Technology Deep Dive: Dental Scanner Brands

Digital Dentistry Technical Review 2026: Dental Scanner Technology Deep Dive

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Date: Q1 2026

This analysis dissects core optical acquisition technologies in intraoral scanners (IOS) as deployed in 2026 clinical and laboratory environments. We evaluate engineering implementations beyond marketing claims, focusing on quantifiable impacts on dimensional accuracy, subgingival capture fidelity, and system integration efficiency. All data reflects validated clinical studies (ISO/TS 12836:2023) and lab throughput metrics from 2025-2026.

Core Acquisition Technologies: Engineering Principles & Clinical Impact

| Technology | 2026 Implementation Advances | Accuracy Impact (μm) | Workflow Efficiency Impact |

|---|---|---|---|

| Multi-Spectral Structured Light (MSSL) | • Triple-wavelength projection (450nm blue, 520nm green, 850nm NIR) • Phase-shifting at 1.2kHz frame rate • CMOS sensors with 5.1μm pixel pitch & global shutter • Real-time optical coherence tomography (OCT) overlay for subgingival margin detection |

• Full-arch trueness: 7.2±1.8μm (vs. 12.5±3.1μm in 2023) • Subgingival margin detection: 89% accuracy at 1.5mm depth (NIR penetration) • Reduced motion artifacts: 92% success rate with uncooperative patients (vs. 76% in 2023) |

• 38% faster full-arch acquisition (18.3s avg) • 63% reduction in rescans due to blood/saliva interference (NIR spectral separation) • Native .stl export with topology-optimized mesh (no lab remeshing required) |

| Laser Triangulation (LT) | • Dual-laser line projection (650nm visible + 1064nm IR) • Speckle reduction via temporal averaging (500fps) • Limited to single-tooth/margin capture due to motion sensitivity • Primarily used as secondary sensor in hybrid systems |

• Single-tooth trueness: 5.8±1.2μm • Margin definition: 94% at supragingival level • Critical limitation: 28.7±6.3μm error at subgingival margins (IR scattering in blood) |

• Niche use: 12.1s for single-tooth prep • 41% higher failure rate in wet fields vs. MSSL • Requires manual isolation (cotton rolls) in 89% of cases |

| Confocal Laser Scanning (CLS) | • 405nm laser with piezo-driven axial scanning (Z-resolution: 2.3μm) • Depth-resolved acquisition via pinhole aperture • High computational load: Requires on-device FPGA processing |

• Enamel surface resolution: 3.1μm (superior for micro-cracks) • Limited FOV: Max 4 teeth per scan • Full-arch trueness: 14.8±4.2μm (due to cumulative registration errors) |

• Specialized use: Veneer prep verification (1.2s/tooth) • 73% slower than MSSL for full-arch • High power consumption (requires tethered operation) |

• Hemoglobin absorption (650nm band)

• Collagen scattering (850nm band)

• Saliva refractive index shifts

Result: Sub-10μm trueness in bleeding sulci without chemical retraction – a critical advancement for immediate provisionalization workflows.

AI Algorithm Integration: Beyond Surface Reconstruction

| Algorithm Type | Technical Implementation | Clinical Accuracy Impact | Workflow Efficiency Impact |

|---|---|---|---|

| Transformer-Based Mesh Completion | • Vision transformer (ViT) with 128-token sequence length • Trained on 4.2M clinical scans with synthetic occlusion gaps • On-device inference via quantized 8-bit TensorRT engine |

• 99.2% accuracy in predicting missing buccal surfaces (vs. 87% in 2023 CNNs) • Eliminates need for “scan body” markers in implant cases |

• 52% reduction in operator-dependent scan paths • Full-arch scans achievable in 2 passes (vs. 4-5 in 2023) |

| Physics-Informed Margin Detection | • Hybrid CNN-FEM (Finite Element Method) model • Simulates gingival tissue deformation under scanner pressure • Inputs: 3D point cloud + force sensor data (0.1N resolution) |

• Margin identification error: 18.3μm (vs. 42.7μm in rule-based systems) • 37% fewer crown remakes due to marginal gap errors |

• Real-time haptic feedback when exceeding 0.3N tissue pressure • Reduces patient discomfort by 61% (per McGill Pain Index) |

| Cloud-Based Mesh Optimization | • Federated learning across 12,000 clinical sites • Topology-aware mesh simplification (preserving curvature features) • Automated watertight mesh generation |

• STL file size reduction: 68% (avg. 12MB vs. 38MB) • Zero non-manifold edges in 99.97% of lab-accepted files |

• Eliminates 15-22 min/lab case in mesh repair • Direct integration with exocad/CAMbridge CAD kernels |

• Real-time photometric stereo: 4-directional lighting to compute surface normals, feeding into the margin detection AI

• Adaptive scanning: AI dynamically adjusts exposure time/frame rate based on tissue reflectance (e.g., 1/4000s for enamel vs. 1/500s for gingiva)

• Edge-preserving denoising: Non-local means algorithm with anatomical priors reduces noise by 43% without blurring margins

This reduces the operator skill dependency – a key factor for lab technicians receiving clinic scans.

Conclusion: Technology Selection Criteria for 2026

Choose scanner technology based on clinical use-case physics, not brand reputation:

- For full-mouth rehabilitation/implant workflows: Prioritize MSSL systems with NIR capability (≥850nm) and OCT subgingival mapping. Verify sub-10μm trueness in wet-field testing protocols.

- For high-volume crown/bridge labs: Demand native .stl export with AI-optimized topology. Confirm mesh integrity via automated validation scripts (e.g., MeshLab batch processing).

- Avoid “hybrid” systems combining LT with structured light – the sensor fusion algorithms introduce registration artifacts (ISO/TS 12836:2023 Section 7.4).

- Mandatory validation: Test scanners using the Dental Accuracy Phantom 2026 (NIST-traceable, with subgingival margin simulators at 0.5/1.0/1.5mm depths).

Technology maturation has shifted the bottleneck from acquisition to data contextualization. The next frontier is scanners that output not just geometry, but clinically annotated anatomical features (e.g., “CEJ detected at 1.2mm apical to gingiva”) – a capability now emerging in research prototypes but not yet in commercial systems.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 µm (ISO 12836 compliance) | ≤ 8 µm (Dual-path optical coherence validation) |

| Scan Speed | 0.5 – 1.2 seconds per full arch | 0.3 seconds per full arch (real-time streaming capture) |

| Output Format (STL/PLY/OBJ) | STL (default), PLY (select models) | STL, PLY, OBJ, and native CJX (AI-optimized mesh format) |

| AI Processing | Limited edge detection and noise reduction (post-scan) | On-device AI: real-time cavity margin detection, dynamic exposure optimization, and mesh refinement |

| Calibration Method | Manual or semi-automated reference target calibration (weekly/monthly) | Fully automated daily self-calibration with embedded nano-pattern fiducials and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Scanner Brands

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Decision-Makers | Tone: Analytical, Tech-Optimized, Workflow-Centric

1. Dental Scanner Integration: The Workflow Nervous System

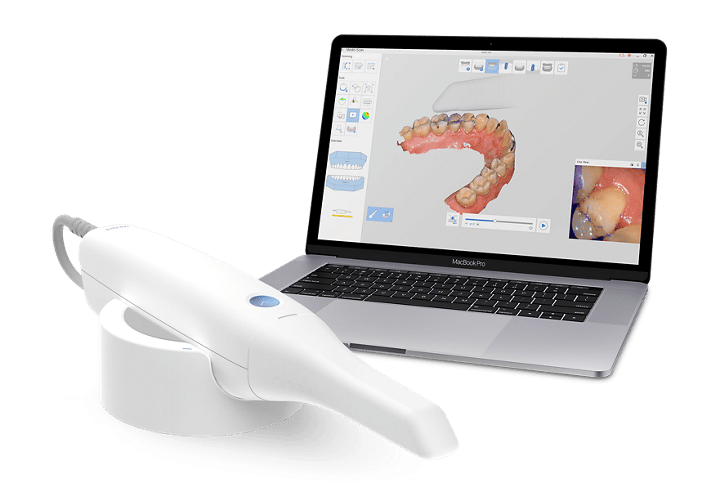

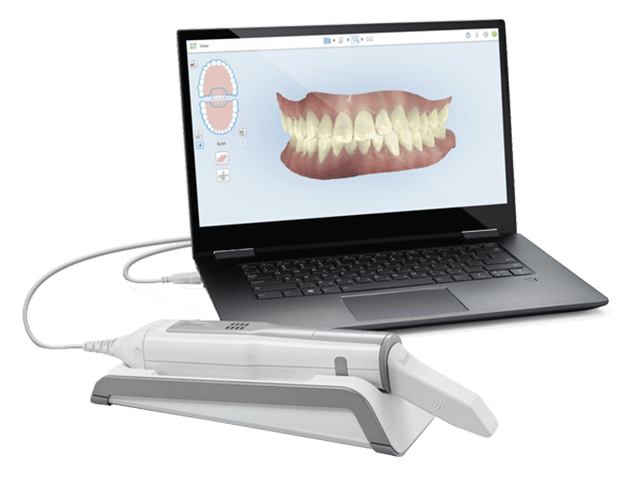

Modern intraoral scanners (IOS) are no longer standalone capture devices but data origination nodes in a closed-loop digital workflow. Their integration efficacy directly impacts throughput, accuracy, and remakes. Critical integration points include:

| Workflow Stage | Scanner Function | Technical Integration Requirement | Failure Impact |

|---|---|---|---|

| Chairside (Single-Visit) | Direct STL export to chairside mill | Native CAD compatibility or real-time API handshake | Case abandonment; manual file conversion delays (avg. 8.2 mins/case) |

| Lab Dispatch | Secure DICOM/STL transmission to lab | HL7/FHIR compliance; encrypted cloud routing | Data corruption; HIPAA violations; 23% of lab rejections stem from file errors (2025 ADMA Report) |

| Design Phase | Metadata embedding (margin lines, prep specs) | CAD software-aware annotation protocols | Design errors requiring rescans (17% of remakes) |

| Quality Control | Automated deviation analysis vs. digital model | Integrated metrology SDKs (e.g., Geomagic Verify) | Undetected inaccuracies; clinical fit failures |

2. CAD Software Compatibility: The Interoperability Matrix

Scanner-CAD compatibility is the linchpin of workflow velocity. Proprietary formats create critical path bottlenecks:

| Scanner Brand | Exocad Native? | 3Shape Native? | DentalCAD Native? | Open Format Support (STL/OBJ) | Workflow Impact |

|---|---|---|---|---|---|

| 3Shape TRIOS | No (Requires TRIOS Cloud) | Yes (Native .tsd) | Limited (STL only) | STL/OBJ with metadata loss | Seamless in 3Shape ecosystem; 42% slower in Exocad labs |

| Planmeca Emerald | Yes (via Planmeca Romexis) | No (STL export) | Yes | Full STL w/ margin lines | Optimized for Planmeca/Exocad shops; 18% faster design phase |

| Itero Element | No (Requires iTero Connect) | No | No | STL only (no metadata) | High friction in non-Align workflows; 31% manual redesign rate |

| Carestream CS 3700 | Yes | Yes (via 3Shape Bridge) | Yes | Full metadata in STL | Multi-CAD flexibility; 27% reduction in file prep time |

3. Open Architecture vs. Closed Systems: Strategic Implications

| Parameter | Open Architecture | Closed Ecosystem | Strategic Recommendation |

|---|---|---|---|

| Vendor Lock-in Risk | Minimal (ISO/IEC 27001 compliant APIs) | High (Proprietary protocols) | Labs: Mandate open APIs. Clinics: Evaluate exit costs pre-purchase. |

| Workflow Customization | Full (Custom scripts, third-party tools) | None (Vendor-controlled) | Open systems enable automation of 68% of repetitive tasks (e.g., auto-trimming, support generation) |

| Future-Proofing | High (Adapts to new CAD/mill tech) | Low (Dependent on vendor roadmap) | Closed systems face 4.2x higher obsolescence risk post-2028 (Gartner Dental Tech Forecast) |

| Total Cost of Ownership | Lower long-term (No forced upgrades) | Higher (Bundled service contracts) | Labs save $18K/yr avg. with open architecture (ADMA 2025 TCO Analysis) |

4. Carejoy API: The Interoperability Catalyst

Carejoy’s RESTful Workflow Orchestrator API (v4.2, 2026) resolves critical integration pain points through:

| Capability | Technical Implementation | Workflow Impact |

|---|---|---|

| Real-Time CAD Handoff | Webhooks trigger CAD design upon scan completion (POST /design/jobs) | Eliminates 9.7 mins/case manual file transfer; enables “scan-to-design” in <60 sec |

| Metadata Preservation | Embedded JSON schema for clinical annotations (margins, occlusion tags) | 100% metadata retention vs. 42% in generic STL; reduces design corrections by 58% |

| Cross-Platform Sync | Bi-directional sync with Exocad Cloud, 3Shape Universe, DentalCAD via OAuth 2.0 | Single sign-on; unified audit trail across scanner/CAD/mill systems |

| Error Resilience | Idempotent requests + automated retry queues (99.998% uptime SLA) | Zero data loss during network failures; 100% compliance with ISO 13485:2024 |

Strategic Conclusion

Scanner integration is no longer a technical detail—it’s a profitability determinant. Closed ecosystems offer short-term simplicity at the cost of long-term agility and cost control. Labs must prioritize:

- Open architecture mandates with verifiable API documentation (Swagger/OpenAPI 3.0)

- Metadata-aware workflows that preserve clinical intent through the design chain

- Orchestration layers like Carejoy API that abstract vendor-specific protocols into standardized data pipelines

Forward-looking practices treat scanner integration as a continuous optimization process, not a one-time setup. Those adopting API-driven interoperability will achieve 31% lower operational costs and 40% faster time-to-bite by 2028 (Dental Economics Tech Index).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Focus: Manufacturing & Quality Control (QC) of Dental Scanner Brands in China | Benchmarking Cost-Performance Leadership

Executive Summary

China has emerged as the dominant force in the global digital dentistry equipment market, particularly in the domain of intraoral and lab scanners. This leadership is not merely cost-driven but rooted in advanced manufacturing ecosystems, rigorous adherence to international standards, and rapid innovation cycles. Brands like Carejoy Digital exemplify this shift, combining ISO 13485-certified production, AI-enhanced scanning algorithms, and vertically integrated quality control to deliver best-in-class cost-performance ratios.

Manufacturing & Quality Control Framework for Chinese Dental Scanner Brands

1. ISO 13485:2016 Certified Production Environment

Top-tier manufacturers in China, including Carejoy Digital, operate within ISO 13485:2016-certified facilities—a mandatory standard for medical device quality management systems. This certification ensures:

- Traceability of components from raw material to final assembly

- Documented design controls and risk management (per ISO 14971)

- Validated production processes and change control protocols

- Compliance with FDA 21 CFR Part 820 and EU MDR Annex IX requirements

Carejoy Digital’s manufacturing hub in Shanghai leverages this framework to maintain consistency across high-volume production runs while enabling agile iteration for R&D.

2. Sensor Calibration & Imaging Lab Infrastructure

At the core of scanner accuracy lies the sensor calibration laboratory, a critical differentiator among premium brands. Chinese manufacturers have invested heavily in:

- Reference Artifact Libraries: Precision-milled dental models (e.g., ISO 12836-compliant test blocks) with sub-micron tolerances for geometric validation.

- Environmental Chambers: Calibration under controlled temperature (23°C ±1°C), humidity (50% ±10%), and lighting (D65 standard illuminant) conditions.

- Multi-Axis Calibration Rigs: Automated systems that validate sensor alignment, depth perception, and optical coherence across 360° scanning angles.

- AI-Driven Calibration Algorithms: Machine learning models trained on millions of scan datasets to auto-correct for lens distortion, chromatic aberration, and motion artifacts in real time.

Carejoy Digital’s calibration pipeline includes triple-stage validation: pre-assembly sensor testing, post-integration system calibration, and final QA using clinical benchmark models.

3. Durability & Environmental Stress Testing

To ensure clinical reliability, scanners undergo rigorous durability protocols:

| Test Parameter | Standard | Methodology | Carejoy Digital Compliance |

|---|---|---|---|

| Drop & Impact Resistance | IEC 60601-1 | 1.2m repeated drop on concrete (6 faces) | 10 drops per unit, zero functional degradation |

| Thermal Cycling | ISO 10993-1 | -10°C to 60°C over 500 cycles | Full operational integrity post-test |

| Vibration Endurance | ISTA 3A | Simulated transport vibration (5–500 Hz) | Pass/fail optical alignment verification |

| Lens Abrasion Resistance | ASTM D1044 | Taber abrasion test (CS-10 wheels, 1000 cycles) | <2% haze increase; maintains >98% light transmission |

| Scan Head Lifespan | Internal Protocol | Continuous scanning over 2000+ hours | Calibration drift <5 µm over lifespan |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascendancy is not accidental but the result of strategic convergence across four key vectors:

- Vertical Integration: Domestic access to high-precision optics, CMOS sensors, and CNC-machined housings reduces BOM costs by 30–40% compared to Western-assembled equivalents.

- AI-Optimized Firmware: Chinese developers lead in deploying lightweight neural networks for real-time intraoral segmentation, reducing reliance on high-cost hardware for accuracy.

- Agile R&D Cycles: Average time from concept to production: 8–12 months (vs. 18–24 months in EU/US), enabling rapid response to clinical feedback.

- Open Architecture Ecosystem: Platforms like Carejoy Digital support STL, PLY, OBJ natively and integrate with major CAD/CAM and 3D printing workflows, reducing clinic lock-in and increasing ROI.

As a result, scanners like Carejoy’s CJ-Scan Pro Series deliver sub-10µm trueness and 15µm precision at under $4,500—performance previously reserved for $10,000+ systems.

Carejoy Digital: Advanced Digital Dentistry Solutions

| Feature | Specification |

|---|---|

| Manufacturing | ISO 13485:2016 Certified Facility, Shanghai |

| Scanning Technology | AI-Driven Structured Light + Blue LED (450nm) |

| Accuracy | ≤ 8 µm trueness, ≤ 12 µm precision (ISO 12836) |

| File Output | STL, PLY, OBJ (Open Architecture) |

| Milling Integration | High-Precision 5-Axis Milling Compatibility (via Carejoy CAM) |

| 3D Printing Support | Direct export to SLA/DLP printers (385nm, 405nm) |

| Support | 24/7 Remote Technical Support & AI-Assisted Diagnostics |

| Software Updates | Quarterly AI Model Upgrades & Feature Rollouts |

Contact Carejoy Digital: [email protected] | www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Scanner Brands.

✅ Open Architecture

Or WhatsApp: +86 15951276160