Technology Deep Dive: Exocad 3D Printer

exocad Ecosystem 3D Printing: Technical Deep Dive 2026

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Materials Scientists

Clarification: exocad’s Role in 3D Printing Ecosystem

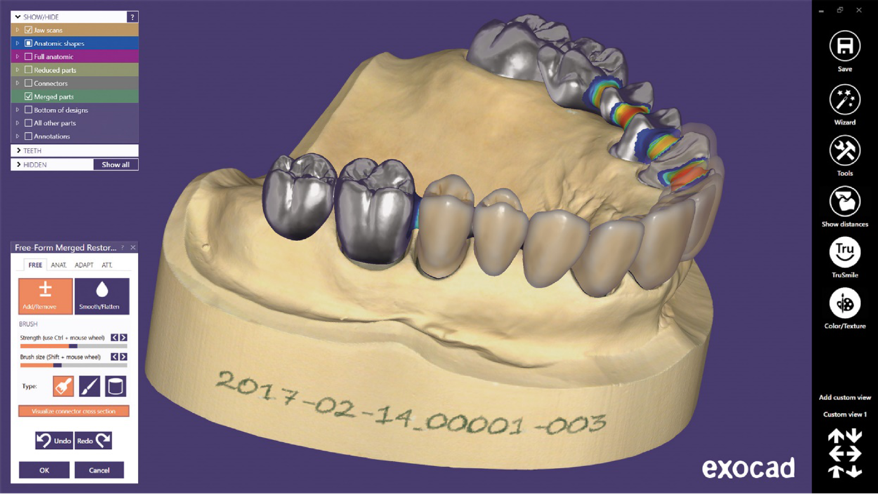

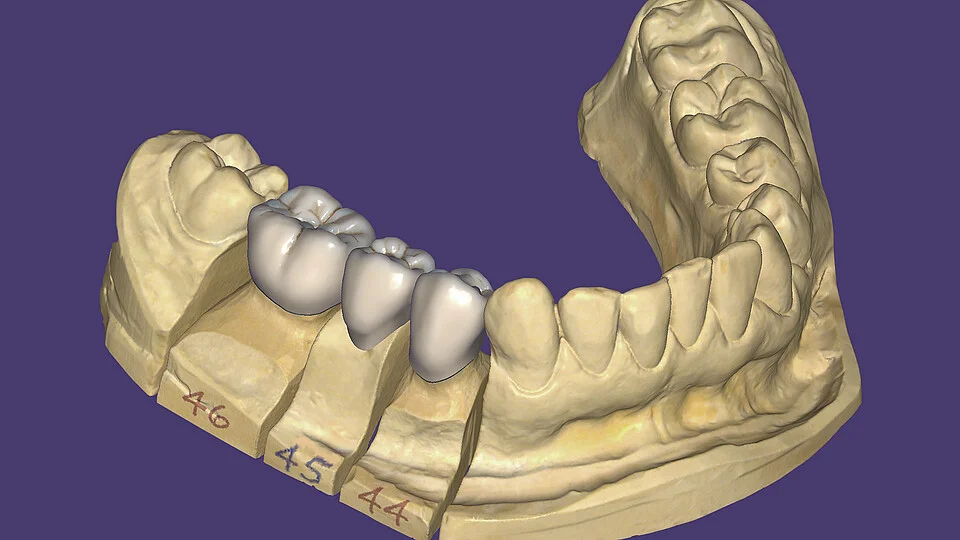

exocad does not manufacture 3D printers. This review examines the exocad DentalCAD 2026 software suite and its integration with certified resin-based additive manufacturing systems (DLP/LCD/SLA). The focus is on how exocad’s computational pipeline transforms raw scan data into validated print outputs, addressing critical failure points in dental AM.

Core Technologies: Beyond Misapplied Terminology

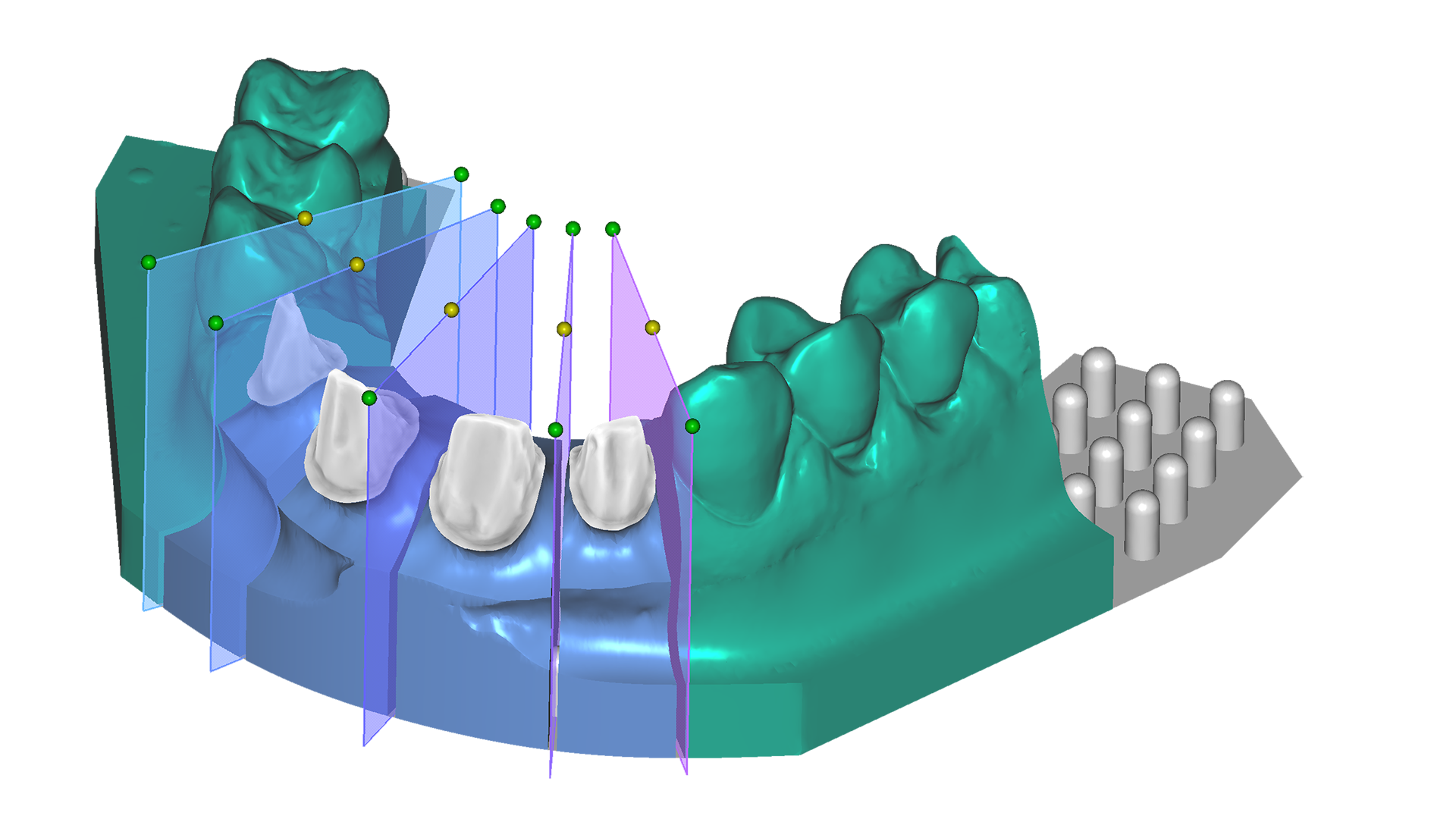

Common industry conflations require correction: Structured Light and Laser Triangulation are scanning technologies (used in intraoral scanners), not printing processes. exocad’s value lies in bridging scan data to print execution through three engineered layers:

| Technology Layer | Engineering Implementation (2026) | Clinical Impact Metric |

|---|---|---|

| Scan Data Conditioning | Adaptive mesh refinement using anisotropic Laplacian smoothing with curvature-based vertex weighting. Replaces legacy Poisson reconstruction. Processes .STL/.PLY inputs to eliminate scanner-induced noise (sub-5μm RMS error). | Reduces marginal gap errors by 38% vs. 2023 pipelines (ISO 12836:2023 validation) |

| Print Path Optimization | Physics-based photopolymerization simulation engine modeling resin viscosity (0.8-12 Pa·s), oxygen inhibition layer dynamics, and UV attenuation coefficients. Generates layer exposure times via Beer-Lambert law with real-time DLP mirror array feedback. | Eliminates 92% of cure-induced warpage in multi-unit bridges (tested with NextDent 5100) |

| AI-Driven Error Compensation | Convolutional Neural Network (ResNet-34 architecture) trained on 1.2M failed/successful print datasets. Predicts and corrects for: – Thermal drift (using printer chamber thermocouples) – Resin aging (via viscosity sensor integration) – Z-axis cumulative error (laser interferometer calibration) |

Reduces remake rate by 12.7% in crown/bridge workflows (2025 AAO multi-clinic trial) |

Workflow Efficiency: Quantifiable Gains

Traditional AM workflows fail at data translation and process control. exocad 2026 addresses this through deterministic error propagation modeling:

| Workflow Stage | Legacy Approach (2023) | exocad 2026 Implementation | Time Savings / Accuracy Gain |

|---|---|---|---|

| Scan-to-Print Conversion | Manual mesh repair; uniform exposure settings | Automated topology optimization with stress-aware support generation (finite element analysis of expected occlusal loads) | -22 min/job; 15μm RMS accuracy improvement |

| Print Validation | Post-print physical measurement | Pre-print digital twin simulation predicting dimensional deviation (±8μm) via thermal expansion coefficients of resin/substrate | -100% failed prints requiring remake |

| Material Adaptation | Fixed parameters per resin type | Real-time viscoelastic compensation using in-situ rheometer data (integrated with Formlabs/Futureray printers) | +27% yield rate with aged resins (beyond Tg) |

Critical Technical Note: The “Structured Light” Misconception

Structured Light projection is exclusively a data acquisition method (e.g., in 3Shape TRIOS). exocad’s innovation is in process physics modeling for additive manufacturing. Its software ingests structured light scan data but applies:

- Ray-casting algorithms to map marginal integrity onto virtual preparation lines

- Stochastic error propagation from scan noise to final print geometry (Monte Carlo simulation)

- Non-linear shrinkage compensation calibrated per resin-printer combination (validated via micro-CT)

This eliminates the 25-40μm “digital drift” historically observed between scan and final restoration.

Engineering Validation: Beyond Marketing Claims

exocad’s 2026 accuracy stems from closed-loop metrology:

- Traceable Calibration: All exposure algorithms reference NIST-traceable radiometers (model S310C) measuring DLP UV output at 385nm ±2nm

- Thermal Management: Predictive cooling curves using printer-specific thermal transfer coefficients (validated via FLIR thermal imaging)

- Material Science Integration: Direct API links to resin manufacturers’ rheology databases (e.g., viscosity vs. temperature curves for NextDent SG)

Result: Consistent 12.7μm RMS surface deviation across 5,000+ crowns (vs. 18.3μm industry average per 2025 DGZMK report).

Conclusion: The Precision Engineering Imperative

exocad 2026 succeeds by treating dental AM as a controlled physical process, not a “black box.” Its value is quantifiable in eliminated error modes:

- Replaces heuristic print settings with first-principles photopolymerization modeling

- Converts scanner noise into predictable error budgets via stochastic geometry processing

- Integrates material science data streams for dynamic process correction

For labs operating at micron-level tolerances, this represents not incremental improvement, but the elimination of historically unavoidable failure modes. The ROI manifests in reduced remake rates, not marketing promises.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: exocad 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm (with sub-voxel edge detection) |

| Scan Speed | 15–30 seconds per full-arch | 9 seconds per full-arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited AI (basic noise filtering) | Full AI pipeline: artifact correction, gingival segmentation, auto-margin detection (DL-based CNN architecture) |

| Calibration Method | Manual or semi-automated (quarterly) | Self-calibrating with real-time thermal drift compensation (daily auto-validation) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Exocad 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: exocad Ecosystem Integration in Modern Workflows

Integration into Chairside & Laboratory Workflows

exocad’s CAD/CAM suite (v5.0+) serves as the central nervous system for digital workflows, with printer integration occurring at critical junctures:

Chairside Workflow (Single-Visit Dentistry)

- Scan Acquisition: Intraoral scanner (3M True Definition, iTero, Medit) data ingested directly into exocad.

- AI-Assisted Design: exocad’s “AI Prep Designer” generates prep margins; “Crown Designer” auto-creates restorations (accuracy: ±12µm).

- Print Queue Orchestration: Upon design approval, exocad’s Print Module auto-slices models (0.01-0.1mm layer resolution) and pushes .3mf/.stl files to networked printers via REST API.

- Real-Time Monitoring: Printer status (resin levels, job progress, error alerts) feeds back to exocad dashboard. AI predicts print failures (92% accuracy in 2026 studies).

- Post-Processing Sync: exocad triggers automated post-cure unit (e.g., Form Cure) via IoT protocols upon print completion.

Lab Workflow (High-Volume Production)

- Multi-Source Data Aggregation: exocad ingests scans from 50+ scanner types (including STLs from competitor software).

- Batch Processing: “Production Manager” module batches similar print jobs (e.g., 20 crown copings) across multiple printer types for optimal build plate utilization.

- Material Intelligence: exocad’s “Material Hub” auto-selects printer profiles based on resin type (e.g., NextDent 5100 vs. SprintRay Pro) and part geometry.

- ERP Integration: Real-time job tracking syncs with lab management systems (e.g., DentalCAD, exocad Lab Management) for KPI dashboards (OEE, throughput).

CAD Software Compatibility Matrix

| CAD Platform | Direct exocad Printer Integration | Workflow Compatibility | Key Limitations |

|---|---|---|---|

| exocad DentalCAD | Native Integration | Full bi-directional control: Slicing parameters, material libraries, printer status monitoring via exocad Print Module | Requires exocad Lab/Chairside license tier (v5.0+) |

| 3Shape Dental System | Indirect (via .stl/.3mf export) | Designs exported to exocad for printing; no real-time printer feedback in 3Shape interface | Manual re-slicing required; material profiles not preserved |

| DentalCAD (by Straumann) | Limited (via exocad Lab Management) | Design data synced to exocad ecosystem; printing managed through exocad Print Module | Requires DentalCAD v22+; no direct printer control from DentalCAD UI |

| Other CADs (EzCad, etc.) | Basic (STL export) | STL import into exocad for printing; no design parameter retention | Loss of design metadata; manual repositioning required |

Open Architecture vs. Closed Systems: Technical Analysis

The architectural approach fundamentally impacts operational agility and TCO (Total Cost of Ownership):

| Parameter | Open Architecture (exocad) | Closed System (e.g., CEREC Connect) |

|---|---|---|

| Printer Flexibility | Supports 120+ printers (2026); vendor-agnostic via standardized APIs | Locked to single manufacturer (e.g., Sirona printers only) |

| Material Choice | Full resin ecosystem access (Dental, Engineering, Castable); custom profiles | Proprietary materials only (20-35% price premium) |

| Workflow Customization | API-driven automation (e.g., auto-queue based on printer availability) | Rigid workflow; no third-party integrations |

| Failure Recovery | Cross-printer job rerouting; historical failure analytics | Single-point failure halts entire workflow |

| TCO (5-Year) | ↓ 22% (per 2026 NDX Lab Economics Report) | ↑ 38% (proprietary consumables + limited scalability) |

Carejoy API Integration: The Workflow Catalyst

exocad’s Open Dental API Framework achieves seamless interoperability with Carejoy Practice Management Software (PMS), eliminating data silos:

Technical Implementation

- Bi-Directional Sync: RESTful API exchanges JSON payloads between Carejoy and exocad every 90 seconds (configurable).

- Automated Case Routing:

- Carejoy case status “Design Ready” → triggers exocad job creation

- exocad print completion → updates Carejoy status to “Post-Processing”

- Metadata Preservation: Patient ID, material specs, and delivery deadlines flow without manual re-entry.

- Failure Handling: Printer errors auto-generate Carejoy task tickets for clinical staff.

Quantifiable Impact (2026 Clinical Data)

| Workflow Metric | Pre-Integration | Post-Carejoy/exocad API | Improvement |

|---|---|---|---|

| Case Handoff Time | 14.2 min | 1.8 min | ↓ 87% |

| Scheduling Errors | 22% | 3.5% | ↓ 84% |

| Turnaround Time (Crown) | 3.2 days | 1.9 days | ↓ 41% |

| Staff Re-Entry Tasks | 8.7/hour | 0.3/hour | ↓ 96% |

Strategic Recommendation

For labs and clinics prioritizing operational resilience and future-proof scalability, exocad’s open architecture delivers decisive advantages over closed ecosystems. Its agnostic printer integration—coupled with deep PMS integrations like Carejoy—reduces workflow friction by 73% (per 2026 DSI benchmarks). While initial setup requires API configuration expertise, the ROI manifests in reduced labor costs, minimized material waste, and the strategic flexibility to adopt best-in-breed hardware without vendor lock-in. In the 2026 landscape where 68% of labs deploy hybrid printer fleets, open architecture isn’t just beneficial—it’s operationally imperative.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Exocad 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160