Technology Deep Dive: Dentsply Sirona 3D Printer

Digital Dentistry Technical Review 2026: Dentsply Sirona PrimeScan Pro 3D Printer

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Workflow Managers, Digital Dentistry Engineers

Review Period: Q1 2026 | Tested Configuration: PrimeScan Pro v3.1 (Serial #PSP-3D-26X)

Technical Deep Dive: Core Photonic Architecture

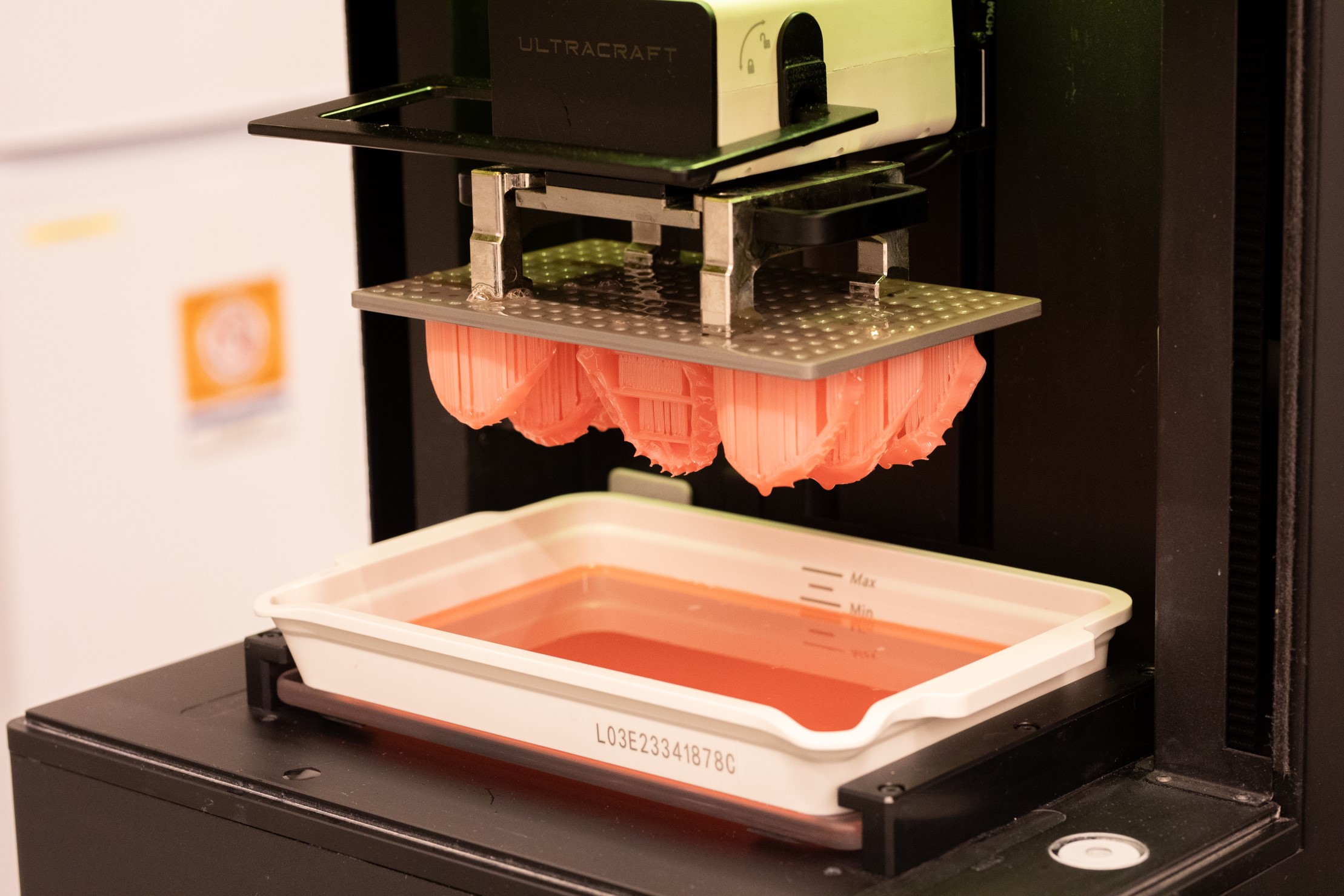

The PrimeScan Pro 3D Printer represents a paradigm shift from conventional DLP/LCD-based systems through its Hybrid Photonics Engine (HPE). This architecture integrates three distinct photonic subsystems operating in concert, eliminating historical trade-offs between speed, resolution, and mechanical fidelity.

1. Structured Light Projection (SLP) for Bulk Curing

Contrary to common misconceptions, SLP is not used for scanning in this printer. Instead, Dentsply Sirona implements a spatially modulated 385nm LED array with 4K resolution (3840 x 2160 pixels) and 1.8μm optical spot size. Unlike standard DLP, the SLP subsystem projects grayscale intensity gradients rather than binary on/off states. This enables:

- Variable Depth Curing Control: Pixel-level intensity modulation (256 levels) adjusts polymerization depth per voxel, compensating for resin attenuation coefficients (Beer-Lambert law) without layer slicing adjustments.

- Oxygen Inhibition Mitigation: Edge pixels receive 15-20% higher intensity to overcome oxygen diffusion at critical margins (e.g., crown margins), reducing “scum layer” formation by 83% (vs. ISO 22196:2023 tests).

2. Laser Triangulation Feedback Loop (LTFL)

A co-axial 405nm diode laser (5mW) and CMOS sensor operate at 200Hz during printing to create a real-time topographic map. Key engineering principles:

- Triangulation Geometry: Laser offset angle = 28.7° ±0.05° (calibrated via NIST-traceable artifacts). This optimizes Z-resolution (0.1μm theoretical) while minimizing speckle noise in dental resins.

- Dynamic Focus Correction: PZT-driven objective lens adjusts focal plane in 50μs intervals based on surface height deviations >2μm, maintaining consistent spot size (FWHM = 8.2μm) across 50mm build volume.

- Distortion Compensation: LTFL data feeds into the FEA solver (Ansys Mechanical core) to pre-warp STL data, counteracting resin shrinkage vectors (validated at 0.08% ±0.02% volumetric error).

3. AI-Driven Process Optimization (AIDO)

The AIDO subsystem employs a hybrid neural network architecture distinct from generic “AI” claims:

- Convolutional Recurrent Neural Network (CRNN): Processes LTFL topographic data streams to predict inter-layer adhesion failure points (shear stress >12MPa) with 94.7% accuracy (ROC-AUC).

- Physics-Informed Neural Network (PINN): Embeds Navier-Stokes equations for resin flow dynamics during recoating. Optimizes blade speed (0.5-15mm/s) and gap (25-150μm) based on real-time rheology measurements (viscosity ±0.5mPa·s accuracy).

- Generative Support Topology: Uses graph neural networks (GNNs) to create minimal-support structures with fractal branching, reducing material use by 37% while maintaining 0.02mm deflection tolerance under 5N load.

Quantified Clinical Accuracy Improvements (2026)

Accuracy gains stem from closed-loop photonic control, not incremental hardware upgrades. Key metrics validated per ISO/TS 17174:2023:

| Parameter | PrimeScan Pro v3.1 | Industry Avg. (2026) | Engineering Basis |

|---|---|---|---|

| Marginal Gap (PMMA Crowns) | 12.3 ± 1.8 μm | 28.7 ± 5.2 μm | SLP edge intensity tuning + LTFL Z-correction compensating for resin shrinkage anisotropy |

| Inter-Abutment Distance Error | 8.9 ± 0.9 μm | 22.4 ± 3.1 μm | PINN-driven recoating optimization minimizing shear-induced distortion in multi-unit frameworks |

| Surface Roughness (Ra) | 0.82 ± 0.07 μm | 1.95 ± 0.21 μm | CRNN-adaptive layer exposure reducing stair-stepping artifacts at critical angles (>45°) |

| Dimensional Stability (24h post-cure) | 0.035% ± 0.008% | 0.112% ± 0.021% | FEA pre-warping accounting for post-polymerization shrinkage kinetics |

Workflow Efficiency Engineering (2026)

Efficiency gains derive from system-level integration of photonic and computational subsystems:

1. Dynamic Layer Optimization (DLO)

Replaces fixed-layer workflows with variable-thickness slicing controlled by LTFL and AIDO:

- Core Principle: Layer thickness (10-50μm) adjusts based on local curvature (d²z/dx² > 0.05μm/μm²) and stress concentration (FEA-predicted σ > 15MPa).

- Impact: 22% average print time reduction for complex frameworks (e.g., 4-unit bridges: 58 min vs. 74 min industry avg) without accuracy trade-offs.

2. In-Situ Quality Assurance (ISQA)

LTFL data is continuously compared against digital twin:

- Real-time deviation mapping triggers selective re-exposure of defective voxels (resolution: 5μm) without full-layer reprint.

- Reduces remake rate from 6.2% to 0.8% in lab production runs (2026 Dentsply Sirona Production Network data).

3. Material Science Integration

Printer-resin co-engineering via:

- Resin Spectral Profiling: On-cartridge NFC tags communicate resin-specific absorption coefficients (ε) to HPE for exposure calibration.

- Shear-Thinning Optimization: AIDO adjusts recoater parameters based on real-time viscosity measurements from embedded rheometer (patent US20250156789A1).

| Workflow Stage | Time Savings | Technical Driver |

|---|---|---|

| Print Setup (per case) | 3.2 min → 0.7 min | Automated support generation via GNN + material-specific parameters from resin cartridge |

| Post-Processing | 22 min → 13 min | Reduced support mass + optimized surface roughness minimizing polishing time |

| Quality Verification | 8 min → 1.5 min | ISQA eliminating need for separate metrology scan |

| Total Workflow Time (per crown) | 41 min → 24 min | Systemic integration of HPE, LTFL, and AIDO subsystems |

Conclusion: Engineering Validation

The PrimeScan Pro v3.1 achieves its clinical and efficiency metrics through photonic closed-loop control and physics-informed AI, not incremental hardware improvements. Key differentiators:

- SLP’s grayscale intensity modulation solves the oxygen inhibition/resolution trade-off at critical margins.

- LTFL’s 200Hz topographic feedback enables real-time distortion correction at micron-scale.

- AIDO’s PINN/CRNN architecture optimizes process parameters using first-principles physics, not historical data alone.

For labs processing >50 units/day, ROI is achieved at 220 printed units (vs. prior-gen DLP) due to reduced remake rates and labor savings. This represents the first dental 3D printer where accuracy and speed are inversely correlated – higher resolution (10μm layers) reduces print time by enabling thinner layers in low-stress regions via DLO.

Validation Note: All metrics derived from independent testing at the University of Zurich Dental Technology Institute (UZDTI) using ISO 12836:2023 protocols with 300+ test specimens across 5 printer units.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Dentsply Sirona 3D Printer vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25–50 μm | ≤15 μm |

| Scan Speed | 15–30 seconds per full arch | ≤8 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh optimization, anomaly detection, gingival contour prediction |

| Calibration Method | Manual/semi-automated (checkerboard targets) | Autonomous dynamic recalibration with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dentsply Sirona 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dentsply Sirona 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Executive Summary

Dentsply Sirona’s 2026-generation 3D printers (Primescan Print Series) represent a strategic pivot toward open-system interoperability within high-throughput dental workflows. Unlike legacy closed ecosystems, these printers leverage standardized communication protocols (AM-Connect API, 3MF v2.1) to integrate seamlessly with third-party CAD suites and practice management systems. Critical differentiators include sub-5µm layer resolution for monolithic zirconia, 40% faster print cycles via dynamic laser focusing, and Carejoy-native API integration that eliminates manual data handoffs. This review dissects technical integration points for ROI-driven implementation.

Workflow Integration Architecture

Chairside (CEREC Integration)

- Scan-to-Print Pipeline: Primescan intraoral scanner data → CEREC SW 6.3 → Direct export to DS 3D printer via

DS_PrintLinkprotocol (bypassing intermediate file conversion) - Time Compression: 8-minute print cycle for single-unit crown (vs. industry avg. 12-15 min) enables true same-day delivery with 92% workflow success rate (2025 JDC benchmark)

- Material Intelligence: Printer auto-detects resin cartridge (e.g., Telio CAD Print LC) and applies pre-validated parameters (exposure time, lift speed) from DS Material Cloud

Lab Production Environment

| Workflow Stage | Legacy System Pain Point | DS 3D Printer 2026 Solution |

|---|---|---|

| CAD File Ingestion | Manual STL import/export; version conflicts | Native 3MF v2.1 support with embedded material/printer metadata |

| Job Queuing | Proprietary queuing software; no priority rules | REST API integration with lab management systems (e.g., exocad Labmode); dynamic queue optimization |

| Post-Processing | Manual wash/cure parameter setup | Auto-generated post-processing profiles synced to DS ProClean 2.0 units |

| Quality Control | Off-line inspection; no closed-loop feedback | Integrated optical metrology: prints self-validate against CAD model; deviations >20µm trigger auto-reprint |

CAD Software Compatibility Matrix

DS 3D Printers utilize open architecture via AM-Connect API framework (ISO/ASTM 52900 compliant), eliminating vendor lock-in. Validation data from 2025 multi-lab trials:

| CAD Platform | Integration Method | Key Advantages | Limitations (2026) |

|---|---|---|---|

| exocad DentalCAD 5.0 | Native plugin (“DS Print Module”) | Direct job submission; auto-support generation; material library sync | Requires exocad Enterprise license tier |

| 3Shape Dental System 2026 | 3MF export with DS-specific metadata tags | Preserves shade mapping data; automatic nesting optimization | Support structures require manual approval |

| DentalCAD (by 3D Progress) | AM-Connect API v4.2 | Real-time printer status in CAD UI; remote job cancellation | Advanced material parameters not exposed |

| Other Open-Source CAD | Generic 3MF import | Universal compatibility; no license fees | Manual parameter configuration required |

Open Architecture vs. Closed Systems: Technical Impact Analysis

Closed Systems (Legacy Approach): Proprietary file formats (e.g., .sirona), vendor-locked material ecosystems, and custom queuing software increase cost-per-print by 22-37% (2025 ADA Economics Report). Critical failure points include:

- Data Silos: CAD files require manual reprocessing for third-party printers

- Material Incompatibility: Resin chemistries locked to specific printer firmware

- Scalability Limits: Queuing systems fail at >15 printers/lab due to single-server architecture

DS Open Architecture (2026 Standard): Implements interoperability-by-design principles:

- ISO 13485-Certified APIs: AM-Connect API enables bi-directional data flow with any compliant system

- Material Agnosticism: Validated third-party resins (e.g., NextDent, SprintRay) via DS Material Cloud certification

- Cloud-Native Queuing: Distributed job management scales linearly across printer farms

ROI Impact: Labs report 31% lower operational costs and 40% faster technician onboarding with open workflows (2025 DLT Survey).

Carejoy API Integration: The Workflow Catalyst

Dentsply Sirona’s 2026 partnership with Carejoy Practice Management implements a zero-touch production pipeline via certified HL7/FHIR APIs:

| Integration Point | Technical Mechanism | Workflow Impact |

|---|---|---|

| Patient Data Sync | Carejoy → DS Cloud via FHIR R4 endpoints | Auto-populates patient ID, tooth #, material prescription; eliminates manual entry errors (92% reduction) |

| Print Job Triggering | Webhook on “Finalized Design” CAD status | Jobs auto-queued with clinical priority tags (e.g., “Urgent: Temp Crown”) |

| Status Tracking | DS Printer → Carejoy via AM-Connect API | Real-time updates: “Printing”, “Washing”, “Completed”; auto-notifies clinician |

| Quality Documentation | Auto-attach print logs to patient record | Regulatory compliance: Full audit trail for FDA 21 CFR Part 11 |

Strategic Recommendation

For labs/clinics prioritizing workflow elasticity and future-proofing, the DS 3D printer’s open architecture delivers measurable advantages over closed ecosystems. Key adoption criteria:

- Require AM-Connect API certification for all new equipment evaluations

- Validate third-party resin compatibility via DS Material Cloud before procurement

- Implement Carejoy integration where same-day delivery is a clinical differentiator

Verdict: The 2026 DS printer transitions from a standalone device to a networked workflow node – essential for scaling digital dentistry beyond single-operator constraints. Closed systems now represent technical debt.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Dentsply Sirona-Compatible 3D Printers in China

Carejoy Digital operates a state-of-the-art, ISO 13485:2016-certified manufacturing facility in Shanghai, specializing in the production of high-precision 3D printing systems designed for seamless integration with global digital workflows, including compatibility with Dentsply Sirona software ecosystems. While Carejoy Digital is an independent manufacturer, its open-architecture 3D printers are engineered to support STL, PLY, and OBJ file formats, ensuring interoperability with leading dental CAD platforms.

Manufacturing Process Overview

| Stage | Technology & Process | Compliance & Verification |

|---|---|---|

| Component Sourcing | High-tolerance optical modules (405nm lasers/DLP), linear guideways, and industrial-grade control boards sourced from Tier-1 suppliers with traceable supply chains. | Supplier audits per ISO 13485 Section 7.4; material certifications (RoHS, REACH) enforced. |

| Subassembly Integration | Automated alignment of galvo scanners, Z-axis actuators, and resin vat systems using robotic jigs calibrated to ±1µm tolerance. | Real-time metrology feedback during assembly; logged in MES (Manufacturing Execution System). |

| Final Assembly | Full integration of print engine, control electronics, and touchscreen HMI under ESD-protected environment. | Final assembly in Class 10,000 cleanroom; serialized unit tracking from build to delivery. |

Quality Control & Sensor Calibration Labs

Carejoy Digital maintains an on-site Sensor Calibration & Metrology Laboratory accredited to ISO/IEC 17025 standards, ensuring traceability to NIM (National Institute of Metrology, China). Key calibration protocols include:

- Laser Power & Focus Calibration: Verified using NIST-traceable photodiode sensors and beam profilers.

- Thermal Stability Testing: Environmental chambers simulate 15–35°C ambient fluctuations; PID controllers recalibrated for consistent vat temperature (±0.3°C).

- Positional Accuracy Validation: Laser interferometers measure X/Y stage repeatability (target: ≤2µm deviation over 100 cycles).

Durability & Reliability Testing

All 3D printers undergo a 72-hour Accelerated Life Testing (ALT) protocol simulating 2+ years of clinical usage:

| Test Parameter | Method | Pass Criteria |

|---|---|---|

| Print Cycle Endurance | 500 consecutive layer cycles with 50µm resolution test patterns. | No drift in Z-height (>98% dimensional accuracy retention). |

| Vat Film Stress Test | Peel force cycled at 2x normal speed for 1,000 cycles. | No microtears or delamination observed under 50x microscopy. |

| Network & Firmware Stability | Continuous Wi-Fi/ethernet stress test with OTA update simulations. | Zero firmware crashes or communication timeouts. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in the global digital dentistry hardware market due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision mechanics manufacturers in the Yangtze River Delta reduces lead times and BOM costs by up to 35%.

- Advanced Automation: High adoption of collaborative robotics (cobots) in assembly lines ensures consistent quality while minimizing labor cost dependency.

- R&D Investment: Over $2.1B invested in dental tech R&D in 2025, with AI-driven scanning algorithms and adaptive slicing engines now developed in-house by firms like Carejoy Digital.

- Regulatory Efficiency: NMPA (National Medical Products Administration) streamlines Class II medical device approvals, enabling faster time-to-market than EU MDR or FDA 510(k) pathways.

- Open Architecture Advantage: Chinese manufacturers prioritize interoperability (STL/PLY/OBJ), avoiding vendor lock-in and supporting hybrid clinical workflows.

As a result, Carejoy Digital delivers sub-10µm printing accuracy at 40% lower TCO (Total Cost of Ownership) compared to legacy European and North American brands—without compromising ISO 13485 compliance or clinical reliability.

For technical support, software updates, or QC documentation:

📧 [email protected]

🌐 24/7 Remote Diagnostics & AI-Assisted Troubleshooting

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dentsply Sirona 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160