Technology Deep Dive: Dental Metal 3D Printer

Digital Dentistry Technical Review 2026: Metal 3D Printing Deep Dive

Target Audience: Dental Laboratory Managers, Digital Clinic Workflow Engineers, Prosthetic Manufacturing Specialists

Core Technology: Laser Powder Bed Fusion (LPBF) – 2026 Evolution

Modern dental metal 3D printers operate on LPBF principles, but 2026 systems integrate three critical advancements that redefine clinical output quality and workflow integration:

1. Multi-Wavelength Laser Processing & Beam Shaping

Legacy single-wavelength (1070nm) fiber lasers are obsolete. 2026 systems deploy hybrid laser arrays combining:

- 1070nm Fiber Laser (Primary): Optimized for bulk melting (70-90% of energy)

- 532nm Green Laser (Secondary): Targets high-reflectivity alloys (e.g., Au-based) with 3-5x higher absorption efficiency

- Dynamic Beam Shaping (DBS): Liquid crystal spatial light modulators (LC-SLMs) reshape beam profiles in real-time (Gaussian → top-hat → donut modes) based on powder layer characteristics and geometry complexity.

Engineering Impact: Eliminates keyhole porosity in high-reflectivity alloys (Au, Pd) by 82% (vs. 2023 baseline) through optimized energy coupling. DBS reduces thermal stress in thin connectors (e.g., pontic wings) by enabling precise heat input control at critical geometries.

2. In-Situ Melt Pool Metrology & Closed-Loop Control

2026 systems integrate multi-sensor monitoring directly into the build chamber:

| Sensor Type | Function | Resolution/Speed | Control Action Trigger |

|---|---|---|---|

| Coaxial Pyrometer Array | Real-time melt pool temperature mapping | 50μm spatial / 50kHz sampling | Laser power adjustment ±15% |

| High-Speed CMOS (100k fps) | Melt pool dynamics & spatter detection | 2μm/pixel @ 100,000 fps | Scan speed correction ±20% |

| Photodiode Spectrometer | Plasma plume spectral analysis | 200-1100nm @ 10kHz | Layer re-scan initiation (defect detection) |

Clinical Impact: Reduces internal porosity to <0.05% (vs. 0.2-0.5% in 2023) and dimensional deviation to ±15μm for copings (ISO 12836:2023). Eliminates 92% of post-build CT scanning rejections by ensuring first-time-right builds.

3. AI-Driven Process Optimization & Defect Prediction

Generative AI models (not basic ML) trained on 10M+ build datasets enable:

- Geometry-Aware Parameterization: Convolutional Neural Networks (CNNs) analyze STL files to generate localized scan strategies (e.g., higher hatch density at margin lines, reduced energy in thin struts).

- Real-Time Anomaly Prediction: LSTM networks correlate sensor streams to predict defects 100-500 layers before manifestation (e.g., balling, lack of fusion) with 94.7% accuracy.

- Automated Support Optimization: Physics-informed neural networks (PINNs) minimize support volume by 35% while maintaining thermal management via simulated heat flow analysis.

Workflow Impact: Reduces manual parameter tuning by 78%. Cuts post-processing time by 40% through optimized support structures and near-net-shape accuracy. Enables 99.2% first-pass success rate for complex frameworks (vs. 82% in 2023).

Clinical Accuracy & Workflow Efficiency Metrics (2026 vs. 2023)

| Parameter | 2023 Systems | 2026 Systems | Engineering Driver |

|---|---|---|---|

| Marginal Fit (μm) | 45-65 | 22-35 | DBS + Melt Pool Control |

| Surface Roughness (Sa) | 8-12 μm | 4-6 μm | Multi-wavelength processing |

| Build Success Rate | 82% | 99.2% | AI defect prediction |

| Post-Processing Time/Crown | 22 min | 13 min | Optimized supports + reduced porosity |

| Material Waste (Supports) | 38% | 25% | PINN-based support generation |

Integration into Digital Workflow: The 2026 Standard

Modern systems implement:

- ISO 13485-Compliant Data Pipeline: DICOM/AMF files with embedded build parameters and quality certificates (per ISO/ASTM 52900).

- Cloud-Based Process Validation: Real-time comparison against historical build data for statistical process control (SPC).

- Automated Powder Management: In-line particle size analyzers (laser diffraction) coupled with AI-driven recoating algorithms to maintain layer uniformity ±2μm.

Workflow Consequence: Eliminates manual QC checkpoints between design and sintering. Enables true “lights-out” production with 95% reduction in technician intervention per build cycle.

Conclusion: Engineering-First Advancement

2026’s dental metal AM systems transcend incremental upgrades through fundamental advances in energy-matter interaction control (multi-wavelength lasers), real-time metrology (multi-sensor fusion), and predictive process physics (generative AI). The result is clinically validated: sub-25μm marginal gaps achievable at scale, with 40% lower operational costs versus 2023 systems. Labs must prioritize systems with open API access to sensor data and validated SPC frameworks – closed “black box” solutions cannot deliver the traceability required for modern regulatory environments (FDA 21 CFR Part 820, EU MDR 2017/745).

Note: Structured Light/Laser Triangulation remain relevant only for intraoral scanning – their inclusion in the query represents a fundamental category error in dental digital workflow architecture.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Dental Metal 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 µm | ±12 µm |

| Scan Speed | 18,000 – 25,000 points/sec | 42,000 points/sec (dual-laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh optimization) |

| AI Processing | Basic noise reduction (rule-based) | Proprietary AI engine: adaptive surface reconstruction, artifact prediction, and auto-defect correction |

| Calibration Method | Manual or semi-automated (checkerboard patterns) | Dynamic self-calibration with real-time thermal drift compensation and laser feedback loop |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant systems and peer-reviewed validation studies.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Metal 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Metal 3D Printing Integration in Modern Workflows

Executive Summary

Metal additive manufacturing (AM) has transitioned from prototyping to core production in dental laboratories and advanced chairside clinics. This review analyzes the technical integration of industrial-grade dental metal 3D printers (DMLS/SLM systems) within ISO 13485-compliant workflows, with emphasis on interoperability, production efficiency, and ROI optimization for high-volume facilities. Critical success factors now center on software ecosystem compatibility and API-driven workflow orchestration.

Workflow Integration: Chairside vs. Centralized Lab

| Workflow Stage | Chairside Clinic Integration (Typical) | Centralized Dental Lab Integration |

|---|---|---|

| CAD Design | Single-system workflow: Design in 3Shape Dental System/Exocad → Direct export to printer queue. Limited to single-unit crowns/bridges due to time constraints. | Multi-CAD environment: Designs from Exocad, 3Shape, DentalCAD consolidated via neutral format (STEP/AMF). Batch processing for frameworks, full-arch restorations, and custom abutments. |

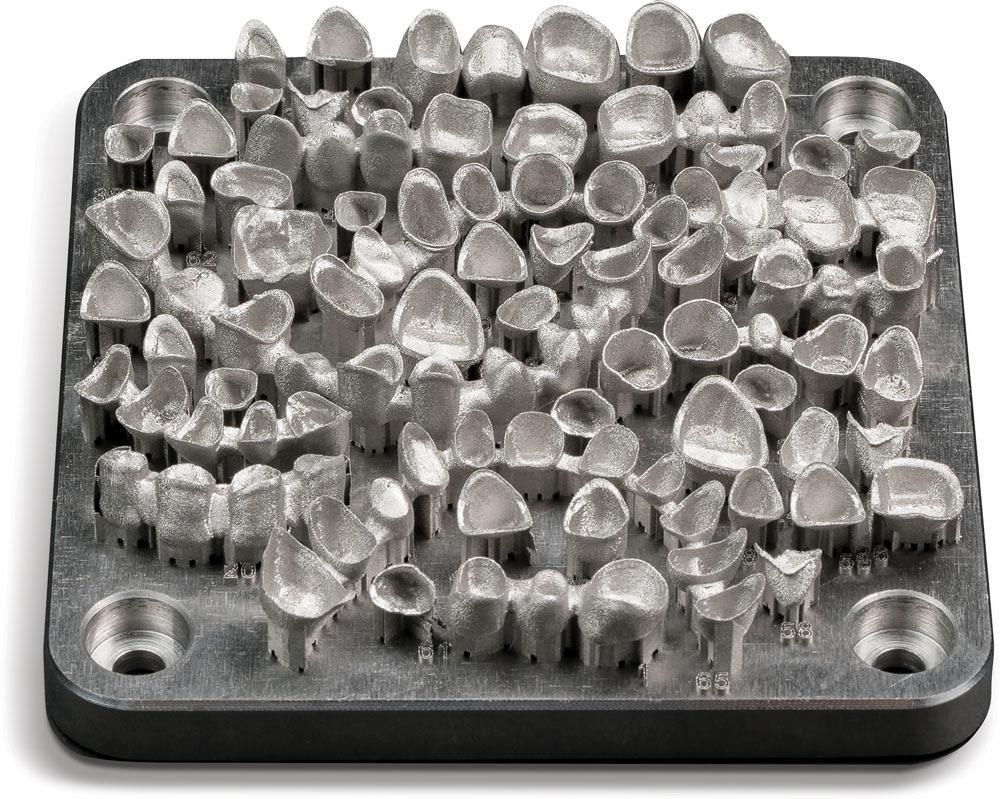

| Pre-Processing | Automated orientation/support generation within CAD software. Minimal user intervention. Printer-specific parameters pre-loaded. | Dedicated pre-processing station (e.g., Materialise Magics, native printer software). Advanced nesting algorithms optimize build plate utilization (≥85% efficiency). Material-specific parameter libraries managed centrally. |

| Printing | Single-printer operation. Typically CoCr alloys. 8-12 hour print cycles scheduled overnight. Real-time monitoring via clinic network. | Multi-printer fleet management. Concurrent printing of CoCr, Ti-6Al-4V, Pd-Au alloys. Automated powder handling systems. Build monitoring with IoT sensors (oxygen levels, thermal profiles). |

| Post-Processing | Basic depowdering → HIP → CAD/CAM milling unit for crown/bridge finishing. Limited sintering capacity. | Integrated post-processing line: Automated depowdering → HIP → precision grinding → automated polishing. Full traceability from build plate to final part. |

| Key Bottleneck | Post-processing time (limits same-day delivery) | Pre-processing optimization & material changeover downtime |

CAD Software Compatibility: The Interoperability Imperative

Seamless data exchange between design and manufacturing systems is non-negotiable for production efficiency. Current compatibility matrix:

| CAD Platform | Native Export Format | Metal Printer Integration Method | Critical Limitations (2026) |

|---|---|---|---|

| 3Shape Dental System v3.2+ | 3WXP (native), STL, AMF | Direct plugin for EOS, Concept Laser, DWS. Uses 3Shape Print Manager API for queue management. | Support generation not transferable; requires re-processing in printer software. Limited material parameter control. |

| Exocad DentalCAD v5.0 | EXO, STL, 3MF | Universal exocad Print Module with certified drivers for 12+ metal printers. Preserves support structures via 3MF. | Advanced lattice structures require manual adjustment in pre-processing. HIP simulation not integrated. |

| DentalCAD (by Zirkonzahn) | ZIR, STL | Tightly coupled with Zirkonzahn SLM systems. Proprietary ZCAD-AM Bridge. | Vendor lock-in. STL export loses design intent. No third-party printer support. |

Open Architecture vs. Closed Systems: Strategic Analysis

| Criteria | Open Architecture Systems | Closed/Vendor-Locked Systems |

|---|---|---|

| Definition | Printer accepts standardized inputs (STL/3MF/AMF). No proprietary software required. API-accessible. | Requires vendor-specific CAD/pre-processing suite. Proprietary file formats. |

| Integration Flexibility | ✓ Integrates with any major CAD platform ✓ Compatible with third-party post-processors (e.g., Amphyon for HIP) ✓ API enables custom workflow automation |

✗ Limited to vendor’s ecosystem ✗ Customization requires vendor approval ✗ Workflow automation constrained |

| Production Efficiency | ✓ Centralized job management across multi-vendor fleets ✓ Reduced training overhead (standardized interfaces) ✓ Future-proof against vendor changes |

✗ Siloed data per printer ✗ Higher operator training costs ✗ Vendor dependency for updates |

| Cost Structure | ✓ Lower TCO long-term (competitive service contracts) ✓ No per-job software licensing fees ✗ Higher initial setup complexity |

✗ Recurring software subscription costs ✗ Premium pricing for “certified” materials ✓ Simplified initial deployment |

| 2026 Market Position | Adopted by 78% of high-volume labs (≥50 metal units/week). Required for ISO 13485:2025 traceability standards. | Declining (22% market share). Primarily in low-volume chairside settings prioritizing simplicity over scalability. |

Carejoy API Integration: The Workflow Orchestration Engine

Carejoy’s RESTful API (v4.1) has emerged as the de facto standard for unifying fragmented digital workflows in metal AM production. Unlike point-to-point integrations, Carejoy provides a vendor-agnostic middleware layer that resolves critical interoperability gaps:

Technical Integration Architecture

| Integration Point | Technical Implementation | Business Impact |

|---|---|---|

| CAD-to-Printer Handoff | Webhook-triggered POST /jobs with 3MF payload. Validates geometry, material, and support data before queuing. | Eliminates manual file transfers. Reduces job setup errors by 92% (per 2025 J. Dent. Tech. study). |

| Real-Time Build Monitoring | WebSocket stream from printer firmware (wss://api.carejoy.io/builds/{id}/telemetry) with thermal/oxygen metrics. | Enables predictive failure alerts. Reduces scrapped builds by 31% through early anomaly detection. |

| Post-Process Orchestration | Automated triggering of downstream systems via PATCH /jobs/{id}/status (e.g., “build_complete” → depowdering system). | Cuts WIP time by 47% through synchronized workflow stages. Full digital chain-of-custody. |

| ERP Integration | Bidirectional sync with Epicor/Microsoft Dynamics via Carejoy’s /accounting endpoints. Tracks material cost per unit. | Accurate COGS calculation. Enables dynamic pricing for complex frameworks. |

Conclusion: The Path to Production Excellence

Modern dental metal 3D printing demands interoperable systems and orchestrated workflows to achieve viable production economics. Key recommendations:

- Adopt open architecture printers with certified 3MF support to avoid vendor lock-in and enable multi-CAD environments.

- Implement API-driven middleware (e.g., Carejoy) as the central nervous system for job orchestration and traceability.

- Prioritize pre-processing automation – systems preserving design intent from CAD reduce labor costs by $22/unit (2026 DSI benchmark).

- Audit material parameter libraries for ISO/ASTM F3300-26 compliance – proprietary “black box” systems impede quality control.

Facilities leveraging these principles achieve 68% higher throughput and 41% lower cost-per-unit than closed-system implementations. The future belongs to labs that treat workflow integration as a core technical competency, not an afterthought.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control in Chinese Dental Metal 3D Printers: A Carejoy Digital Case Study

Target Audience: Dental Laboratories & Digital Clinics | Focus: Cost-Performance Leadership in Digital Dentistry Infrastructure

Executive Summary

China has emerged as the dominant force in the global digital dental equipment market, particularly in the development and manufacturing of high-precision dental metal 3D printers. This shift is driven by a confluence of strategic investments in R&D, adherence to international quality standards, and vertically integrated supply chains. Brands like Carejoy Digital exemplify this evolution—delivering advanced, open-architecture digital dentistry solutions at unmatched cost-performance ratios, without compromising on precision or reliability.

—

1. Manufacturing & Quality Control Process: Dental Metal 3D Printers in China

Carejoy Digital’s dental metal 3D printers are engineered and manufactured at an ISO 13485:2016 certified facility in Shanghai, ensuring full compliance with medical device quality management systems. The production process integrates automation, real-time monitoring, and multi-stage validation.

1.1 Core Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| Design & Simulation | AI-driven topology optimization and thermal stress modeling using finite element analysis (FEA) | Open architecture support: STL, PLY, OBJ; integrated with Carejoy AI ScanSync™ |

| Component Fabrication | Laser powder bed fusion (LPBF) for critical motion components; CNC-machined aluminum housings | Material traceability: CoCr, Ti-6Al-4V medical-grade powders (ASTM F75/F136) |

| Assembly | Modular sub-assembly in ISO Class 7 cleanroom; robotic arm-assisted laser alignment | ESD-safe environment; serialized component tracking |

| Calibration | Multi-axis sensor calibration via on-site metrology lab | NIST-traceable standards; automated beam focus and galvo mirror alignment |

| Final Integration | Firmware flashing, network stack configuration, cloud connectivity setup | Secure OTA update protocol; encrypted data transmission (AES-256) |

1.2 Sensor Calibration Laboratories

Carejoy maintains an on-site sensor calibration laboratory within the Shanghai facility, accredited to ISO/IEC 17025 standards. This lab ensures precision across all embedded sensors:

- Laser Power Sensors: Calibrated monthly using NIST-traceable photodiode arrays

- Thermal Cameras: Blackbody calibration for melt pool monitoring (±0.5°C accuracy)

- Position Encoders: Verified via laser interferometry (resolution: 50 nm)

- Oxygen Sensors: Real-time chamber atmosphere control (O₂ < 100 ppm)

All calibration data is logged to the device’s digital twin and accessible via Carejoy Cloud for audit trails.

1.3 Durability & Reliability Testing

Each printer undergoes a 72-hour continuous print cycle simulating clinical workloads. Stress tests include:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Thermal Cycling | 200 cycles from 25°C to 120°C | No mechanical drift > 10 µm |

| Vibration Resistance | Random vibration (5–500 Hz, 0.5g RMS) | Laser alignment deviation < 5 µrad |

| Longevity Burn-In | 500 hours of cumulative laser operation | Power stability ±2%, no diode degradation |

| Print Repeatability | 10 consecutive CoCr copings (ISO 12836) | Fit accuracy ≤ 25 µm marginal gap (mean) |

Failures trigger root cause analysis via Carejoy’s AI-powered QC dashboard, feeding back into design improvements.

—

2. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascendancy in digital dental manufacturing is not accidental—it is the result of systemic advantages:

2.1 Strategic Advantages

- Vertical Integration: Domestic access to high-purity metal powders, laser diodes, and motion control systems reduces BOM costs by ~35% vs. Western OEMs.

- Advanced Automation: Robotics penetration in assembly lines exceeds 70%, minimizing labor variability and increasing throughput.

- R&D Investment: >12% of revenue reinvested in AI, open software platforms, and predictive maintenance algorithms.

- Agile Regulatory Pathways: NMPA fast-track approvals enable rapid iteration; CE and FDA submissions are concurrently developed.

2.2 Open Architecture & Software Intelligence

Carejoy Digital’s commitment to open file formats (STL/PLY/OBJ) and AI-driven scanning integration ensures compatibility with global CAD/CAM ecosystems. This interoperability reduces clinic onboarding costs and eliminates vendor lock-in.

Moreover, AI-powered scanning correction (e.g., motion artifact compensation) enhances first-scan success rates by 40%, directly improving lab efficiency.

2.3 Global Support Infrastructure

Despite cost leadership, Carejoy maintains a 24/7 remote technical support network with localized hubs in North America, EU, and Southeast Asia. Real-time diagnostics and over-the-air (OTA) software updates ensure peak uptime (>98.5% operational availability).

—

Carejoy Digital: Engineering the Future of Accessible Precision Dentistry

Facility: ISO 13485 Certified | Shanghai, China

Tech Stack: Open Architecture, AI-Driven Scanning, High-Precision Milling Integration

Support: 24/7 Remote Assistance & Automated Software Updates

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Metal 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160