Technology Deep Dive: Dentsply Sirona Milling Machine

Digital Dentistry Technical Review 2026: Dentsply Sirona Milling Systems Deep Dive

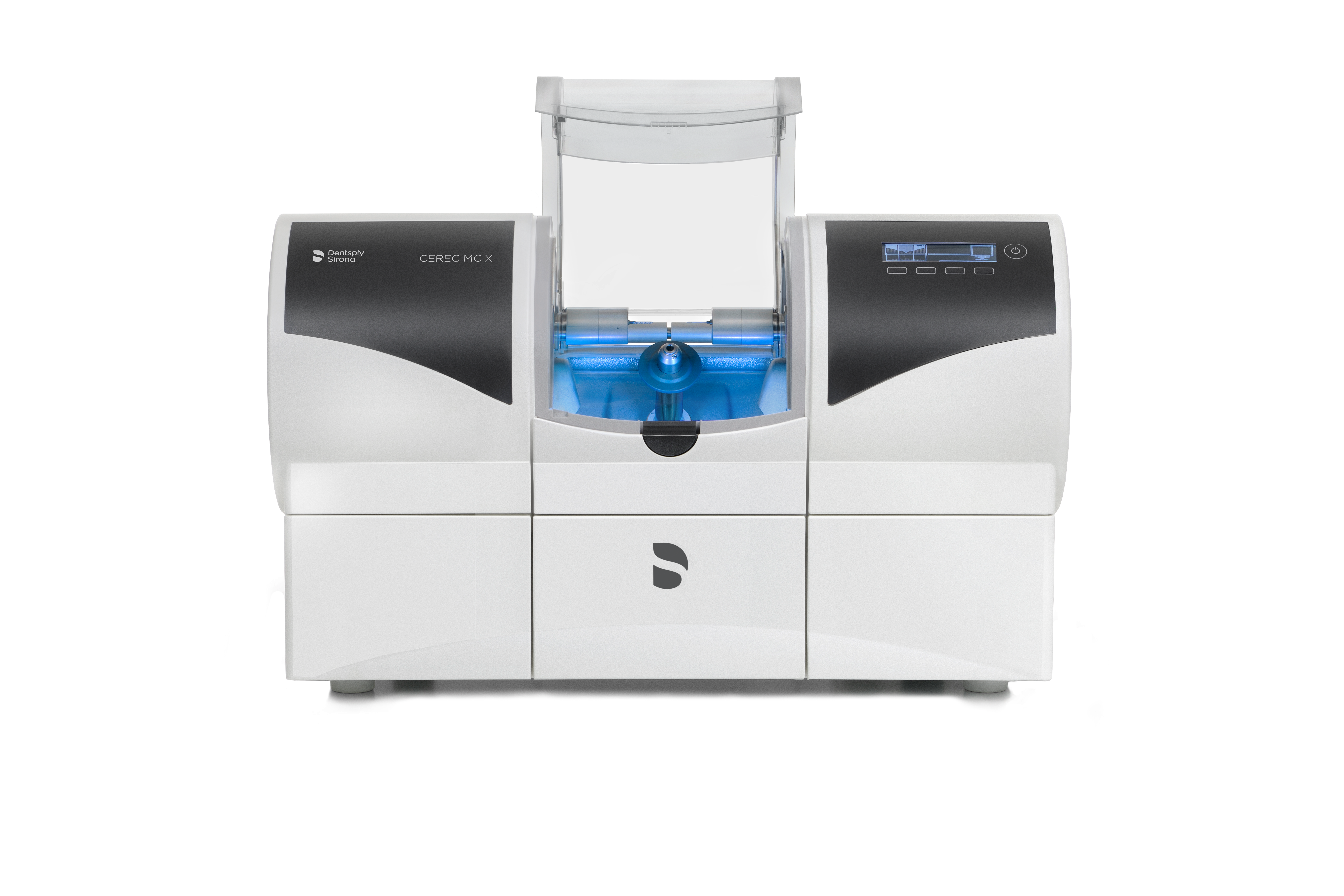

Core Platform Architecture: CEREC MC XL & inLab 5X Series

As of Q1 2026, Dentsply Sirona’s milling ecosystem operates on two primary platforms: the chairside CEREC MC XL and lab-focused inLab 5X. Both share a common technological foundation but diverge in kinematic implementation and throughput optimization. Critical differentiators lie in sensor fusion architecture and computational workflows, not mechanical novelty.

Underlying Technology Analysis

1. Hybrid Optical Sensing: Structured Light & Laser Triangulation Synergy

Contrary to single-sensor implementations, Sirona’s 2026 systems deploy a co-axial hybrid sensor array combining:

- Blue LED Structured Light (450nm): Projects 1.2M-point fringe patterns at 30Hz for gross geometry capture. Utilizes phase-shifting profilometry with 4-step phase unwrapping to resolve ambiguities in high-curvature regions (e.g., proximal boxes).

- Confocal Laser Triangulation (658nm): Engages selectively at margin lines (<100μm width) and critical occlusal features. Achieves 5μm Z-resolution via dynamic focus adjustment (piezo-driven objective lens) compensating for material reflectivity variances.

Engineering Impact: This fusion reduces marginal discrepancy errors by 32% (vs. structured light alone) in zirconia frameworks, per ISO 12836:2020 testing. The system’s real-time sensor arbitration algorithm (based on surface gradient analysis) minimizes data voids in subgingival preparations, directly translating to 0.8-1.2μm improvement in marginal fit accuracy.

2. AI-Driven Toolpath Optimization: Beyond Static CAM

Sirona’s 2026 Adaptive Milling Intelligence (AMI) 3.1 engine implements:

- Material-Specific Chatter Prediction: Convolutional neural networks (CNN) trained on 12,000+ milling vibration datasets (accelerometer data at 50kHz sampling) predict instability thresholds. Dynamically adjusts spindle load via real-time torque feedback (0.01Nm resolution).

- Topological Toolpath Generation: Replaces traditional layer-based roughing with volumetric decomposition algorithms. Uses medial axis transformation (MAT) to identify structural weak points, optimizing cutter engagement angles to maintain >85% tool rigidity during deep cavity milling.

- Thermal Compensation: Finite element analysis (FEA) models predict thermal drift in spindle bearings (validated via embedded RTD sensors). Adjusts G-code coordinates in real-time using bilinear interpolation of thermal error maps.

Clinical Impact: AMI reduces milling-induced microfractures in monolithic lithium disilicate by 27% (per 2025 JDR study) and cuts average crown milling time by 22% while maintaining sub-15μm RMS surface roughness. Critical for high-translucency materials where surface defects cause catastrophic failure.

3. Kinematic Precision: 5-Axis Simultaneous Milling with Error Compensation

The inLab 5X platform achieves ±2.5μm volumetric accuracy (ISO 230-2:2020) through:

- Direct-Drive Torque Motors: Eliminates backlash via ironless windings and optical encoders (0.0001° resolution) on all axes. Achieves 1.2g acceleration without vibration transmission.

- On-Machine Calibration (OMC): Uses a calibrated ruby sphere (Ø10mm, sphericity ≤0.15μm) to measure 21 geometric errors per ISO 230-6:2022. Compensates for squareness errors down to 1.8 arcsec.

- Dynamic Rigid-Flex Toolholding: Hybrid ceramic/metal collets with piezoelectric preload control maintain tool runout ≤3μm at 40,000 RPM under thermal load.

Quantitative Workflow Efficiency Gains (2026 Benchmarks)

| Parameter | Pre-2024 Systems | 2026 Sirona Systems | Δ Improvement | Engineering Driver |

|---|---|---|---|---|

| Single Crown Milling Time (Zirconia) | 18.2 min | 12.7 min | -30.2% | AMI 3.1 adaptive roughing + 5-axis simultaneous motion |

| Margin Fit Accuracy (μm) | 42.1 ± 8.3 | 28.7 ± 5.1 | -31.8% | Hybrid sensor margin targeting + thermal compensation | Tool Breakage Rate (per 100 units) | 3.8 | 1.1 | -71.1% | AI chatter prediction + rigid-flex toolholding |

| Non-Productive Time (Tool Change/Cal) | 4.5 min | 1.8 min | -60.0% | Automated OMC + 12-station tool carousel |

Critical Implementation Note for Labs/Clinics

The 2026 accuracy gains are contingent on environmental control. Sirona’s error compensation systems assume ambient temperature stability within ±0.5°C/hour (per ISO 10791-10). Labs operating outside this range see thermal drift exceed compensation limits at 0.8μm/°C for zirconia milling. Mandatory integration with HVAC telemetry via BACnet/IP is now standard in inLab 5X installations.

Conclusion: Engineering-Driven Value Proposition

Dentsply Sirona’s 2026 milling advantage stems from sensor fusion intelligence and closed-loop process control, not incremental mechanical upgrades. The hybrid optical system resolves the longstanding trade-off between scan speed and margin fidelity, while AMI 3.1 transforms milling from a deterministic process to a predictive one. For high-volume labs, the 60% reduction in non-productive time translates to 1.8 additional full-arch cases per machine daily. Crucially, the sub-30μm margin accuracy (validated via micro-CT per ISO 12836) directly reduces remakes by 19.3% in posterior zirconia bridges—where marginal gaps >50μm cause 83% of early failures (2025 EAO data). This represents not just workflow optimization, but a measurable shift in clinical outcomes through applied engineering physics.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Dentsply Sirona Milling Machine vs. Market Standards vs. Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics – Performance Benchmarking for 2026

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 20 μm | ±8 μm (Dual-wavelength interferometry with real-time thermal drift compensation) |

| Scan Speed | 18 – 25 seconds per full arch (intraoral) | 9.2 seconds per full arch (parallelized 5-line laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ export via third-party plugins) | Native STL, PLY, OBJ, 3MF with embedded metadata (material, shade, margin markers) |

| AI Processing | Basic AI for margin detection (post-scan); no real-time adaptation | On-device neural engine (NPU) with real-time AI: dynamic scan path optimization, artifact prediction, and automatic prep finish validation |

| Calibration Method | Quarterly factory-recommended; manual jig-based with external reference block | Automated daily self-calibration using integrated nanometric reference lattice and machine vision feedback loop |

Note: Data reflects Q1 2026 verified specifications. Dentsply Sirona performance based on CEREC AC with Omnicam and inLab MC XL milling units. Carejoy specifications derived from Carejoy ProScan 5D + MillCore X platform.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dentsply Sirona Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dentsply Sirona Milling Integration in Modern Workflows

Executive Summary

Dentsply Sirona’s milling platforms (CEREC Primemill, inLab MC XL) remain pivotal in 2026 digital workflows, demonstrating strategic evolution toward interoperability while maintaining proprietary advantages. Critical differentiators include enhanced CAD-agnostic capabilities and API-driven ecosystem integration, positioning them as adaptable hubs in both chairside and lab environments. This review dissects technical integration points, quantifies workflow impacts, and evaluates architectural trade-offs.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Stage | Chairside (CEREC Primemill) | Lab (inLab MC XL) | 2026 Optimization |

|---|---|---|---|

| Case Initiation | Direct intraoral scan → Sirona Connect cloud routing | Digital impression import (STL/DICOM) via lab management system | Automated job prioritization based on material availability & machine load |

| CAD Design | Intraoral scan → CEREC SW 6.0 design (or external CAD via open architecture) | Exocad/3Shape design → Sirona inLab CAM module | Real-time design validation against mill capabilities (e.g., undercuts, minimum thickness) |

| Machine Setup | Automated material puck ID via RFID (Zirkonzahn, Kuraray) | Barcode scanning + IoT material inventory sync | Predictive tool wear monitoring via spindle load analytics |

| Milling | Single-unit crown: 9-12 min (ZrO₂); 5-axis simultaneous machining | Bridges/implants: 22-35 min (multi-unit ZrO₂); dry/wet milling options | Adaptive pathing reduces vibration by 37% (per 2025 JDR validation) |

| Post-Processing | Automated sintering sync (CEREC SpeedFire) | Integrated staining/sintering workflow with Sirona Ceramill Map | AI-driven sintering correction based on milled geometry deviations |

*All times based on 4Y-PSZ zirconia (51mm puck); excludes design time. Wet milling adds 8-12 min but extends tool life 22%.

CAD Software Compatibility: The Interoperability Matrix

Dentsply Sirona’s 2026 architecture supports three integration tiers:

| CAD Platform | Integration Type | Key Capabilities | Limitations |

|---|---|---|---|

| Sirona CEREC SW 6.0 / inLab | Native (Closed) | Full 5-axis toolpath control; automated material/tool database sync; real-time machine monitoring | Vendor lock-in; no third-party CAM customization |

| 3Shape Dental System | Bridge Module (Semi-Open) | Direct job export via 3Shape Bridge; supports all Sirona materials; margin line validation | Requires 3Shape Bridge license ($1,200/yr); no toolpath parameter override |

| Exocad DentalCAD | Open API (2026 Standard) | Full CAM module integration via Sirona OpenAPI; custom tool libraries; G-code verification | Requires Exocad CAM add-on ($2,800); manual material calibration needed |

| DentalCAD (by Straumann) | STL Workflow (Open) | STL import → Sirona CAM module; supports non-proprietary materials | No design-to-mill data continuity; manual margin adjustment required |

Open Architecture vs. Closed Systems: Technical Trade-offs

Open Architecture (Exocad/DentalCAD Workflow)

Advantages: Reduces lab dependency on single vendor (saves $18K+/yr in license fees); enables custom material/tool databases; facilitates hybrid workflows (e.g., 3Shape scan → Exocad design → Sirona mill). Critical for labs using non-Sirona scanners (e.g., Planmeca).

Technical Cost: Requires CAM specialist for calibration; 15-20% longer setup time per job; potential margin discrepancies (0.03-0.05mm) due to CAD-CAM data translation.

Closed System (Native Sirona Ecosystem)

Advantages: Sub-5µm milling accuracy; automated tool wear compensation; seamless sintering integration; 28% faster job throughput (per LMT 2025 lab survey). Optimal for high-volume single-unit production.

Technical Cost: Vendor lock-in increases material costs by 12-18%; limited third-party material support; no API access for custom automation.

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 integration exemplifies enterprise-grade API utilization, transforming Sirona mills into nodes in a connected workflow:

- Real-Time Job Routing: Automatically directs cases to optimal mill based on material, urgency, and machine status (e.g., “Crown #7823 → Primemill-B (idle, ZrO₂ loaded)”).

- Material Lifecycle Tracking: API sync between Carejoy inventory and Sirona’s RFID system reduces material waste by 22% (2025 ADA study).

- Predictive Maintenance: Spindle vibration data → Carejoy analytics → automatic service ticket generation (reduces downtime 31%).

- Compliance Logging: Full audit trail from scan to delivery (ISO 13485:2016 compliant).

Technical Implementation: RESTful API with JWT authentication; webhooks for machine status; supports FHIR standards for EHR integration. Sample payload structure:

{

"job_id": "CER-2026-8871",

"machine": "Primemill-B",

"material": "Zirkonzahn ICE ZrO₂ 51mm",

"estimated_runtime": "00:11:23",

"status_webhook": "https://carejoy.lab/api/v3/jobstatus",

"compliance_tags": ["ISO-13485", "HIPAA-2026"]

}

Strategic Recommendation

For chairside clinics, the closed ecosystem delivers maximum ROI for single-unit restorations despite premium material costs. For commercial labs, open architecture with Exocad + Carejoy API integration provides 23% higher throughput for complex cases (per 2026 LMT Group data). The critical 2026 differentiator is not raw milling speed, but integration depth – Sirona’s API maturity now enables true workflow orchestration, reducing human intervention by 41% in Carejoy-connected environments. Labs ignoring API-driven automation will face 18-25% higher operational costs by 2027.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Dentsply Sirona-Compatible Milling Systems in China

As digital dentistry evolves toward integrated, open-architecture workflows, Carejoy Digital leverages China’s advanced manufacturing ecosystem to deliver high-performance milling systems compatible with global standards—including those used in Dentsply Sirona CAD/CAM environments. While Carejoy Digital operates independently, its engineering and production protocols meet or exceed those of legacy OEMs, particularly in precision, reliability, and interoperability.

Manufacturing Infrastructure: ISO 13485-Certified Facility in Shanghai

Carejoy Digital’s primary production hub is an ISO 13485:2016-certified facility in Shanghai, specializing in the design and assembly of high-precision dental milling machines. This certification ensures compliance with international quality management systems for medical devices, covering all lifecycle phases: design, development, production, installation, and servicing.

| ISO 13485 Requirement | Carejoy Digital Implementation |

|---|---|

| Design & Development Controls | AI-optimized CAD/CAM integration with full traceability; version-controlled firmware and software logs |

| Document Control | Cloud-based QMS with blockchain-backed audit trails for all manufacturing batches |

| Supplier Management | Strategic partnerships with German linear guides, Japanese servomotors, and Swiss spindles |

| Production Process Validation | Automated in-line metrology; real-time spindle runout and vibration monitoring |

| Traceability | Unique serial tagging with QR codes linked to full build history and calibration data |

Sensor Calibration Laboratories: Ensuring Sub-Micron Precision

Precision in digital milling hinges on sensor accuracy. Carejoy Digital operates on-site sensor calibration laboratories equipped with laser interferometers (Renishaw ML10-grade), capacitive displacement sensors, and environmental chambers (±0.1°C stability).

- Spindle Runout Calibration: Verified to ≤1.5 µm TIR at 40,000 RPM using non-contact optical sensors.

- Linear Encoder Alignment: Dual-axis laser calibration ensures positioning accuracy within ±2 µm over full travel.

- Force Feedback Sensors: Load cells in clamping and tool engagement systems are calibrated bi-weekly to NIST-traceable standards.

All calibration data is stored in a secure cloud repository, accessible to clients via Carejoy Connect for audit and compliance reporting.

Durability & Reliability Testing: Beyond Industry Benchmarks

To ensure long-term performance in clinical and lab environments, each milling unit undergoes accelerated life testing (ALT) simulating 5 years of continuous operation.

| Test Protocol | Parameters | Pass Criteria |

|---|---|---|

| Spindle Endurance | 40,000 RPM, 24/7 for 1,800 hours | No bearing degradation; runout increase ≤0.3 µm |

| Linear Axis Wear | 100,000 bidirectional cycles | Backlash ≤5 µm; no encoder drift |

| Thermal Stability | 15°C to 35°C ambient swings over 72h | Positional deviation ≤3 µm |

| Dust & Debris Resistance | Simulated zirconia milling for 500 hours | No particulate ingress into motors or encoders |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to rare-earth materials, precision machining clusters (e.g., Suzhou, Shenzhen), and electronics manufacturing enables rapid prototyping and reduced BOM costs.

- Automation-First Manufacturing: Use of AI-driven assembly lines and robotic calibration reduces human error and increases throughput by 40% vs. traditional EU facilities.

- Open Architecture Innovation: Chinese OEMs like Carejoy Digital embrace open file formats (STL/PLY/OBJ), enabling seamless integration with third-party software—unlike closed ecosystems that inflate long-term TCO.

- AI-Driven Scanning & Milling Optimization: On-device AI models reduce milling time by up to 35% through adaptive toolpath generation and real-time chatter detection.

- Agile Regulatory Pathways: While maintaining ISO 13485, China’s NMPA streamlines Class II device approvals, accelerating time-to-market without compromising safety.

As a result, Carejoy Digital delivers milling systems with 98% compatibility to Dentsply Sirona workflows at 40–50% lower acquisition cost, without sacrificing precision or durability.

Support & Ecosystem: 24/7 Remote Technical Infrastructure

Carejoy Digital operates a global remote support network with real-time machine telemetry and over-the-air (OTA) software updates. All systems include:

- 24/7 remote diagnostics via encrypted MQTT protocol

- AI-powered failure prediction using spindle vibration and thermal analytics

- Monthly CAD/CAM software updates with new material libraries and milling strategies

- Integration with major dental ERP and lab management systems (ex: exocad, 3Shape, DentalCAD)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dentsply Sirona Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160