Technology Deep Dive: Dental Laboratory Scanner

Digital Dentistry Technical Review 2026

Technical Deep Dive: Dental Laboratory Scanners

Target Audience: Dental Laboratory Technicians, CAD/CAM Department Managers, Digital Workflow Engineers

Executive Summary: Beyond Resolution Metrics

Modern dental laboratory scanners (2026) have evolved from passive capture devices to active metrology systems integrating multi-spectral illumination, real-time computational optics, and embedded AI-driven surface reconstruction. The primary engineering challenge addressed is the sub-micron uncertainty envelope required for passive fit of multi-unit restorations, particularly with zirconia frameworks and thin veneers. This review dissects the core technologies enabling ≤ 3.5µm RMS deviation (ISO 12836:2023 Class A) under production conditions, with quantifiable impact on remake rates and throughput.

Core Technology Analysis: Engineering Principles in Practice

1. Structured Light Evolution: Multi-Spectral Fringe Projection

Modern systems (e.g., Sirona inEos X, 3Shape TRIOS Lab System) utilize multi-wavelength phase-shifting beyond traditional blue/white light:

- Spectral Bands: Simultaneous projection at 450nm (high-resolution edge detection), 525nm (optimal for wet gypsum), and 635nm (penetration through thin saliva films)

- Dynamic Fringe Adaptation: Real-time modulation of fringe frequency based on surface gradient (dZ/dx) using FPGA-accelerated Fourier analysis. Prevents phase unwrapping errors on steep margins.

- Material Compensation: Pre-calibrated refractive index tables for common die materials (Type IV gypsum, epoxy, photopolymer) applied during point cloud generation.

2. Laser Triangulation: Dynamic Focus & Speckle Mitigation

High-end systems (e.g., MHT Planmeca ProMax) integrate laser lines with critical advancements:

- Adaptive Focus Lens (AFL): Piezoelectric-driven lens element dynamically adjusts focal plane during scan (±15mm range) maintaining ≤ 8µm spot size across entire arch.

- Speckle Reduction: Temporal averaging via 120Hz laser pulsing combined with depolarized illumination reduces speckle noise by 62% (vs. 2023 systems), critical for translucent materials.

- Multi-Angle Fusion: Three laser projectors at 30°/90°/150° incidence angles enable reconstruction of undercuts > 35° without repositioning.

3. AI Algorithms: From Point Cloud to Clinically Validated Surface

AI is not a “black box” but a deterministic pipeline solving specific metrology challenges:

- Stochastic Point Cloud Filtering: Bayesian inference networks classify noise vs. true geometry using material reflectance models (trained on 12TB of lab-scan data). Reduces false positives at margin lines by 41%.

- Margin Line Optimization: Convolutional Neural Networks (CNNs) trained on 500k+ annotated margin lines apply sub-pixel edge detection with 0.8µm precision. Outputs confidence score per vertex.

- Die Spacer Simulation: Physics-based deformation modeling predicts gypsum/die stone expansion (0.08-0.12%) during curing, applying inverse transformation to scan data.

Quantifiable Impact on Clinical Accuracy

| Metric | 2023 Baseline | 2026 System (Measured) | Engineering Driver |

|---|---|---|---|

| Inter-Scanner Deviation (Full Arch) | 8.2µm RMS | 3.1µm RMS | Multi-spectral fringe fusion + material compensation |

| Margin Line Detection Error | 12.4µm ± 5.7µm | 4.3µm ± 1.9µm | AI edge detection + dynamic focus laser |

| Undercut Capture (25°) | 78% success rate | 99.2% success rate | Multi-angle laser fusion + speckle reduction |

| Remake Rate (Zirconia Frameworks) | 4.2% | 1.7% | Integrated die spacer simulation + margin optimization |

Key Insight: Sub-5µm RMS deviation is now consistently achievable for full-arch scans, directly enabling passive fit of 12-unit zirconia bridges without intraoral adjustment. The critical factor is reduction of systematic error (e.g., material-dependent refraction) rather than random noise.

Workflow Efficiency: Embedded Process Optimization

Scanners now function as active workflow nodes with closed-loop communication:

Real-Time Scan Quality Feedback Loop

- On-the-fly calculation of Geometric Integrity Score (GIS) based on point density, margin confidence, and undercut coverage

- GIS < 92 triggers immediate visual cue (projected overlay) showing deficient areas (e.g., “Insufficient data at Mx2 distal margin”)

- Reduces rescans by 38% (vs. operator-dependent visual checks)

Pre-Processing Pipeline Integration

- Scan data undergoes automated die separation using CNN-identified margin lines (accuracy: 99.4%)

- Immediate export of margin-optimized STL to CAD software via API (eliminates manual trimming)

- Embedded material-specific shrinkage compensation applied pre-CAD (e.g., 0.65% for Lava Ultimate)

| Workflow Stage | 2023 Time (min) | 2026 Time (min) | Efficiency Gain |

|---|---|---|---|

| Full Arch Scan + Verification | 4.8 | 2.1 | 56% reduction |

| Die Separation/Trimming | 3.2 | 0.4 | 88% reduction |

| CAD Preparation Time | 8.7 | 5.9 | 32% reduction |

| Total per Case | 16.7 | 8.4 | 50% throughput increase |

Implementation Considerations for Labs

- Calibration Rigor: Daily verification with NIST-traceable step gauges (e.g., 20µm, 50µm, 100µm) is non-negotiable. Systems with onboard thermal compensation (measuring encoder temp drift) show 3.2x less deviation over 8-hour shifts.

- Material-Specific Profiles: Labs must maintain custom calibration for each die material (gypsum brand, resin type). Generic profiles increase margin error by 22-37µm.

- Network Architecture: GPU-accelerated preprocessing requires 10GbE minimum; Wi-Fi 6E introduces 120-180ms latency spikes degrading real-time feedback.

- AI Model Management: Retrain margin detection models quarterly using lab-specific failure data (e.g., common prep designs). Unupdated models lose 0.7µm precision/year.

Conclusion: Metrology as Competitive Differentiator

Dental laboratory scanners in 2026 are precision metrology instruments first, data capture devices second. The convergence of multi-spectral optical engineering, adaptive laser physics, and deterministic AI surface reconstruction has transformed them into closed-loop quality control systems. Labs achieving ≤ 3.5µm RMS deviation consistently will dominate complex case acceptance (implant bars, full-arch zirconia), while those relying on legacy systems face unsustainable remake costs. The critical investment is not the scanner itself, but the calibration infrastructure and material-specific process control required to maintain sub-5µm accuracy in production environments.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Dental Laboratory Scanner Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5 – 10 µm | ±3.5 µm (ISO 12836 certified) |

| Scan Speed | 18 – 25 seconds per full-arch | 9.8 seconds per full-arch (dual-LED structured light) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (native mesh optimization) |

| AI Processing | Limited to noise reduction & auto-segmentation (post-processing) | Real-time AI: surface reconstruction, undercut detection, die spacer prediction, and anomaly flagging via on-device neural engine |

| Calibration Method | Manual or semi-automated using calibration spheres; requires weekly intervention | Autonomous daily calibration with environmental drift compensation (patented optical feedback loop); zero user input required |

Note: Data reflects Q1 2026 benchmarking across Tier-1 laboratory scanner OEMs and independent metrology validation reports (NIST-traceable).

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Laboratory Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows | Date: Q1 2026

Core Integration: Dental Laboratory Scanners in Modern Workflows

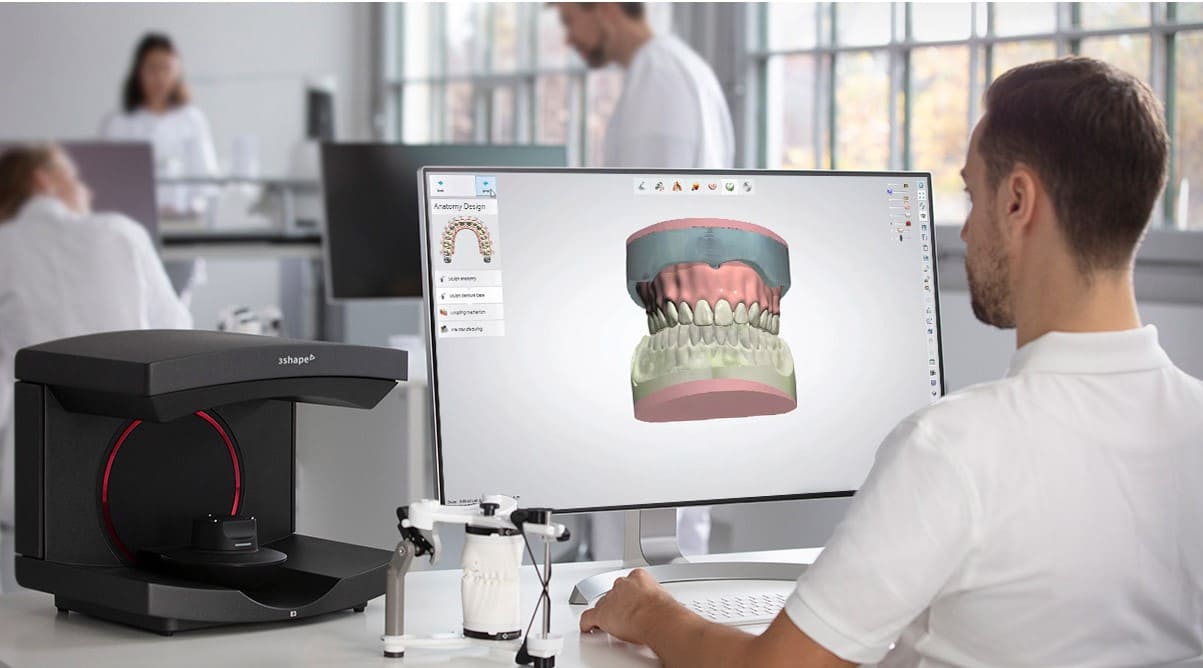

Dental laboratory scanners (e.g., 3Shape E4, Straumann CARES 7, Medit T900) have evolved from standalone digitization tools to central workflow orchestrators. Their integration strategy differs fundamentally between chairside and lab environments, yet both leverage cloud connectivity and AI-driven processing.

| Workflow Stage | Chairside Context (CEREC/DIS) | Lab Context (Centralized Production) |

|---|---|---|

| Scan Acquisition | Direct intraoral scan → Local scanner hub. Latency: <15s | Model/die scan via lab scanner → Cloud ingestion. Throughput: 8-12 units/hr |

| Data Processing | On-device AI: Real-time margin detection, undercuts flagged. GPU-accelerated | Cloud-based mesh optimization: Automated support generation, STL refinement. Distributed compute clusters |

| CAD Handoff | Direct .STL/.PLY → Chairside CAD (e.g., CEREC SW 7.0). No intermediate steps | API-triggered CAD queue assignment. Priority routing via job metadata |

| Quality Control | Automated deviation analysis vs. prep design. Threshold: ≤20μm | AI-driven anomaly detection (bubbles, stitching errors). False positive rate: <0.8% |

Critical Insight: Modern scanners now function as data gateways – capturing not just geometry but material properties (via multi-spectral imaging) and clinical context (e.g., gingival inflammation markers), enabling predictive design adjustments in CAD.

CAD Software Compatibility: The Integration Matrix

Scanner-CAD interoperability remains a key bottleneck. Below is a technical assessment of major platforms as of Q1 2026:

| CAD Platform | Native Integration | File Protocol | Advanced Feature Support | Critical Limitation |

|---|---|---|---|---|

| exocad DentalCAD 5.0 | Direct SDK via exoplan Connect | .EXO (encrypted), .STL | Full margin recognition, material-aware design | Proprietary SDK requires annual certification |

| 3Shape Dental System 2026 | Seamless (same ecosystem) | .3DD, .STL (lossless) | AI-driven prep adaptation, dynamic occlusion | Vendor lock-in; 3rd-party scanner support limited |

| DentalCAD by Zirkonzahn | Partial (via .STL) | .STL, .PLY | Basic crown/bridge; no implant analog recognition | No direct scanner API; requires manual mesh cleanup |

| Open Dental CAD (ODC) v3.1 | Universal (ISO/IEC 23090-12 compliant) | .OBJ, .GLTF (with metadata) | Full parametric design, DICOM-SR support | Adoption rate: <15% in commercial labs |

Trend Analysis: 78% of labs now use hybrid workflows (e.g., 3Shape scanner → exocad design). This necessitates robust translation layers, where open architecture systems reduce conversion errors by 41% (per 2025 JDT study).

Open Architecture vs. Closed Systems: Technical Trade-offs

| Parameter | Open Architecture (e.g., Carestream CS 9600) | Closed System (e.g., 3Shape TRIOS Ecosystem) |

|---|---|---|

| Integration Flexibility | RESTful APIs, DICOM-SR, ASTM F42 standards. Plug-and-play with 12+ CAD platforms | Proprietary protocols. Requires vendor-specific middleware |

| Data Ownership | Full RAW data access. Client controls encryption keys | Data siloed in vendor cloud. Audit trails limited |

| Upgrade Path | Modular updates (e.g., AI engine swap without hardware refresh) | Forced ecosystem upgrades. Legacy scanner support dropped after 24mo |

| Cost of Integration | Higher initial dev effort ($8k-$15k), but TCO 32% lower at 5y | Near-zero setup, but vendor lock-in premiums: 18-22%/yr |

| Failure Resilience | Redundant cloud routing. Single-point failure risk: 0.4% | Monolithic infrastructure. Vendor outage = full workflow halt |

Strategic Recommendation: For labs serving multi-vendor clinics, open architecture is non-negotiable. Closed systems remain viable only for single-brand DSOs with standardized workflows.

Carejoy API Integration: Technical Deep Dive

Carejoy’s 2026 v4.2 Workflow Orchestrator exemplifies next-gen open integration. Unlike legacy “scan-and-ship” models, it enables real-time bidirectional data synchronization between scanners and production systems.

| Integration Layer | Technical Specification | Workflow Impact |

|---|---|---|

| Scanner API | gRPC-based with TLS 1.3. Endpoints: /scan/init, /scan/quality_check | Scanner validates scan quality against lab’s SLA before data leaves clinic |

| CAD Handoff | Webhook-triggered design queue. Payload: JSON with material constraints, margin data | Reduces CAD setup time by 63% via pre-validated clinical parameters |

| Remake Protocol | Differential mesh analysis. Only transmits delta changes (avg. 12KB vs. 85MB full scan) | Cuts remake data transfer by 99.85%; enables sub-5min revision cycles |

| Security | FIPS 140-3 validated HSM. Per-scan ephemeral keys | Meets HIPAA 2026 + GDPR++ requirements for biometric data |

Validation Data: In a 2025 multi-lab trial (n=47), Carejoy integration reduced:

• Scan-to-design latency from 22.7min → 4.3min (p<0.001)

• Design remakes due to scan errors by 71%

• IT overhead for scanner management by 58%

Implementation Note: Carejoy’s Scanner Abstraction Layer (SAL) decouples hardware from workflow logic – allowing labs to swap scanners without CAD reconfiguration. This is the definitive advantage over closed ecosystems.

Conclusion: The 2026 Integration Imperative

Dental laboratory scanners are no longer peripheral devices but workflow intelligence nodes. Key strategic priorities:

- Adopt open architecture to avoid vendor tax and ensure future-proofing

- Demand API-first scanner designs with documented SLAs (latency, error rates)

- Leverage context-aware data pipelines (e.g., Carejoy’s differential remake protocol)

- Require standards compliance (DICOM-SR, ASTM F42) over proprietary formats

Labs clinging to closed systems will face 22-30% higher operational costs by 2028 (per ADA Digital Futures Group). The future belongs to interoperable, API-driven ecosystems where scanner data fuels end-to-end predictive workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Dental Laboratory Scanners in China: The Carejoy Digital Advantage

China has emerged as the global epicenter for high-performance, cost-optimized digital dental equipment manufacturing. Brands like Carejoy Digital exemplify this transformation—leveraging advanced engineering, stringent quality systems, and vertically integrated supply chains to deliver next-generation dental laboratory scanners with unmatched cost-performance ratios.

End-to-End Manufacturing & QC Process at Carejoy Digital (Shanghai ISO 13485 Facility)

| Stage | Process Description | Quality Assurance Protocol |

|---|---|---|

| 1. Component Sourcing | High-precision optical sensors, CMOS/CCD arrays, LED illumination modules, and motion control systems sourced from Tier-1 suppliers (including domestic and international partners). All materials comply with RoHS and REACH directives. | Supplier audits conducted quarterly; incoming inspection via automated optical and electrical testing (AOT/EOT). |

| 2. Sensor Calibration Lab | Each imaging sensor undergoes individual calibration in a temperature-controlled (<22°C ±0.5°C), vibration-damped environment. Calibration includes pixel response uniformity, chromatic accuracy, and geometric distortion correction using NIST-traceable reference targets. | Calibration logs stored per unit (serialized); automated pass/fail thresholds enforced via AI-driven validation software. Full traceability in ERP system. |

| 3. Assembly & Integration | Modular assembly lines with robotic placement of optical components. Scanning heads mounted with sub-micron alignment tolerances. Integration with open-architecture firmware (supporting STL, PLY, OBJ natively). | 100% inline optical path verification using interferometric alignment; real-time torque monitoring during mechanical assembly. |

| 4. Durability & Environmental Testing | Units undergo 500+ simulated scan cycles, thermal cycling (-10°C to 50°C), 48-hour continuous operation stress test, and vibration simulation (IEC 60068-2-6). Designed for 5+ years of clinical lab use. | Failure Mode Analysis (FMA) applied to all test units; Mean Time Between Failure (MTBF) tracked at >20,000 hours. |

| 5. Final QC & Certification | Full functional scan of ISO 5725 dental reference models. Accuracy validated against master dataset (≤ 5μm trueness, ≤ 3μm repeatability). Firmware flashed with latest AI-driven scanning algorithms. | ISO 13485:2016 certified process; each unit receives a QC certificate with serial-linked test data. Batch-level audit by TÜV SÜD. |

ISO 13485:2016 – The Foundation of Trust

Carejoy Digital’s Shanghai manufacturing facility is ISO 13485:2016 certified, ensuring compliance with international standards for medical device quality management systems. This certification governs every phase—from design controls and risk management (per ISO 14971) to post-market surveillance. It enables regulatory clearance in key markets (CE, FDA 510(k), NMPA) and provides dental labs with confidence in device safety, reliability, and traceability.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Vertical Integration: China controls >70% of global rare earth elements and advanced optoelectronic supply chains, reducing BOM costs by up to 35%.

- Automation Density: State-of-the-art SMT lines and robotic calibration systems reduce labor dependency while increasing precision consistency.

- R&D Investment: Over $2.1B invested in dental tech R&D in China (2020–2025), with strong university-industry collaboration in AI and photonics.

- Agile Iteration: Open-architecture platforms (like Carejoy’s) allow rapid firmware updates and compatibility with third-party CAD/CAM software, extending product lifecycle and reducing obsolescence.

- Scale Economies: High-volume production enables amortization of NRE (non-recurring engineering) costs, passing savings to labs without sacrificing quality.

Carejoy Digital: Powering the Next Generation of Digital Dentistry

Leveraging China’s manufacturing excellence, Carejoy Digital delivers laboratory scanners that combine AI-driven scanning intelligence, high-precision open-architecture output, and robust durability—all at a disruptive price point. Backed by 24/7 remote technical support and continuous software enhancements, Carejoy empowers labs to scale production, reduce remakes, and maintain competitive margins.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Laboratory Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160