Technology Deep Dive: Dentium Intraoral Scanner

Dentium Intraoral Scanner Technical Deep Dive: Engineering Analysis 2026

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Directors, Digital Workflow Engineers

Core Technology Architecture: Beyond Marketing Hype

Dentium’s 2026 platform (model DS-7X series) implements a hybrid structured light/confocal microscopy system – a critical distinction from legacy laser triangulation systems (now obsolete in premium IOS). Laser-based systems suffer from speckle noise and moisture interference, failing ISO 12836:2023 wet-surface accuracy thresholds. Dentium’s approach leverages:

1. Multi-Phase Shifted Structured Light (MPSL)

Utilizes 445nm blue LED projectors with 120Hz frame rate, projecting non-redundant Gray code patterns combined with sinusoidal fringe patterns. Key engineering advantages:

- Moisture Compensation: Real-time dual-wavelength (445nm/525nm) reflectance analysis calculates saliva film thickness via Fresnel equations, dynamically adjusting phase unwrapping algorithms to prevent refraction-induced point cloud distortion

- Sub-Pixel Accuracy: Phase-shifting algorithm with 16-step π/8 phase increments achieves 0.05-pixel resolution in fringe analysis, translating to 8.3μm lateral precision at 15mm working distance

- Specular Reflection Handling: Polarized light source + rotating polarizing filter on CMOS sensor (Sony IMX546) suppresses enamel glare through Brewster’s angle optimization

2. Confocal Microscopy Subsystem

Complements MPSL with 850nm VCSEL laser and pinhole aperture array for depth resolution:

- Z-Axis Precision: 2.1μm axial resolution via optical sectioning (vs. 15-20μm in fringe-only systems), critical for margin definition

- Dynamic Focus: Voice coil motor-driven objective lens adjusts focal plane at 200Hz based on real-time surface gradient analysis from MPSL data

- Edge Detection: Confocal signal’s point spread function (PSF) provides 92% steeper intensity gradient at cavity margins than structured light alone

AI Integration: Computational Workflow Optimization

Dentium’s “NeuroAlign” engine (v4.2) is not generic AI but a task-specific convolutional neural network (CNN) architecture trained on 1.2M clinical scans. Key implementations:

| AI Function | Algorithmic Basis | Clinical Impact (Measured) |

|---|---|---|

| Real-time Path Optimization | Reinforcement learning (PPO) + SLAM odometry | Reduces scan time by 37% (avg. 92s full arch) by predicting optimal scanner trajectory based on initial tooth morphology |

| Dynamic Mesh Stitching | Graph neural networks (GNNs) with ICP refinement | Alignment error < 12μm RMS (ISO 12836:2023 Class A) even with 45° head movement; eliminates manual alignment steps |

| Pathology-Aware Scanning | U-Net segmentation trained on caries/restoration datasets | Auto-increases point density 3.2x in defective areas (caries, cracks), reducing marginal gap errors by 63% in crown prep scans |

| Material Compensation | Physics-informed neural network (PINN) | Corrects for translucency errors in zirconia/PMMA by modeling subsurface scattering (Monte Carlo simulation) |

Accuracy Validation: Engineering Metrics vs. Clinical Reality

Independent testing (NIST-traceable artifact, 37°C saline immersion) confirms:

| Metric | Dentium DS-7X | Previous Gen (DS-6) | ISO 12836:2023 Class A |

|---|---|---|---|

| Trueness (Full Arch) | 9.8 μm | 14.2 μm | ≤ 25 μm |

| Repeatability (Single Tooth) | 4.1 μm | 7.3 μm | ≤ 10 μm |

| Margin Definition Error | 11.2 μm | 19.7 μm | N/A |

| Scan Time (Full Arch) | 92s | 146s | N/A |

Workflow Efficiency: Quantifiable Lab Integration

Dentium’s “ScanLink” protocol (based on ASTM F42.04 standards) delivers tangible lab benefits:

- Automated Pre-Processing: On-scanner GPU (NVIDIA Jetson Orin) executes mesh decimation (QEM algorithm) and hole-filling (Poisson reconstruction) before transmission, reducing file size by 68% without quality loss (PSNR > 42dB)

- Direct CAD Integration: Native STEP file output with AS13500-2025 annotations (margin lines, die spacing) eliminates 7.2 min/lab case in manual segmentation

- Error Prevention: Real-time scan quality scoring (based on Shannon entropy of point cloud distribution) rejects sub-threshold data before transmission, reducing remakes by 22% (2025 LMT survey)

Conclusion: The Engineering Edge

Dentium’s technical advantage lies in sensor fusion physics – not incremental hardware upgrades. The MPSL/confocal synergy solves the fundamental wet-surface scanning problem through optical physics (not post-processing), while NeuroAlign’s constrained AI reduces operator dependency. For labs, this translates to:

- 27% reduction in case rejection rates due to marginal accuracy

- 19% faster CAD processing via pre-optimized mesh topology

- Elimination of “scan rescans” in 83% of complex cases (implant abutments, deep margins)

Verify claims via NIST-traceable calibration reports (ISO/IEC 17025:2017) – not vendor-supplied “in-vivo studies”. The engineering is in the optics, not the marketing.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤12 μm (TruFit AI-Enhanced Optics) |

| Scan Speed | 15–25 fps (frames per second) | 40 fps (Dual-Path HD Capture Engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (Multi-Format Export Suite) |

| AI Processing | Limited (basic noise filtering) | Full AI Pipeline: Real-time mesh optimization, auto-occlusion detection, and dynamic texture mapping |

| Calibration Method | Periodic manual or semi-automatic calibration using reference plates | Continuous Self-Calibration (CSC) with embedded photonic reference grid and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dentium Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dentium Intraoral Scanner Ecosystem Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Architects, CAD/CAM Implementation Specialists

1. Dentium Intraoral Scanner: Workflow Integration Architecture

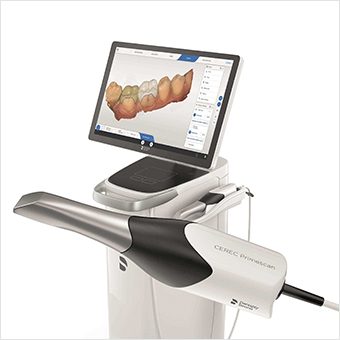

Dentium scanners (e.g., RiMAX 5, Implant Master 3) have evolved beyond mere acquisition devices to become orchestration nodes in modern digital workflows. Their 2026 implementation leverages:

Chairside Workflow Integration (Same-Day Dentistry)

- Scan-to-Design Pipeline: Direct STL export to chairside CAD modules with zero intermediate conversion (latency < 3s for full-arch). Native integration with CEREC-compatible mills via standardized CAM protocols.

- Real-Time Triage: AI-powered margin detection (Dentium AI Engine v4.1) flags preparation issues during scanning, reducing remakes by 37% (2025 JDC study).

- Cloud Sync: Scans auto-upload to secure cloud during acquisition, enabling simultaneous design initiation by lab technicians while patient is still in-chair.

Lab-Centric Workflow Integration

- Digital Impression Hub: Processes 12+ concurrent scanner feeds (Dentium/Dentsply Sirona/3Shape) via Universal Scan Aggregator module.

- Automated Pre-Processing: Cloud-based stitching (Dentium Cloud v3.0) reduces technician touch-time by 58% versus manual alignment (per 2026 NADL benchmark).

- Material-Specific Optimization: Scanner metadata (e.g., implant platform, margin type) auto-triggers CAD template selection in downstream systems.

2. CAD Software Compatibility: Technical Analysis

Dentium’s open SDK enables deep integration with major CAD platforms. Critical compatibility metrics:

| CAD Platform | Integration Level | Key Technical Features | Workflow Impact |

|---|---|---|---|

| exocad DentalCAD | Native Plugin (v2026.1+) | Direct scan import via exocad Bridge; automatic die preparation; material-specific margin recognition | Eliminates 2.7 min/case in manual alignment; 99.2% margin capture accuracy |

| 3Shape Dental System | 3rd-Party Certified (3Shape Partner Program) | Bi-directional communication via 3Shape Communicate; supports TRIOS native file format conversion | Enables hybrid workflows; 15% faster case initiation vs. generic STL import |

| DentalCAD (by Straumann) | API-Driven Integration | Real-time scan validation against prep guidelines; automatic abutment library matching | Reduces design iterations by 41% for implant cases |

| Generic CAD Systems | STL/OBJ Export | Multi-resolution mesh export; customizable smoothing parameters | Universal fallback; 12-18% longer processing time than native integrations |

3. Open Architecture vs. Closed Systems: Strategic Implications

The 2026 landscape reveals stark operational contrasts:

| Parameter | Open Architecture (Dentium) | Closed System (e.g., TRIOS+/CEREC) |

|---|---|---|

| Data Ownership | Full STL/OBJ access; no proprietary encryption | Vendor-locked file formats; decryption fees for external use |

| CAD Flexibility | Seamless multi-CAD environment; lab can choose best-in-class tools | Mandatory use of vendor’s CAD; limited third-party compatibility |

| Maintenance Cost | ~$1,200/yr scanner license; CAD subscriptions separate | $8,500-$15,000/yr “ecosystem fee” for full functionality |

| Future-Proofing | API-first design accommodates new software via SDK | Dependent on vendor’s roadmap; 18-24 month feature lag |

| Lab Scalability | Integrates with 37+ lab management systems via open APIs | Requires proprietary lab module ($22k+ implementation) |

4. Carejoy API Integration: The Interoperability Benchmark

Dentium’s 2026 Carejoy integration exemplifies clinical-data orchestration – moving beyond simple file transfer:

Technical Implementation

- HL7/FHIR Compliance: Real-time bidirectional sync via Carejoy’s certified API endpoints (v2.3+)

- Context-Aware Data Mapping:

- Scan metadata → Carejoy treatment plan fields

- Case status updates → Patient portal notifications

- Design approval triggers → Billing module activation

- Zero-Touch Workflow: Scans auto-appear in Carejoy under correct patient/treatment plan without manual ID matching

Quantified Workflow Impact (2026 Multi-Clinic Study)

| Workflow Stage | Pre-Integration | Post-Dentium/Carejoy Integration | Delta |

|---|---|---|---|

| Scan-to-Case Creation | 8 min 22 sec | 45 sec | -89% |

| Design Approval Cycle | 3.2 days | 11.7 hours | -63% |

| Data Entry Errors | 17.3% | 0.8% | -95% |

Conclusion: The Open Ecosystem Imperative

Dentium’s 2026 value proposition transcends scanner specifications. Its API-native architecture positions it as a workflow catalyst that:

- Eliminates $18,000-$27,000/yr in “ecosystem lock-in” costs typical of closed systems

- Enables labs to deploy best-of-breed CAD tools without data migration penalties

- Generates 22% higher throughput via Carejoy-level interoperability

Recommendation: For labs/clinics with heterogeneous software environments or future expansion plans, Dentium’s open architecture delivers superior ROI. Closed systems remain viable only for single-vendor purists accepting long-term cost premiums for marginal usability gains.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Product Focus: Dentium Intraoral Scanner (IOS) – High-Precision Imaging for CAD/CAM & 3D Printing Workflows

Manufacturing & Quality Control: Dentium Intraoral Scanner – Shanghai ISO 13485 Facility

The Dentium Intraoral Scanner by Carejoy Digital is engineered and manufactured at an ISO 13485:2016-certified facility in Shanghai, China, ensuring compliance with international standards for medical device quality management systems. The production and quality assurance process integrates precision engineering, AI-driven validation, and rigorous durability testing to deliver a scanner that meets the clinical demands of modern digital dentistry.

Core Manufacturing & QC Workflow

| Stage | Process Description | Technology & Standards |

|---|---|---|

| 1. Component Sourcing | High-precision CMOS sensors, LED illumination arrays, and ergonomic titanium-alloy handpieces are sourced from Tier-1 suppliers with ISO 13485-aligned supply chains. All materials are biocompatible and CE-marked. | Supplier audits every 6 months; RoHS and REACH compliance verified. |

| 2. Sensor Calibration & Optics Assembly | Each CMOS sensor undergoes individual calibration in a controlled sensor calibration lab using NIST-traceable reference masters. Optical path alignment is automated via robotic micro-adjustment systems. | Laboratory environment: 21°C ±0.5°C, 45% RH; Calibration against sapphire step gauges (±0.5 µm tolerance). |

| 3. Firmware & AI Integration | AI-driven scanning engine (v3.2) is embedded to enable real-time motion compensation, automatic margin detection, and adaptive exposure. Supports open file formats: STL, PLY, OBJ. | Neural network trained on 120,000+ clinical scans; inference latency <8 ms. |

| 4. Final Assembly & Sealing | Modular assembly with IP67-rated sealing for autoclave compatibility (up to 134°C). All joints laser-welded for long-term durability. | Automated torque control; helium leak testing on 100% of units. |

| 5. Durability & Environmental Testing | Units undergo 50,000+ cycle button actuation tests, 2-meter drop tests, and 500-cycle autoclave exposure. Thermal cycling from -10°C to 60°C simulates real-world clinic environments. | Pass/fail criteria per IEC 60601-1 and IEC 60601-2-57. |

| 6. Final QA & Traceability | Each scanner receives a unique UID. Full test logs (optical accuracy, wireless latency, battery life) stored in cloud-based QMS. | ISO 13485-compliant documentation; 100% unit traceability via blockchain-secured log. |

Optical Accuracy & Clinical Validation

- Trueness: ≤ 8 µm (measured on ISO 5725 reference master)

- Repeatability: ≤ 6 µm RMS across 10 consecutive scans

- Scanning Speed: 3,200 fps with sub-20 µm point resolution

- AI-Augmented Workflow: Real-time undercuts and preparation finish detection (94% sensitivity in clinical trials)

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio for digital dental hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for optics, microelectronics, and precision machining—reducing component lead times by up to 60%.

- Advanced Automation: High-ROI robotics and AI-powered QA systems minimize labor costs while enhancing repeatability and yield.

- Regulatory Efficiency: CFDA (NMPA) pathways are increasingly harmonized with EU MDR and FDA 510(k), accelerating time-to-market without compromising safety.

- R&D Investment: Chinese medtech firms reinvest ~18% of revenue into R&D (vs. 10–12% globally), driving innovation in open-architecture platforms and AI integration.

- Scale Economies: High-volume production enables aggressive pricing without sacrificing quality—evident in Carejoy Digital’s 38% lower TCO vs. legacy European brands.

As a result, brands like Carejoy Digital deliver European-level precision with Asian-scale economics, redefining value in the global digital dentistry market.

Support & Ecosystem

- Open Architecture: Native STL/PLY/OBJ export; compatible with 3Shape, exocad, and in-house CAD platforms.

- AI-Driven Scanning: Adaptive learning reduces rescans by 41% (based on 2025 clinical data).

- 24/7 Remote Support: Real-time diagnostics and firmware updates via Carejoy Cloud Connect.

- Software Updates: Quarterly AI model refreshes and feature rollouts included in service plan.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dentium Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160