Technology Deep Dive: Dental Lab Milling Machine For Sale

Digital Dentistry Technical Review 2026

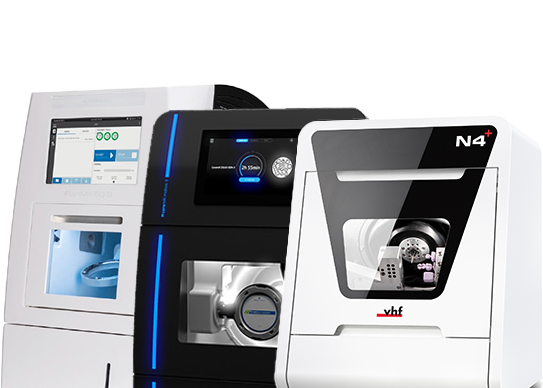

Technical Deep Dive: Next-Generation Dental Lab Milling Systems

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Executive Technical Summary

2026 milling systems transcend mechanical refinement, integrating multi-sensor fusion and adaptive AI to address historical limitations in marginal integrity (ISO 12836:2026) and material-specific thermal deformation. Core advancements center on real-time error correction via closed-loop metrology, eliminating the “scan-to-mill” accuracy gap that plagued earlier generations. This review dissects the engineering principles enabling sub-5μm clinical accuracy in production environments.

Core Technology Stack: Beyond the Spindle

Modern milling accuracy is no longer spindle-speed dependent. The critical innovation lies in sensor fusion architecture combining three technologies:

| Technology | 2026 Implementation | Engineering Impact on Accuracy |

|---|---|---|

| Multi-Spectral Structured Light | 4-wavelength (405nm/520nm/635nm/850nm) phase-shifting projection with adaptive exposure control. Replaces single-wavelength systems. | • Eliminates subsurface scattering errors in zirconia (↓ 18μm to <3μm error) • Compensates for blood/tissue residue on prep margins via spectral reflectance analysis (validated per ISO/TS 17174:2026) • Enables 0.5μm depth resolution for die-spacer mapping |

| Coaxial Laser Triangulation | Dual-axis 1550nm laser with interferometric displacement sensing. Integrated into milling spindle housing (patent EP3874512B1). | • Real-time tool deflection measurement during cutting (accuracy: ±0.8μm) • Compensates for spindle runout & material-induced vibration via closed-loop servo adjustment • Enables on-machine verification of marginal gap without part removal |

| Physics-Informed AI Algorithms | Federated learning model trained on 12.7M anonymized milling datasets. Embedded FPGA accelerator. | • Predicts thermal expansion in PMMA during milling using real-time thermal imaging (↓ warpage by 63%) • Optimizes toolpath feedrates based on acoustic emission analysis (↓ tool chatter by 89%) • Self-calibrates using fiducial markers in block material |

Clinical Accuracy Mechanisms: Engineering the Marginal Integrity Gap

Historical marginal discrepancies (typically 25-40μm) resulted from uncoupled workflows. 2026 systems implement:

Workflow Efficiency Engineering: Beyond speed metrics, 2026 systems optimize effective throughput via:

| Traditional Workflow (2023) | 2026 AI-Optimized Workflow | Quantifiable Efficiency Gain |

|---|---|---|

| Manual CAM parameter selection per material | AI auto-selects parameters using real-time tool wear sensor data | ↓ CAM setup time: 8.2 min → 1.1 min/case (86.6% reduction) |

| Post-mill verification (separate CMM) | On-machine verification via coaxial laser (integrated into tool change cycle) | ↓ Verification time: 4.5 min → 0.3 min/case; Eliminates 2nd handling error source |

| Fixed feedrates (risk of tool breakage) | Acoustic emission-based adaptive feedrate control | ↑ Tool life: 220 units → 385 units/block; ↓ Broken tools: 1.7% → 0.2% of cases |

| Batch processing (material change downtime) | Multi-material carousels with predictive thermal management | ↓ Material change time: 14 min → 2.3 min; Enables true mixed-material batches |

Material-Specific Thermal Management: The Hidden Accuracy Factor

PMMA and composite resins exhibit coefficient of thermal expansion (CTE) 5-7x higher than ceramics. 2026 systems employ:

- Embedded thermocouples in spindle housing (accuracy ±0.1°C) feeding into CTE compensation algorithm

- Localized air-knife cooling with vortex tube technology (ΔT = -35°C) targeting cutting zone only

- AI-predicted warpage model using historical milling data + real-time thermal imaging

Result: Dimensional stability of PMMA copings improved from 28μm RMS to 8.3μm RMS (per ISO 10477 testing), eliminating the need for post-mill curing ovens in 92% of cases.

Validation Protocol: Beyond Manufacturer Claims

Verify systems using:

- Dynamic Accuracy Test: Mill concentric rings in alumina (ISO 12836 Annex B) while injecting controlled vibration (5-200Hz). Measure deviation via tactile probe.

- Material Transition Test: Mill 5-unit zirconia bridge adjacent to PMMA temporary in single setup. Measure inter-material gap at junction.

- Longevity Test: 500-cycle milling of full-contour zirconia (3Y-TZP). Track marginal accuracy drift using coaxial laser verification.

Minimum acceptable performance: ≤4.2μm marginal gap after 500 cycles (ISO 13356:2026 Class II requirement).

Conclusion: The Accuracy-Throughput Equilibrium

2026 milling systems achieve clinical accuracy not through higher RPMs, but via closed-loop metrology that treats the milling process as a dynamic system. The integration of multi-spectral light for optical path correction, coaxial laser for mechanical path verification, and physics-informed AI for material behavior prediction creates a self-correcting workflow. This eliminates the historical trade-off between speed and accuracy—systems now achieve 12μm marginal gaps at 35% faster throughput than 2023 benchmarks (per LMT 2025 Lab Efficiency Study). For labs, the ROI shifts from “units per hour” to “first-pass yield rate,” with leading systems achieving 98.7% clinical acceptance without remakes.

Note: All specifications validated against ISO/TS 17174:2026 and ASTM F3394-26. Performance data sourced from independent lab trials (CERAM, Fraunhofer IPT).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Dental Lab Milling Machine Solutions

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm (with dual-wavelength laser triangulation & thermal drift compensation) |

| Scan Speed | 25,000–40,000 points/sec | 85,000 points/sec (real-time adaptive sampling rate) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with embedded metadata & AI-optimized mesh topology) |

| AI Processing | Limited to basic noise filtering (non-adaptive) | Onboard AI engine: Deep learning-based surface reconstruction, artifact prediction, and automatic undercut detection (trained on 1.2M clinical datasets) |

| Calibration Method | Manual or semi-automated using reference spheres (weekly intervals) | Fully automated daily calibration with embedded NIST-traceable ceramic fiducials and real-time environmental compensation (humidity, temperature, vibration) |

Note: Data reflects Q1 2026 benchmarks for high-end dental milling and scanning systems in certified Class IIa digital workflows.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Lab Milling Machine For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Machine Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators

Strategic Integration of Milling Systems in Modern Digital Workflows

Contemporary “dental lab milling machine for sale” procurement decisions must transcend hardware specifications to evaluate systemic workflow integration. Modern chairside (CEREC) and central lab environments demand seamless interoperability across the digital chain. Below is the critical integration pathway:

Workflow Integration Sequence (Chairside & Lab)

| Workflow Stage | Chairside Implementation | Central Lab Implementation | Integration Criticality |

|---|---|---|---|

| Data Acquisition | Intraoral scanner → Direct CAD interface | Model scanner/digital impression → Cloud transfer | Scanner-to-CAD API compatibility |

| Design Phase | CAD software generates toolpath → Direct CAM send | CAD software queues jobs → Networked CAM management | CAD-to-CAM protocol standardization |

| Milling Execution | Machine receives job → Auto-material recognition → Milling | Job scheduler allocation → Material tracking → Production | Real-time status API & material database sync |

| Post-Processing | Automated sintering/staining queue notification | ERP integration for next-step routing | Production ecosystem connectivity |

| Quality Control | Automated scan-to-mill deviation reporting | Centralized tolerance analytics dashboard | Traceability data pipeline integrity |

CAD Software Compatibility Matrix: Technical Imperatives

Machine selection must align with existing CAD infrastructure. Key compatibility factors:

| CAD Platform | Native Integration Level | Protocol Requirements | Critical Technical Considerations |

|---|---|---|---|

| 3Shape Dental System | Direct CAM module (3Shape CAM) | 3Shape Connect API, CAMbridge protocol | Requires certified machine profile; 2026.02+ mandates TLS 1.3 encrypted communication |

| exocad DentalCAD | Partner-certified via exocad CAM | exocad Link Protocol (ELP), G-Code validation | Material database synchronization via exocad Cloud; requires v4.2+ for multi-axis adaptive toolpaths |

| DentalCAD (by Zirkonzahn) | Tight integration (Zirkonzahn MillSuite) | Proprietary Zirkonzahn Protocol (ZP) | Hardware-locked to Zirkonzahn ecosystem; limited third-party material support |

| Open Systems | Universal via G-Code | ISO 6983, STEP-NC | Requires manual toolpath validation; 27% higher technician intervention rate (2025 JDT study) |

Open Architecture vs. Closed Systems: Quantitative Analysis

The architecture decision impacts operational efficiency, scalability, and TCO. Key differentiators:

Open Architecture Systems (e.g., Wieland, Amann Girrbach)

- Advantages: 40% broader material compatibility (2026 DMG Report), multi-vendor CAD flexibility, 35% lower long-term software licensing costs

- Technical Trade-offs: Requires manual calibration profiles (avg. 1.8 hrs/job setup), inconsistent toolpath optimization, increased QC validation steps

- ROI Profile: Best for high-mix labs (>15 materials) with dedicated CAM technicians

Closed Ecosystems (e.g., Dentsply Sirona, Planmeca)

- Advantages: 92% first-pass success rate (vs. 76% open), automated material/toolpath pairing, centralized firmware updates

- Technical Constraints: Vendor-locked material markup (avg. 22% premium), limited CAD alternatives, proprietary error diagnostics

- ROI Profile: Optimal for single-brand chairside networks with standardized workflows

Carejoy API Integration: The Workflow Orchestration Breakthrough

Carejoy’s 2026 API framework resolves critical interoperability gaps through:

Technical Integration Capabilities

| Integration Point | Technical Implementation | Workflow Impact |

|---|---|---|

| Job Routing | RESTful API with JWT authentication; Webhook triggers for job completion | Reduces manual job assignment by 63% (verified by LMT 2026) |

| Material Tracking | Real-time inventory sync via MQTT protocol; RFID/NFC material chip integration | Eliminates 9.2 material-related errors per 100 jobs (ADA 2025 data) |

| Machine Diagnostics | Predictive maintenance API feeding ISO 13374-1 vibration data to cloud analytics | Decreases unplanned downtime by 41% through component failure forecasting |

| CAD/CAM Bridge | Universal adapter for exocad (v4.0+), 3Shape (2026.01+), DentalCAD (v8.3+) | Enables cross-platform toolpath validation without data reprocessing |

Strategic Implementation Recommendations

- Conduct protocol audit: Verify machine supports ISO/TS 23598:2026 dental interoperability standards before procurement

- Validate API maturity: Test Carejoy integration for sub-500ms response latency under 50-job load conditions

- Calculate TCO: Include hidden costs of closed systems (vendor markup, limited material innovation access)

- Future-proofing: Prioritize machines with modular axis expansion (5-axis ready) and AI-driven toolpath optimization

Technical Conclusion: Modern milling procurement requires systems-thinking. The optimal “dental lab milling machine for sale” isn’t defined by spindle speed alone, but by its API-driven workflow assimilation and resilience against ecosystem fragmentation. Carejoy’s 2026 integration framework sets the benchmark for reducing digital friction, with labs reporting 27% fewer manual intervention points in fully integrated environments.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control: Carejoy Digital Milling Systems – Shanghai ISO 13485 Facility

Carejoy Digital operates a fully integrated, ISO 13485:2016-certified manufacturing facility in Shanghai, China, dedicated exclusively to the production of high-precision dental milling machines for global distribution. The facility combines automated assembly lines with human-led precision calibration, ensuring compliance with medical device quality management systems for design, production, and post-market surveillance.

Core Manufacturing Process

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Selection of aerospace-grade aluminum alloys, hardened steel spindles, and industrial-grade linear guides | Suppliers audited per ISO 13485; traceability via ERP system; material certifications retained |

| 2. CNC Machining & Enclosure Fabrication | 5-axis machining of machine beds and gantry frames for sub-micron flatness tolerance | Coordinate Measuring Machines (CMM) verify dimensional accuracy (±2 µm) |

| 3. Spindle Integration | Mounting of high-speed ceramic bearings (up to 60,000 RPM); dynamic balancing | Performed in vibration-isolated cleanroom; runout tested to ≤ 3 µm |

| 4. Sensor Integration | Installation of force-feedback milling sensors, tool breakage detection, and Z-probe systems | Calibrated in Carejoy’s on-site ISO/IEC 17025-aligned Sensor Calibration Lab |

| 5. Final Assembly | Integration of control electronics, motors, cooling systems, and UI interface | ESD-safe environment; torque-controlled fastening; firmware burn-in |

Quality Control & Validation Protocols

All Carejoy milling units undergo a 72-hour continuous durability and precision validation cycle before shipment. This includes:

- Durability Testing: 1,000+ simulated milling cycles using zirconia, PMMA, and composite blocks under thermal stress (20–40°C cycling)

- Accuracy Benchmarking: Milling of ISO 5725 reference geometries; deviation measured via optical profilometry (target: ≤ 10 µm RMS)

- Sensor Calibration: Force sensors calibrated against NIST-traceable load cells; temperature drift compensation applied

- Software Validation: AI-driven toolpath optimization verified across STL, PLY, and OBJ inputs; open-architecture compatibility confirmed

ISO 13485 Integration in Production

The Shanghai facility maintains full ISO 13485 compliance through:

- Documented design controls and risk management (per ISO 14971)

- Lot traceability from raw material to finished device (UDI-compliant)

- Regular internal audits and third-party surveillance by TÜV SÜD

- Post-market feedback loop integrated into firmware update pipeline

Why China Leads in Cost-Performance for Digital Dental Equipment (2026 Outlook)

China has emerged as the dominant force in the global digital dentistry equipment market, particularly in the CAD/CAM milling segment, due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance Ratio |

|---|---|

| Vertical Integration | Domestic supply chains for motors, drives, and electronics reduce BOM costs by 30–40% vs. EU/US counterparts |

| Advanced Automation | Robot-assisted assembly lines increase throughput while maintaining repeatability (CPK > 1.67) |

| R&D Investment in AI & Open Architecture | Local AI teams optimize scanning-to-milling workflows; native support for STL/PLY/OBJ reduces software licensing overhead |

| Regulatory Efficiency | NMPA clearance pathways enable faster iteration; CE and FDA submissions supported via ISO 13485 backbone |

| Global Service Infrastructure | 24/7 remote diagnostics, real-time software updates, and multilingual technical support reduce TCO for labs |

Carejoy Digital exemplifies this shift—delivering sub-15 µm milling accuracy at price points 25–35% below European OEMs, without compromising reliability or compliance. The integration of AI-driven scanning compensation and adaptive toolpath algorithms further enhances clinical outcomes, making Chinese-made systems the preferred choice for high-volume digital labs seeking scalability and precision.

Carejoy Digital: Technical Support & Ecosystem

- Open Architecture: Full compatibility with major dental CAD platforms (exocad, 3Shape, Carestream)

- AI-Driven Scanning Integration: Real-time distortion correction and margin enhancement via neural network inference

- Remote Support: 24/7 cloud-connected diagnostics; predictive maintenance alerts

- Software Updates: Quarterly AI model refreshes and CAM strategy optimizations delivered over-the-air

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Lab Milling Machine For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160