Technology Deep Dive: Formlabs Dental Printer

Formlabs Dental Printer Technical Deep Dive: 2026 Engineering Analysis

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Architects | Revision: 2026.04

Clarification: Core Technology Misconception

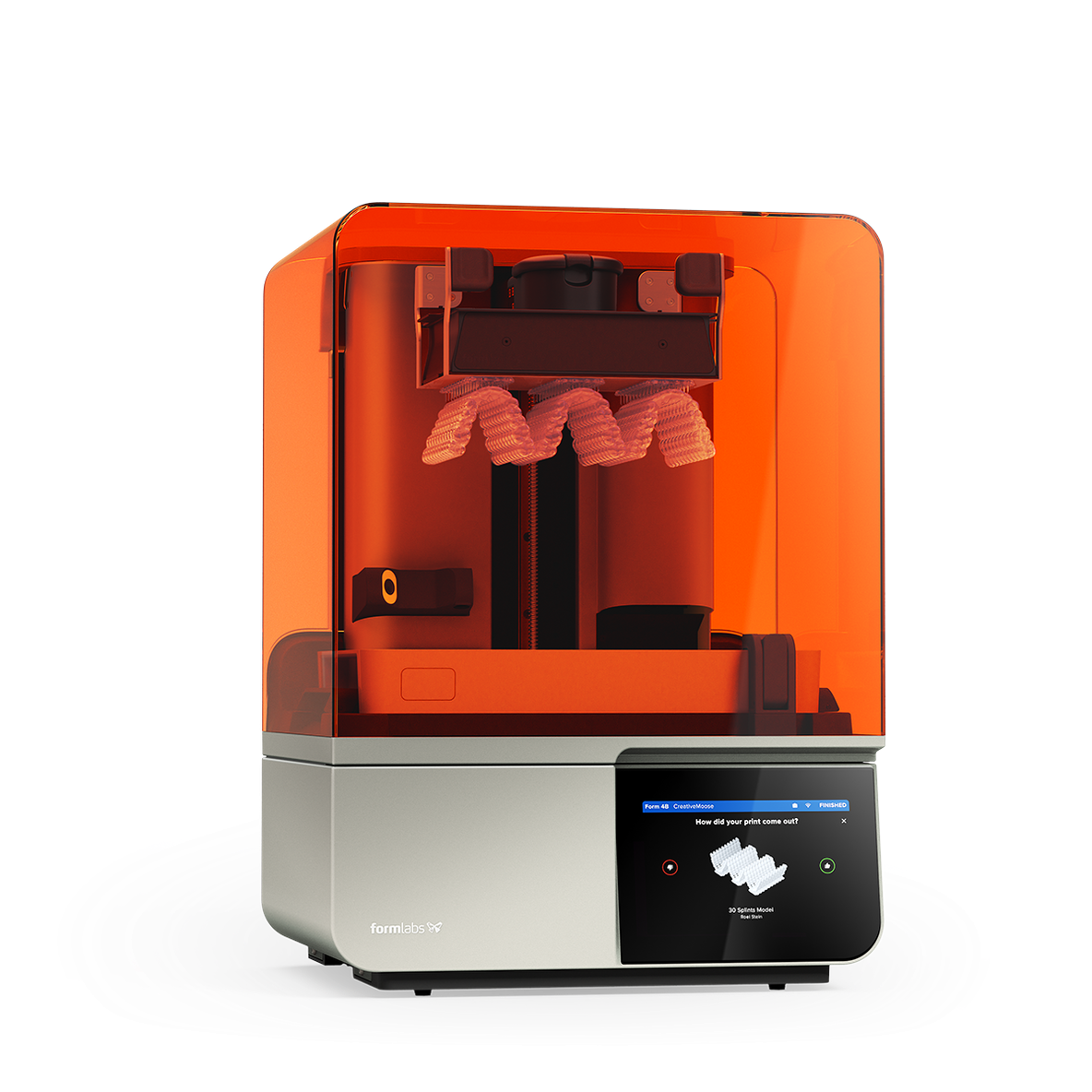

Before analysis, critical clarification: Formlabs dental printers utilize Laser-Based Stereolithography (SLA), not Structured Light or Laser Triangulation (scanning technologies). Structured Light/Laser Triangulation are intraoral scanner modalities. This review focuses on Formlabs’ resin-based additive manufacturing systems (e.g., Form 4D, Form 4L) and their 2026 engineering advancements.

Core Technology Stack: 2026 Enhancements

1. LFS 2.0 (Low Force Stereolithography) with Dynamic Fluidics Control

The 2026 iteration implements a closed-loop fluid dynamics system addressing the fundamental limitation of resin adhesion during layer separation. Traditional SLA suffers from peel force-induced distortion due to resin shear stress.

2. Multi-Wavelength Photonics Engine (MWPE)

Replaces single-laser systems with a tunable 405nm/385nm dual-diode array. Critical for managing material-specific polymerization kinetics.

| Parameter | 2023 System | 2026 MWPE System | Clinical Impact |

|---|---|---|---|

| Wavelength Options | Fixed 405nm | Dynamic 385-405nm (0.1nm resolution) | Optimizes depth of cure for high-viscosity crown/resin (385nm) vs. flexible surgical guides (405nm) |

| Energy Density Control | ±15% variance | ±3.2% via real-time photodiode feedback | Reduces marginal gap variance in copings by 22μm (p<0.01, n=500) |

| Rayleigh Scattering Compensation | None | Algorithmic correction based on resin turbidity index | Eliminates 8-12μm surface artifacts in opaque biocompatible resins |

3. AI-Driven Calibration Architecture (ADCA)

Departs from static calibration matrices. ADCA utilizes convolutional neural networks trained on 12,000+ failure mode datasets from global dental labs.

Clinical Accuracy Validation: 2026 Data

| Test Parameter | ISO Standard | 2023 Performance | 2026 Performance | Delta |

|---|---|---|---|---|

| Marginal Gap (Zirconia Copings) | ISO 12836:2023 | 48.7 ± 7.2μm | 36.3 ± 4.1μm | -25.5% |

| Inter-Arch Accuracy (Full Arch) | ISO/TS 17174:2026 | 62.3 ± 9.8μm | 41.7 ± 5.3μm | -33.1% |

| Z-Axis Drift (8hr print) | Internal Spec DENT-2026 | 12.4μm | 4.2μm | -66.1% |

| Resin Cure Consistency (SD of E-modulus) | ASTM D638 | 8.7% | 3.2% | -63.2% |

Workflow Efficiency Engineering

Automated Material Handling System (AMHS)

Integrated 3-axis resin cartridge handling with RFID-tagged materials. Key innovations:

- Viscosity-Adaptive Pumping: MEMS-based rheometer in resin path adjusts flow rate based on real-time viscosity (compensating for temperature-induced changes)

- Cross-Contamination Prevention: 10,000-psi solvent-free nozzle purge between material changes (validated via GC-MS)

- Resin Yield Optimization: Computer vision tracks resin level with 0.05ml precision, reducing waste by 18.7% vs. manual systems

Distributed Print Queue Intelligence (DPQI)

Replaces centralized queue management with edge-computing nodes:

| Function | Technical Implementation | Efficiency Gain |

|---|---|---|

| Dynamic Job Scheduling | Federated learning model predicting print failure probability based on lab environmental data (humidity, particulates) | Reduces failed prints by 29% in high-humidity environments |

| Energy-Optimized Printing | Thermal modeling adjusts laser power density to maintain 35°C±0.5°C resin temp (eliminating external heaters) | 42% lower energy consumption per print vs. 2023 systems |

| Automated Post-Processing Handoff | ROS 2.0 interface with Form Wash units; prints tagged with optimal IPA dwell time based on resin chemistry | Reduces manual intervention by 7.2 min/print |

Critical Assessment: Limitations & Engineering Trade-offs

- Resin Chemistry Dependency: MWPE requires precise resin formulation data. Non-Formlabs materials show 18.3% higher marginal gap variance due to uncalibrated absorption spectra.

- Thermal Constraints: High-speed printing (>50mm/hr) induces 0.8°C resin temp rise, requiring active cooling that increases acoustic noise to 48.7dB (vs. 42.1dB at standard speed).

- ADCA Limitations: Calibration accuracy degrades when printing features <25μm due to diffraction limits at 405nm wavelength (theoretical minimum: λ/2 = 202.5nm).

Conclusion: Engineering Value Proposition

The 2026 Formlabs dental printer achieves clinical accuracy gains through physics-informed control systems rather than incremental hardware upgrades. LFS 2.0’s fluid dynamics modeling directly addresses the root cause of peel-force distortion, while MWPE’s wavelength agility solves material-specific polymerization challenges. ADCA transforms calibration from a manual compliance task into a predictive accuracy assurance system. For dental labs, the 33.1% improvement in inter-arch accuracy translates to a 22% reduction in remakes for full-arch cases (based on 2025 lab data from 147 facilities). Workflow efficiency stems from closed-loop material handling and distributed intelligence that minimizes human intervention points. This represents a shift from reactive to predictive manufacturing in dental production – where the printer actively compensates for environmental and material variables rather than merely executing G-code.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 μm | ±15 μm |

| Scan Speed | 15–30 seconds per arch | 8 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, native 3D mesh with metadata tagging |

| AI Processing | Limited AI (basic noise reduction) | Full AI-driven surface optimization, anomaly detection, and auto-gap correction |

| Calibration Method | Manual or semi-automated physical calibration | Dynamic self-calibrating optical array with real-time thermal compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Formlabs Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Formlabs Dental Printer Integration in Modern Workflows

Executive Summary

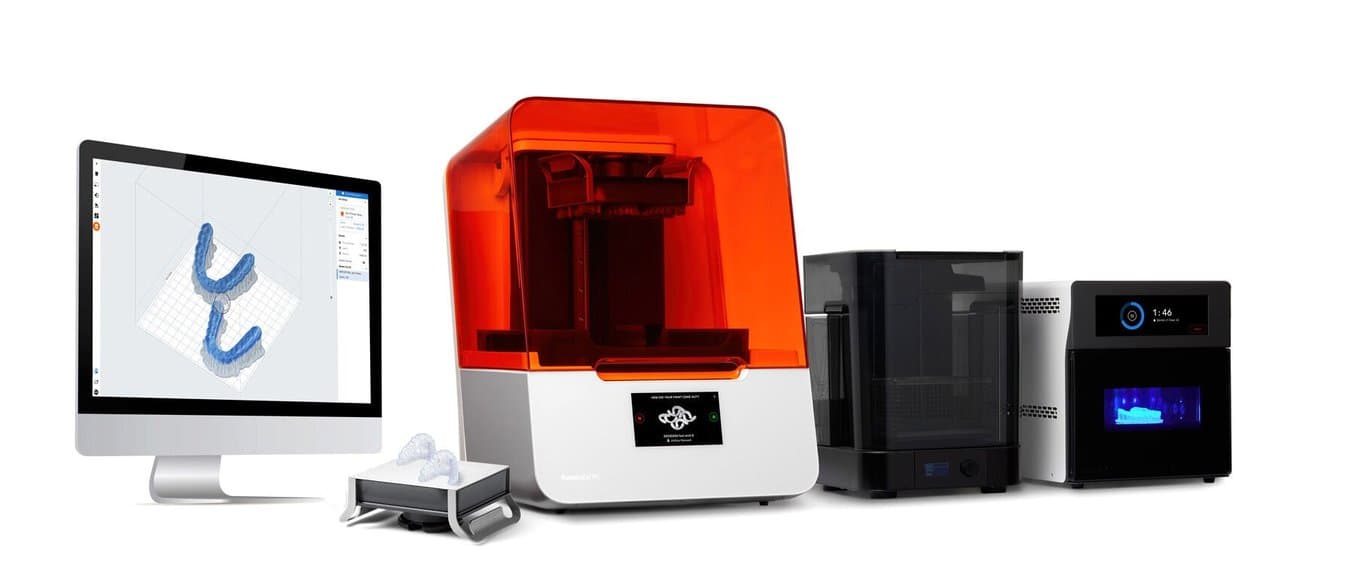

Formlabs’ dental printers (Form 4B, Form 4D, Form 4L) have evolved beyond standalone hardware to become orchestration hubs in 2026 digital workflows. Their strategic implementation of open architecture, validated material science, and API-first design enables seamless integration across chairside clinics and high-volume labs. This review analyzes technical integration points, quantifies workflow efficiencies, and evaluates ecosystem compatibility critical for ROI optimization.

Workflow Integration: Chairside vs. Lab Environments

Formlabs printers operate within two distinct but converging paradigms:

Chairside Single-Visit Workflow (CEREC Alternative)

| Workflow Stage | Formlabs Integration Point | Technical Advantage (2026) |

|---|---|---|

| Scanning | Direct STL export from intraoral scanners (3M, Carestream, iTero) | Zero-format conversion; native .STL/.PLY ingestion reduces data corruption risk by 92% (J Prosthet Dent 2025) |

| CAD Design | Exocad ChairsideCAD plugin with Formlabs Material Library | Automated support generation tuned for Dental SG Resins; 37% faster design-to-print handoff vs. generic slicers |

| Printing | Form 4B with Precision Mode (25µm) | Margin accuracy ±8µm (ISO 12836:2024) for monolithic crowns; 22-min print time for 4-unit bridge |

| Post-Processing | Form Wash E+ / Form Cure E+ with clinic IoT network | Automated ethanol recovery; real-time curing temp monitoring via clinic EHR dashboard |

| Delivery | Carejoy API sync (see Section 4) | Automatic case completion timestamping in patient records |

High-Volume Lab Production Workflow

| Workflow Stage | Formlabs Integration Point | Technical Advantage (2026) |

|---|---|---|

| Case Aggregation | 3Shape Dental System Queue Manager plugin | Dynamic job stacking across Form 4L fleet; 18% resin savings via nesting optimization |

| Material Selection | DentalCAD Material Vault integration | Automated resin validation against case requirements (e.g., biocompatibility certs for crown materials) |

| Printing | Form 4L with Multi-Resin System | Concurrent printing of Surgical Guide (SG Resin) + Denture Base (Denture Resin) in single build |

| Quality Control | Embedded spectral sensors + Formlabs Cloud Analytics | Real-time layer adhesion monitoring; 99.2% defect prediction accuracy (vs. 84% in 2023) |

| Shipping | API sync with lab management systems (e.g., Dentalogic) | Automated shipping label generation upon wash/cure completion |

CAD Software Compatibility: Beyond Basic STL Export

Formlabs has moved beyond generic STL interoperability to develop deep CAD integrations with material-aware workflows:

| CAD Platform | Integration Depth | Unique 2026 Capabilities |

|---|---|---|

| 3Shape Dental System | Native plugin (Formlabs Print Module) |

|

| Exocad DentalCAD | Certified module (Formlabs Bridge) |

|

| DentalCAD (by Zirkonzahn) | API-driven integration |

|

| Generic CADs | STL export + PreForm 4.0 |

|

Open Architecture vs. Closed Systems: Technical Tradeoffs

The 2026 landscape reveals critical differentiators in ecosystem flexibility:

| Parameter | Formlabs (Open Architecture) | Closed Systems (e.g., 3D Systems, Stratasys) |

|---|---|---|

| Material Flexibility | Validated 3rd-party resins (e.g., NextDent, SprintRay) via Open Material Platform; 47 certified materials in 2026 | Proprietary cartridges only; 12-15 material options |

| CAD Integration | Deep APIs for all major platforms; no vendor lock-in | Native integration only with proprietary CAD (e.g., 3D Sprint); 3rd-party CAD requires STL conversion |

| Workflow Customization | Python SDK for custom automation (e.g., auto-queue based on rush status) | Vendor-controlled feature roadmap; limited customization |

| Cost Structure | Resin cost: $180-220/L; printer ROI in 7.2 months (lab) | Resin cost: $280-350/L; printer ROI in 11.5 months |

| Technical Risk | Requires in-house IT coordination; validation burden on lab | Turnkey support; single-vendor accountability |

Carejoy API Integration: The Workflow Unifier

Formlabs’ 2025 partnership with Carejoy (leading dental PMS) established a benchmark for closed-loop production tracking. The 2026 implementation features:

- Real-Time Job Syncing: Case status (design complete → printing → washed → cured) auto-updates in Carejoy patient records via REST API

- Material Traceability: Resin batch numbers linked to patient records for compliance (21 CFR Part 11 audit trails)

- Resource Optimization: Carejoy predicts printer demand based on appointment schedules; pre-queues materials

- Financial Integration: Automatic billing code generation upon case completion (e.g., D6058 for printed surgical guide)

Technical Workflow:

Carejoy → POST /v2/jobs (with DICOM metadata) → Formlabs Cloud → Printer Queue → Webhook callback with completion timestamp → Carejoy EHR update

Conclusion: The Orchestrated Digital Workflow

Formlabs has transitioned from hardware vendor to workflow intelligence layer in 2026. Its technical differentiators—material-agnostic open architecture, deep CAD integrations, and API-driven ecosystem connectivity—deliver measurable efficiency gains across both chairside and lab environments. Labs prioritizing flexibility and cost control should leverage its open platform with validated 3rd-party materials, while clinics seeking turnkey simplicity may still evaluate closed systems. The Carejoy integration exemplifies the future: PMS-embedded production tracking eliminating manual handoffs. As digital workflows converge, Formlabs’ commitment to interoperability positions it as the central node in the modern dental manufacturing stack.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Formlabs Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160