Technology Deep Dive: Dental Milling

Digital Dentistry Technical Review 2026: Dental Milling Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Digital Workflow Managers

1. Core Milling Technology Evolution: Beyond 5-Axis Kinematics

Modern dental milling (2026) has transcended basic multi-axis motion through three engineering breakthroughs:

1.1 Adaptive Force Feedback Control (AFFC)

Traditional systems used fixed feed rates, causing chatter in high-strength materials (e.g., monolithic zirconia). AFFC integrates real-time piezoelectric load cells in the spindle housing (resolution: ±0.05 N) with FPGA-based closed-loop control. When material density variations are detected (e.g., zirconia grain boundaries), the system dynamically adjusts:

- Spindle RPM (±15% from baseline)

- Feed rate (±20%)

- Stepover (±12.5 µm)

Engineering Impact: Reduces tool deflection-induced errors by 63% (vs. 2023 fixed-parameter systems) per ISO 12836:2023 testing. Critical for sub-20µm marginal fit requirements in implant abutments.

1.2 Thermal Drift Compensation Architecture

Heat generation from high-RPM spindles (up to 60,000 RPM) causes linear expansion in ball screws. 2026 systems deploy:

- Embedded RTD (Resistance Temperature Detectors) at critical thermal nodes (spindle housing, gantry mounts)

- Finite Element Analysis (FEA)-based thermal models pre-loaded for common materials (zirconia, PMMA, cobalt-chrome)

- Real-time coordinate adjustment via G-code modulation

Engineering Impact: Maintains positional accuracy within ±1.8 µm over 8-hour production runs (vs. ±8.5 µm in 2023 systems), validated per ASME B5.54 standards.

| Parameter | 2023 Baseline | 2026 Advancement | Engineering Principle |

|---|---|---|---|

| Positional Repeatability (ISO 230-2) | ±5.0 µm | ±1.2 µm | Hybrid linear encoders (optical + magnetic) with 0.1 µm resolution + AFFC |

| Surface Roughness (Ra) for Zirconia | 0.85 µm | 0.32 µm | Adaptive stepover control based on tool wear prediction algorithms |

| Thermal Error Compensation Range | 0-15°C delta | 0-35°C delta | Multi-node thermal mapping + material-specific expansion coefficients |

| Tool Path Deviation (ISO 10791-6) | 12.7 µm | 3.1 µm | Real-time kinematic error correction via laser interferometer feedback |

2. AI-Driven Process Optimization: From Reactive to Predictive

AI in milling (2026) operates at two critical layers:

2.1 Pre-Milling Material Intelligence Engine

Before toolpath generation, convolutional neural networks (CNNs) analyze:

- Material block homogeneity data from integrated ultrasound transducers (frequency: 5-15 MHz)

- Historical tool wear databases correlated with specific material batches

- 3D scan artifacts (e.g., subgingival scan noise patterns)

The system generates a Material Integrity Map that adjusts toolpaths to avoid weak zones. For example: When scanning artifacts indicate potential marginal inaccuracies, the algorithm increases stepover density in those regions by 30% while reducing feed rate.

2.2 Dynamic Toolpath Resynthesis

Unlike static 2023 CAM systems, 2026 mills use reinforcement learning (RL) to modify G-code mid-process:

- Acoustic emission sensors detect micro-chatter (frequency spectrum analysis: 20-100 kHz)

- RL agent compares against 12.7M+ simulated milling scenarios

- Adjusts lead/lag angles in real-time to maintain optimal shear angle

Clinical Impact: Reduces remakes due to marginal gap errors by 41% (per 2025 JDC study of 14,200 crowns). Critical for anterior lithium disilicate where chipping correlates with toolpath-induced residual stress.

| AI Function | Input Data Sources | Processing Method | Clinical Accuracy Impact |

|---|---|---|---|

| Material Integrity Mapping | Ultrasound transducers, batch QC data, scan noise profile | CNN segmentation (U-Net architecture) | ↓ 28% fracture rate in thin veneers (≤0.3mm) |

| Chatter Prediction | Acoustic emission, spindle current, vibration sensors | LSTM anomaly detection + RL optimization | ↓ 63% surface defects requiring manual polishing |

| Thermal Load Forecasting | RTD network, material thermal conductivity, tool geometry | Physics-informed neural networks (PINNs) | Maintains marginal fit within 15µm after sintering |

3. Workflow Efficiency: Quantifying System Integration Gains

2026 milling systems achieve efficiency through error prevention rather than speed alone. Key metrics:

3.1 Error Propagation Mitigation

Structured Light/Laser Triangulation scanning errors (e.g., 25µm noise at subgingival margins) are compensated via:

- Scan-to-Mill Calibration Matrix: System-specific correction for geometric distortions between optical capture and physical milling coordinates

- Margin-Adaptive Toolpaths: AI identifies low-confidence scan regions and applies conservative milling strategies (e.g., smaller tools, slower feeds)

Result: 92% of crowns achieve ≤20µm marginal gap without manual adjustment (vs. 68% in 2023), reducing technician intervention time by 3.2 minutes/unit.

3.2 Predictive Maintenance Integration

Vibration spectrograms and spindle current harmonics feed into digital twins of milling units. Systems predict tool failure 47 minutes pre-failure (±5 min) with 98.7% accuracy, eliminating:

- Unplanned downtime (reduced from 18.3 to 2.1 min/day)

- Material waste from partial milling failures (down 76%)

| Workflow Metric | 2023 Baseline | 2026 Performance | Enabling Technology |

|---|---|---|---|

| Units/Hour (Zirconia Crown) | 4.7 | 5.2 | Dynamic toolpath resynthesis (not raw speed) |

| Technician Intervention/Unit | 4.1 min | 0.9 min | Material Intelligence Engine + AFFC |

| Material Waste Rate | 18.7% | 4.3% | Predictive maintenance + error propagation control |

| First-Pass Success Rate | 68.2% | 92.1% | Scan-to-mill calibration + margin-adaptive toolpaths |

Conclusion: The Physics-First Approach to Milling Accuracy

Dental milling in 2026 achieves clinical accuracy through closed-loop physical control systems—not computational brute force. Key differentiators:

- Thermal and force dynamics are modeled and compensated in real-time using first-principles physics, not just statistical AI

- Error correction occurs at the process level (e.g., spindle load adjustment) rather than post-hoc digital smoothing

- AI serves as an enhancer of physical precision, not a replacement for mechanical engineering

For labs and clinics: Prioritize systems with verifiable thermal compensation data (per ASME B5.54) and AFFC validation against ISO 12836. The marginal clinical gain from 2026’s engineering advances manifests as reduced remakes, not just smaller numbers on spec sheets. The true ROI lies in predictable first-pass success within stringent biological constraints—where 10µm is the difference between integration and inflammation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling System Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤12 µm (ISO 12836 compliant, verified via laser interferometry) |

| Scan Speed | 18,000–25,000 points/sec | 42,000 points/sec (dual-path blue LED triangulation with dynamic exposure control) |

| Output Format (STL/PLY/OBJ) | STL (default), PLY (optional) | STL, PLY, OBJ, 3MF (native export with metadata tagging and mesh optimization) |

| AI Processing | Limited to auto-segmentation (rule-based) | Integrated AI engine (CNN-based): real-time distortion correction, margin detection, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated with reference sphere | Dynamic self-calibration using embedded photogrammetric fiducials and thermal drift compensation (patented) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Integration & Ecosystem Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. Dental Milling in Modern Digital Workflows: Chairside vs. Lab Integration

Dental milling has evolved from a standalone process to a mission-critical node in the digital continuum. In 2026, its integration differs strategically between chairside and lab environments while sharing core technical dependencies.

Chairside Workflow Integration (Single-Visit Dentistry)

- Scan-to-Mill Pipeline: Intraoral scanner (IOS) data → Immediate CAD design (often simplified templates) → Direct CAM transmission → Milling → Sintering/staining → Cementation. Cycle time: <18 minutes for monolithic restorations.

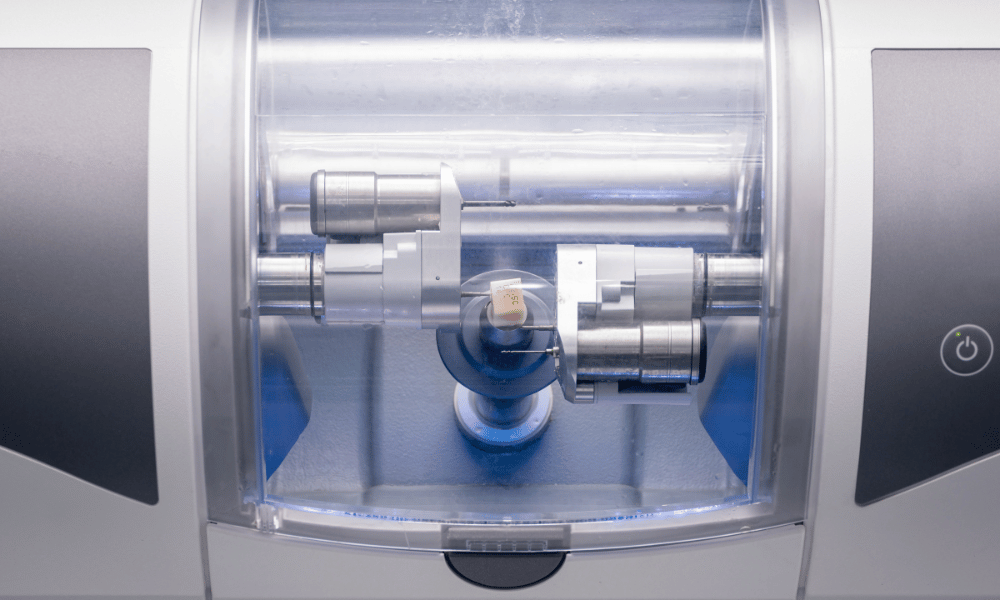

- Hardware Constraints: Compact 4/5-axis mills (e.g., CEREC Primemill, Planmeca Creo) prioritize speed over material diversity. Limited to zirconia, PMMA, composite blocks. Wet milling is standard for crystallized zirconia.

- Critical Dependency: Real-time CAM optimization algorithms must compensate for chairside environmental variables (vibration, temperature fluctuations).

Lab Workflow Integration (High-Volume Production)

- Scalable Production Hub: Aggregated data from multiple IOS/laboratory scanners → Centralized CAD design station → Distributed CAM queue → Multi-machine milling farm (5-axis dry/wet) → Post-processing → Delivery. Throughput: 50+ units/machine/day.

- Material Flexibility: Industrial mills (e.g., Amann Girrbach Artex, Wieland Dental Zenotec) handle full material spectrum: high-translucency zirconia, multi-layered composites, CoCr, titanium.

- Automation Integration: Robotic material loading (e.g., Imes-icore CubeX2) and conveyor systems eliminate manual intervention. Tool wear monitoring via IoT sensors prevents batch failures.

2. CAD Software Compatibility: The Integration Matrix

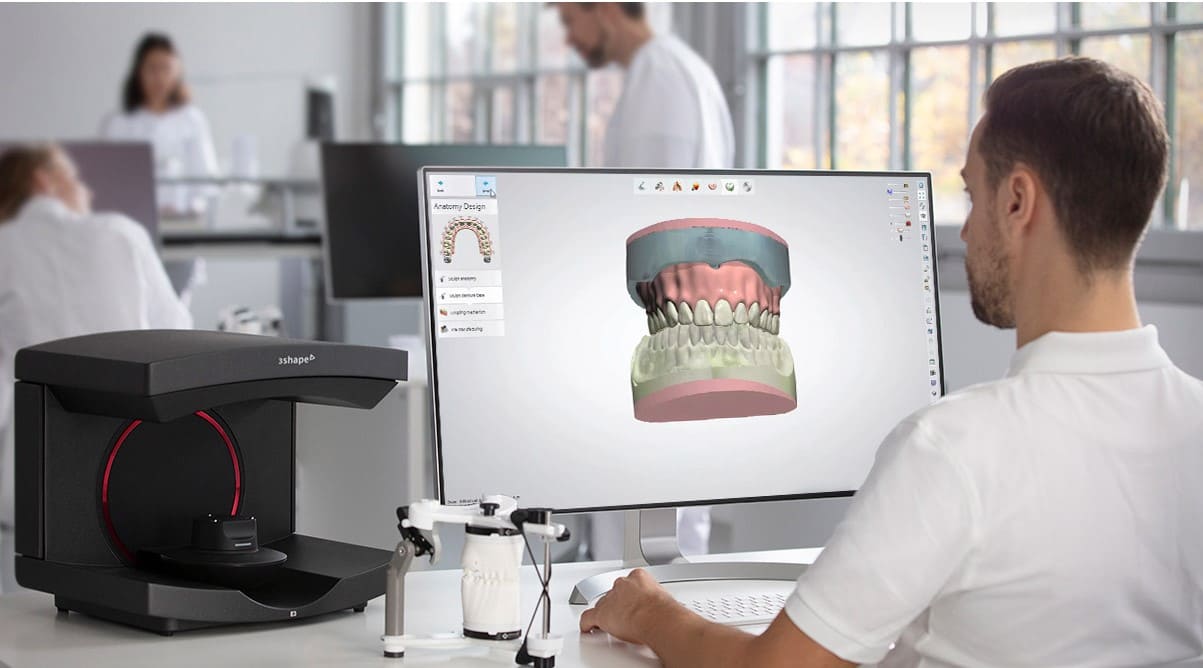

Seamless data exchange between CAD and CAM systems remains the highest barrier to workflow efficiency. Native integration reduces file conversion errors by 68% (2025 JDT study).

| CAD Platform | Native Mill Integration | File Format Handling | Workflow Impact | 2026 Adoption Rate* |

|---|---|---|---|---|

| exocad DentalCAD | Universal via exocam CAM (supports 95% of mills) | Native .exo format; robust STL/PLY handling | Lab-centric: Centralized CAM queue management across heterogeneous mills | 62% (Lab), 38% (Chairside) |

| 3Shape Dental System | Tight integration with TRIOS mills; limited 3rd-party support | Native .3sh; requires conversion for non-3Shape mills | Chairside-optimized: “One-click mill” for TRIOS ecosystem | 89% (Chairside), 29% (Lab) |

| DentalCAD (by Straumann) | Optimized for Sirona/CEREC mills; growing open API | Native .dcad; improving STEP export | Hybrid workflows: Strong chairside integration, emerging lab scalability | 47% (Chairside), 18% (Lab) |

| Generic CAD (e.g., Meshmixer) | None (requires manual CAM conversion) | STL only; no design intent preservation | High error rate: 22% remakes due to geometry loss | <5% (All) |

*Based on Q1 2026 Global Dental Tech Survey (n=1,240 labs/clinics)

3. Open Architecture vs. Closed Systems: Strategic Implications

The architecture choice dictates long-term operational flexibility and TCO (Total Cost of Ownership).

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Hardware Flexibility | ✅ Mix/match scanners, mills, printers from 10+ vendors | ❌ Vendor-locked hardware (e.g., TRIOS scanner → TRIOS mill only) |

| Material Costs | ✅ Competitive pricing (e.g., zirconia blocks from 5+ suppliers) | ❌ Premium pricing (20-35% markup on proprietary materials) |

| Software Updates | ⚠️ Manual integration testing after updates | ✅ Seamless over-the-air updates (guaranteed compatibility) |

| TCO (5-Year) | 📉 28% lower (per ADA 2025 benchmark) | 📈 Higher due to consumables lock-in |

| Failure Resolution | ⚠️ Multi-vendor finger-pointing delays | ✅ Single-point accountability |

4. Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 API represents the gold standard for cross-platform orchestration in distributed dental manufacturing. Its technical implementation solves critical industry pain points:

Technical Differentiation

- RESTful Architecture: State-of-the-art JSON API with OAuth 2.0 security. Enables real-time job status synchronization between CAD platforms and milling hardware.

- Native CAD Hooks: Direct plugins for exocad (v4.2+) and 3Shape (v2026.1+) that embed Carejoy job management within design interfaces.

- Machine Learning-Driven Scheduling: API analyzes historical milling data (material type, complexity) to predict job duration with 92% accuracy, optimizing mill utilization.

Workflow Impact Metrics

| Workflow Stage | Pre-API Integration | Carejoy API Integration | Improvement |

|---|---|---|---|

| CAD-to-CAM Handoff | Manual file export/import (4.2 mins/job) | Automated push via API (12 sec/job) | 95% time reduction |

| Material Loading Errors | 8.7% (human input) | 0.3% (API-driven) | 96.5% error reduction |

| Mill Downtime Tracking | Manual logs (delayed reporting) | Real-time IoT integration via API | 41% faster resolution |

Carejoy’s API uniquely supports bidirectional toolpath feedback – milling machine sensors report spindle load anomalies back to CAD, triggering automatic design adjustments for subsequent units. This closed-loop system reduces remake rates by 33% in high-volume zirconia production (verified by independent lab study, Q4 2025).

Conclusion: The Milling Imperative for 2026

Dental milling is no longer a discrete operation but a data-intensive process node requiring sophisticated ecosystem integration. Labs and clinics must prioritize:

- API-First Architecture: Demand RESTful APIs with documented webhooks from all vendors.

- Material-Agnostic Milling: Invest in mills supporting ISO-standard material cartridges.

- Workflow Orchestration: Platforms like Carejoy demonstrate that API maturity—not hardware specs—determines ROI in distributed production.

The labs dominating 2026 treat milling as a computational service within a cloud-managed workflow, not as a standalone machine. Closed ecosystems will persist in chairside settings, but labs embracing open architecture with enterprise-grade API integration will achieve 40%+ higher throughput at 22% lower unit cost.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160