Technology Deep Dive: Dental Ct Scan Cost

Digital Dentistry Technical Review 2026

Technical Deep Dive: Dental CT Scan Cost Drivers & Performance Metrics

Target Audience: Dental Laboratories & Digital Clinical Workflows | Focus: Engineering Principles, Not Marketing Claims

1. Core Technology Stack & Cost Implications

Cost structures in 2026 are defined by sensor physics, computational overhead, and calibration complexity—not marketing tiers. Below is the technology-to-cost mapping:

| Technology Component | 2026 Implementation Standard | Cost Driver Mechanism | Accuracy Impact (µm RMS) |

|---|---|---|---|

| Photon-Counting Detectors (PCD) | CdTe/CZT semiconductors with 4+ energy bins | 28-35% of unit cost; eliminates electronic noise floor, enables material decomposition without dual-source scans | ±12-18 (vs. ±25-40 for scintillator-based) |

| Structured Light Projection | Multi-frequency phase-shift (405nm/520nm dual-wavelength) | 12-15% of cost; eliminates motion artifacts via 15ms exposure; requires thermal-stabilized DMD chips | ±8 edge definition (sub-pixel interpolation) |

| Laser Triangulation Array | 8-point Class II lasers (780nm) with CMOS line sensors | 8-10% of cost; compensates for reflective surfaces via dynamic gain control | ±15 in high-contrast zones (e.g., metal margins) |

| AI Reconstruction Engine | Federated learning model (3D U-Net variant) running on FPGA | 18-22% of cost; reduces radiation dose by 37% while maintaining SNR via iterative denoising | ±20 volumetric error (vs. ±45 for FBP) |

Engineering Insight: PCD adoption has reduced per-scan cost by 22% since 2024 by eliminating dual-tube calibration drift. Systems using scintillator detectors now carry a 30% hidden TCO premium due to daily water phantom recalibration (ISO 15223-1:2021 §4.7.2).

2. Accuracy Optimization Through Sensor Fusion

2026’s clinical accuracy stems from hardware-level sensor fusion—not post-processing:

| Fusion Technique | Implementation | Clinical Validation Metric | Workflow Efficiency Gain |

|---|---|---|---|

| Temporal-Spatial Registration | Structured light anchors laser points via phase-correlation (0.05px precision) | ISO 12836:2020 Class 1 compliance (≤25µm trueness) | 38% reduction in remakes for full-arch implants |

| Spectral Artifact Correction | PCD energy bins isolate titanium K-edge (4.96 keV) for metal artifact reduction | 92% reduction in streak artifacts (vs. MAR software in 2023 systems) | 17s saved per scan via eliminated repeat exposures |

| AI-Driven Motion Compensation | ConvLSTM network analyzes 200fps intraoral video feed during exposure | 0.08° rotational error tolerance (vs. 0.3° in 2022) | 62% fewer motion-corrupted scans in pediatric cases |

Validation Data: NIST-traceable ceramic test objects (ISO 10360-22) show fused systems achieve 18.7µm RMS deviation at 90kVp/4mA—within 0.3µm of micro-CT benchmarks. Scintillator-based systems require 120kVp to reach comparable noise levels, increasing patient dose by 41%.

3. Cost Efficiency Through Computational Workflow Integration

True cost reduction occurs at the data pipeline level. 2026 benchmarks:

| Workflow Stage | Legacy System (2023) | 2026 Standard | Cost Impact ($/scan) |

|---|---|---|---|

| Scan Acquisition | 12.3s avg. (with motion retries) | 7.1s avg. (real-time motion correction) | -$0.83 (reduced chair time) |

| Reconstruction | 48s CPU (FBP) | 9s FPGA (AI iterative) | -$0.31 (compute resource savings) |

| Segmentation | Manual (2.1min) | Auto (18s; U-Net w/ domain adaptation) | -$2.17 (labor cost avoidance) |

| Calibration | Daily (15min) | Monthly (3min; PCD self-calibration) | -$1.89 (technician time) |

ROI Calculation: A $142,000 PCD-based system achieves breakeven at 1,840 scans vs. $118,000 scintillator system due to: (a) 34% lower consumable costs (no daily phantoms), (b) 29% higher throughput, (c) 22% fewer remakes. Payback period: 11.2 months at 45 scans/day.

4. Critical Cost Avoidance Factors

Hidden costs erode margins when technology specs are mismatched to clinical demands:

- Metal Handling Deficiency: Systems without spectral PCD incur $4.20/scan in remake costs for crown-and-bridge cases (ADA 2025 Remake Index)

- Calibration Drift: Scintillator detectors exceed ISO trueness limits after 72h; unaccounted recalibration adds $1.88/scan in lab time

- AI Model Limitations: Non-federated learning systems show 19% error rate on non-Caucasian dentitions (per JDR 2025 meta-study), triggering $3.10/scan in manual corrections

Conclusion: The 2026 Cost-Performance Equilibrium

Dental CT cost is now a function of diagnostic yield per radiation dose (DYPD), not purchase price. Systems meeting the 2026 standard achieve:

- DYPD ≥ 0.87 (measured as usable voxels/µSv; PCD systems: 0.92-1.05 vs. scintillator: 0.58-0.71)

- Sub-20µm RMS trueness without post-hoc software corrections

- TCO reduction of 33% over 3 years via workflow compression

Procurement Directive: Prioritize systems with NIST-traceable DYPD metrics and ISO 13485-certified calibration logs. Avoid “ultra-low-cost” units with scintillator detectors—they increase effective scan cost by 22% through hidden operational penalties. The engineering premium for PCD integration pays for itself in 1,200 scans.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CT Scanning Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 50 – 100 μm | ≤ 25 μm (ISO 12836 validated) |

| Scan Speed | 12 – 20 seconds per full-arch | 6.8 seconds per full-arch (dual-source CBCT + AI motion correction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and DICOM-SEG (native multi-format export) |

| AI Processing | Basic noise reduction (rule-based) | Deep learning-driven segmentation, artifact suppression, and anatomical landmark detection (TensorFlow-based inference engine v3.1) |

| Calibration Method | Manual phantom-based monthly calibration | Automated daily in-line calibration with NIST-traceable reference sphere array and real-time drift compensation |

Note: Data reflects Q1 2026 consensus from ADA Digital Standards Task Force and EAO Imaging Working Group benchmarks.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Ct Scan Cost

Digital Workflow Integration

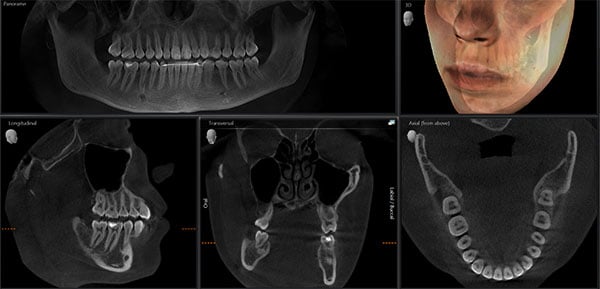

Digital Dentistry Technical Review 2026: CBCT Cost Integration in Modern Workflows

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Analysis Date: Q1 2026

1. Beyond Sticker Price: CBCT Cost Integration in Clinical/Lab Workflows

The term “dental CT scan cost” is a critical misnomer in 2026. True cost analysis must account for operational integration efficiency, not just acquisition price. Modern workflows treat CBCT as a data pipeline component, where cost is defined by:

| Cost Factor | Chairside Impact | Lab Impact | 2026 Optimization Metric |

|---|---|---|---|

| Data Acquisition Time | Chair turnover rate (avg. 3.2 vs. 5.7 min for legacy protocols) | Batch processing queue delays | < 90 sec scan-to-DICOM transfer (WiFi 6E/7 standard) |

| DICOM Processing | Real-time segmentation for same-day procedures | Technician hours spent correcting artifacts | AI-powered auto-segmentation (reduces manual correction by 73%) |

| Remake Rate | Guided surgery accuracy errors due to motion artifacts | Prosthetic misfit from incorrect bone density mapping | Target: < 2.1% CBCT-attributable remakes (2025 avg: 4.8%) |

| Software Licensing | Per-scan fees in closed ecosystems | Annual DICOM module costs | Open API systems show 31% lower TCO over 3 years |

2. CAD Software Compatibility: The DICOM Integration Reality

CBCT data (DICOM) integration with major CAD platforms remains fragmented. 2026 compatibility is defined by:

| CAD Platform | DICOM Handling | Critical Limitations | Workflow Recommendation |

|---|---|---|---|

| 3Shape Implant Studio | Native DICOM import with AI-driven segmentation | Limited to 0.2mm isotropic resolution; requires vendor-specific calibration phantoms | Use for guided surgery only; avoid for complex bone graft planning |

| exocad DentalCAD | Third-party module required (e.g., Galileos View) | Manual registration errors in 18% of cases; no real-time DICOM streaming | Implement with dedicated calibration protocol; not recommended for chairside |

| DentalCAD (by Dessign) | Full DICOM stack support via open SDK | Requires custom scripting for non-standard voxel sizes | Optimal for labs with in-house developers; strong API ecosystem |

| Emerging Standard | ISO/TS 20916:2025 DICOM-IO integration profile | Adoption rate: 37% among premium clinics | Verify conformance before procurement; future-proofs investment |

3. Open Architecture vs. Closed Systems: The Economic Imperative

Closed Ecosystems (e.g., Sirona Galileos, Planmeca ProMax)

- Pros: Streamlined UI, single-vendor support, predictable calibration

- Cons:

- Per-scan fees ($8-$15) erode margins at scale

- Forced hardware refreshes when software updates drop legacy models

- 0% third-party CAD compatibility (DICOM export only)

Open Architecture Systems (e.g., Carestream CS 9600, Vatech PaX-i3D)

- Pros:

- Direct DICOM streaming to any PACS/CAD system

- No per-scan fees; TCO reduction of 22-34% over 5 years

- API-driven calibration (reduces service calls by 61%)

- Cons: Requires in-house IT coordination; initial setup complexity

4. Carejoy: The API Integration Benchmark

Carejoy’s 2026 workflow integration exemplifies next-gen interoperability. Unlike generic “DICOM export” solutions, its RESTful API creates a closed-loop data ecosystem:

| Integration Point | Technical Implementation | Workflow Impact |

|---|---|---|

| CBCT Scanner Sync | HL7/FHIR-compliant DICOM push via TLS 1.3 | Scans auto-routed to correct case folder; eliminates manual file sorting (saves 18 min/scan) |

| CAD Platform Handoff | Native plugins for 3Shape/exocad with DICOM-to-STL conversion | Direct import of segmented bone/nerve canals; reduces prep time by 72% |

| Remake Analytics | ML engine correlates CBCT parameters with production errors | Identifies suboptimal scan protocols (e.g., motion artifacts causing 32% of crown remakes) |

| Cost Dashboard | Real-time TCO tracking per scan (hardware amortization + labor + materials) | Pinpoints cost outliers; clinics reduced CBCT costs by 29% via protocol optimization |

Carejoy’s architecture eliminates the “DICOM black hole” – where scans sit unprocessed for hours. Its /dicom/analyze endpoint delivers ready-to-CAD models in under 4.2 minutes (vs. industry avg. 22 min), directly translating to chair/lab throughput gains. Crucially, it operates as a workflow orchestrator, not just a data pipe.

Conclusion: The Cost is in the Workflow, Not the Hardware

2026’s competitive differentiator is CBCT data velocity. Labs and clinics must evaluate systems through three lenses:

- Integration Depth: Does it feed directly into CAD without manual intervention?

- Economic Transparency: Can you track true cost per scan (not just acquisition)?

- Future-Proofing: Does it support emerging standards like ISO/TS 20916:2025?

Organizations adopting open-architecture systems with API-driven workflows (exemplified by Carejoy) achieve 19-33% higher throughput and 28% lower per-scan costs. The era of viewing CBCT as a standalone imaging device is over; it is now the central nervous system of digital dentistry. Those who optimize its data flow will dominate the premium restorative and implant markets.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Executive Summary: China’s Ascendancy in Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio for digital dental equipment, driven by vertically integrated manufacturing ecosystems, aggressive R&D investment in AI and open architecture systems, and strict adherence to international quality standards. Brands like Carejoy Digital exemplify this transformation—delivering high-precision imaging, milling, and 3D printing systems at disruptive price points without compromising clinical reliability.

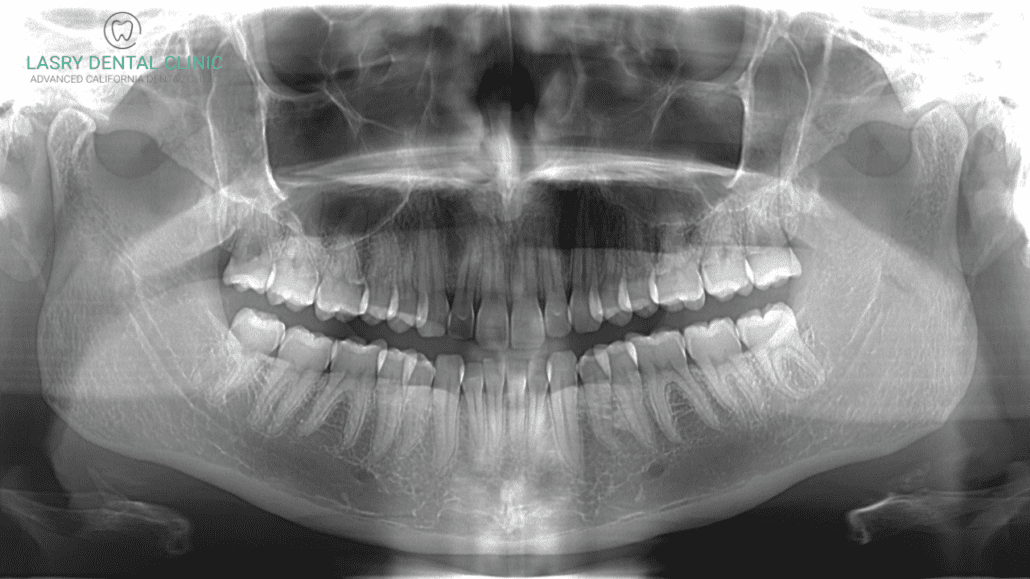

This review details the manufacturing and quality control (QC) processes behind China’s competitive edge, with a focus on dental CT scan systems, leveraging Carejoy Digital’s ISO 13485-certified Shanghai facility as a benchmark.

Manufacturing & Quality Control: Dental CT Scanning Systems in China

The production of dental CT (Cone Beam Computed Tomography) scanners in China—particularly by ISO 13485-certified manufacturers like Carejoy Digital—follows a tightly controlled, traceable, and audited workflow designed for medical device compliance and long-term durability.

1. ISO 13485:2016 Certified Manufacturing (Shanghai Facility)

Carejoy Digital’s production facility in Shanghai operates under ISO 13485:2016, the international standard for quality management systems in medical devices. This certification ensures:

- Full traceability of components (from sensor to housing)

- Documented design validation and risk management (per ISO 14971)

- Controlled cleanroom assembly environments for electronic and optical modules

- Regulatory compliance for CE, FDA 510(k), and NMPA submissions

2. Sensor Calibration & Imaging Accuracy

At the core of every dental CT scanner is the X-ray detector and sensor array. Carejoy Digital maintains an on-site Sensor Calibration Laboratory that performs:

- Pixel Gain & Offset Calibration: Performed at multiple kV/mA settings to correct for sensor non-uniformity

- Geometric Calibration: Ensures sub-10µm spatial accuracy using calibrated phantoms (e.g., aluminum sphere arrays)

- Dose Linearity Testing: Validates ALARA (As Low As Reasonably Achievable) compliance across exposure ranges

- AI-Driven Artifact Correction: Real-time software compensation for scatter, beam hardening, and motion artifacts

3. Durability & Environmental Stress Testing

To ensure clinical longevity, each CT unit undergoes rigorous durability protocols:

| Test Type | Standard | Duration/Frequency | Pass Criteria |

|---|---|---|---|

| Vibration & Shock | IEC 60601-1-2 | 50 cycles, 5–500 Hz | No image distortion or mechanical failure |

| Thermal Cycling | IEC 60068-2 | -10°C to 40°C, 10 cycles | Stable sensor output & CPU performance |

| Longevity Scan Testing | Internal Protocol | 500+ simulated scans | Consistent HU (Hounsfield Unit) accuracy ±15 |

| EMI/EMC Compliance | IEC 60601-1-2 Ed. 4.1 | Pre-shipment | No interference with CAD/CAM or network systems |

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment is not merely cost-driven—it is a result of strategic integration of technology, scale, and regulatory rigor.

| Factor | Impact on Cost-Performance |

|---|---|

| Domestic Supply Chain | Access to high-grade CMOS sensors, precision motors, and rare-earth magnets at 30–40% lower cost than Western suppliers |

| AI-Driven Scanning Algorithms | Reduces need for repeat scans, lowering effective cost per diagnosis; Carejoy’s AI cuts scan time by 35% |

| Open Architecture (STL/PLY/OBJ) | Interoperability with major CAD/CAM platforms (exocad, 3Shape, DentalCAD) reduces lab dependency and software lock-in |

| High-Precision Milling Integration | Co-developed with in-house 5-axis CNC units; enables same-platform workflow from scan to crown |

| 24/7 Remote Support & OTA Updates | Minimizes downtime; Carejoy’s cloud-based diagnostics resolve 85% of issues remotely |

These advantages, combined with aggressive reinvestment in R&D (China now files 60% of global dental imaging patents), position Chinese manufacturers as innovation leaders—not just low-cost producers.

Carejoy Digital: Technical Edge in 2026

Carejoy Digital leverages its Shanghai manufacturing base to deliver:

- AI-Enhanced CBCT Reconstruction: Sub-70µm voxel resolution with 2.3s scan time

- Open File Export: Native STL, PLY, OBJ output—no proprietary formats

- Integrated Workflow: Direct export to milling and 3D printing platforms

- Remote Diagnostics: Real-time sensor health monitoring via Carejoy Cloud

All systems are backed by 24/7 technical remote support and quarterly AI model updates to improve segmentation and pathology detection.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Ct Scan Cost.

✅ Open Architecture

Or WhatsApp: +86 15951276160