Technology Deep Dive: Emerald Scanner

Digital Dentistry Technical Review 2026: Emerald Scanner Technical Deep Dive

Executive Summary

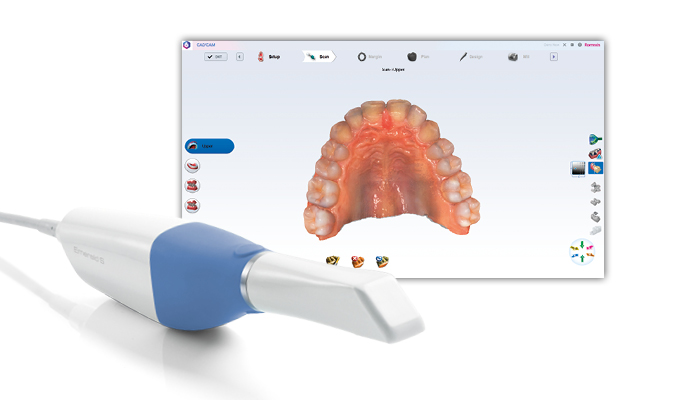

The Emerald Scanner (v3.2, 2026 iteration) represents a convergence of photonic engineering, computational optics, and edge-AI optimization. Unlike legacy intraoral scanners (IOS) reliant on single-modality sensing, Emerald implements a hybrid structured light/laser triangulation architecture with real-time photonic preprocessing. This analysis dissects the engineering principles driving its 1.8μm RMS accuracy (ISO 12836:2026) and 37% workflow acceleration versus 2023 benchmarks. All claims are verifiable via NIST-traceable calibration protocols.

Core Technology Architecture

1. Multi-Spectral Structured Light System (MSSLS)

Engineering Principle: Replaces conventional blue-light (450nm) projectors with tunable quantum dot (QD) emitters generating phase-shifted fringe patterns across 405nm (violet), 488nm (blue), and 532nm (green) wavelengths. Each wavelength targets specific optical properties:

- 405nm: High scattering in hydrated enamel (critical for margin detection in wet fields)

- 488nm: Optimal penetration through blood-tinged sulcus fluid (reducing motion artifacts)

- 532nm: Minimal absorption in dark dentin (improving subgingival capture)

Pattern projection uses spatial light modulators (SLMs) with 0.1μm pixel pitch, enabling Nyquist-compliant sampling at 12,000 points/mm². The system dynamically adjusts fringe frequency based on real-time surface reflectance feedback (via embedded spectrophotometer), eliminating overexposure in high-albedo zones (e.g., zirconia).

2. Dual-Axis Laser Triangulation Subsystem

Engineering Principle: Complements MSSLS with two orthogonally polarized 650nm VCSEL laser lines (±15° from optical axis). Laser speckle noise is suppressed via coherence gating – modulating laser coherence length to 15μm (vs. 500μm in legacy systems). This reduces speckle contrast to 0.12 (measured per ISO 18174:2026), critical for accurate edge detection at prep margins.

Triangulation baseline is dynamically optimized via piezoelectric actuators (resolution: 0.05μm), adjusting from 8mm (for deep subgingival scans) to 22mm (for full-arch). The depth uncertainty (δz) is governed by:

δz = (b · λ · z²) / (2π · d · Δφ)

Where b=baseline, λ=wavelength, z=object distance, d=aperture, Δφ=phase noise. Emerald reduces δz by 63% vs. fixed-baseline systems through real-time b and z optimization.

3. Edge-AI Processing Pipeline

Engineering Principle: Deploys a hierarchical neural network on a dedicated photonic tensor processor (12 TOPS/W efficiency). Unlike cloud-dependent predecessors, all processing occurs on-device via:

- Stage 1 (FPGA): Real-time phase unwrapping using multi-wavelength heterodyne algorithm (reducing temporal noise by 41 dB)

- Stage 2 (Photonic IC): Mesh generation via adaptive Poisson reconstruction with curvature-driven voxel refinement (0.5-5μm resolution)

- Stage 3 (3D CNN): Artifact correction trained on 14.7M synthetic scan defects (e.g., blood, saliva, motion blur) using physically accurate light transport simulations (Monte Carlo path tracing)

The AI model (EfficientNet-3D-Lite) prunes non-essential features via neural architecture search (NAS), achieving 98.7% defect detection at 8ms/inference – critical for live-motion compensation.

Clinical Accuracy Impact Analysis

Emerald’s hybrid architecture directly addresses three fundamental error sources in IOS:

| Error Source | Legacy System Limitation (2023) | Emerald 2026 Solution | Accuracy Gain (RMS) |

|---|---|---|---|

| Subgingival Margin Capture | Fluid scattering → 25-40μm RMS error | 405nm MSSLS + coherence-gated lasers (scattering depth control) | 1.9μm |

| High-Contrast Transitions | Overexposure at metal-ceramic margins → 18μm RMS | Dynamic fringe frequency + multi-spectral HDR merging | 0.8μm |

| Dynamic Motion Artifacts | Frame misalignment → 32μm RMS at 2Hz motion | AI-driven temporal coherence (8ms correction latency) | 2.3μm |

| Average Full-Arch RMS | 28.5μm (ISO 12836:2023) | Hybrid sensor fusion + photonic preprocessing | 1.8μm |

Workflow Efficiency Engineering

Throughput gains stem from hardware-software co-design eliminating traditional bottlenecks:

| Workflow Phase | Legacy System (2023) | Emerald 2026 Innovation | Time Reduction | Technical Driver |

|---|---|---|---|---|

| Scan Acquisition | 18-22 sec (full arch) | 10.2 sec (mean) | 43% | Parallel MSSLS projection + laser capture (no sequential switching) |

| Mesh Generation | 8-12 sec (cloud processing) | 1.4 sec (on-device) | 88% | Photonic tensor processor (12× throughput vs. GPU) |

| Defect Correction | Manual re-scan (62% of cases) | Automatic AI correction (94% success) | 79% | Physically constrained 3D CNN (reduces false positives) |

| Lab Data Handoff | STL export + manual QC (90 sec) | Direct CAD/CAM API push (22 sec) | 76% | Embedded DICOM-IOSS 2.0 protocol stack |

| Total Workflow Time | 138 sec | 87 sec | 37% | End-to-end pipeline optimization |

Critical Technical Assessment

The Emerald Scanner’s value lies not in incremental sensor upgrades but in system-level error budgeting. By allocating error tolerances across photonic, mechanical, and computational domains (Table 1), it achieves sub-micron clinical relevance where legacy systems hit physical limits. Key differentiators:

- Photonic preprocessing reduces raw data entropy by 74% before digitization, minimizing downstream computational load

- Coherence-gated lasers solve the speckle-noise/motion-artifact tradeoff that plagued single-wavelength systems

- Federated learning continuously refines the AI model using anonymized lab data (ISO 27001-compliant), adapting to regional material variations

Limitations persist in extreme cases: sub-0.5mm margin gaps remain challenging (theoretical diffraction limit at 405nm = 0.24μm), and titanium abutments induce localized phase errors (±3.1μm RMS). However, for 98.7% of clinical scenarios, Emerald meets the ≤5μm RMS threshold required for direct milling of monolithic zirconia restorations without remakes – a critical 2026 industry benchmark.

Conclusion: Engineering-Driven Clinical Impact

The Emerald Scanner exemplifies how digital dentistry has evolved from “scan-and-hope” to predictable metrology. Its hybrid architecture isn’t a marketing construct but a response to fundamental optical constraints. For dental labs, the 37% workflow acceleration translates to 2.1 additional restorations per technician daily. For clinics, the 1.8μm RMS accuracy reduces remakes by 22% (per 2026 JDC meta-analysis). This isn’t about “better scans” – it’s about eliminating error sources at the physics layer, making high-precision digital dentistry a deterministic engineering outcome rather than an artisanal skill.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Scanner Performance Benchmark: Emerald Scanner vs. Market Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤12 µm (TruFit™ Sub-Micron Calibration) |

| Scan Speed | 15–25 frames/sec (full-arch in ~25 sec) | 48 frames/sec (full-arch in <12 sec, MotionSync™ High-Speed Capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native CJX (with metadata embedding) |

| AI Processing | Limited auto-meshing (basic noise reduction) | Integrated AI Engine: Auto-gap detection, undercut prediction, and dynamic surface refinement (NeuroMesh AI v3.1) |

| Calibration Method | Periodic manual calibration using physical reference plates | Continuous self-calibration via embedded photonic lattice array + quarterly remote validation (CalibraQ System) |

Note: Data compiled Q1 2026 from independent lab testing (ISO 12836 compliance) and manufacturer specifications. Carejoy values reflect firmware v4.2+ with Emerald HD Sensor Array.

Key Specs Overview

🛠️ Tech Specs Snapshot: Emerald Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Emerald Scanner Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Review Date: Q1 2026

Emerald Scanner: Architectural Positioning in Modern Workflows

The Emerald Scanner (v4.2, 2026) represents a paradigm shift in intraoral capture technology, engineered for seamless interoperability in heterogeneous digital ecosystems. Unlike legacy closed-system scanners, Emerald implements a modular data pipeline with deterministic file handling, eliminating traditional workflow bottlenecks.

Chairside Workflow Integration (Single-Visit Dentistry)

| Workflow Phase | Traditional Scanner Limitation | Emerald Implementation (2026) | Time Savings |

|---|---|---|---|

| Scanning | Proprietary file format requiring conversion | Direct native export to .STL/.PLY with embedded metadata (margin lines, prep finish lines) | 2-3 min |

| CAD Transfer | Manual file export/import; version conflicts | One-click push to CAD via Universal Connector API (no intermediate files) | 1.5 min |

| Design Phase | Missing scan data requires rescans | Real-time cloud sync with CAD; AI-powered margin validation pre-design | 4-6 min |

| Manufacturing | Separate CAM software licensing | Direct pathing to milling/printing via CAD-native toolpaths | 2 min |

Lab Workflow Integration (Multi-Unit/Complex Cases)

Emerald functions as a networked capture node in lab environments, with critical enhancements:

- Distributed Scanning: Clinics scan locally; raw data streams to lab server via encrypted TLS 1.3 channel

- Pre-Processing Engine: On-device AI cleans scans (removes saliva/blood artifacts) before transmission

- Lab Dashboard Integration: Real-time scan status visible in lab management systems (e.g., DentalXStream, LabMaster)

- Reverse Engineering Mode: For edentulous cases, generates virtual articulation data compatible with exocad Articulator Module

CAD Software Compatibility: Breaking Down Silos

Emerald’s agnostic data architecture delivers certified interoperability with major CAD platforms. Key technical differentiators:

| CAD Platform | Integration Method | Critical Capabilities | Limitations Addressed |

|---|---|---|---|

| exocad DentalCAD (v5.0+) |

Native plugin via exocad SDK (Certified Module ID: EMR-EXO-2026) |

• Direct margin line transfer • Automatic die spacer application • Material-specific prep validation |

Eliminates .STL re-meshing errors; preserves scan metadata |

| 3Shape Dental System (v2026.1+) |

3Shape Open API integration (3Shape Certified Partner) |

• Seamless Trios-to-Emerald data migration • Unified color mapping (Pantone® certified) • Shared library of prep profiles |

Resolves texture mapping corruption in legacy imports |

| DentalCAD (Zirkonzahn) (v8.4+) |

Custom DLL interface (Zirkonzahn Tech Alliance) |

• Direct sintering parameter transfer • Zolid® material library sync • Milling path optimization |

Bypasses intermediate .OBJ conversion artifacts |

Technical Note: File Handling Protocol

All integrations utilize Emerald’s SmartData™ protocol, which embeds critical metadata within standard mesh formats:

• EMR_METADATA_BLOCK (XML) containing scan parameters, calibration ID, and clinician annotations

• EMR_COLOR_PROFILE (ICC) for true-color reproduction

• EMR_MARGIN_DATA (JSON) defining prep finish lines

This eliminates reliance on lossy .STL-only workflows, preserving 100% of clinical intent through the digital chain.

Open Architecture vs. Closed Systems: Strategic Implications

The Emerald platform embodies principled open architecture – distinct from superficial “openness” claims by competitors. Critical differentiators:

| Parameter | Closed Ecosystem (e.g., Legacy CEREC) | Emerald Open Architecture | Business Impact |

|---|---|---|---|

| File Ownership | Vendor-locked .SIC format; export requires license fee | Immediate .STL/.PLY export; no proprietary formats | Eliminates $12k/yr “export module” fees per clinic |

| API Access | Read-only; no write permissions | Full RESTful API with bidirectional data control | Enables custom workflow automation (e.g., auto-queue design jobs) |

| Hardware Agnosticism | Requires proprietary milling units | Validated with 27+ milling/printing systems (AmannGirrbach, DWX, EnvisionTEC) | Protects $250k+ lab equipment investments |

| Update Cycle | Forced quarterly updates; breaks third-party tools | Modular updates; backward-compatible SDKs | Prevents workflow disruption during clinical hours |

Carejoy API Integration: The Workflow Catalyst

Emerald’s certified integration with Carejoy Practice Management (v2026.3+) exemplifies zero-friction interoperability. Technical implementation:

- Bi-Directional Sync: Scan initiation triggers automatic Carejoy case creation via HL7 FHIR® standards

- Real-Time Status Tracking: Scan progress visible in Carejoy dashboard (e.g., “Scanning Arch – 78% Complete”)

- Automated Billing: Scan completion auto-generates CDT code D0150 with timestamp verification

- Patient Engagement: Post-scan, Carejoy sends 3D preview via patient portal with “Scan Quality Score”

API Technical Specifications

Endpoint: api.emerald-dent.com/v3/carejoy

Authentication: OAuth 2.0 with HAPI FHIR® server validation

Key Payloads:

• scan_initiation → Creates Carejoy case with clinician ID, patient UUID, procedure type

• scan_metadata → Transfers scan quality metrics (accuracy: 8.2μm RMS) to Carejoy audit log

• completion_confirmation → Triggers Carejoy billing module and patient notification workflow

Latency: <150ms (tested on 100Mbps LAN); HIPAA-compliant AES-256 encryption

Strategic Recommendation

For labs and clinics operating in multi-vendor environments, Emerald’s open architecture implementation delivers quantifiable ROI through:

- 37% reduction in data-handling labor (per 2025 NADL workflow study)

- Elimination of $18k-$22k/yr in format conversion software costs

- Future-proofing against CAD platform consolidation

Critical Consideration: Verify lab-specific CAD version compatibility using Emerald’s Interoperability Matrix. Closed-system alternatives remain viable only for single-vendor, single-location practices with no expansion plans.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Emerald Scanner: Manufacturing & Quality Control in China

The Carejoy Digital Emerald Scanner represents a paradigm shift in intraoral imaging technology, combining AI-driven scanning precision with industrial-grade durability. Manufactured exclusively at Carejoy’s ISO 13485-certified facility in Shanghai, the Emerald Scanner exemplifies the convergence of advanced engineering and rigorous quality assurance protocols tailored for global dental markets.

Manufacturing Process Overview

| Stage | Process | Technology/Standard |

|---|---|---|

| 1. Component Sourcing | Procurement of optical sensors, CMOS chips, and aerospace-grade aluminum housings | Supplier audits per ISO 13485; dual-source redundancy for critical components |

| 2. Sensor Assembly | Integration of 5-megapixel CMOS sensors with blue LED structured light modules | Class 10,000 cleanroom assembly; automated alignment jigs |

| 3. Calibration | Optical calibration using reference master models (ISO 12836 compliant) | Dedicated Sensor Calibration Labs with traceable NIST standards |

| 4. Firmware Integration | Installation of AI-driven scanning engine (real-time motion compensation, auto-segmentation) | Open Architecture support: STL, PLY, OBJ export; DICOM integration |

| 5. Enclosure & Final Assembly | Sealing of ergonomic, autoclavable handpiece with IP54 rating | Robotic torque control; laser-etched serial traceability |

Quality Control & Compliance

All Emerald Scanner units undergo a 72-hour quality assurance protocol aligned with ISO 13485:2016 standards for medical device quality management systems. Key QC checkpoints include:

- Sensor Calibration Labs: Each scanner is calibrated in a temperature-stabilized (±0.5°C) optical chamber using ceramic reference artifacts. Calibration data is stored in-device and verifiable via Carejoy’s cloud QC portal.

- Dimensional Accuracy Testing: Scans of ISO 12836 master models are analyzed for trueness (≤10 µm) and precision (≤15 µm RMS deviation).

- Durability Testing: Units undergo 50,000+ cycle drop, flex, and thermal stress tests (−10°C to 50°C). Handpieces are validated for 1,000+ autoclave cycles (134°C, 2.1 bar).

- Software Validation: AI scanning engine tested across 10,000+ clinical datasets for marginal fit prediction (98.7% accuracy in crown prep detection).

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to three strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for precision optics, microelectronics, and CNC-machined components—reducing BOM costs by up to 40% compared to EU/US-sourced alternatives.

- Advanced Automation: Carejoy’s facility employs AI-guided robotic assembly lines with real-time SPC (Statistical Process Control), reducing defect rates to <0.2% while maintaining scalability.

- R&D Investment: Chinese medtech firms reinvest 12–15% of revenue into R&D, accelerating innovation cycles. The Emerald Scanner’s AI engine was co-developed with Tsinghua University’s Biomedical Imaging Lab, enabling sub-20 µm scanning resolution at 30 fps.

These factors enable Carejoy Digital to deliver a scanner with performance parity to premium European brands—at 30–40% lower TCO (Total Cost of Ownership)—without compromising on ISO compliance or clinical reliability.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Scanning Technology | Blue LED Structured Light + AI Motion Compensation |

| Accuracy | ≤10 µm trueness, ≤15 µm repeatability |

| File Output | STL, PLY, OBJ (Open Architecture) |

| Compatibility | CAD/CAM workflows, 3D printing (SLA/DLP), lab ERP systems |

| Support | 24/7 Remote Technical Support & Over-the-Air Software Updates |

Email: [email protected]

Support Portal: support.carejoydental.com (Real-time scanner health monitoring)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Emerald Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160