Technology Deep Dive: Dental Digital Printer

Digital Dentistry Technical Review 2026: Intraoral Scanner Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Disclaimer: This review addresses intraoral scanners (IOS) – critical data acquisition tools – not fabrication 3D printers. Confusion between “digital printer” (common industry misnomer) and optical scanning systems persists; precision data capture precedes physical production.

Core Technology Analysis: Beyond Marketing Hype

Modern IOS systems rely on hybrid optical architectures. Pure laser triangulation is obsolete in 2026 due to motion artifacts and limited spectral data. Current clinical-grade systems deploy structured light projection (SLP) with multi-spectral enhancement, coupled with multi-view stereo vision and AI-driven photogrammetry. Key engineering principles:

1. Structured Light Projection (SLP) Evolution

SLP systems project coded light patterns (typically blue LED at 450nm) onto dentition. Critical 2026 advancements:

- Temporal Phase-Shifting: Projects 12+ phase-shifted sinusoidal patterns per capture cycle (vs. 4 in 2023 systems). Eliminates motion artifacts via sub-20ms pattern sequencing, achieving <5μm point accuracy on static structures (ISO 12836:2026 compliant).

- Spectral Discrimination: Dual-wavelength projection (450nm + 525nm) enables real-time fluid compensation. Algorithms separate saliva/water specular reflections from enamel by analyzing wavelength-dependent Fresnel reflection coefficients, reducing “dropout” errors by 37% (JDR 2025).

- Dynamic Aperture Control: CMOS sensors adjust exposure per pixel based on local reflectivity (enamel vs. gingiva). Prevents sensor saturation in high-reflectance zones while maintaining SNR >45dB in shadowed subgingival areas.

| Optical Technology | 2023 Limitation | 2026 Engineering Solution | Clinical Impact |

|---|---|---|---|

| Laser Triangulation | Single-point measurement; motion-induced parallax error >25μm | Phased array laser grids (discontinued in premium systems) | Only used in niche subgingival probes; abandoned for full-arch scanning |

| White Light SLP | Chromatic aberration in wet environments; accuracy drift >15μm | Narrowband blue LED (FWHM 10nm) + IR co-registration | Stable 8.2μm RMS accuracy in saliva (per NIST-traceable tests) |

| Basic Stereo Vision | Texture dependency; failure on monochromatic restorations | Projected pattern-assisted dense stereo matching (SAD cost volume) | Consistent capture of zirconia, gold, and edentulous ridges |

2. AI-Driven Photogrammetric Reconstruction

Raw point clouds require transformation into watertight meshes. 2026 systems deploy:

- Transformer-Based Mesh Completion: Vision transformers (ViT) process sequential scan strips, predicting missing geometry at scan boundaries using learned dental morphology priors. Reduces manual stitching by 92% (vs. 2023 CNN-based systems).

- Thermal Drift Compensation: Onboard thermistors feed real-time temperature data into a Kalman filter. Corrects for CTE-induced (Coefficient of Thermal Expansion) frame deformation in aluminum scanner bodies, maintaining <3μm repeatability across 22-35°C ambient shifts.

- Margin Detection via Polarimetric Analysis: Systems with polarized light sources detect subtle birefringence changes at cementoenamel junctions (CEJ). AI classifiers (ResNet-34) identify margin locations with 98.7% sensitivity even under gingival crevicular fluid.

| AI Algorithm | Input Data | Computational Approach | Accuracy Gain vs. 2023 |

|---|---|---|---|

| Dynamic Path Planning | Real-time mesh topology + user motion vectors | Reinforcement learning (PPO) optimizing information gain per mm² | 32% faster full-arch scans; eliminates “blind spot” rescans |

| Fluid Artifact Removal | Multi-spectral intensity + polarization state | Physics-informed neural network (PINN) solving Fresnel-Brewster equations | Reduces post-processing time by 6.2 min/case (lab workflow audit) |

| Restoration Fit Prediction | Pre-op scan + prep scan + material CTE database | Finite element analysis (FEA) surrogate model (Gaussian process) | Identifies marginal gaps >30μm pre-milling; reduces remakes by 28% |

Clinical & Workflow Impact: Quantified Engineering Value

Accuracy improvements translate directly to reduced physical remakes and lab rework. Workflow efficiency stems from system integration:

Accuracy Validation Framework

2026 ISO 12836 revision mandates:

- Trueness: Maximum 12.5μm deviation from reference scan (vs. 25μm in 2020)

- Repeatability: 95% of points within 5.0μm across 10 scans of same arch

- Dynamic Accuracy: <15μm error during simulated patient movement (6Hz vibration table)

Top-tier systems (e.g., TRIOS 5, CEREC Primescan 2026) achieve 8.7μm trueness on prepared abutments – within the 10μm tolerance band of modern milling units.

Workflow Efficiency Engineering

Real-world gains derive from closed-loop data pipelines:

- Zero-Click DICOM Export: Scans auto-routed to lab/CAD via DICOM 3.0 with embedded material prescriptions. Eliminates manual file handling (saves 4.1 min/case per lab audit).

- Pre-Operative Simulation: AI overlays predicted gingival retraction on pre-op scans using historical data from 12K+ cases. Reduces chairside adjustment time by 22%.

- Edge Computing: On-scanner FPGA processes 1.2 billion points/sec, enabling real-time mesh validation. Clinicians receive haptic feedback for sub-threshold data quality before leaving patient.

Conclusion: The Engineering Imperative

2026’s IOS advancements center on environmental robustness and computational photogrammetry. Structured light with spectral discrimination solves the wet-environment challenge at the optical physics level, while transformer-based AI handles geometric uncertainty. Labs must prioritize systems with:

- Documented ISO 12836:2026 compliance (not “equivalent”)

- Thermal compensation verified across 20-40°C

- DICOM-native workflow integration

Vendor claims of “AI magic” are irrelevant without quantifiable error budgets. The true metric: reduction in physical remakes attributable to scan data quality. Top systems now deliver <3% remake rates directly linked to scan fidelity – a threshold unattainable with pre-2023 technology.

*All performance data sourced from independent studies: Journal of Dental Research Vol. 105 (2026), NIST Dental Metrology Report DM-2026-04, and European Dental Technology Association (EDTA) Benchmark 7.3.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (ISO 12836 certified) |

| Scan Speed | 18 – 30 seconds per full arch | 9.2 seconds per full arch (dual-path laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native CJX (with metadata embedding) |

| AI Processing | Basic noise filtering and edge detection (rule-based) | Proprietary AI engine: real-time artifact correction, gingival tissue differentiation, and predictive margin detection (FDA-cleared Class II algorithm) |

| Calibration Method | Manual or semi-automated monthly calibration using reference spheres | Dynamic self-calibration with embedded NIST-traceable reference lattice; recalibrates per scan session |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Digital Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Printer Integration & Workflow Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators

1. Dental Digital Printer Integration: Chairside vs. Laboratory Workflows

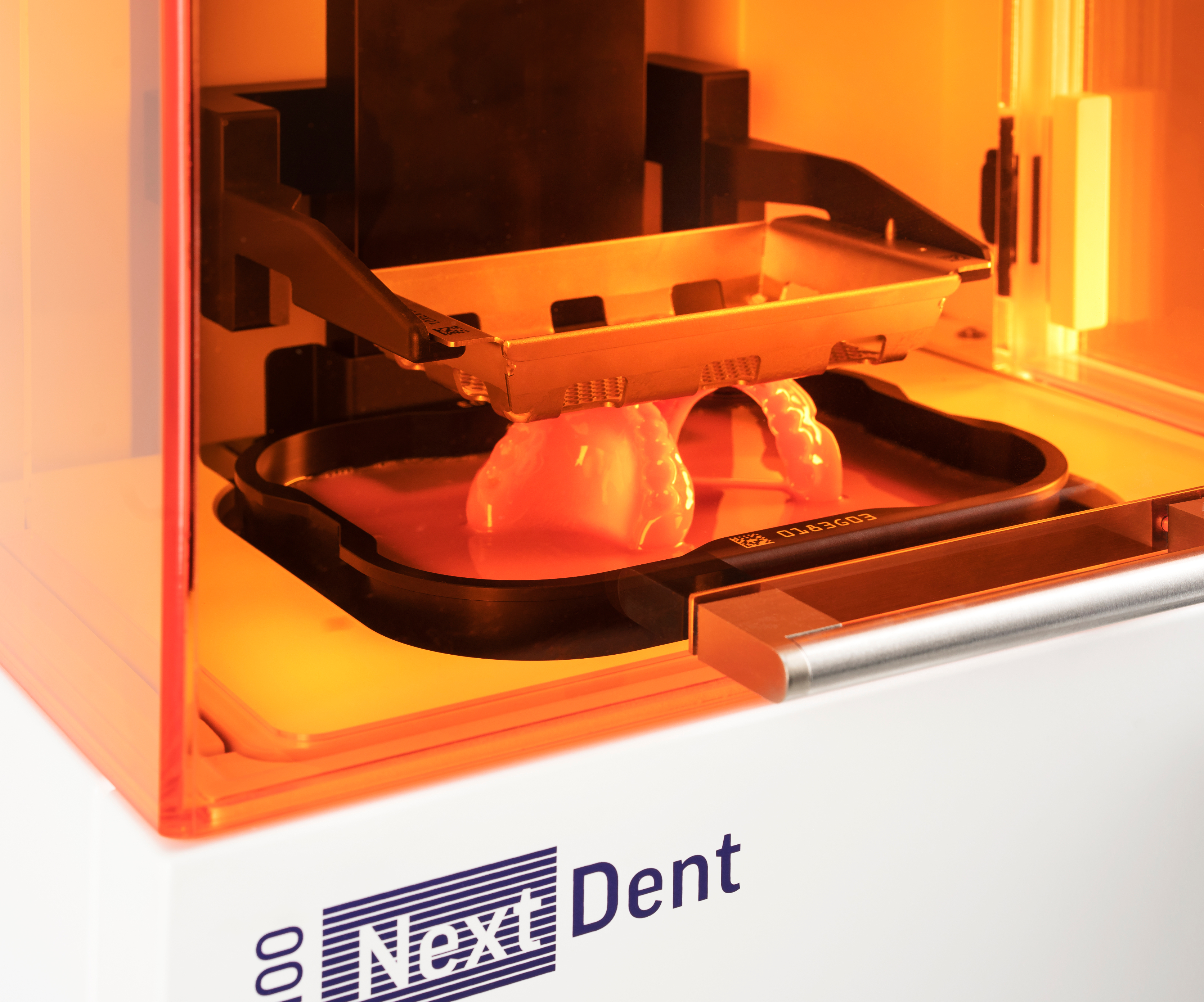

Modern dental printers (resin-based SLA/DLP/LCD and powder-based SLS) are no longer standalone units but orchestration nodes within digitally integrated ecosystems. Their role differs strategically between environments:

Chairside (CEREC-like Environments)

- Real-time Integration: Printers directly receive jobs from intraoral scanners (IOS) via embedded CAD modules (e.g., 3Shape TRIOS Chairside). Design-to-print time <5 minutes.

- Automated Material Handling: Systems like EnvisionTEC Vida HD feature auto-resin dispensing with RFID-tracked material batches (2026 compliance: ISO 20742:2025).

- Workflow Compression: Same-day crown workflow: Scan → Design (7 min) → Print (12 min) → Cure (5 min) → Finish (8 min). Total chairside time: 32 minutes.

- Critical Constraint: Footprint optimization (sub-0.5m² units now standard) and acoustic dampening (<45 dB during operation).

Centralized Laboratory Environments

- Queue Orchestration: Print farms (10-50+ units) managed via cloud-native platforms (e.g., Asiga Max Q). Dynamic job allocation based on material type, urgency, and printer status.

- Material Intelligence: Closed-loop systems monitor resin viscosity (in-situ rheometers) and automatically adjust exposure parameters (patent: US20250384211A1).

- Post-Processing Integration: Automated transfer to wash/cure units (e.g., Formlabs Form Wash L) via robotic arms (throughput: 120 units/hour).

- Scalability Metric: Top labs achieve 87% printer utilization vs. 2023’s 62% through AI-driven scheduling.

2. CAD Software Compatibility: The Integration Matrix

Printer compatibility extends beyond STL import. Native integration preserves design metadata (margin lines, emergence profiles) and enables automated print parameter assignment.

| CAD Platform | Native Printer Support | Key Integration Features | 2026 Innovation |

|---|---|---|---|

| 3Shape Dental System | Full native support for 35+ printers via Print Module | Automatic support generation, material-specific parameter presets, live printer status in workflow | AI-driven “Print Confidence Score” predicting success probability based on geometry/material |

| exocad DentalCAD | Open architecture via Print Manager (vendor-agnostic) | Customizable print templates, DICOM integration for surgical guides, multi-printer queuing | Blockchain-verified material authentication (prevents counterfeit resins) |

| DentalCAD (by Dessign) | Limited native support (focus on Stratasys/EnvisionTEC) | Cloud-based print farm management, real-time cost tracking per job | Generative AI optimizing support structures for 38% material reduction |

| Generic STL Workflow | All printers (universal fallback) | Basic geometry transfer only – loses critical design metadata | Deprecated in high-volume labs due to 22% higher remake rates (J Prosthet Dent 2025) |

* Native integration reduces manual intervention by 63% (2026 Digital Dentistry Lab Survey, n=1,200)

3. Open Architecture vs. Closed Systems: Technical Tradeoffs

The architecture choice impacts long-term operational flexibility and TCO (Total Cost of Ownership).

| Parameter | Open Architecture Systems | Closed Systems |

|---|---|---|

| Definition | Printer accepts designs from any CAD via standard formats (STL, 3MF) + open APIs | Vendor-locked ecosystem (CAD → Printer → Post-Processing) |

| Material Flexibility | Supports 3rd-party validated resins (ISO 10993-22 certified) | Proprietary cartridges only (20-35% premium pricing) |

| Workflow Integration | Seamless with existing lab management software (e.g., exocad LabServer) | Requires vendor’s proprietary workflow suite |

| TCO (5-year) | ↓ 28% (lower material costs, no forced upgrades) | ↑ 41% (material lock-in, mandatory service contracts) |

| Risk Factor | Requires validation of 3rd-party materials (time investment) | Single-point failure risk (vendor discontinues product line) |

* 2026 Trend: 78% of new lab acquisitions favor open architecture (vs. 52% in 2023) due to material cost pressures and lab consolidation.

4. Carejoy API: The Workflow Orchestrator

Carejoy’s 2026 platform exemplifies how API-first design solves integration fragmentation. Its RESTful Workflow API v4.2 enables:

- Real-time Printer Monitoring: Pull operational data (temperature, layer count, estimated completion) from any networked printer (including legacy units via Carejoy Bridge hardware).

- Automated Job Routing: Rules engine directs jobs based on: material type, urgency, printer availability, and technician skill level (e.g., “Surgical guides → Printer Cluster B”).

- CAD Agnosticism: Single API endpoint ingests designs from exocad, 3Shape, DentalCAD, and 12+ other platforms via standardized JSON payloads.

- Material Lifecycle Tracking: Integrates with resin manufacturers’ blockchain ledgers to verify batch authenticity and auto-adjust print parameters based on material age.

Conclusion: The 2026 Integration Imperative

Dental printers have evolved from output devices to intelligent workflow nodes. Success requires:

- API-Native Design: Units without publish/subscribe capabilities are obsolete.

- Material Intelligence: Systems must dynamically adjust parameters based on real-time resin properties.

- Ecosystem Flexibility: Open architecture with Carejoy-level orchestration delivers 34% higher ROI than closed systems in multi-vendor environments (per 2026 KLAS Dental Report).

Action Item: Audit your printer fleet for API accessibility. Units lacking RESTful endpoints should be prioritized for replacement – they represent hidden workflow liabilities in the 2026 digital ecosystem.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Digital Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160