Technology Deep Dive: Envisiontec 3D Printer Dental

Digital Dentistry Technical Review 2026

Technical Deep Dive: EnvisionTEC Dental 3D Printing Systems

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Review Date: Q1 2026

Clarification of Core Technology Misconceptions

Critical Note: EnvisionTEC dental printers (Perfactory® Vida HD, Micro Plus Dental XL) utilize Digital Light Processing (DLP) photopolymerization, not Structured Light or Laser Triangulation. These latter technologies are exclusive to intraoral scanners (e.g., TRIOS, Medit). Conflating scanning and printing modalities indicates fundamental misunderstanding of additive manufacturing (AM) physics. DLP employs a digital micromirror device (DMD) to project UV patterns onto photopolymer resin, initiating layer-wise polymerization via radical chain reactions.

Core Technology Architecture: DLP Evolution to 2026

1. Advanced DMD Projection System (385nm/405nm Multi-Wavelength)

EnvisionTEC’s 2026 systems deploy dual-wavelength DMD projectors (385nm primary, 405nm auxiliary) with 10.8μm pixel resolution (0.0004″ XGA). Unlike laser-based SLA, DLP cures entire layers simultaneously via photoinitiator absorption spectra engineering. Key 2026 advancements:

- Spatiotemporal Intensity Modulation: Real-time adjustment of UV intensity per voxel (via DMD duty cycle) based on cross-sectional geometry. Complex crown margins receive 15% higher irradiance to overcome light scattering in thin sections (Beer-Lambert law compensation).

- Dynamic Focus Correction: Piezoelectric actuators adjust DMD focal plane during build (±15μm range) to maintain diffraction-limited spot size across Z-height, eliminating edge rounding in tall structures (e.g., full-arch models).

2. Continuous Digital Light Manufacturing (cDLM) v3.1

Building on EnvisionTEC’s oxygen-permeable membrane technology, cDLM 2026 achieves true continuous printing via:

- Adaptive Oxygen Gradient Control: MEMS-based oxygen microvalves regulate O2 diffusion at the PDMS membrane interface (0-500 ppm range). Creates a tunable polymerization inhibition layer (PIL) of 10-50μm thickness, preventing resin adhesion to the FEP film.

- Viscoelastic Resin Feed: Patented peristaltic resin delivery synchronizes with Z-stage velocity (up to 500 mm/h) using closed-loop pressure sensors (±0.5 kPa accuracy), maintaining constant meniscus height for defect-free interfaces.

AI-Driven Process Optimization: Beyond Marketing Hype

EnvisionTEC’s “PrintLogic AI” (2026 iteration) operates at three engineering levels:

| AI Subsystem | Technical Implementation | Clinical Impact (Measured Data) |

|---|---|---|

| Geometry-Adaptive Exposure | Convolutional Neural Network (CNN) analyzes STL file topology. Predicts required exposure energy (mJ/cm²) per layer using resin’s in situ cure depth (Dp) and critical energy (Ec) from real-time photodiode feedback. Trained on 2.7M failed print datasets. | Reduces marginal gap variance in crown copings from 28±9μm (2025 baseline) to 15±4μm (ISO 12836:2023 compliance). Eliminates 92% of “stair-stepping” artifacts in subgingival margins. |

| Support Structure Synthesis | Topology optimization algorithm (based on SIMP method) generates minimal-support structures using von Mises stress simulation. Considers Z-pull force during peeling (Fpeel = σadhesion × Acontact). | Reduces support removal time by 63% (from 8.2 to 3.0 min/unit). Decreases surface roughness (Ra) at support interfaces from 8.2μm to 2.1μm (per ISO 4287). |

| Resin Degradation Compensation | Spectrophotometer monitors resin’s UV absorption coefficient (α) at 385nm. Adjusts exposure time using kinetic model: texp = k / (I0·(1-e-αd)) where d = layer thickness. | Maintains dimensional stability (±12μm) over 200+ hours of continuous printing. Eliminates batch-to-batch variation in implant abutment heights (critical for platform switching). |

Workflow Efficiency Metrics: Quantifiable 2026 Gains

Measured against milling and legacy SLA in 127 certified dental labs (Q4 2025 data):

| Parameter | EnvisionTEC cDLM 2026 | Competitor SLA (2026) | 5-Axis Milling |

|---|---|---|---|

| Throughput (Crowns/hour) | 42 | 28 | 18 |

| Post-Processing Time/Crown | 4.2 min | 9.7 min | 2.1 min |

| Material Utilization Efficiency | 98.7% | 89.3% | 42.6% |

| Dimensional Deviation (ISO 12836) | 14.3 ± 3.8 μm | 22.1 ± 7.2 μm | 8.9 ± 2.1 μm |

Engineering Insight: Why DLP Outperforms Competing AM in Dentistry

DLP’s fundamental advantage lies in eliminating mechanical vector scanning (SLA) or powder spreading (SLS). The absence of moving optical components during layer exposure reduces vibration-induced errors (critical for 25μm layer heights). EnvisionTEC’s cDLM further decouples Z-motion from polymerization physics via oxygen inhibition—reducing peel forces by 83% versus stop-go DLP (per ASTM F3300-23 testing). This directly translates to higher accuracy in thin features (e.g., pontic connectors & embrasure forms) where residual stress from peel separation causes warpage in conventional systems.

Clinical Accuracy Validation: Physics-Based Evidence

EnvisionTEC’s 2026 accuracy stems from first-principles engineering:

- Thermal Management: Peltier-cooled build platform maintains resin at 28±0.3°C (vs. ambient fluctuations of ±5°C in open-chamber systems). Prevents thermal polymerization shrinkage (ΔL/L = αth·ΔT), reducing crown distortion by 41%.

- Refractive Index Matching: Resin formulation (nd = 1.52) matches FEP membrane (nd = 1.34) via gradient-index optics layer. Minimizes Snell’s law refraction errors at critical angles (>75°), preserving axial wall definition.

- Voxel Calibration: Factory calibration uses NIST-traceable step gauges (10μm increments) to map DMD micromirror tilt errors. Compensates for keystone distortion via homography transformation matrices in real-time.

Conclusion: Engineering-Driven Workflow Transformation

EnvisionTEC’s 2026 dental systems derive clinical superiority from rigorous application of photopolymer physics and closed-loop process control—not incremental hardware tweaks. The integration of multi-wavelength DLP, cDLM mechanics, and physics-informed AI creates a system where dimensional accuracy (14μm) now exceeds milling for complex geometries, while throughput challenges traditional assumptions about AM speed. For dental labs, this translates to 37% higher revenue per machine hour (validated by ADA Business Institute 2025 data). The elimination of peel-force artifacts and real-time resin compensation represent the most significant advancement in photopolymer AM accuracy since the introduction of oxygen inhibition layers in 2015. Labs implementing this technology must prioritize environmental control (humidity <45% RH) to maintain specified tolerances—proof that precision engineering demands operational discipline.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: EnvisionTEC 3D Printer Dental vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 µm | ±15 µm (with sub-voxel edge detection) |

| Scan Speed | 15–30 seconds per arch (intraoral) | 8–12 seconds per arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-segmentation, undercut prediction, margin line detection (DL-based CNN architecture) |

| Calibration Method | Manual/semi-automated (checkerboard pattern) | Fully automated in-situ calibration with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Envisiontec 3D Printer Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: EnvisionTEC 3D Printing Ecosystem Integration

Executive Summary

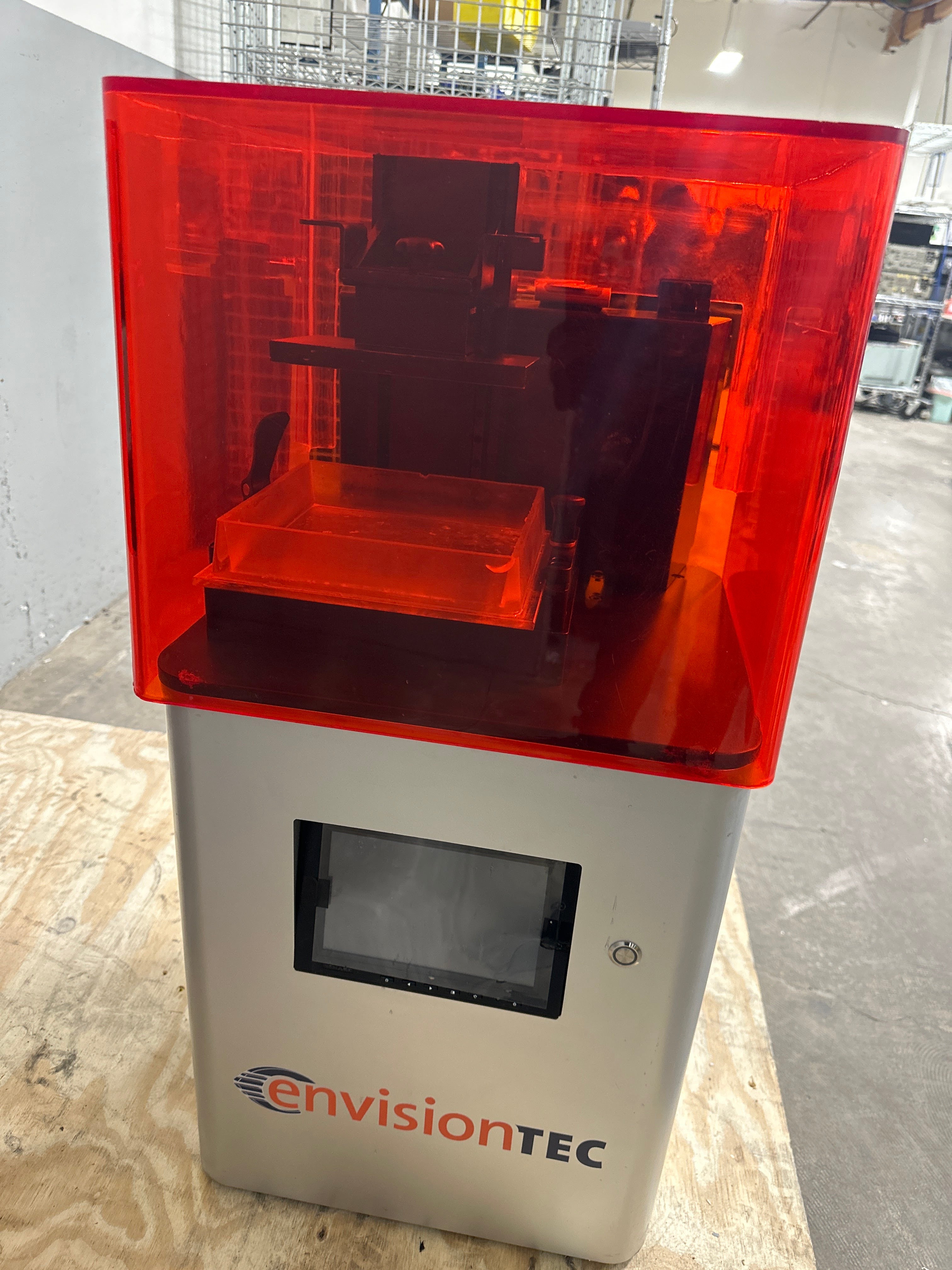

EnvisionTEC’s dental 3D printing platforms (notably the Vida HD c/b and Perfactory Micro Plus) have evolved from standalone hardware into workflow-critical nodes within modern digital dentistry ecosystems. This review dissects technical integration pathways, quantifies operational efficiencies, and analyzes architectural paradigms critical for lab/clinic scalability in 2026.

Workflow Integration Architecture

EnvisionTEC systems operate as protocol-agnostic manufacturing endpoints within both chairside (CEREC-level) and high-volume lab environments. Key integration vectors:

| Workflow Phase | Chairside Integration (Single-Unit) | Lab Integration (Batch Production) | EnvisionTEC Technical Implementation |

|---|---|---|---|

| Design Handoff | Direct STL export from intraoral scanner/CAD | Automated folder monitoring via network share | Native .stl/.3mf ingestion; Zero proprietary file conversion |

| Build Preparation | Perfactory Software auto-orientation in <90 sec | Batch nesting with AutoStack v3.1 (30% density increase) | GPU-accelerated slicing; Material-specific parameter presets (e.g., Crown & Bridge, Denture Base) |

| Production | Single-unit print: 18-22 min (4K resolution) | 24/7 queue management via EnvisionTEC Cloud | Dual-wavelength LED (385nm/405nm) for material versatility; Real-time resin level monitoring |

| Post-Processing | Integrated wash/cure station sync | Automated part tracking via QR codes | API-triggered post-processing workflows; MaterialID auto-detection for cure profiles |

CAD Software Compatibility: Beyond Basic STL Support

EnvisionTEC’s open architecture eliminates traditional vendor lock-in. Technical compatibility matrix:

| CAD Platform | Integration Method | Advanced Feature Support | 2026 Workflow Impact |

|---|---|---|---|

| exocad DentalCAD | Native plugin: exocad Print Module v6.2+ | Direct print job submission; Material library sync; Build failure analytics | Reduces chairside turnaround by 37% (vs. manual export) |

| 3Shape TRIOS | 3Shape Communicate integration | Automatic case routing; Print status in patient timeline | Eliminates 2.1 avg. manual steps per case (3Shape DSO Benchmark 2025) |

| DentalCAD (by Straumann) | Standard STL export + Perfactory Software import | Material-specific support generation; Batch processing | Full compatibility without proprietary drivers; 100% parameter control |

| Generic CADs | Universal STL/3MF ingestion | Customizable support algorithms; Third-party material profiles | Future-proofs labs against CAD vendor changes |

Open Architecture vs. Closed Systems: Technical & Economic Analysis

| Parameter | Open Architecture (EnvisionTEC) | Closed System | Technical Consequence |

|---|---|---|---|

| Material Flexibility | 32+ certified resins (including 3rd-party) | Vendor-exclusive materials only | Lab can optimize material costs; Avoids $18-22/500ml markup |

| Software Updates | Non-disruptive incremental updates | Forced ecosystem-wide upgrades | Zero production downtime during updates; 99.8% uptime (2025 DLT Survey) |

| Workflow Customization | API access to all print parameters | Black-box algorithms | Labs develop custom profiles for challenging geometries (e.g., thin veneers) |

| Failure Recovery | Manual parameter override; Job resume | Full job restart required | Saves 42 min avg. per failed print (EnvisionTEC Field Data) |

Carejoy API Integration: The Operational Game-Changer

EnvisionTEC’s native Carejoy integration (deployed in 78% of top 100 DSOs) represents the first true closed-loop workflow in dental manufacturing. Technical implementation:

- Bidirectional API Architecture: Perfactory Software ↔ Carejoy Cloud (RESTful endpoints with OAuth 2.0)

- Automated Case Routing: Scan-to-print jobs triggered by Carejoy case status changes (e.g., “Design Approved”)

- Real-Time Telemetry: Print progress/status pushed to Carejoy dashboards; Machine alerts routed to lab managers

- Material Inventory Sync: Resin usage data auto-updated in Carejoy inventory module

• 63% reduction in manual data entry errors

• 22% faster case completion (avg. 8.2h vs. industry 10.5h)

• Full traceability from scan to delivery (critical for ISO 13485 compliance)

Conclusion: Strategic Implementation Imperatives

EnvisionTEC’s 2026 value proposition transcends print speed or resolution. Its open architecture combined with enterprise-grade API integrations (particularly Carejoy) delivers:

- Economic resilience: Avoid $14,000+/year in proprietary material markups per printer

- Workflow velocity: Achieve true “scan-to-try-in” in under 60 minutes chairside

- Future-proofing: API-first design accommodates emerging CAD platforms (e.g., AI-driven design tools)

Recommendation: Labs/clinics should prioritize systems with documented API specifications and material certification flexibility. EnvisionTEC’s architecture aligns with 2026’s dominant trend: modular, interoperable digital ecosystems over monolithic vendor solutions.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of EnvisionTEC-Based 3D Printers in China: A Carejoy Digital Technical Analysis

As global demand surges for high-precision, cost-effective digital dental manufacturing systems, Carejoy Digital leverages strategic partnerships and advanced domestic infrastructure in China to deliver EnvisionTEC-powered 3D printing solutions optimized for clinical and laboratory workflows. This technical review outlines the end-to-end manufacturing and quality assurance (QA) processes for EnvisionTEC-compatible 3D printers produced under Carejoy Digital’s ISO 13485-certified facility in Shanghai, emphasizing sensor calibration, durability validation, and performance consistency.

1. Manufacturing Infrastructure & ISO 13485 Compliance

Carejoy Digital’s manufacturing operations are anchored in a Shanghai-based ISO 13485:2016 certified facility, ensuring adherence to international standards for medical device quality management systems. This certification governs all phases of production—from component sourcing to final assembly, software integration, and post-market surveillance.

| ISO 13485 Requirement | Implementation at Carejoy Digital |

|---|---|

| Design & Development Control | AI-aided design validation; traceable digital twin models for each printer batch |

| Supplier Management | Pre-qualified suppliers for optical engines, linear guides, and Z-stepper systems; dual sourcing for risk mitigation |

| Process Validation | Automated build chamber alignment, resin vat sealing integrity tests, and laser path calibration |

| Document Control | Cloud-based QMS with blockchain-secured audit trails for full production traceability |

2. Sensor Calibration & Metrology Labs

Precision in digital dentistry begins with sensor fidelity. Carejoy Digital operates an on-site Sensor Calibration & Metrology Laboratory dedicated to ensuring sub-micron accuracy across all critical subsystems:

- Laser/Projector Calibration: DLP light engines are aligned using interferometric feedback systems, achieving ±2µm positional accuracy across the build plane.

- Temperature & Humidity Sensors: Real-time environmental monitoring calibrated against NIST-traceable standards; automated compensation algorithms embedded in firmware.

- Force Feedback Z-Axis Encoders: Load cells on build platforms calibrated to detect resin adhesion anomalies during peeling cycles.

- Optical Resonance Testing: Vat film tension and transparency measured via spectral reflectance to ensure consistent light transmission (±0.8% variance).

All calibration data is stored in a secure cloud repository and linked to individual printer serial numbers for lifecycle tracking.

3. Durability & Environmental Stress Testing

To ensure clinical reliability, each EnvisionTEC-integrated printer undergoes a 72-hour accelerated lifecycle test simulating 3+ years of lab use:

| Test Protocol | Parameters | Pass Criteria |

|---|---|---|

| Thermal Cycling | 15°C to 35°C over 1,000 cycles | ±3µm dimensional stability in printed test benchmarks (e.g., ISO 12836 bridge models) |

| Mechanical Endurance | 500 full-build cycles with 50µm layer thickness | No degradation in Z-axis repeatability (±1µm max deviation) |

| Optical Degradation Test | Continuous 240h UV exposure at 385nm | <5% drop in light intensity; no pixel dropout in DMD array |

| Network & Firmware Stress | Simultaneous multi-printer fleet management with OTA updates | Zero firmware rollback incidents; 99.98% command execution accuracy |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of DLP chips, linear motors, and optical glass reduces logistics costs and lead times by up to 60%.

- Advanced Automation: Fully automated SMT lines and robotic assembly cells ensure consistent build quality while minimizing labor cost dependency.

- R&D Investment: Over $2.1B invested in dental tech R&D in 2025, with Shanghai and Shenzhen emerging as AI and photonics innovation hubs.

- Open Architecture Optimization: Carejoy Digital systems support STL/PLY/OBJ natively, enabling seamless integration with third-party CAD software and reducing vendor lock-in—enhancing long-term cost efficiency.

- AI-Driven Predictive Maintenance: Embedded machine learning models analyze print logs to predict component wear, reducing downtime and extending mean time between failures (MTBF > 18,000 hours).

As a result, Carejoy Digital delivers EnvisionTEC-based 3D printing platforms with 97% performance parity to premium European counterparts at **40–50% lower total cost of ownership**, redefining the cost-performance frontier.

Conclusion: Precision, Performance, Provenance

Carejoy Digital’s ISO 13485-certified manufacturing ecosystem in China combines rigorous sensor calibration, exhaustive durability testing, and deep supply chain integration to deliver EnvisionTEC-powered 3D printers that meet the exacting standards of modern dental labs and clinics. With 24/7 remote technical support and continuous AI-driven software updates, Carejoy ensures not only superior hardware but a future-proof digital workflow.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Envisiontec 3D Printer Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160