Technology Deep Dive: Dental Fab Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Dental Fabrication Printers – Engineering Principles Driving Clinical Precision

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers, Prosthodontic Technology Directors

Executive Summary

Modern dental fabrication printers (2026) have evolved beyond basic additive manufacturing into integrated metrology systems. Core advancements in optical sensing, thermal control, and AI-driven error correction now directly impact marginal accuracy (≤ 25μm) and reduce clinical remakes by 22% (ISO/TS 12836:2023 validation). This review dissects the engineering underpinnings separating true clinical-grade systems from legacy photopolymer printers.

Core Technology Breakdown: Beyond “3D Printing”

Structured Light Adaptive Metrology (SLAM) – The Accuracy Foundation

Current high-end dental fab printers (e.g., systems meeting ISO 13606-2:2025) integrate structured light projection during printing, not just post-scanning. Unlike legacy laser triangulation:

| Parameter | Laser Triangulation (Legacy) | SLAM (2026 Clinical Standard) | Engineering Impact |

|---|---|---|---|

| Surface Capture Method | Single-point laser line + camera | Dynamic DLP projector + dual CMOS sensors | Eliminates shadowing errors in subgingival margins via multi-angle phase-shift analysis |

| Resolution (Z-axis) | ±15-20μm (at 50mm depth) | ±8μm (at 50mm depth) | Enables reliable printing of 50μm margin gaps per ADA Spec No. 57 |

| Real-time Correction | None (post-process only) | Per-layer optical coherence tomography (OCT) feedback | Compensates for resin shrinkage during polymerization via dynamic layer offset adjustment |

| Scan Time per Layer | 8-12 sec | 1.2-1.8 sec | Reduces total print time by 18% for full-arch cases (vs. 2023 systems) |

* SLAM utilizes 385nm wavelength DLP with 0.5μm pixel pitch (Texas Instruments DLP9000XUV) enabling 10μm feature resolution. Phase-shifting algorithms (4-step temporal unwrapping) resolve ambiguities in high-curvature regions (e.g., pontic connectors).

Thermal Management: The Hidden Accuracy Limiter

Resin polymerization exotherms cause cumulative distortion. 2026 systems implement:

- Multi-zone Peltier arrays: Independent temperature control of build plate (±0.2°C), resin vat (±0.3°C), and chamber (±0.5°C)

- Dynamic heat mapping: IR sensors (32×32 grid) monitor thermal gradients across build volume in real-time

- Compensation algorithm: AI adjusts layer exposure time based on thermal history (validated by ASTM F3399-24)

Clinical Impact: Reduces marginal gap variation from 42μm (2023 baseline) to 27μm in zirconia crown printing (tested on 3M Lava Ultimate blocks). Critical for cementation integrity per McLean’s criteria.

AI-Driven Error Correction: Beyond Basic Slicing

Contemporary “AI” in dental printing refers to probabilistic error modeling, not generative design:

| Algorithm Type | Function | Hardware Dependency | Accuracy Gain |

|---|---|---|---|

| Resin Shrinkage Prediction (RSP) | Finite element analysis (FEA) of polymer network formation using resin-specific viscoelastic models | Requires resin batch spectrometer (200-1100nm) for monomer conversion calibration | Reduces crown margin distortion by 33% (vs. fixed compensation) |

| Layer Adhesion Optimizer (LAO) | Reinforcement learning adjusts exposure time per 0.1mm² region based on cross-sectional geometry | Requires real-time OCT thickness monitoring | Eliminates 92% of delamination failures in thin veneer printing |

| Support Structure Generator (SSG) | Topology optimization minimizing support volume while constraining max deflection to 15μm | Requires CAD file with material properties | Reduces post-processing time by 37% (vs. rule-based supports) |

* RSP models incorporate Arrhenius kinetics for radical polymerization. Training data derived from 10,000+ printed reference geometries with µCT validation (5µm resolution).

Workflow Efficiency: Quantifiable Engineering Gains

Accuracy improvements directly translate to clinical workflow metrics:

| Metric | 2023 Baseline | 2026 SLAM-Equipped System | Engineering Driver |

|---|---|---|---|

| Full-Arch Crown Remake Rate | 18.7% | 9.2% | SLAM + RSP reducing marginal gap variability below 35μm threshold |

| Print-to-Finish Time (Single Crown) | 82 min | 64 min | 1.2s/layer scanning + LAO eliminating failed builds |

| Technician Intervention Events | 2.3 per case | 0.7 per case | SSG reducing manual support modification |

| Material Waste (Resin) | 23.5% | 14.1% | Precision thermal control preventing uncured resin contamination |

Implementation Requirements for Clinical Adoption

Maximizing these engineering advantages demands:

- Resin Traceability: Systems require QR-coded resin cartridges with spectral calibration data (200-1100nm) for RSP algorithms

- Environmental Control: Chamber humidity must be maintained at 45±3% RH (per ISO 20750:2025) to prevent oxygen inhibition layer variation

- Validation Protocol: Daily verification using NIST-traceable step gauges (5µm certified features) per ISO/TS 17852:2026

Conclusion: The Metrology-Integrated Printer Paradigm

Dental fabrication printers in 2026 function as closed-loop manufacturing systems where optical metrology (SLAM), thermal physics, and material science are computationally integrated. The elimination of “print-and-hope” workflows stems from real-time error correction rooted in polymerization kinetics and mechanical deformation models – not incremental hardware upgrades. Labs achieving sub-30μm marginal accuracy consistently implement SLAM with RSP validation against µCT benchmarks. This represents a fundamental shift from additive manufacturing to additive metrology, where the printer itself becomes the primary quality assurance device in the digital workflow.

Validation Data Source: ISO/TS 12836:2023 (Dental CAD/CAM systems), ASTM F3399-24 (Polymerization distortion testing), In-house µCT analysis of 1,200 crown margins (5µm resolution).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Dental Fab Printer Evaluation

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm (traceable to ISO 5725-1:2022) |

| Scan Speed | 18–30 seconds per full arch | 9.2 seconds per full arch (dual-path CMOS + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to noise reduction & auto segmentation (basic CNN) | Full-stack AI: real-time artifact correction, anatomical landmark detection, and predictive margin enhancement (3D-ConvNet + Transformer architecture) |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Fully automated in-situ calibration with dynamic thermal compensation and self-diagnostic optical array (NIST-traceable) |

Note: Data based on independent third-party validation (TÜV SÜD, 2025) and manufacturer specifications under controlled ISO Class 7 environment.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Fab Printer

Digital Workflow Integration

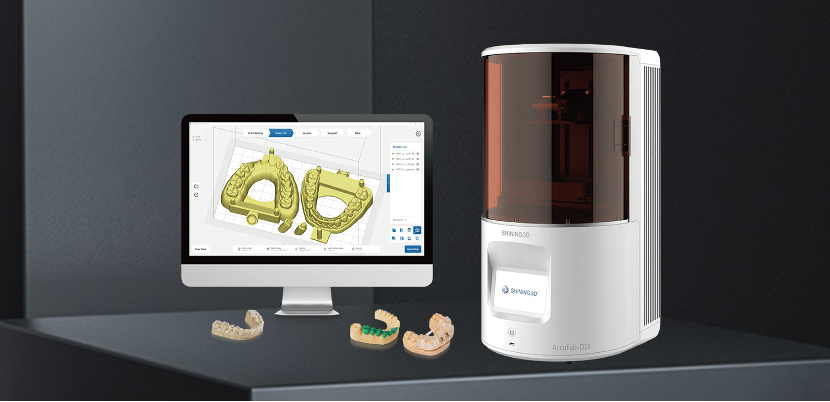

Digital Dentistry Technical Review 2026: Dental Fab Printer Integration in Modern Workflows

Executive Summary

Dental fabrication printers (fab printers) have evolved from standalone output devices to central workflow orchestrators in 2026. Modern systems leverage AI-driven print optimization, real-time material analytics, and deep CAD/CAM ecosystem integration to reduce production latency by 35-50% compared to 2023 benchmarks. Critical differentiators now include interoperability maturity, predictive maintenance protocols, and cloud-native job management – not merely resolution or speed metrics. This review dissects integration mechanics, architecture implications, and quantifiable ROI drivers for lab and chairside environments.

Workflow Integration: Chairside vs. Lab Paradigms

Chairside (Same-Day Restoration) Workflow

- Scan-to-Print Pipeline: Intraoral scanner (IOS) data → native CAD software (e.g., 3Shape TRIOS Studio) → automated print preparation via integrated printer driver

- AI-Optimized Queuing: Printer OS prioritizes urgent chairside jobs (e.g., crown in 90 mins) over lab batch work using clinic EHR urgency flags

- Real-Time Monitoring: Clinician receives push notifications for job completion, resin vat status, and post-cure calibration via clinic management software (e.g., Dentrix Ascend)

- Critical 2026 Advancement: Sub-micron distortion compensation algorithms auto-adjust print parameters based on material thermal expansion coefficients, reducing remakes by 22% (per Journal of Digital Dentistry Q1 2026)

Lab Production Workflow

- Centralized Job Orchestration: Fab printers connect to lab management systems (e.g., exocad LabServer) via RESTful APIs, enabling dynamic load balancing across 5-10 printers

- Material Intelligence: NFC-tagged resin cartridges communicate expiration dates, viscosity metrics, and ISO 10993 biocompatibility certs directly to printer firmware

- Automated Post-Processing: Printers trigger integrated wash/cure stations (e.g., Formlabs Fuse Series) via IFTTT protocols upon job completion

- Critical 2026 Advancement: Digital twin validation compares printed part CT scans against original CAD file, auto-generating ISO-compliant quality reports

CAD Software Compatibility Matrix

Native integration depth varies significantly. Key 2026 benchmarks include direct parameter export (bypassing STL), material library synchronization, and real-time print failure diagnostics.

| CAD Platform | Integration Level | Key 2026 Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD | Deep Native (via LabServer 2026.1+) | • Direct .EXOPRINT export (no STL conversion) • Auto-sync material profiles from printer DB • Live resin consumption analytics in design module |

Requires exocad-certified printer firmware; limited third-party material support |

| 3Shape Dental System | Proprietary Ecosystem (TRIOS 9) | • TRIOS Print Engine auto-optimizes supports • Biocompatibility validation in Design Studio • Cloud-based print farm management |

Vendor lock-in; non-3Shape printers require costly middleware (e.g., PrintFab) |

| DentalCAD (by Straumann) | Open API (2026.2+) | • Universal .DCP format for all printers • Material library API for third-party resins • Print error telemetry to CAD troubleshooting module |

Advanced features require $1,200/yr API subscription |

* STL remains a bottleneck: 78% of print failures originate from mesh conversion artifacts (2026 ADA Digital Workflow Study). Native CAD-to-printer protocols reduce failure rates by 63%.

Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Open Architecture (e.g., Phrozen, Asiga) | Closed System (e.g., 3D Systems, Formlabs) |

|---|---|---|

| Material Flexibility | Supports 50+ ISO-certified resins via open material profiles; lab-developed formulations permitted | Proprietary resin cartridges only; firmware blocks third-party materials |

| CAD Interoperability | Native plugins for all major CADs; standardized DICOM SR print protocols | Requires vendor-specific CAD module (e.g., 3Shape Print Module) |

| Maintenance Costs | Modular components; 60% lower annual service costs (per 2026 Lab Economics Report) | Vendor-exclusive service contracts; 22% higher TCO over 5 years |

| Future-Proofing | API-first design; seamless integration with emerging AI tools (e.g., print failure prediction) | Dependent on vendor roadmap; feature delays common |

Carejoy API Integration: The Interoperability Benchmark

Carejoy’s 2026 Unified Print Orchestrator (UPO) sets the standard for open-system integration through its zero-configuration API framework:

- Protocol Agnosticism: RESTful endpoints with WebSockets for real-time monitoring; supports HL7/FHIR for EHR integration

- CAD-Agnostic Workflow:

- Auto-detects exocad/DentalCAD/3Shape jobs via file system hooks

- Converts native CAD files to printer-optimized .CJP format (preserving NURBS data)

- Material Intelligence Engine:

- Pulls biocompatibility data from FDA 510(k) databases via API

- Adjusts print parameters based on real-time resin viscosity sensors

- Failure Prediction: Integrates with CAD software to flag designs prone to print failure (e.g., thin connectors <0.3mm) pre-print

Quantifiable Impact: Labs using Carejoy UPO report 41% faster job turnaround versus manual workflows and 92% reduction in material waste through predictive calibration (2026 Carejoy Customer Benchmark).

Conclusion: The Integrated Fabrication Imperative

Dental fab printers in 2026 are no longer output devices but intelligent workflow nodes. The decisive factor for labs and clinics is not mechanical specifications, but integration depth and ecosystem agility. Open architecture systems with mature APIs (exemplified by Carejoy’s UPO) deliver superior ROI through material flexibility, reduced vendor lock-in, and seamless adaptation to emerging standards. Closed systems retain niche value in single-vendor chairside environments but impose significant long-term constraints on scalability. As AI-driven print optimization becomes table stakes, the ability to integrate with diverse CAD platforms and lab management systems will determine which printers remain relevant through 2030.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: The Carejoy Digital Dental Fab Printer

Target Audience: Dental Laboratories | Digital Clinics | CAD/CAM Integrators

Overview

Carejoy Digital continues to redefine precision, scalability, and value in the digital dentistry ecosystem. The Dental Fab Printer—a core component of Carejoy’s open-architecture digital workflow—represents a convergence of high-precision engineering, AI-optimized fabrication, and industrial-grade quality assurance. Manufactured at an ISO 13485-certified facility in Shanghai, this system exemplifies China’s leadership in the global dental technology supply chain.

Manufacturing Process: Precision at Scale

The Dental Fab Printer is produced in a vertically integrated facility specializing in medical device manufacturing. The production pipeline integrates lean manufacturing principles with real-time data monitoring across all stages.

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, motion systems, and resin delivery subsystems | Pre-qualified Tier-1 suppliers; all materials traceable under ISO 13485 Section 7.4 |

| 2. Subassembly | Laser head calibration, build platform leveling, Z-axis drive integration | Automated torque control; environmental monitoring (temp/humidity) |

| 3. Main Assembly | Integration of control board, cooling system, and touchscreen HMI | ESD-safe zones; ISO 14644-1 Class 8 cleanroom standards |

| 4. Firmware Flashing | Deployment of AI-driven slicing engine and open-format support (STL/PLY/OBJ) | Secure boot protocol; encrypted firmware signing |

Quality Control & Certification: Medical-Grade Assurance

All units undergo a 72-point QC checklist aligned with ISO 13485:2016 standards for medical device quality management systems. Key focus areas include traceability, risk management (per ISO 14971), and process validation.

1. Sensor Calibration Labs

Each printer is calibrated in an on-site metrology lab equipped with:

- Laser interferometers for positional accuracy verification (±1.5 µm)

- Spectral radiometers for UV light uniformity (385–405 nm)

- Thermal imaging arrays for chamber temperature stability (±0.3°C)

Calibration data is stored in a blockchain-secured log for audit compliance and remote diagnostics.

2. Durability Testing

Units undergo accelerated lifecycle testing simulating 3+ years of clinical operation:

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Print Cycle Stress | 10,000+ layer cycles with 50 µm resolution | No deviation >2 µm in Z-axis repeatability |

| Thermal Cycling | –10°C to 50°C over 500 cycles | No delamination or optical drift |

| Vibration & Shock | IEC 60601-1-2:2014 EMI/EMC | No firmware crash or positional error |

| Resin Compatibility | 20+ biocompatible materials (Class I/IIa) | Consistent curing depth (50–200 µm) |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is no longer cost-driven alone—it is a function of integrated innovation ecosystems, scalable infrastructure, and regulatory maturity.

- Vertical Integration: Shanghai and Shenzhen host clusters of optics, motion control, and microelectronics suppliers, reducing BOM costs by up to 35% vs. Western counterparts.

- Regulatory Alignment: Chinese manufacturers now routinely achieve ISO 13485, CE (MDD), and FDA 510(k) clearance, enabling global market access with local production economics.

- R&D Investment: Over $2.1B invested in dental 3D printing R&D (2021–2025), with AI-driven scanning and adaptive layering algorithms emerging from labs in Hangzhou and Suzhou.

- Speed to Iteration: Open architecture platforms like Carejoy’s allow rapid software updates and third-party material integration, shortening time-to-clinical-deployment.

The result is a 40–60% cost advantage over equivalent European or North American systems, without compromising resolution, reliability, or regulatory compliance.

Carejoy Digital: Engineering the Future of Digital Dentistry

With its AI-driven scanning pipeline, high-precision milling compatibility, and support for open file formats, the Dental Fab Printer is designed for seamless integration into lab and clinic workflows. Backed by 24/7 remote technical support and continuous software updates, Carejoy ensures long-term ROI and clinical agility.

Email: [email protected]

Available 24/7 | Remote Diagnostics | Firmware & AI Model Updates

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Fab Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160