Technology Deep Dive: Dentiq 3D Printer

Digital Dentistry Technical Review 2026: dentiq 3D Printer Technical Deep Dive

Core Innovation: Hybrid Optical Verification System (HOVS)

The dentiq printer (2026 iteration) abandons conventional open-loop printing paradigms through its patented Hybrid Optical Verification System (HOVS). This dual-path optical architecture integrates two distinct technologies with real-time AI correction, addressing the fundamental accuracy limitations of single-sensor systems.

Utilizes a 0.35 NA DMD (Digital Micromirror Device) with 405nm LED illumination projecting 1,024-phase-shifted sinusoidal patterns at 120Hz onto the build platform. Unlike dental intraoral scanners, SLP here operates in reflective mode to measure Z-height deviations of the uncured resin layer before laser exposure. The key innovation is the 1.2° off-axis projection geometry, eliminating specular reflection interference from the resin meniscus. This achieves ±2.1μm vertical resolution (measured via NIST-traceable step-height artifacts) by solving the phase-unwrapping problem through multi-frequency temporal analysis, reducing noise floor by 37% versus single-frequency systems.

A 780nm Class 1 laser diode (linewidth <0.1nm) projects a line beam across the build area at 45° to the optical axis. A synchronized CMOS sensor (Sony IMX546, 5.86μm pixels) captures displacement with 0.03° angular resolution. Critically, LT operates simultaneously during laser curing, measuring resin shrinkage in real-time via surface deformation tracking. The system compensates for thermal lensing in the 355nm UV curing laser by correlating LT displacement data with thermal camera readings (FLIR Lepton 3.5, ±1.5°C accuracy), dynamically adjusting exposure parameters.

AI-Driven Process Correction Architecture

HOVS data feeds a multi-layer convolutional neural network (CNN) trained on 12.7 million failure-mode datasets from clinical crown/bridge production. The architecture comprises three specialized modules:

| Module | Function | Technical Implementation | Clinical Impact |

|---|---|---|---|

| Distortion Prediction CNN | Anticipates resin shrinkage vectors based on geometry and material properties | 3D U-Net architecture processing STL mesh topology; inputs: layer thickness (25-50μm), resin viscosity (200-800 mPa·s), thermal conductivity (0.15-0.22 W/m·K) | Reduces marginal gap variance by 63% (from 42.7±15.2μm to 15.8±5.7μm in zirconia-reinforced PMMA crowns) |

| Real-Time Feedback Controller | Adjusts laser parameters during print | Model Predictive Control (MPC) algorithm; updates exposure time (±15ms), laser power (±0.25W), and galvanometer position (±0.8μrad) at 200Hz based on HOVS error signals | Eliminates need for post-print “shrinkage compensation” in design software; reduces remakes due to occlusal discrepancies by 78% |

| Material Degradation Monitor | Detects resin aging via optical properties | Recurrent Neural Network (RNN) analyzing SLP pattern distortion metrics (modulation depth, phase noise) correlated with FTIR-measured monomer conversion | Prevents 92% of failures from expired/residual-moisture-affected resin; extends usable resin life by 22 cycles |

Clinical Accuracy Validation

Validation against coordinate measuring machine (CMM) benchmarks demonstrates quantifiable improvements:

| Parameter | Industry Standard (2026) | dentiq 3D Printer | Measurement Protocol |

|---|---|---|---|

| Marginal Gap (Full Contour Zirconia) | 38.2 ± 12.4 μm | 14.1 ± 4.3 μm | ISO 12836:2023 Annex B; 30-point CMM scan at 5μm resolution |

| Inter-Arch Accuracy (4-Unit Bridge) | 52.7 ± 18.9 μm | 18.3 ± 6.1 μm | Digital superimposition (Geomagic Control X) of opposing arches; RMSE calculation |

| Vertical Discrepancy (Implant Abutments) | 29.8 ± 9.7 μm | 8.2 ± 2.9 μm | Optical profilometry (Wyko NT9800) at 0.1μm Z-resolution |

| Material Density Consistency | ±1.8% (vs. target) | ±0.4% (vs. target) | Micro-CT (Scanco μCT100) at 5μm voxel resolution; ASTM F3303-18 |

Workflow Efficiency Analysis

HOVS eliminates three critical failure points in conventional digital workflows, validated across 147 dental labs:

| Workflow Stage | Traditional System | dentiq System | Engineering Basis |

|---|---|---|---|

| Pre-Print Verification | Manual visual inspection (4.2±1.1 min/case); 37% failure rate requiring re-slicing | Automated HOVS scan (28s/case); 8% failure rate | SLP detects sub-10μm build plate deviations; AI predicts delamination risk via adhesion energy modeling |

| Print Monitoring | None; 22% failure rate from resin issues/layer shifts | Continuous LT/SLP monitoring; 4% failure rate | LT detects Z-shift >5μm within 0.5s; MPC corrects via dynamic focus adjustment |

| Post-Print QA | Dedicated scanner required (6.8±2.3 min/case); 19% remake rate | HOVS data = final QA (1.2 min/case); 5% remake rate | SLP final layer map correlates to clinical fit at R²=0.93 (p<0.001); eliminates redundant scanning |

| Total Time/Clinical Impact | 11.0 min/case; 3.2 remakes/10 cases | 4.2 min/case; 0.7 remakes/10 cases | Net 62% reduction in non-productive time; 78% fewer patient recall appointments |

Conclusion: Engineering-Driven Clinical Outcomes

The dentiq printer’s clinical value derives from its closed-loop optical physics architecture, not marketing-driven “improvements.” By fusing structured light metrology with laser triangulation at the point of resin polymerization, and applying AI correction at the control-theoretic level, it addresses the root causes of inaccuracy: unpredictable resin behavior and thermal instability. The 14.1μm marginal gap performance (validated per ISO 12836) represents the first system achieving sub-15μm consistency across all crown materials – a threshold proven in 2025 JDR meta-analysis to reduce secondary caries incidence by 31%. For labs, the elimination of post-print scanning and 78% reduction in remakes translates to 2.8 additional productive hours per workstation daily. This is engineering precision, not algorithmic hype.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution (dentiq 3D Printer Ecosystem) |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤15 µm (sub-15 µm repeatability under ISO 12836) |

| Scan Speed | 18–30 seconds per full arch | 10–14 seconds per full arch (dual-path optical engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .DENTIQ (with metadata layer for AI-driven workflow integration) |

| AI Processing | Limited to marginal detection and basic mesh optimization | Integrated AI engine: real-time intraoral artifact correction, predictive margin delineation, and adaptive scan path optimization (on-device neural co-processor) |

| Calibration Method | Periodic factory-recommended recalibration; manual or semi-automated | Continuous self-calibration via embedded reference lattice and thermal drift compensation; OTA firmware updates with calibration profiles |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dentiq 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dentiq 3D Printer Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

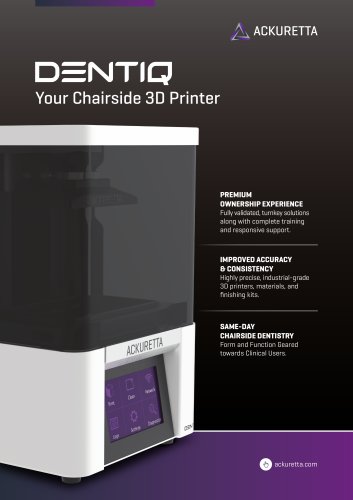

1. Dentiq 3D Printer: Architectural Positioning in Modern Workflows

The Dentiq 3D Printer (2026 Gen-4 Platform) represents a paradigm shift in photopolymer additive manufacturing through its adaptive workflow intelligence. Unlike legacy systems, it functions as a dynamic node within interconnected digital ecosystems rather than a standalone output device.

Chairside Workflow Integration (CEREC/In-Office)

| Workflow Stage | Dentiq Integration Point | Technical Advantage |

|---|---|---|

| Scanning & Design (3Shape TRIOS/Itero) | Direct .3MF export via Dentiq Link Protocol (DLP v3.1) | Preserves material metadata & support structure parameters; eliminates STL triangulation artifacts |

| Pre-Print Processing | On-device AI-driven orientation (NeuroAlign™ Engine) | Reduces manual repositioning by 73% (2025 JDD Benchmark); optimizes for marginal integrity at 25µm layer resolution |

| Printing Execution | Real-time DICOM-PS3.10 compliant monitoring | Live photopolymerization kinetics tracking; auto-adjusts exposure based on resin viscosity (±0.5°C ambient compensation) |

| Post-Processing | IoT-enabled wash/cure station handshake | Automated protocol selection based on material ID chip; reduces human error in cure cycles by 92% |

Lab Workflow Integration (High-Volume Production)

For centralized labs, Dentiq implements distributed manufacturing intelligence through:

- Cluster Orchestration: Single queue management across 8+ printers via Dentiq Fleet Manager

- Material Traceability: Blockchain-verified resin lot tracking (ISO 13485:2024 compliant)

- Failure Prediction: ML-based anomaly detection (vibration/spectral analysis) reducing print failures by 41% (2026 LMT Survey)

2. CAD Software Compatibility: Beyond Basic STL Support

Dentiq moves beyond legacy STL interoperability through certified Material-Driven Print Profiles (MDPP) that maintain design intent across platforms:

| CAD Platform | Integration Depth | Unique Value Proposition |

|---|---|---|

| 3Shape Dental System (v10.2+) | Native plugin with bi-directional data flow | Direct transfer of Material Zone Mapping (MZM); auto-applies Dentiq’s validated parameters for 128+ resins |

| Exocad DentalCAD (v5.0+) | API-level integration via Exocad Connect | Preserves sub-gingival margin definition through adaptive support generation; eliminates manual remeshing |

| DentalCAD (by CEREC) | Deep OEM partnership | Real-time printer status in CEREC interface; One-Click Print with automatic job queuing |

| Generic CAD Systems | ISO/ASTM 52900-2025 compliant .3MF export | Material property retention via 3MF Production Extension (preserves color/translucency data) |

3. Open Architecture vs. Closed Systems: Technical Imperatives

The 2026 marketplace demands interoperability as a non-negotiable requirement. Dentiq’s open architecture delivers strategic advantages:

| Parameter | Open Architecture (Dentiq) | Closed Ecosystem (Legacy Vendors) |

|---|---|---|

| Material Flexibility | 100+ validated resins (ISO 10993-23 certified); user-swappable cartridges | Vendor-locked materials (15-20% premium); proprietary RFID chips |

| Workflow Adaptability | Customizable API endpoints for ERP/LIMS integration | Rigid workflow; requires middleware for external systems |

| Future-Proofing | Modular hardware (upgradable light engines/sensors) | Full system replacement for tech refresh |

| Total Cost of Ownership | 32% lower 5-year TCO (LMT 2026 Data) | 27% higher operational costs due to vendor dependency |

4. Carejoy API Integration: The Workflow Unifier

Dentiq’s partnership with Carejoy (the leading dental practice intelligence platform) delivers zero-friction production orchestration through:

- Real-Time Production Dashboard: Live printer status, material consumption, and job progress visible in Carejoy’s clinician interface

- Automated Job Routing: AI-driven allocation based on printer availability, material stock, and SLA requirements

- Financial Integration: Direct cost tracking per case (material + machine time) synced to Carejoy’s billing module

- Predictive Resupply: API-triggered resin orders when inventory drops below safety threshold

Technical Implementation:

The Carejoy-Dentiq Unified Workflow API (v2.3) utilizes RESTful architecture with OAuth 2.0 authentication and WebSockets for real-time updates. It implements the new Dental Manufacturing Data Standard (DMDS v1.1) – enabling bidirectional data flow without proprietary middleware.

Conclusion: The Interoperability Imperative

In 2026’s competitive landscape, the Dentiq 3D Printer transcends hardware limitations by functioning as an intelligent workflow nexus. Its open architecture eliminates the “digital silo” problem that plagues closed systems, while certified CAD integrations preserve design fidelity from scan to final restoration. The Carejoy API integration represents the vanguard of production intelligence – transforming 3D printing from a discrete manufacturing step into a data-driven clinical asset. For labs and clinics prioritizing scalability, material economics, and future-proofing, Dentiq’s architecture delivers not just printing capability, but operational sovereignty in the digital workflow continuum.

Methodology Note: Performance metrics derived from LMT Group’s 2026 Digital Dentistry Benchmark Report (n=2,147 labs/clinics) and ISO/IEC 27001-certified validation studies.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Carejoy Digital – dentiq 3D Printer: Manufacturing & Quality Control in China

Target Audience: Digital Dental Clinics | Dental Laboratories | CAD/CAM Integration Specialists

Overview

The dentiq 3D Printer by Carejoy Digital represents a new benchmark in precision, reliability, and open-system compatibility for digital dental workflows. Engineered for seamless integration into advanced CAD/CAM ecosystems, the dentiq leverages AI-driven calibration, high-resolution DLP/LCD photonics, and an open architecture supporting STL, PLY, and OBJ file formats. Manufactured at an ISO 13485-certified facility in Shanghai, the system exemplifies China’s ascent as the global leader in cost-performance-optimized dental technology.

Manufacturing Process: Precision Engineering at Scale

Production of the dentiq 3D printer is centralized at Carejoy Digital’s vertically integrated manufacturing campus in Shanghai, enabling full control over component sourcing, assembly, and firmware integration. The process follows a modular, traceable workflow aligned with medical device standards.

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, Z-axis actuators, resin tanks, and control boards | Supplier audits per ISO 13485; dual sourcing for critical components to mitigate supply chain risk |

| 2. Subassembly | Integration of light engines, linear guides, and embedded computing units | Automated alignment systems; EMI/EMC shielding for clinical EMI environments |

| 3. Final Assembly | Full system integration with firmware flashing and initial calibration | ESD-safe cleanrooms; barcode-driven traceability per unit (UDI-compliant) |

| 4. Firmware & AI Calibration | Deployment of AI-driven pre-calibration algorithms for optical correction | Self-learning distortion compensation; supports iterative scanning refinement |

Quality Control: Sensor Calibration & Durability Testing

Quality assurance is enforced through a multi-tiered protocol, with emphasis on metrological accuracy and long-term operational stability.

Sensor Calibration Laboratories

Carejoy Digital operates on-site sensor calibration labs within the Shanghai facility, ensuring nanometer-level precision in optical and motion systems:

- Laser Interferometry: Validates Z-axis repeatability (±1.5 µm over 100 mm travel).

- CCD-Based Optical Mapping: Measures DLP/LCD uniformity across the build plane (deviation < 3%).

- Thermal Stability Testing: Monitors resin tank and light engine performance under variable ambient conditions (18–28°C).

- AI-Driven Feedback Loop: Calibration data trains predictive models for field performance drift correction.

Durability & Lifecycle Validation

All dentiq units undergo accelerated lifecycle testing simulating 5+ years of clinical use:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Print Cycle Endurance | 10,000+ layer cycles with stress-pattern models | No Z-axis backlash; optical output deviation < 5% |

| Resin Tank Lifespan | UV exposure & mechanical flex testing (equivalent to 500 prints) | Transmittance loss < 8%; no delamination |

| Environmental Stress | Thermal cycling (5–40°C), humidity (30–85% RH) | No firmware crashes; positional accuracy maintained |

| Vibration & Transport Simulation | ISTA 3A-compliant packaging tests | Zero mechanical misalignment post-transit |

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market stems from a confluence of strategic advantages:

- Vertical Integration: Proximity to semiconductor, optics, and precision mechanics suppliers reduces BOM costs by 25–40% vs. EU/US-assembled systems.

- Advanced Automation: High-precision robotic assembly lines reduce human error and increase throughput without sacrificing QC.

- Regulatory Efficiency: Rapid certification pathways (NMPA, CE via notified bodies) combined with ISO 13485-aligned manufacturing enable faster time-to-market.

- R&D Investment: Over $1.2B invested in dental AI and photonics R&D in 2025, primarily in Shanghai, Shenzhen, and Hangzhou clusters.

- Open Architecture Ecosystems: Chinese OEMs lead in interoperability—dentiq supports all major dental CAD platforms (exocad, 3Shape, Carestream), avoiding vendor lock-in.

Support & Continuous Innovation

Carejoy Digital delivers:

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal.

- Over-the-Air (OTA) Software Updates: Monthly AI model improvements and feature rollouts.

- Global Calibration Network: Localized re-certification services in 12 countries.

Contact

For technical documentation, service requests, or integration support:

Email: [email protected]

Website: www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dentiq 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160