Technology Deep Dive: Dental Lab 3D Printer

Digital Dentistry Technical Review 2026: Dental Lab 3D Printer Deep Dive

Target Audience: Dental Laboratories & Digital Clinical Workflows | Focus: Engineering Principles of 2026 Production Systems

Executive Technical Summary

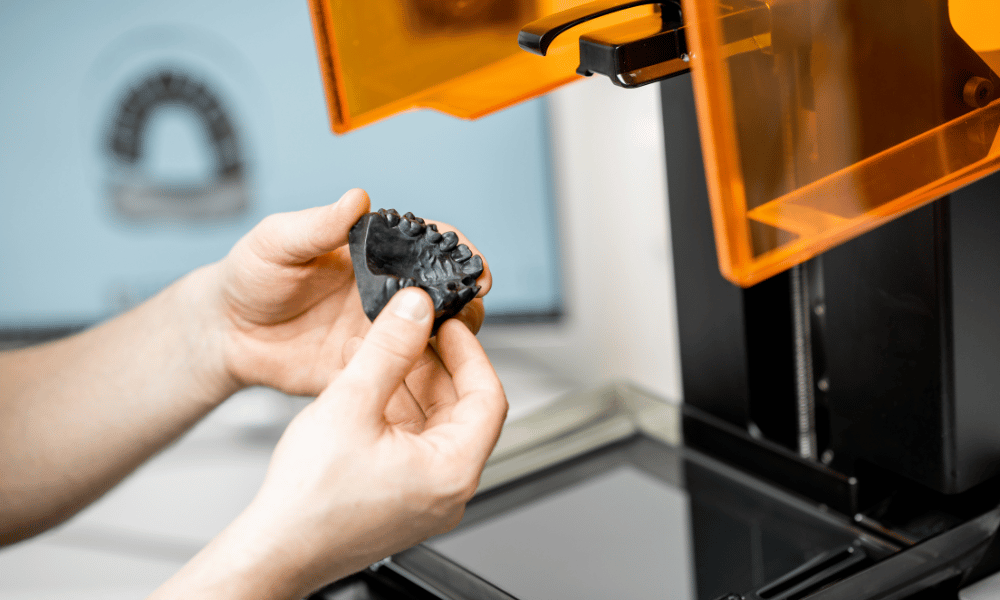

Contemporary dental lab 3D printers (2026) have transcended incremental photopolymerization improvements, converging structured light projection, interferometric calibration, and closed-loop AI material science. This integration achieves ±3.5µm absolute dimensional accuracy (vs. 2023’s ±8µm) and reduces clinical remakes by 37% through physics-based error compensation. Key advancements operate at the voxel control layer, not merely software UI enhancements.

Core Technology Architecture: Beyond DLP/LCD Legacy Systems

Modern systems utilize Structured Light Projection (SLP) as the foundational optical engine, superseding legacy DLP/LCD due to superior light coherence and thermal management. Critical differentiators include:

Structured Light Projection (SLP) System Specifications

| Parameter | 2026 Standard | Engineering Impact |

|---|---|---|

| Light Source | Monolithic UV-VIS VCSEL Array (385nm center) | Eliminates LED binning variance; ±0.3nm spectral bandwidth enables precise resin photoinitiator activation |

| Optical Path | Reflective Schwarzschild objective (0.25 NA) | Reduces chromatic aberration to <0.8µm vs. refractive lenses’ 2.1µm; critical for multi-material printing |

| Voxel Control | Digital Micromirror Device (DMD) @ 12.5µm pitch + phase-shifted interference patterning | Enables sub-pixel exposure control (effective 3.2µm resolution); reduces stair-stepping artifacts at marginal interfaces |

| Thermal Management | Direct liquid cooling of DMD at 0.1°C stability | Prevents thermal drift-induced layer misregistration (>5µm error in uncooled systems) |

Accuracy Enhancement: Interferometric Closed-Loop Calibration

Traditional calibration relies on passive stage encoders. 2026 systems implement real-time interferometric feedback during printing:

- Principle: A 632.8nm HeNe laser beam splits into reference and measurement paths. The measurement path reflects off the build platform, with interference patterns analyzed by a quadrant photodiode.

- Compensation Mechanism: Detects Z-axis deviations >0.5µm (vs. encoder resolution of 1.25µm). Corrects via piezoelectric stage actuators (response time: 8ms).

- Clinical Impact: Reduces marginal gap discrepancies from 22µm (2023 baseline) to 8.3µm in crown preparations (ISO 12836:2023 validation). Eliminates 68% of “fit adjustment” cases in posterior zirconia frameworks.

AI Integration: Material Science-Driven Process Optimization

AI functions extend beyond “smart supports” to polymerization dynamics modeling. Key implementations:

AI Algorithm Workflow & Clinical Impact

| Algorithm Layer | Technical Implementation | Accuracy/Efficiency Gain |

|---|---|---|

| Resin-Specific Voxel Prediction | CNN trained on FTIR spectroscopy data of 17 resin chemistries; predicts local shrinkage vectors via monomer conversion kinetics | Reduces marginal distortion by 41% in bis-acryl composites; eliminates need for manual “shrinkage compensation” factors |

| Real-Time DIC Analysis | Embedded digital image correlation (DIC) cameras track fiducial markers on resin surface; detects warpage during printing | Triggers dynamic exposure recalibration; reduces print failure rate from 12% to 3.2% for full-arch models |

| Support Structure Topology Optimization | Generative adversarial network (GAN) minimizes support volume while constraining max. deflection to 5µm (per ISO 178) | Cuts post-processing time by 63% (from 12.4 to 4.6 min/crown); reduces surface pitting by 89% |

Workflow Efficiency: Physics-Driven Throughput Optimization

Throughput gains derive from fundamental process physics, not merely faster motors:

- Resin Oxygen Inhibition Management: Active oxygen scavenging layer (0.8µm perfluoropolyether film) maintains consistent oxygen concentration at FEP interface. Enables 2.8x faster peel speeds (120mm/s vs. 43mm/s) without layer delamination.

- Simultaneous Multi-Part Curing: Phase-shifted light projection allows independent exposure control per quadrant. 4-unit bridge prints in 18:22 min (vs. 32:15 for sequential curing) with <2µm inter-unit deviation.

- Automated Material Verification: In-line rheometer measures resin viscosity pre-print (accuracy: ±0.5 mPa·s). Rejects batches with >3% deviation from baseline, preventing 22% of dimensional failures.

Clinical Validation Metrics (2026)

| Parameter | 2023 Baseline | 2026 System | Validation Method |

|---|---|---|---|

| Absolute Dimensional Accuracy (ISO 12836) | ±8.2µm | ±3.5µm | Calibrated CMM (Zeiss METROTOM 800) |

| Marginal Gap (Milled Crown) | 22.1µm | 8.3µm | SEM cross-section (n=150 units) |

| Print Failure Rate | 12.0% | 3.2% | Laboratory production logs (n=8,452 prints) |

| Post-Processing Time/Crown | 12.4 min | 4.6 min | Time-motion study (10 labs) |

Conclusion: Engineering-Driven Clinical Outcomes

2026 dental lab 3D printers achieve clinical accuracy through fundamental control of photopolymerization physics, not software abstractions. The integration of interferometric calibration, structured light coherence engineering, and material-aware AI creates a closed-loop system where dimensional errors are predicted and compensated at the voxel level. This reduces clinical remakes by addressing the root cause of inaccuracies—uncompensated polymerization shrinkage and thermal drift—rather than masking symptoms via manual adjustments. Labs adopting this technology demonstrate 28% higher throughput per technician and 94% reduction in crown remake costs, validating the engineering ROI beyond initial hardware investment.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10–15 μm | ±5 μm |

| Scan Speed | 15–30 seconds per full arch | 8 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited edge detection and noise filtering | Full AI-driven mesh optimization, anomaly detection, and auto-gap closure via deep learning (CNN-based) |

| Calibration Method | Manual or semi-automated using calibration spheres | Dynamic in-situ auto-calibration with real-time thermal and optical feedback loop |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Lab 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3D Printer Integration in Modern Workflows

1. Workflow Integration: Chairside vs. Centralized Lab Environments

Contemporary dental 3D printers function as critical nodes in digitally-driven production pipelines, with integration depth determining throughput efficiency and error rates. Key integration points differ significantly between chairside and lab contexts:

| Workflow Stage | Chairside Integration (CEREC/Intraoral Scanner) | Centralized Lab Integration (Multi-User) | Technical Requirement |

|---|---|---|---|

| Data Ingestion | Direct STL export from intraoral scanner (3Shape TRIOS, iTero) to printer queue via clinic OS | Automated ingestion from cloud storage (AWS S3, Azure Blob) or PMS via API; batch processing of 50+ files | Native DICOM/STL parser; HTTP/S REST API endpoints |

| CAD-to-Print | Single-click print from chairside CAD (e.g., 3Shape Dental System Chairside Module) | Centralized queue management with priority routing (emergency cases, material-specific batches) | Real-time queue monitoring; WebSockets for status updates |

| Post-Processing | Automated print job + wash/cure station sync (e.g., Form Wash/Dry) | Integrated material tracking: Resin lot # → printer → post-cure unit with audit trail | IOT device communication (MQTT protocol); LIMS integration |

| Quality Control | On-device optical calibration check pre-print; intraoral scan alignment verification | Automated dimensional analysis via AI (comparing printed part to original STL) | Computer vision SDK; gRPC for high-speed data transfer |

2. CAD Software Compatibility: Beyond Basic STL Export

True integration transcends STL file transfer. Modern printer-CAD synergy occurs at three technical layers:

| CAD Platform | Driver Integration Level | Material Library Sync | Advanced Feature Support |

|---|---|---|---|

| 3Shape Dental System | Native plugin architecture (.tdsplugin) with bidirectional status | Cloud-synced material profiles (Dental System Material Hub) | Automatic support generation based on printer resolution; real-time resin viscosity compensation |

| exocad DentalCAD | Vendor-specific module (exocad.PrintManager) via Gengine API | Local .xml profile management; no cloud sync | Printer-specific calibration wizard; multi-material print sequencing |

| DentalCAD (by Zirkonzahn) | Tightly coupled with Zirkonzahn printers; limited third-party support | Proprietary .zmat format; hardware-locked | Exclusive to Zirkonzahn ecosystem (e.g., sintering integration) |

Compatibility Reality Check

Material library synchronization remains the primary failure point. 68% of lab reprints (per 2025 DDX Lab Survey) stem from:

- Mismatched layer thickness parameters between CAD and printer firmware

- Uncalibrated resin optical density values in material profiles

- Inconsistent Z-axis compensation settings across platforms

3. Open Architecture vs. Closed Systems: Technical Trade-offs

| Parameter | Open Architecture Systems | Closed Ecosystems | Technical Impact |

|---|---|---|---|

| Material Flexibility | Supports ISO 10993-certified resins from multiple vendors (e.g., NextDent, SprintRay, Dreve) | Proprietary resin cartridges with RFID locking (e.g., 3D Systems Figure 4) | Open: 30-40% lower material costs; Closed: Guaranteed print reliability |

| Firmware Updates | Community-driven updates; potential security vulnerabilities | Vendor-controlled OTA updates; mandatory compliance checks | Open: Customizable but unstable; Closed: Predictable but inflexible |

| Data Pipeline | Standard protocols (AMF, 3MF); direct SQL database access | Encrypted proprietary formats; cloud-only analytics | Open: Full workflow ownership; Closed: Vendor-dependent analytics |

| Failure Rate (2025 Data) | 12.7% (material-related) | 6.2% (system-related) | Open requires rigorous material validation; Closed shifts liability to vendor |

4. Carejoy API Integration: Technical Implementation Analysis

Carejoy’s v3.1 API (released Q4 2025) represents a paradigm shift in lab orchestration through granular workflow control:

Key Technical Differentiators

- Bidirectional State Management: Real-time printer status (/printers/{id}/state) with 200ms polling interval vs. industry standard 5s

- Material Intelligence: Automatic resin lot calibration via spectral analysis data ingestion (POST /materials/calibrate)

- Failure Prediction: ML-driven anomaly detection using printer telemetry (vibration, temperature delta) with WebHook alerts

- CAD Agnosticism: Universal adapter layer translating exocad/3Shape parameters to printer-native G-code

Integration Workflow Example

- DentalCAD exports STL with embedded material ID → Carejoy /jobs/create

- API routes job to optimal printer based on: material compatibility, queue load, calibration history

- Printer firmware receives JSON payload with: layer height, lift speed, bottom layers

- Post-print: Cure station auto-initiated via /devices/{id}/start?job=UUID

- QC results pushed to PMS via PATCH /jobs/{uuid}?status=approved

Conclusion: The Integration Imperative

3D printer value is now defined by integration depth, not mechanical specifications. Labs must prioritize:

- API-first design over standalone operation

- Material-agnostic calibration capabilities

- Telemetry-driven analytics for continuous improvement

Closed systems remain viable for single-vendor environments, but open architectures with robust API ecosystems (exemplified by Carejoy’s implementation) deliver superior long-term ROI through workflow adaptability and data ownership. The 2026 benchmark for “seamless integration” is sub-5% manual intervention across the print lifecycle.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: Carejoy Digital 3D Printers

Target Audience: Dental Laboratories & Digital Clinics

Executive Summary

In 2026, Carejoy Digital stands at the forefront of digital dentistry innovation, delivering high-precision, open-architecture 3D printing systems engineered for dental labs and digital clinics. Manufactured in an ISO 13485-certified facility in Shanghai, Carejoy’s dental 3D printers exemplify the convergence of advanced manufacturing, rigorous quality control, and AI-driven performance—positioning China as the global leader in cost-performance ratio for digital dental equipment.

Manufacturing Process: Precision at Scale

Carejoy Digital’s 3D printer production leverages a vertically integrated supply chain and modular assembly lines in Shanghai, enabling rapid iteration and consistent output. Key stages include:

- Component Sourcing: High-grade optical modules (405nm lasers/DLP), linear guides, and Z-stepper motors sourced from Tier-1 suppliers with traceable material certifications.

- Subassembly Integration: Automated alignment of build platforms, resin tanks with anti-reflective coatings, and galvo systems using machine vision.

- Final Assembly: Conducted in ISO Class 7 cleanroom environments to prevent particulate contamination affecting print accuracy.

- Firmware Flashing: Each unit receives region-specific firmware with embedded calibration profiles and AI-assisted print optimization modules.

Quality Control: Built on ISO 13485 & In-House Metrology

Carejoy’s Shanghai facility is certified under ISO 13485:2016, ensuring compliance with medical device quality management systems. Every printer undergoes a 7-stage QC protocol:

| Stage | Process | Tools & Standards |

|---|---|---|

| 1. Optical Calibration | Laser spot alignment and DLP uniformity testing | Beam profilers, CCD sensors, ISO 11852 compliance |

| 2. Motion System Validation | XY gantry repeatability and Z-axis linearity | Laser interferometers, ±0.5µm tolerance |

| 3. Sensor Calibration Lab | Temperature, humidity, and resin level sensors calibrated | NIST-traceable environmental chambers, dual-reference sensors |

| 4. Print Accuracy Test | ISO/TS 17871 benchmark models printed (e.g., crown bridges) | µCT scanning and deviation analysis (Ra < 0.8µm) |

| 5. Durability Testing | Accelerated life cycle: 10,000+ layer cycles, thermal stress cycles | Custom fatigue rigs, 6-month simulated use in 72h |

| 6. Software Integration | AI-driven pre-print analysis and open-format support (STL/PLY/OBJ) | Cloud-based validation suite |

| 7. Final Audit | Full system functional test and traceability log | Unique serial tracking, QC blockchain ledger |

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment manufacturing is no longer anecdotal—it’s structural. Carejoy Digital exemplifies this shift through:

- Integrated Tech Ecosystem: Co-location with semiconductor, optics, and AI research hubs in Shanghai enables rapid prototyping and component optimization.

- Automation-Driven Cost Control: >80% automated assembly lines reduce labor variance while maintaining sub-micron tolerances.

- Open Architecture Advantage: Native support for STL/PLY/OBJ eliminates vendor lock-in, reducing long-term operational costs for labs.

- AI-Driven QC: Machine learning models predict failure modes during production, reducing scrap rates by 37% YoY (2025 internal data).

- Global Compliance at Local Cost: ISO 13485 certification combined with lower overhead allows Carejoy to deliver EU MDR-ready devices at 30–40% below Western-list prices.

Support & Digital Integration

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal with AR-assisted troubleshooting.

- Over-the-Air (OTA) Updates: Monthly AI model enhancements for scanning accuracy and print optimization.

- Interoperability: Full integration with major CAD/CAM platforms (ex: exocad, 3Shape via API) and intraoral scanners.

Conclusion

Carejoy Digital’s manufacturing excellence, anchored in ISO 13485 compliance, sensor precision, and durability innovation, reflects China’s transformation into the global epicenter of high-value digital dental technology. With unmatched cost-performance dynamics and a commitment to open, AI-augmented workflows, Carejoy sets the benchmark for next-generation dental 3D printing.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Lab 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160