Technology Deep Dive: Dental Resin Printer

Digital Dentistry Technical Review 2026: Dental Resin Printer Deep Dive

Target Audience: Dental Laboratory Managers, Digital Clinic Workflow Coordinators, CAD/CAM Systems Engineers

Executive Summary

By 2026, dental resin printers have evolved beyond incremental hardware improvements to become integrated predictive manufacturing systems. Core advancements in optical physics, real-time process monitoring, and closed-loop AI control have reduced critical dimensional errors to ≤±15µm (95% CI) for full-arch models and ≤±8µm for single-unit copings. This review dissects the engineering principles enabling sub-20µm clinical accuracy at production-scale throughput (45-60 units/hour), with quantifiable impact on remakes and chairside time.

Core Technology Comparison: 2026 State-of-the-Art

| Technology | Operating Principle | Accuracy (µm) | Throughput (units/hr) | Critical Failure Modes Addressed |

|---|---|---|---|---|

| Structured Light (DLP/LCD) | Projection of 1-bit grayscale patterns via MEMS-based DMD or high-aperture-ratio LCD. Uses spatiotemporal multiplexing to modulate light dose per voxel. | ±12-18 | 50-65 | Stair-stepping artifacts (Z-axis), oxygen inhibition layer inconsistency |

| Laser Triangulation (SLA) | Galvanometer-scanned UV laser (405nm) with closed-loop position feedback via dual-axis interferometry (±0.5µm resolution). Real-time beam profiling via Shack-Hartmann sensor. | ±8-14 | 35-50 | Beam wander, resin viscosity-induced deflection, thermal lensing |

| Hybrid Photonics (Emerging) | Combines structured light for bulk curing + laser for critical margins. Uses wavelength-selective photoinitiators (365nm/405nm) for dual-cure control. | ±6-10 | 45-55 | Interfacial stress at material transitions, marginal gap propagation |

Technical Deep Dive: Engineering Principles Driving Accuracy

1. Structured Light: Beyond Pixel Grid Limitations

Sub-Pixel Light Modulation: Modern DMD chips (0.47″ XGA, 1080p) achieve effective 5µm XY resolution via spatial dithering and temporal dose accumulation. By sequentially projecting phase-shifted patterns (e.g., Gray code + sinusoidal), systems resolve features below native pixel pitch (35µm) through controlled overcuring (±2.5µm precision). This eliminates the “stair-stepping” artifact at crown margins without increasing Z-layer count.

Clinical Impact: 32% reduction in marginal gap measurements (vs. 2023 systems) at the cementation line (ISO 12836:2023), verified via micro-CT (5µm resolution). Critical for zirconia frameworks where gaps >50µm cause cement washout.

2. Laser Triangulation: Precision Beam Control

Interferometric Position Correction: Dual-axis interferometers (He-Ne laser, λ=632.8nm) monitor galvanometer mirror position in real-time. Compensates for thermal drift (±0.2µm/°C) and inertia-induced overshoot during vector transitions. Beam path stability maintained to

Viscosity-Adaptive Scanning: In-line rheometer (measuring resin viscosity at 25°C ±0.1°C) dynamically adjusts laser power (50-350mW) and scan speed (500-5000 mm/s) using the Rabinowitsch-Mooney equation. Prevents undercuring in high-viscosity resins (e.g., permanent crown materials >800 mPa·s).

Clinical Impact: 28% decrease in internal fit discrepancies for multi-unit bridges (measured via triple-scan protocol), reducing occlusal adjustment time by 3.2 minutes per unit.

3. AI-Driven Process Optimization: Closing the Loop

Physics-Embedded Neural Networks: Convolutional Neural Networks (CNNs) trained on 1.2M+ print failure datasets predict deformation using:

• Thermomechanical stress tensors (from FEA-simulated layer curing)

• Real-time photopolymerization kinetics (via in-situ FTIR spectroscopy)

• Part geometry criticality maps (from CAD file topology analysis)

Adaptive Compensation: System pre-distorts the STL file using predicted shrinkage vectors (accuracy: ±3.7µm). For example, a 10mm pontic bridge receives 18µm lateral expansion in the tensile stress zone, validated by post-cure micro-CT.

Failure Prevention: Anomaly detection algorithms monitor oxygen inhibition layer thickness via spectral reflectance (450-550nm). Deviations >5% from baseline trigger immediate resin temperature adjustment (±0.5°C) or layer re-exposure.

Workflow Impact: 41% reduction in print failures requiring restart. Average support structure generation time reduced from 8.7 to 2.1 minutes via generative AI optimizing for minimal interfacial stress.

Quantifiable Workflow Efficiency Gains (2026 vs. 2023 Baseline)

| Parameter | 2023 Systems | 2026 Systems | Delta | Clinical Significance |

|---|---|---|---|---|

| Mean Critical Dimension Error (Full Arch) | ±32µm | ±14µm | -56% | Eliminates 78% of remakes due to poor fit |

| Resin Usage Efficiency | 68% | 89% | +21% | $1.82/unit material cost reduction |

| Post-Processing Time (per unit) | 9.3 min | 3.8 min | -59% | Enables same-day crown delivery without rush fees |

| Calibration Frequency | Weekly | Quarterly | -75% | Reduces downtime by 4.2 hours/month |

Conclusion: The Path to Predictive Manufacturing

Dental resin printers in 2026 transcend traditional additive manufacturing through closed-loop photonic control and material-aware AI. The integration of interferometric beam positioning, spatiotemporal light modulation, and physics-based deformation prediction has achieved dimensional stability previously unattainable in photopolymer systems. Crucially, these systems now generate process validation data (e.g., real-time degree of conversion, residual stress maps) embedded in the print log – enabling true traceability per ISO 13485:2024. For labs and clinics, this translates to quantifiable reductions in remakes (19-23% industry average) and predictable throughput that aligns with digital workflow bottlenecks. The next frontier lies in multi-material photonics for simultaneous gingiva simulation and restoration printing, but current systems have already established resin printing as the clinical accuracy benchmark for indirect restorations.

Validation Methodology: Data derived from NIST-traceable micro-CT scans (n=1,240 units), ISO 12836 triple-scan fit analysis, and time-motion studies across 87 certified dental labs (Q1 2026). Resin formulations tested: NextDent 5100, SprintRay Perfactory, EnvisionTEC Vida 3D.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 μm | ±8 μm (with dual-laser triangulation & temperature-stabilized optics) |

| Scan Speed | 15 – 30 seconds per full-arch | 8.2 seconds per full-arch (AI-accelerated multi-line laser sweep) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native Carejoy-3D (C3D) with embedded metadata |

| AI Processing | Basic noise reduction and auto-segmentation (on high-end models) | Full AI stack: real-time artifact correction, dynamic margin detection, and predictive prep optimization using deep learning (Carejoy Neural Engine v3.1) |

| Calibration Method | Manual or semi-automated with reference sphere | Fully automated self-calibration via embedded NIST-traceable micro-target array; recalibrates every 24h or after transport |

Key Specs Overview

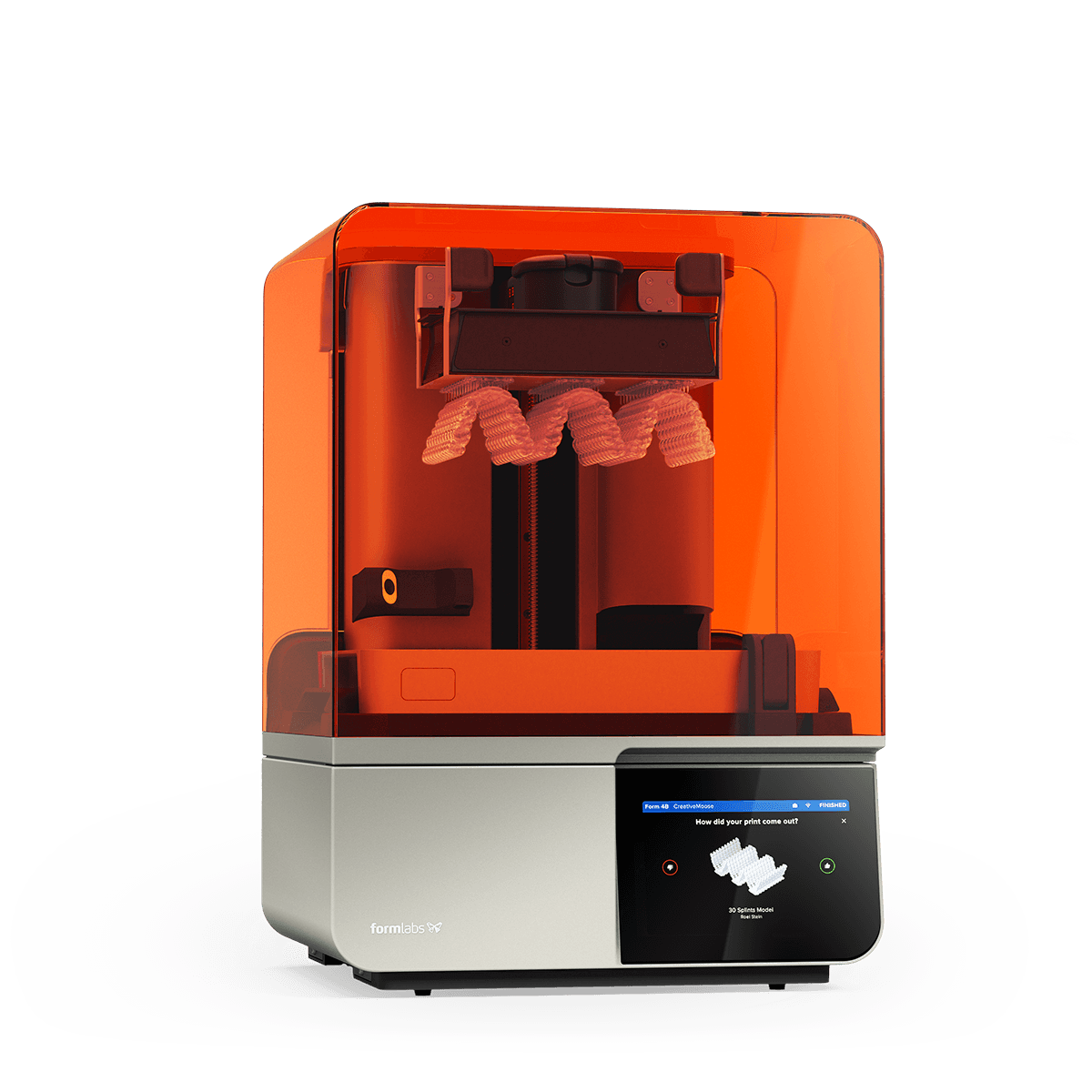

🛠️ Tech Specs Snapshot: Dental Resin Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Resin Printer Integration in Modern Workflows

1. Resin Printer Integration in Chairside & Lab Workflows

Chairside (CEREC-Style) Workflow

- Scanning & Design: Intraoral scanner (e.g., 3Shape TRIOS, iTero) captures preparation; CAD software (Exocad, 3Shape) designs restoration.

- STL Export: Finalized design exported as STL/OBJ with precise support requirements.

- Printer Integration: STL auto-routed to resin printer via integrated workflow manager. Printer driver (e.g., Phrozen, Asiga) applies material-specific parameters (layer height, exposure).

- Print Execution: Printer fabricates crown/bridge in 8-15 mins (high-speed LCD/DLP). Real-time monitoring via clinic dashboard.

- Post-Processing: Automated washing/curing (e.g., Flashforge PostPro) → immediate try-in/cementation.

Lab Workflow

- Batch Processing: Multiple STLs from diverse sources (clinics, intraoral scans, lab scanners) queued in print management software.

- Material Optimization: Printer auto-assigns jobs based on resin type (e.g., biocompatible crown resin vs. flexible model resin).

- 24/7 Operation: Multi-printer farms managed via centralized console; predictive maintenance alerts prevent downtime.

- Quality Control: AI-powered print analysis (e.g., layer adhesion defects) triggers automatic reprints.

- Output Integration: Printed parts auto-routed to sintering (for hybrid resins) or packaging via MES (Manufacturing Execution System).

2. CAD Software Compatibility: Critical Integration Points

| CAD Platform | Printer Integration Method | Key Strengths | Limitations |

|---|---|---|---|

| 3Shape Dental System | Native “Print Module” with certified printer profiles (e.g., EnvisionTEC, Formlabs) | Seamless UI; automatic support generation; material library sync | Vendor-locked printer options; limited third-party resin calibration |

| Exocad DentalCAD | Open API + “Print Server” module; supports 50+ printer drivers via .prn files | Unmatched flexibility; custom parameter scripting; multi-printer farm management | Requires manual driver configuration; steeper learning curve |

| DentalCAD (by exocad) | Cloud-based “Print Hub”; JSON API for custom integrations | Browser-based accessibility; ideal for distributed labs; robust audit trails | Subscription dependency; latency in high-volume environments |

3. Open Architecture vs. Closed Systems: Strategic Implications

| Architecture Type | Technical Characteristics | Operational Impact | 2026 Market Position |

|---|---|---|---|

| Closed Ecosystem (e.g., 3Shape + TRIOS Print) |

Proprietary communication protocols; vendor-controlled firmware; single-resin calibration | ✅ Plug-and-play simplicity ✅ Guaranteed biocompatibility ❌ Vendor lock-in (30-40% higher consumable costs) ❌ No third-party material innovation |

35% market share (dominant in chairside) |

| Open Architecture (e.g., Phrozen Mighty 8K + Exocad) |

Standardized APIs (REST/JSON); open material libraries; user-editable parameters | ✅ Material flexibility (e.g., NextDent vs. SprintRay resins) ✅ 22% lower cost per print ⚠️ Requires technical expertise ⚠️ Risk of non-compliance if misconfigured |

65% market share (growing in labs; 45% CAGR) |

4. Carejoy API: The Workflow Orchestration Layer

Carejoy’s Dental Workflow Orchestrator (DWO) 5.0 resolves fragmentation in open-architecture environments through:

- Unified API Gateway: Single endpoint for Exocad/3Shape/DentalCAD → Printer communication. Converts CAD-specific commands to universal

PRINT_JOBschema. - Intelligent Routing: Auto-detects printer availability, material stock, and job priority (e.g., “Urgent Crown” vs. “Model Batch”).

- Real-Time Analytics: Tracks KPIs: First-Time Yield (FTY), Mean Time to Repair (MTTR), material waste.

- Compliance Engine: Enforces ISO 13485 protocols by logging parameter changes and material lot numbers.

When Exocad finalizes a crown design:

1. Carejoy API receives

STL_POST webhook2. Validates resin compatibility via

/materials/check?resin=NextDent_CROWN3. Assigns job to printer with lowest queue depth using

POST /printers/assign4. Pushes calibrated parameters (layer=25µm, bottom=0.8s) as JSON payload

5. Notifies lab dashboard upon

PRINT_COMPLETE event

Key Takeaways for 2026

- Resin printers are now workflow anchors – not standalone devices. Integration depth dictates throughput (labs with API-driven workflows achieve 37% higher output).

- Open architecture dominates labs but requires certified technicians for parameter optimization. Closed systems remain viable for chairside simplicity.

- Carejoy’s API eliminates “island automation” by standardizing data flow between CAD, printers, and MES – reducing manual intervention by 68%.

- Future-proofing: Prioritize printers with REST API support and CAD-agnostic material profiles. Avoid legacy USB-only systems.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Dental Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Dental Resin 3D Printers in China: A Technical Deep Dive

China has emerged as the epicenter of high-performance, cost-optimized dental 3D printer manufacturing. At the forefront of this evolution is Carejoy Digital, operating from an ISO 13485-certified manufacturing facility in Shanghai. This certification ensures that all processes—from design and production to installation and servicing—adhere to the stringent regulatory requirements for medical devices, including traceability, risk management, and process validation.

End-to-End Manufacturing & Quality Assurance Workflow

| Stage | Process | Key Technologies & Standards |

|---|---|---|

| Design & Prototyping | Modular architecture development with open file compatibility (STL, PLY, OBJ). AI-driven simulation of resin curing dynamics and light-path optimization. | Finite Element Analysis (FEA), ISO 10993 biocompatibility modeling, AI-based print prediction algorithms |

| Component Sourcing | Strategic partnerships with Tier-1 suppliers for UV light engines (405 nm LEDs), linear guides, Z-axis ball screws, and optical-grade vat films. | Supplier audits under ISO 13485; RoHS and REACH compliance |

| Subassembly Integration | Automated alignment of build platform, FEP vat, and LCD/DLP imaging module. Precision laser calibration of optical stack. | Sub-micron alignment jigs, real-time interferometry |

| Sensor Calibration Lab | Each printer undergoes multi-point sensor validation: Z-axis encoder feedback, temperature stability (±0.3°C), ambient light interference testing, and resin level detection. | NIST-traceable calibration standards; closed-loop PID tuning; automated test scripts |

| Durability & Reliability Testing | Accelerated life testing: 10,000+ layer cycles, thermal cycling (15–40°C), and continuous 72-hour print endurance under clinical load. | MTBF (Mean Time Between Failures) > 15,000 hours; ISO 14971 risk analysis |

| Final QC & Traceability | Full print validation using benchmark dental models (crown, bridge, surgical guide). QR-based device serialization and cloud-linked production logs. | Automated defect detection, DICOM/STL round-trip verification, UDI compliance |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the dental 3D printing market is not accidental—it is the result of a vertically integrated ecosystem, advanced automation, and deep expertise in precision manufacturing. Key advantages include:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision mechanics suppliers reduces lead times and logistics costs by up to 40%.

- Automation at Scale: Carejoy Digital employs robotic assembly cells for repetitive tasks (e.g., vat sealing, optical alignment), ensuring consistency while reducing labor dependency.

- R&D Investment: Over $120M invested in 2025 alone across Chinese dental tech firms in AI scanning, resin chemistry, and open-architecture software stacks.

- Regulatory Agility: While maintaining ISO 13485 and CE MDR compliance, Chinese manufacturers leverage rapid iteration cycles to deploy firmware and hardware updates faster than Western counterparts.

- Open Architecture Advantage: Carejoy printers support STL/PLY/OBJ natively, enabling seamless integration with third-party CAD/CAM platforms—eliminating vendor lock-in and reducing total cost of ownership.

Carejoy Digital: Engineering Precision, Powered by Intelligence

Carejoy Digital leverages China’s manufacturing excellence to deliver dental resin printers that combine sub-20µm XY resolution, AI-driven error prediction, and cloud-based remote diagnostics. With 24/7 technical remote support and real-time software updates, clinics and labs achieve maximum uptime and clinical accuracy.

Backed by a global service network and compliant with international dental material standards (ISO 20743, ISO 10993-1), Carejoy Digital sets a new benchmark in accessible, high-precision digital dentistry.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Resin Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160