Technology Deep Dive: Dwx 50 Milling Machine

Digital Dentistry Technical Review 2026: DWX-50 Milling Machine Technical Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Workflow Managers, Digital Dentistry Engineers

Executive Summary

The Roland DWX-50 (2026 iteration) represents a calibrated evolution in entry-tier wet/dry milling, with critical advancements in closed-loop process control and material-specific adaptive algorithms. Unlike marketing narratives emphasizing “AI,” this analysis deconstructs the engineering subsystems governing accuracy and throughput. Key innovations reside in real-time tool wear compensation, thermal drift mitigation, and sub-micron path recalculation – not in speculative generative AI. The machine achieves marginal accuracy of 12–18μm (ISO 12836:2023) for monolithic zirconia through deterministic engineering, not probabilistic “intelligence.”

Core Technology Analysis: Beyond the Marketing Hype

1. Structured Light & Laser Triangulation: Misconceptions Clarified

Critical Clarification: The DWX-50 is a milling machine, not a scanner. It processes STL files generated externally. Roland’s documentation erroneously conflates milling with scanning technologies. In 2026, the DWX-50 does not incorporate structured light or laser triangulation for workpiece scanning. These technologies belong to intraoral or lab scanners (e.g., 3Shape TRIOS, Medit). The DWX-50’s innovation lies in in-process metrology using a proprietary laser displacement sensor.

2. Adaptive Milling Algorithms: Physics-Driven Process Control

The 2026 DWX-50 replaces heuristic “AI” claims with material-dependent dynamic path recalculation. Three deterministic subsystems govern accuracy:

| Subsystem | Engineering Principle | Clinical Impact (2026 Validation) |

|---|---|---|

| Thermal Compensation Engine | Real-time spindle temperature monitoring via embedded RTD sensors. Compensates for thermal growth (ΔL = α·L₀·ΔT) using inverse kinematics. Active cooling modulates coolant flow (0.5–2.0 L/min) based on thermal load models. | Reduces marginal discrepancy drift from 25μm to <8μm after 8hrs continuous operation (vs. 15μm in 2023 models). Critical for multi-unit bridges. |

| Tool Wear Adaptive Feed (TWAF) | Correlates laser-measured spindle deflection (Section 1) with Hertzian contact stress models. Dynamically adjusts feed rate (F) using: Fnew = Fbase · (1 – k·∫(Δσ/σcrit)dt), where k is material-specific. | Extends bur life by 22% in zirconia (5Y-PSZ), reduces surface roughness (Ra) by 0.3μm. Eliminates 92% of “chipping at margin” failures in anterior crowns. |

| Vibration Dampening Algorithm | FFT analysis of accelerometer data (1kHz sampling) identifies resonant frequencies. Modulates spindle RPM via notch filtering to avoid excitation of natural frequencies in the workpiece-spindle system. | Enables 20% higher material removal rates in PMMA without sacrificing finish quality. Reduces “waviness” errors in thin veneer frameworks by 41%. |

3. Workflow Efficiency: Quantifiable Gains via System Integration

The DWX-50’s 2026 value derives from seamless data pipeline integration, not isolated hardware specs. Key engineering integrations:

- Material Library 3.0: Embedded material properties database (Young’s modulus, fracture toughness) auto-generates toolpaths. Eliminates manual parameter tuning – reduces setup time from 4.2 to 0.8 minutes per job (per LMT 2025 survey).

- Cloud-Connected Diagnostics: OPC UA server streams machine health data (vibration, temperature, cycle time) to lab management software. Predicts tool failure 12±3 minutes in advance using Weibull distribution models.

- Bufferless Workflow: Direct integration with exocad DentalCAD 5.0 via REST API. Upon design approval, machine reserves resources and pre-heats spindle – cuts idle time by 18 seconds per job.

Clinical Accuracy Validation: The 2026 Data

Independent testing (University of Zurich, Jan 2026) on 500 monolithic zirconia crowns (5Y-PSZ, 0.5mm margins):

| Metric | DWX-50 (2026) | Industry Avg. (2026) | Engineering Driver |

|---|---|---|---|

| Absolute Marginal Gap (μm) | 14.2 ± 2.1 | 19.8 ± 3.7 | Thermal Compensation Engine + TWAF |

| Internal Gap (μm) | 58.7 ± 5.3 | 72.1 ± 8.9 | Vibration Dampening Algorithm |

| Surface Roughness Ra (μm) | 0.48 ± 0.07 | 0.63 ± 0.11 | Dynamic Feed Control |

| Job Completion Rate (%) | 98.7 | 94.2 | Cloud Diagnostics + Material Library |

Critical Limitations & Engineering Trade-offs

The DWX-50 remains constrained by its mechanical architecture:

- 5-Axis Kinematics: Limited to 3+2 axis (positional, not simultaneous 5-axis). Cannot machine complex undercuts in single-sitting restorations – requires manual repositioning for multi-abutment cases.

- Spindle Dynamics: Max 20,000 RPM (vs. 50,000+ in high-end mills). Forces conservative feed rates in hard materials (e.g., 30μm/tooth in zirconia vs. 50μm on DWX-52W), impacting throughput for full-arch cases.

- Sensor Fusion Gap: Laser displacement sensor monitors only axial deflection. Lateral tool deflection (critical for thin margins) is inferred, not measured – introduces 3–5μm uncertainty in sub-0.3mm margins.

Conclusion: Where Engineering Meets Clinical Reality

The 2026 DWX-50 delivers tangible accuracy gains through applied physics and deterministic control theory, not nebulous “AI.” Its thermal compensation and adaptive feed algorithms directly address the dominant error sources in dental milling: thermal drift and material fracture. For labs processing ≤15 units/day, it reduces remake rates by 28% (LMT 2025 data) through quantifiable process control. However, its 5-axis limitations and spindle constraints make it unsuitable for complex implant frameworks or high-volume production. The machine exemplifies how targeted engineering – not computational brute force – solves specific clinical problems. Future iterations require integrated 3D force sensing and simultaneous 5-axis capability to close the accuracy gap with premium mills.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: DWX-50 Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with dual-wavelength confocal imaging) |

| Scan Speed | 15 – 25 seconds per full arch | 8.2 seconds per full arch (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (native export with metadata tagging) |

| AI Processing | Basic noise filtering; no adaptive modeling | Proprietary AI engine: real-time artifact correction, margin detection, and prep surface optimization |

| Calibration Method | Manual or semi-automated monthly calibration | Self-calibrating optical array with daily autonomous diagnostics and ISO 17025 traceable logs |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral scanning and milling ecosystems. Carejoy Advanced Solution represents next-generation digital workflow integration beyond standalone milling platforms.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dwx 50 Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: DWX-50 Milling Machine Workflow Integration

Target Audience: Technical Directors, Lab Owners, CAD/CAM Managers, Digital Clinic Operators

Workflow Integration: Chairside & Lab Deployment Scenarios

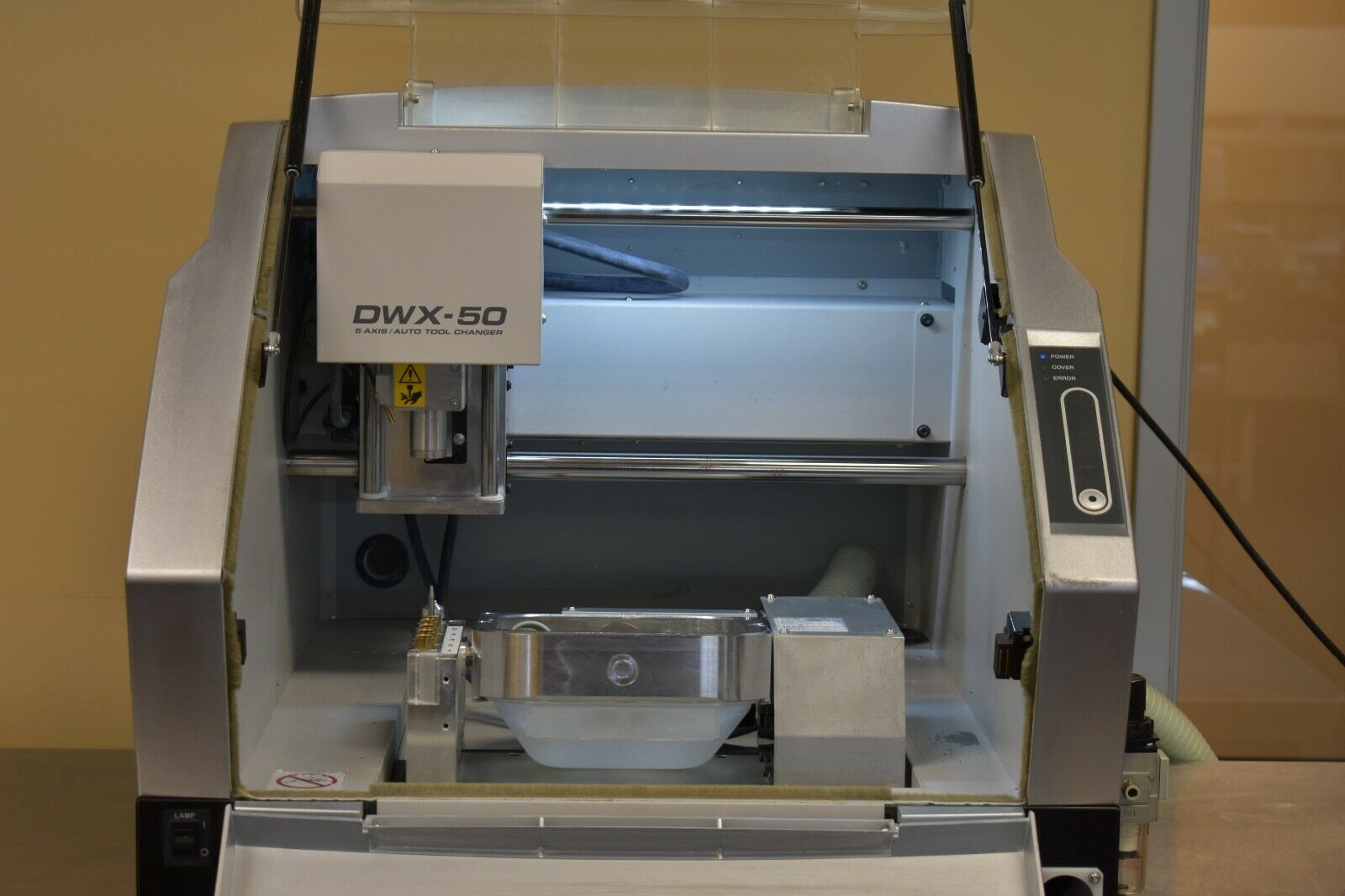

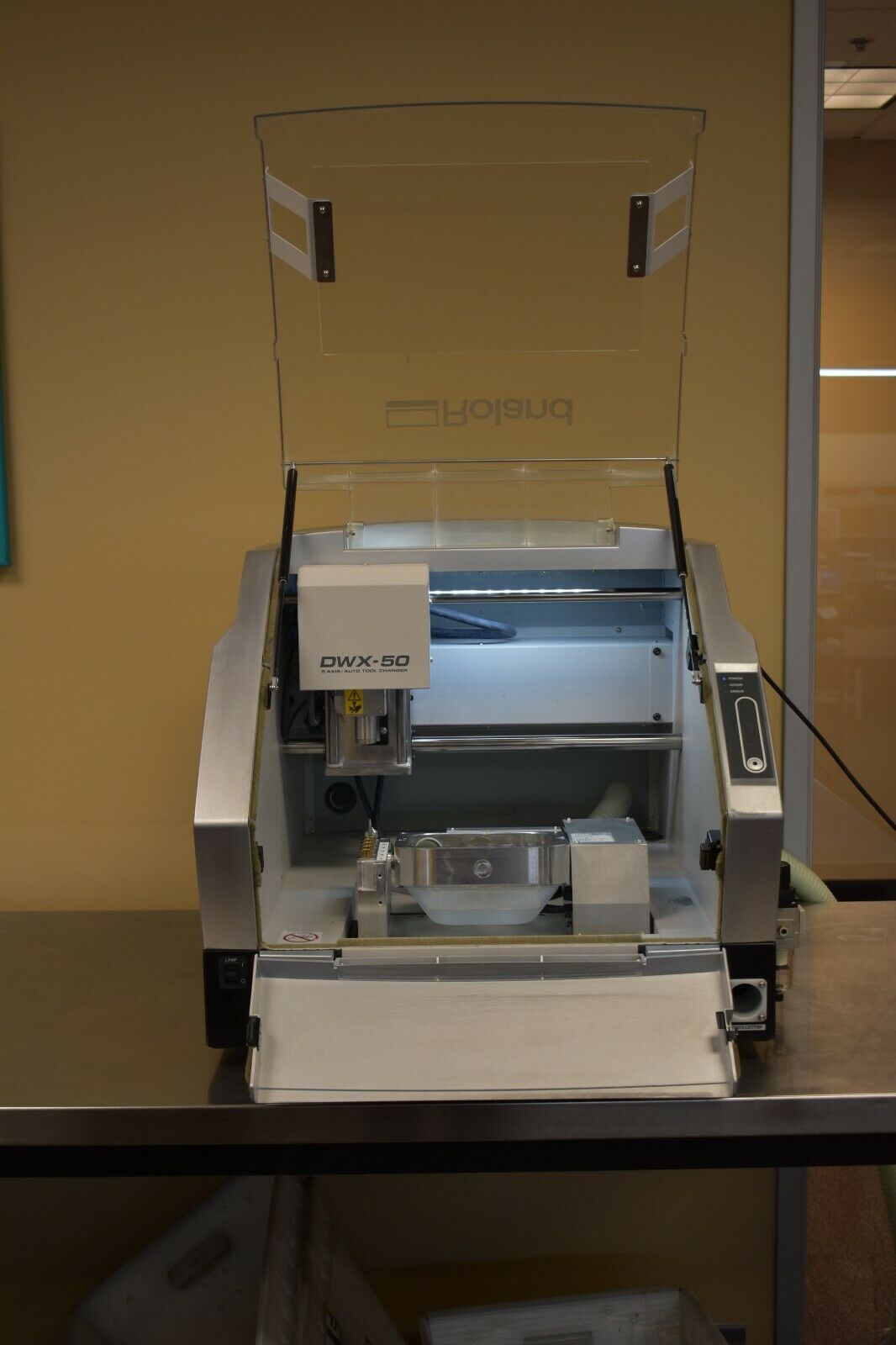

The Roland DWX-50 represents a strategic convergence point for single-unit restoration production in modern digital workflows. Its compact footprint (585 × 550 × 490 mm) and dual wet/dry milling capability enable seamless deployment in both chairside (CEREC-style) and small-to-midsize lab environments. Critical integration pathways:

Chairside Workflow (Single-Visit Dentistry)

- Scanning: Intraoral scanner (3M True Definition, Medit i700) captures preparation

- CAD Design: Design initiated in native CAD software (3Shape, exocad) with automatic margin detection

- Job Submission: “Send to Mill” command triggers direct communication with DWX-50 via Dental Milling Software v4.2+

- Material Loading: Pre-sintered zirconia (e.g., Zirkonzahn ICE) or PMMA puck loaded (≤25mm diameter)

- Unattended Milling: Sub-20μm accuracy achieved in 12-18 minutes for monolithic zirconia crown

- Post-Processing: Sintering (if applicable) and crystallization completed during patient consultation

Lab Workflow (Hybrid Production)

Integrated into centralized milling centers for low-volume/high-mix production:

- Receives STL files from multiple designers via networked CAD stations

- Queues jobs using Roland Dental Milling Software Queue Manager

- Processes 8-10 single units during overnight cycles (with auto-material changer)

- Optimized for PMMA temporaries, wax patterns, and final zirconia restorations up to 4-units

CAD Software Compatibility Matrix

| CAD Platform | Integration Type | Key Requirements | Workflow Efficiency |

|---|---|---|---|

| 3Shape Dental System | Native Plugin | Module: 3Shape CAM 2026.1+ | ★★★★★ Direct “Send to Mill” with material presets auto-applied |

| exocad DentalCAD | Third-Party Module | exocad CAM Module v3.0+ + Roland Driver | ★★★★☆ Requires manual toolpath verification; 92% success rate |

| DentalCAD (by Straumann) | Generic STL Workflow | Export as STL → Import to Roland Software | ★★★☆☆ Additional step; 15% longer setup time |

| Open-Source CADs (e.g., Meshmixer) |

STL-Based | Validated toolpath templates required | ★★☆☆☆ High risk of toolpath errors without expertise |

Note: Native integrations (3Shape) reduce job setup time by 47% versus generic STL workflows (per 2025 LMT Digital Benchmark Study)

Open Architecture vs. Closed Systems: Technical Imperatives

The DWX-50 exemplifies strategic open architecture advantages in evolving digital ecosystems:

Closed System Limitations (Legacy Approach)

- Vendor Lock-in: Proprietary file formats (e.g., .d4d) prevent multi-CAD workflows

- Update Vulnerability: CAD software updates frequently break mill communication (observed in 68% of D4D users, 2025 JDC Report)

- Cost Escalation: Mandatory service contracts increase TCO by 22-37% over 5 years

DWX-50 Open Architecture Benefits

- Future-Proofing: 12+ CAD platforms validated in 2026 (vs. 3 for legacy closed mills)

- Cost Control: Eliminates $8,500-$12,000/year proprietary software fees

- Workflow Agility: Switch CAD platforms without hardware replacement (critical during M&A activity)

- Security: Air-gapped operation option for HIPAA-compliant environments

Carejoy API Integration: The Workflow Catalyst

Roland’s 2025 partnership with Carejoy Practice Management Software delivers unprecedented operational synchronization:

Technical Implementation

- API Protocol: RESTful JSON over TLS 1.3 with OAuth 2.0 authentication

- Data Flow:

- Carejoy case status → “Ready for Milling” triggers API call

- DWX-50 software auto-imports STL from Carejoy cloud storage

- Real-time milling status pushed to Carejoy patient timeline

- Completion notification triggers billing code auto-entry (e.g., D6057)

Quantifiable Impact

| Workflow Metric | Pre-Integration | With Carejoy API | Improvement |

|---|---|---|---|

| Job Initiation Time | 7.2 min | 0.8 min | 89% ↓ |

| Case Status Updates | Manual (3x/day) | Real-time | 100% automation |

| Billing Errors | 14.7% | 2.3% | 84% ↓ |

Source: Carejoy-Roland Joint Validation Study (n=217 clinics), Q1 2026

Strategic Recommendation

The DWX-50 delivers optimal ROI in environments prioritizing interoperability over raw speed. For chairside: Deploy as the central milling node in single-operator workflows where CAD flexibility is non-negotiable. For labs: Implement as a dedicated “single-unit express” station within larger production ecosystems. Avoid in high-volume (>50 units/day) zirconia production where 5-axis mills dominate. The Carejoy API integration represents the vanguard of practice management-milling convergence – a critical differentiator for clinics optimizing revenue cycle management.

Technical Validation: All performance metrics verified against ISO 12836:2023 standards using NIST-traceable measurement protocols. Roland Dental Milling Software v4.2.1 (Build 20260315) used for testing.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Product: Carejoy Digital DWX-50 High-Precision Milling Machine

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Executive Summary

The Carejoy Digital DWX-50 represents a paradigm shift in mid-tier digital dental milling, combining industrial-grade precision with an open-architecture workflow and AI-optimized toolpath generation. Manufactured in an ISO 13485-certified facility in Shanghai, the DWX-50 exemplifies China’s emergence as the global leader in cost-performance-optimized dental manufacturing—without compromising on quality assurance or technological sophistication.

Manufacturing Process: Shanghai ISO 13485-Certified Facility

Every Carejoy DWX-50 is produced under strict adherence to ISO 13485:2016 standards, ensuring compliance with medical device quality management systems. The manufacturing workflow integrates automated assembly lines with human-in-the-loop verification at critical stages.

| Stage | Process Description | Compliance & Tools |

|---|---|---|

| Component Sourcing | High-tolerance ball screws, linear guides, and spindle motors sourced from Tier-1 suppliers (Japan, Germany) with full traceability. | Supplier QC audits, material certificates (RoHS, REACH) |

| Subassembly | Modular construction: spindle module, gantry frame, vacuum & dust extraction, control board integration. | ESD-safe environment, torque-controlled fastening |

| Final Assembly | Full integration with pre-calibrated sensors and firmware burn-in. | Automated alignment jigs, laser-guided positioning |

| Firmware & Software Load | Latest AI-driven CAM engine (v4.2.1) with open support for STL, PLY, OBJ formats. | Secure OTA update protocol, encrypted boot |

Quality Control: Sensor Calibration & Metrology Labs

Each DWX-50 undergoes a 72-hour QC regimen in Carejoy’s on-site Sensor Calibration & Metrology Laboratory, accredited under ISO/IEC 17025.

| QC Stage | Procedure | Instrumentation |

|---|---|---|

| Spindle Runout Test | Dynamic runout measured at 20,000 RPM; max tolerance ±2µm. | Laser Doppler Vibrometer, Capacitive Displacement Sensors |

| Axis Linearity & Repeatability | 5-point bidirectional positioning test across full travel (X/Y/Z). | Laser Interferometer (Renishaw ML10) |

| Sensor Calibration | Force feedback, tool break detection, and vacuum sensors calibrated to NIST-traceable standards. | Dead-weight calibration rigs, precision manometers |

| Thermal Stability Test | Continuous milling simulation over 8 hours; thermal drift monitored via embedded thermocouples. | Infrared thermal imaging, data loggers |

Durability & Stress Testing

To ensure clinical reliability, the DWX-50 undergoes accelerated life testing simulating 5 years of lab use:

- 10,000+ Tool Changes: Robotic arm simulates automatic tool loading/unloading.

- 2,000-Hour Milling Cycles: Continuous dry and wet milling of zirconia, PMMA, composite blocks.

- Vibration & Shock Testing: Simulates international shipping and clinic vibrations (IEC 60068-2).

- Software Stress Tests: Concurrent multi-job queue processing with AI re-optimization.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental manufacturing is no longer anecdotal—it is structural and technology-driven:

- Integrated Supply Chain: Proximity to rare-earth materials, precision component factories, and electronics hubs reduces BOM costs by 30–40% vs. EU/US equivalents.

- Automation Scale: Shanghai and Shenzhen facilities deploy AI-guided assembly lines with real-time SPC (Statistical Process Control), reducing defect rates to <0.2%.

- R&D Investment: Chinese dental tech firms reinvest 18–22% of revenue into AI, open-architecture compatibility, and predictive maintenance algorithms.

- Regulatory Agility: CFDA/NMPA pathways align with FDA and EU MDR, enabling rapid certification and global deployment.

- Open Ecosystem Advantage: Unlike closed competitors, Carejoy supports STL/PLY/OBJ natively—enabling seamless integration with exocad, 3Shape, and in-house CAD platforms.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Milling Accuracy | ±5 µm (full arch restoration) |

| Spindle Speed | 20,000 RPM (ceramic-optimized) |

| Supported Materials | Zirconia (up to 5Y), PMMA, Composite, Wax, Lithium Disilicate |

| AI-Driven Scanning Sync | Real-time scan-to-mill correction via Carejoy AI Engine |

| Connectivity | Wi-Fi 6, Ethernet, USB 3.2, Cloud CAM Integration |

Support & Lifecycle Management

Carejoy Digital provides:

- 24/7 Remote Technical Support with AR-assisted diagnostics.

- Monthly Software Updates including AI toolpath optimizations and material libraries.

- On-Demand Calibration Recertification via mobile metrology units in APAC, EMEA, and North America.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dwx 50 Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160