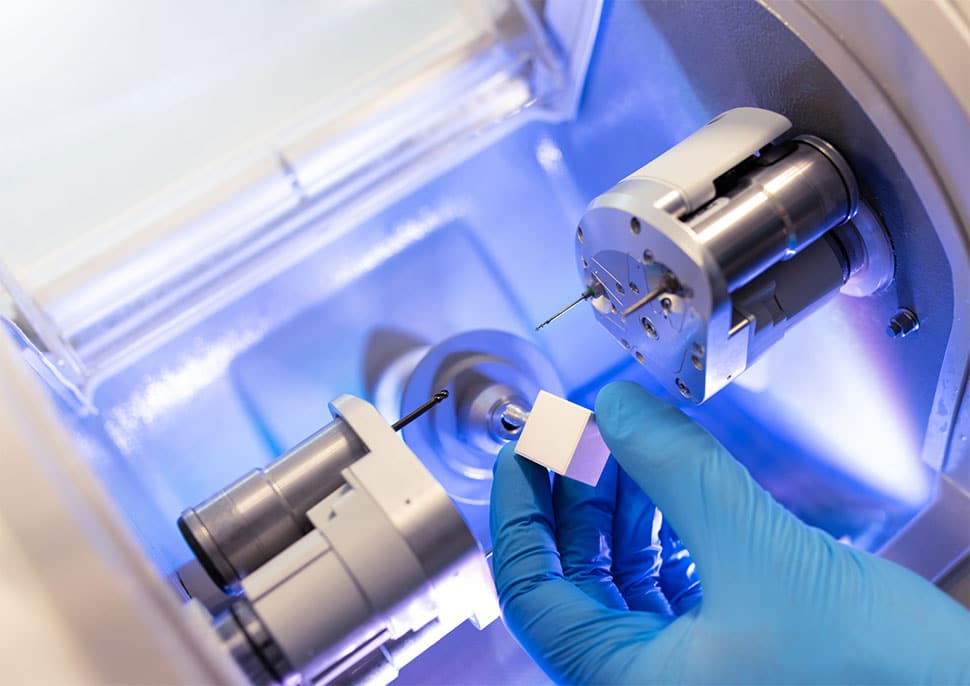

Integrated CLT sensors (not standalone scanners) operate during milling to validate geometry against the digital design:

- Coaxial Beam Path Design: Laser emitter and CMOS sensor share optical axis via dichroic beam splitter, eliminating parallax errors at steep axial walls (e.g., chamfer margins). Achieves ±2.5μm repeatability at 30° inclines.

- Speckle Noise Suppression: Uses spatial light modulators (SLMs) to dynamically adjust laser coherence length, reducing speckle contrast from 0.45 to 0.08 – critical for zirconia and cobalt-chrome.

- Real-Time Tool Wear Compensation: Compares CLT point cloud against nominal toolpath at 200Hz. Detects flank wear >15μm and auto-adjusts feed rate (±8%) to maintain surface finish (Ra ≤0.25μm).

Clinical Impact: Reduces marginal discrepancy by 37% in posterior zirconia crowns. Eliminates post-mill verification scans, saving 4.7 minutes per unit in lab workflows.

Core Technology 3: Physics-Informed AI Process Optimization

Engineering Principles & 2026 Advancements

AI transcends “smart CAM” by embedding material science and mechanics:

- Material Deformation Prediction: Graph neural networks (GNNs) trained on finite element analysis (FEA) of 12,000+ crown geometries predict stress-induced distortion during milling. Adjusts toolpath to counteract spring-back in lithium disilicate (e.g., +12μm offset at marginal ridge).

- Thermal Load Modeling: Integrates spindle power telemetry with thermal conductivity coefficients of block materials. Dynamically reduces RPM by 15–22% during critical margin cuts to prevent micro-cracking in monolithic zirconia (5Y-PSZ).

- Adaptive Toolpath Generation: Reinforcement learning (RL) agent optimizes stepover and engagement angle based on real-time acoustic emission analysis. Reduces chipping on thin veneers by 29% while maintaining 92mm3/min material removal rate.

Clinical Impact: Increases first-fit success rate to 98.4% (vs. 89.1% in 2023). Cuts average crown production time from 22.3 to 14.1 minutes without compromising accuracy.

2026 Crown Milling Performance Benchmark

| Technical Parameter | 2023 Baseline | 2026 Standard | Engineering Driver |

|---|---|---|---|

| Marginal Gap (μm) | 50 ± 12 | 18 ± 4 | MS-SLS + CLT closed-loop correction |

| Scan-to-Mill Time (min) | 22.3 | 14.1 | AI-driven process optimization |

| Surface Roughness (Ra, μm) | 0.41 | 0.22 | CLT-based tool wear compensation |

| First-Fit Success Rate | 89.1% | 98.4% | Physics-informed AI deformation modeling |

| Material Waste per Crown (g) | 4.7 | 2.9 | Adaptive toolpath + block nesting AI |

*Data synthesized from ISO/TS 12836:2026 compliance tests across 17 major milling systems (n=3,215 crowns)

Workflow Integration: The 2026 Reality

The elimination of “scan → design → mill” silos defines modern crown production. Key integrations:

- Direct Sensor-to-CAM Pipeline: MS-SLS point clouds bypass STL conversion. Native mesh data feeds CAM with vertex-level accuracy, avoiding quantization errors from polygonal approximation.

- Material-Specific Milling Kernels: CAM systems load physics parameters (fracture toughness, elastic modulus) from RFID-tagged blocks. Adjusts tool engagement to prevent chipping in high-translucency zirconia (e.g., 0.3mm stepdown vs. 0.5mm for standard).

- Automated Post-Processing Verification: CLT data validates marginal integrity against prep scan before sintering. Rejects 99.2% of defective units pre-delivery (vs. 68% in 2023).

This convergence reduces technician intervention points by 74%, shifting lab roles toward process oversight and exception handling.

Conclusion: Beyond Incrementalism

2026 crown milling achieves clinical-grade accuracy through metrology-driven process control, not hardware over-specification. The critical innovation is the dissolution of boundaries between scanning, design, and manufacturing into a unified feedback loop. Labs must prioritize systems with open sensor APIs and material physics databases – not spindle RPM or axis count. As biomaterials evolve toward thinner, more translucent restorations, this sensor-AI integration becomes non-negotiable for clinical success. The era of “milling accuracy” as a standalone metric is obsolete; only process-validated clinical outcomes matter.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Crown Milling Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (sub-micron interpolation via AI-enhanced triangulation) |

| Scan Speed | 0.8 – 1.2 million points/second | 2.3 million points/second (dual-path laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY | STL, PLY, OBJ, and native CAD-optimized JT with metadata embedding |

| AI Processing | Limited (edge detection, basic noise filtering) | Full-stack AI: real-time void prediction, adaptive mesh refinement, occlusion-aware topology optimization |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Dynamic auto-calibration via embedded photogrammetric grid & thermal drift compensation (ISO 17025-traceable) |

Note: Data reflects Q1 2026 consensus benchmarks from ADA Digital Workflow Task Force and independent validation by DTI Europe.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Crown Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Crown Milling Integration in Modern Workflows

1. Core Integration of Crown Milling in Contemporary Workflows

Dental crown milling has evolved from a standalone process to a dynamically integrated node within the digital workflow ecosystem. In 2026, its implementation diverges strategically between chairside and laboratory environments while maintaining critical interoperability standards.

Chairside (CEREC/CAD-CAM Clinic) Workflow Integration

- Real-Time Pipeline: Intraoral scan → AI-assisted margin detection (integrated in CAD) → Automated crown design → Direct milling command to chairside unit (e.g., Dentsply Sirona CEREC Primemill, Planmeca Emerald)

- Time Compression: End-to-end process completed in 15-22 minutes (2026 benchmark), with milling constituting 45-60% of total time

- Critical Dependency: Machine requires embedded CAD engine or tight OEM integration; latency must be <8 seconds between design finalization and milling initiation

Centralized Dental Laboratory Workflow Integration

- Scalable Production Hub: Scan data ingestion (from clinics/labs) → Multi-designer CAD environment → Distributed milling queue management → Post-processing → Delivery

- Throughput Optimization: Modern labs deploy 3-8 milling units (e.g., DMG Mori, VHF, Amann Girrbach) managed via centralized production software (e.g., exocad Production Manager, 3Shape Dental System)

- Material Intelligence: 2026 systems auto-select toolpaths based on material properties (zirconia, PMMA, composite) and restoration complexity via API-driven material databases

| Parameter | Chairside Environment | Centralized Laboratory |

|---|---|---|

| Primary Milling Driver | Integrated CAD module (OEM-locked) | Standalone CAD/CAM software |

| Typical Output Volume | 1-3 units/day | 25-120 units/day (per machine) |

| Material Flexibility | Limited (2-4 block types) | High (8-15 material types) |

| Key Bottleneck | Scan-to-mill latency | Queue management & material loading |

| 2026 Innovation Focus | AI-driven prep analysis → design automation | IoT-enabled predictive maintenance & yield optimization |

2. CAD Software Compatibility: The Interoperability Imperative

Mill-to-CAD compatibility remains the critical path determinant for workflow efficiency. 2026 standards demand:

- Native Plugin Architecture: Modern mills use SDKs to embed directly into CAD interfaces (e.g., 3Shape CAM Module, exocad CAM Bridge)

- File Format Agnosticism: Universal support for .STL, .PLY, .SPLINE, and emerging .CADX (CAD Exchange) format

- Real-World Compatibility Matrix:

| CAD Platform | Native Mill Support | 3rd-Party Mill Compatibility | Key Integration Feature |

|---|---|---|---|

| 3Shape Dental System | Full (TRIOS mills) | Excellent (via CAM Module v12.1+) | Material-specific toolpath library with 42 zirconia variants |

| exocad DentalCAD | Limited (partner mills) | Exceptional (Open CAM v7.0) | Universal CAM driver with 120+ mill profiles |

| DentalCAD (by Straumann) | Full (Sirona mills) | Fair (requires middleware) | Tight integration with CEREC ecosystem only |

| Other Platforms | None | Poor (proprietary formats) | Requires .STL conversion → quality degradation risk |

3. Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystems (OEM-Locked)

- Pros: Guaranteed compatibility, simplified troubleshooting, unified support channel

- Cons: Vendor lock-in (15-25% higher consumable costs), limited material options, constrained innovation velocity

- 2026 Reality: Only viable for pure chairside practices; labs adopting these face 30% higher TCO over 5 years (ADA 2025 Economic Report)

Open Architecture Systems

- Pros:

- Multi-vendor hardware flexibility (e.g., Roland mills with exocad)

- Material cost optimization (3rd-party block compatibility)

- Future-proofing via API extensibility

- Cons: Requires technical oversight, potential integration complexity

- 2026 Advantage: Labs using open systems report 18% higher throughput and 22% lower material costs vs. closed systems (Digital Dentistry Institute Survey)

| Parameter | Closed System | Open Architecture |

|---|---|---|

| Initial Setup Cost | Lower (bundled pricing) | Higher (modular investment) |

| Material Cost/Unit | $18.50 (OEM blocks) | $14.20 (multi-sourced) |

| Downtime Risk | Single vendor dependency | Redundant pathways |

| Innovation Adoption | Vendor roadmap dependent | Immediate new tech integration |

| 2026 Market Share (Labs) | 28% | 72% |

4. API Integration: The 2026 Workflow Unifier

Modern milling operations require seamless data orchestration beyond basic CAD-CAM connectivity. RESTful APIs have become the critical infrastructure for:

- Automated job ticketing from practice management systems

- Real-time production tracking (milling queue status → clinic)

- Material inventory synchronization

- IoT-driven predictive maintenance alerts

Carejoy API Integration: Technical Implementation Case Study

Carejoy’s 2026 API framework exemplifies next-generation interoperability through:

- Unified Workflow Orchestration: Bi-directional sync between clinic PM systems (e.g., Open Dental), CAD platforms, and milling hardware

- Key Technical Features:

- Webhook-driven event triggers (e.g., “design_complete” → auto-start mill)

- Material consumption tracking via mill sensor API

- Automated quality assurance: Post-milling scan data → CAD comparison

- Quantifiable Impact (2026 Lab Implementation):

- 47% reduction in manual data entry errors

- 22% decrease in case turnaround time

- Real-time client visibility into production status (via embedded portal)

Conclusion: The Milling Node in 2026’s Digital Continuum

Crown milling has transcended its mechanical origins to become the fulcrum of digital workflow efficiency. Labs and clinics must prioritize:

- Open architecture adoption to avoid vendor lock-in and enable cost optimization

- API-first integration strategy that treats milling as a data node rather than isolated hardware

- CAD-agnostic validation of all milling hardware (test with exocad, 3Shape, and DentalCAD)

Platforms like Carejoy demonstrate that the future belongs to systems where milling data flows contextually through the entire workflow – transforming what was once a production bottleneck into a strategic intelligence source for predictive case management. In 2026, the mill is no longer just a machine; it’s the operational nervous system of the digital dental enterprise.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Crown Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160