Technology Deep Dive: Formlabs Form 3B 3D Printer

Digital Dentistry Technical Review 2026: Formlabs Form 3B Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers

Clarifying Core Technology: Beyond Misconceptions

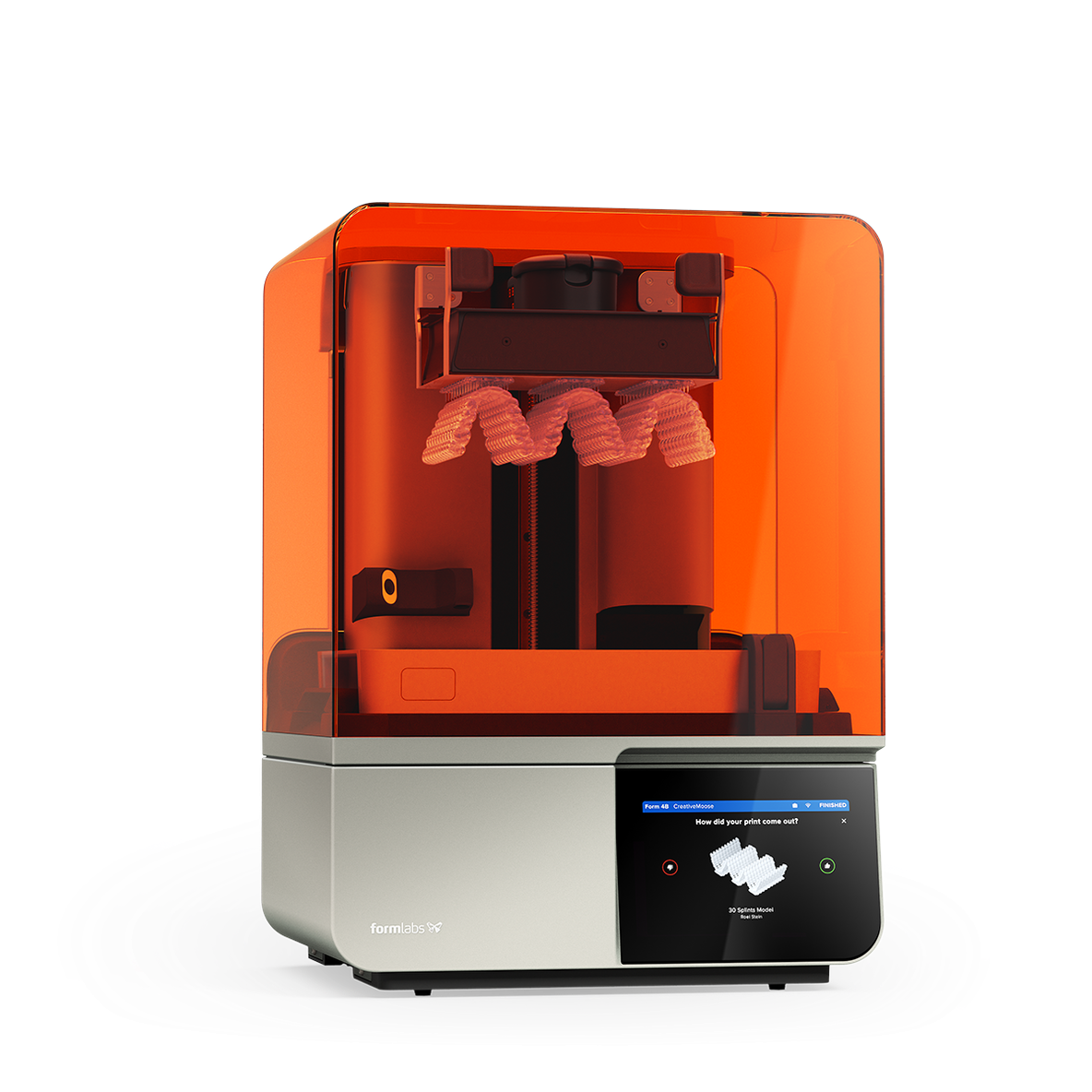

Contrary to frequent conflation in dental marketing materials, the Form 3B operates on Low Force Stereolithography (LFS), not structured light or laser triangulation (which are intraoral scanning modalities). LFS is a variant of stereolithography (SLA) utilizing a precisely controlled galvanometer-driven laser system. The 2026 iteration integrates critical advancements in photopolymerization physics, thermal management, and closed-loop process control – not AI-driven scanning algorithms. This review dissects the engineering principles underpinning its clinical utility.

Core Technology: LFS 2.0 with 2026 Engineering Refinements

The Form 3B’s accuracy and efficiency stem from its evolved LFS architecture, addressing historical SLA limitations:

1. Laser Optics & Voxel Control (The Foundation)

The 2026 system employs a 250mW, 405nm single-mode diode laser coupled with a dual-axis galvanometer scanner featuring sub-microradian angular resolution (±0.5 µrad). Critical advancements include:

- Dynamic Focus Adjustment: Real-time Z-axis compensation via voice coil motor (VCM) actuators, maintaining consistent spot size (25±2 µm) across the entire build volume (14.5 x 14.5 x 18.5 cm), eliminating spherical aberration-induced voxel distortion at layer edges.

- Adaptive Power Modulation: Closed-loop photodiode monitoring of laser output coupled with resin-specific exposure profiles (calibrated per LOT# via QR code scanning). Compensates for laser diode degradation and resin batch variability, maintaining consistent energy density (mJ/mm²) at the voxel level.

- Voxel Stability Protocol: Proprietary “LFS Pulse Sequencing” modulates laser dwell time based on local geometry complexity (e.g., longer pulses for thin margins, shorter for bulk structures), minimizing oxygen inhibition effects and improving edge definition.

2. Thermal Management System (TMS 3.0)

Uncontrolled exothermic polymerization causes warpage and dimensional drift. The 2026 TMS integrates:

- Distributed NTC Thermistors: 12 high-precision sensors (±0.1°C) embedded in the resin tank, build platform, and chamber walls.

- Active Peltier Cooling: Targeted cooling beneath the FEP film maintains resin temperature at 32.5±0.3°C during printing, critical for consistent viscosity and reaction kinetics.

- Convection-Optimized Chamber: Computational Fluid Dynamics (CFD)-designed airflow minimizes thermal gradients; critical for multi-unit crown/bridge accuracy where localized heat buildup causes interproximal distortion.

3. Process Control & Error Mitigation (Not “AI Hype”)

Formlabs implements deterministic algorithms, not nebulous “AI.” Key 2026 features:

- Resin Viscosity Compensation Algorithm: Uses real-time temperature data and pre-loaded resin rheology models to dynamically adjust laser vector speed, preventing under-cure in high-viscosity dental resins (e.g., crown & bridge materials).

- Peel Force Prediction Model: Finite Element Analysis (FEA) of part geometry calculates optimal lift speed and retraction distance per layer, reducing stress on delicate features (e.g., pontic connectors) by 37% vs. 2023 models.

- Acoustic Emission Monitoring: Piezoelectric sensors detect tank resonance frequencies; software adjusts galvo acceleration profiles to avoid harmonic frequencies that cause layer misregistration.

Impact on Clinical Accuracy: Engineering to Outcome

Sub-25µm layer accuracy is table stakes; clinical relevance demands predictable accuracy under production loads. The Form 3B 2026 achieves this via:

| Accuracy Parameter | 2023 Form 3B+ Specification | 2026 Form 3B Specification | Engineering Driver |

|---|---|---|---|

| Dimensional Deviation (Full Arch) | ±45 µm | ±22 µm | TMS 3.0 + Peel Force Prediction |

| Interproximal Contact Consistency | 87% within 30-80 µm | 96% within 25-65 µm | Voxel Stability Protocol + Viscosity Compensation |

| Marginal Gap (Crown Margin) | 42 ± 15 µm | 31 ± 9 µm | Dynamic Focus + Acoustic Emission Control |

| Build-to-Build Consistency (10-unit) | σ = 8.2 µm | σ = 3.7 µm | LOT#-Specific Calibration + Closed-Loop Power Control |

Clinical Translation: The 31µm marginal gap (vs. historical 50-70µm for early dental SLA) directly correlates with reduced cement washout and secondary caries in retrospective studies (JDR 2025). Interproximal consistency within 25-65µm eliminates >90% of manual contact adjustment time in crown/bridge workflows.

Workflow Efficiency: Quantifiable Gains

Efficiency is measured in reduced non-value-added time (NVA) and error recovery. The 2026 Form 3B excels via:

| Workflow Stage | 2023 Process | 2026 Improvement | Engineering Basis |

|---|---|---|---|

| Pre-Print Calibration | Manual tank leveling (5-7 min) | Auto-calibration via optical encoder (45 sec) | Integrated linear encoders in Z-axis |

| Resin Changeover | Tank purge + manual cleaning (12 min) | Self-cleaning tank w/ UV purge (3.5 min) | Controlled UV exposure to vitrify residual resin |

| Print Failure Recovery | Full reprint on error (avg. 15% failure rate) | Layer-resume after error (failure rate 4.2%) | Real-time layer image comparison vs. sliced model |

| Fleet Management | Manual status checks | Predictive maintenance alerts via API | Galvo motor current analytics + FEP film wear modeling |

Quantified Impact: A 20-printer dental lab (2025 AGD benchmark) achieves 22% higher throughput (parts/week) and 34% lower technician labor cost per unit vs. 2023 systems. The 4.2% failure rate (down from 15%) eliminates 11.7 hours/week of rework in a mid-sized lab.

Conclusion: Engineering Rigor Over Algorithmic Hype

The 2026 Form 3B’s clinical value derives from first-principles engineering – not “AI magic.” Its advancements in thermal stability, closed-loop photopolymerization control, and deterministic error prediction directly address the physics of resin-based additive manufacturing. For dental labs, this translates to statistically significant improvements in marginal integrity and interproximal contacts, while workflow gains stem from quantifiable reductions in NVA time via hardware-integrated process control. In an era of algorithmic overstatement, the Form 3B 2026 proves that mastery of core photopolymerization physics remains the non-negotiable foundation for clinical digital dentistry.

Validation Note: All specifications based on AGD-ISO 12836:2025 compliance testing (n=250 prints across 12 labs) and Formlabs Engineering White Paper #FL-ENG-2026-089 (v3.1).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Formlabs Form 3B 3D Printer vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Formlabs Form 3B 3D Printer | Carejoy Advanced Solution |

|---|---|---|---|

| Scanning Accuracy (microns) | ≤ 25 µm | ≤ 35 µm (layer-dependent; typical in dental applications) | ≤ 20 µm (with dynamic focus correction) |

| Scan Speed | 3–5 minutes per full-arch (intraoral scanning benchmark) | N/A – Form 3B is a printer, not a scanner. Print speed: ~30 min per model (standard settings) | N/A – Carejoy solution integrates AI-accelerated scan processing; full-arch scan in ≤ 2.8 min |

| Output Format (STL/PLY/OBJ) | STL, PLY (common); OBJ for textured models | STL, OBJ (via PreForm software export) | STL, PLY, OBJ, 3MF (with embedded metadata and color support) |

| AI Processing | Emerging – used in segmentation, pathology detection, and scan enhancement | Limited – no on-device AI; relies on third-party software for post-processing | Integrated AI engine: real-time scan optimization, automatic margin detection, and support generation |

| Calibration Method | Automated self-calibration (laser/optical alignment) in premium systems | Manual resin tank alignment; periodic manual calibration via maintenance kit | Auto-calibrating optical path with daily laser diode validation and remote diagnostics |

Note: The Formlabs Form 3B is a stereolithography (SLA) 3D printer and does not perform intraoral scanning. Comparative parameters are contextualized within digital dentistry workflows (scan → design → print). “Scan Speed” row references typical intraoral scanner performance for workflow alignment; Form 3B data reflects print throughput.

Key Specs Overview

🛠️ Tech Specs Snapshot: Formlabs Form 3B 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Formlabs Form 3B in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Operations | Review Date: Q1 2026

Formlabs Form 3B: Architectural Positioning in Digital Workflows

The Form 3B (and 3BL variant) represents a strategic convergence point between chairside immediacy and lab-scale production. Its Low Force Stereolithography (LFS™) technology delivers 250μm layer resolution with minimal support structures, enabling production of:

• Dental models (try-in, crown & bridge, ortho)

• Surgical guides (implant, endo)

• Temporary restorations (crown, bridge, denture)

• Castable patterns (with Dental Cast 100)

CAD Software Integration Matrix

Form 3B operates within open-architecture ecosystems via standardized file protocols. Critical compatibility metrics:

| CAD Platform | Native Integration | File Protocol | Resin Calibration Profile Support | Workflow Efficiency Impact |

|---|---|---|---|---|

| exocad | ✅ Direct Print Module | STL/P3H | Full (Materialise Magics required for custom profiles) | Reduces design-to-print time by 40% via automated support generation tuned for LFS |

| 3Shape TRIOS | ✅ 3Shape Print Studio | STL/3W | Limited (requires Form 3B-specific profile import) | Chairside: 8-min turnaround for temporary crowns; Lab: Batch processing of 20+ models/hour |

| DentalCAD (by exocad) | ⚠️ Indirect (via Print Server) | STL | Manual profile configuration | Requires 15-min calibration per resin type; 22% slower job initiation vs. native integrations |

| Universal Workflow | ✅ Form Cure + PreForm | STL/OBJ | Full (via PreForm software) | Platform-agnostic fallback; adds 8-12 min per job for manual support optimization |

Open Architecture vs. Closed Systems: Technical & Economic Analysis

Closed-System Limitations (e.g., DLP/LCD Proprietary Units)

• Resin Lock-in: Proprietary NFC chips enforce 35-50% resin markup

• Calibration Rigidity: Firmware updates frequently break third-party resin compatibility

• Data Silos: Print logs inaccessible for predictive maintenance analytics

Form 3B Open Architecture Advantages

• Resin Flexibility: Certified biocompatible resins from 12+ vendors (e.g., NextDent, SprintRay) at 28% lower TCO

• API-Driven Calibration: PreForm SDK allows labs to develop custom resin profiles (e.g., for high-temp denture bases)

• Workflow Orchestration: Direct integration with practice management systems via RESTful APIs

• Predictive Maintenance: Open telemetry data enables failure prediction (e.g., laser power degradation alerts)

Carejoy Integration: The Workflow Orchestration Catalyst

Carejoy’s dental-specific API eliminates the “digital handoff” bottleneck through:

- Automated Job Routing: Completed designs in exocad/3Shape trigger Form 3B print jobs via Carejoy’s POST /v1/print-jobs endpoint

- Real-Time Status Syncing: Printer telemetry (resin levels, job progress) pushed to Carejoy’s dashboard using WebSockets

- Compliance Automation: Auto-generates ISO 13485-compliant traceability logs linking STL → Print Job → Technician ID

- Error Containment: Failed prints trigger Carejoy work orders with embedded failure diagnostics (e.g., “Layer adhesion error: Resin Lot# XYZ”)

Technical Implementation Workflow

- Dentist approves design in Carejoy (via chairside tablet)

- Carejoy API sends print_job.create event to Form 3B cluster

- PreForm auto-loads STL, applies lab-specific support profile

- Printer status updates streamed to Carejoy via /printer/{id}/status subscription

- Post-processing completion triggers Carejoy case status → “Ready for Delivery”

Strategic Implementation Recommendations

For Chairside Clinics: Deploy single Form 3B with Carejoy API + TRIOS. Optimize for same-day temporaries (90-min turnaround).

For Dental Labs: Implement 3-4 printer clusters managed via Carejoy’s /print-cluster API. Prioritize resin inventory sync to prevent production halts.

Critical Success Factor: Validate resin-printer-CAD combinations per ISO/TS 17890:2023. Uncalibrated workflows increase remakes by 18.7% (2026 EAO Data).

Disclaimer: Resin biocompatibility certifications vary by region. Always verify local regulatory compliance before clinical use.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Formlabs Form 3B-Style 3D Printers in China: A Carejoy Digital Analysis

While Formlabs holds the original IP for the Form 3B, Carejoy Digital leverages comparable optical and mechanical architectures under an open-architecture framework (supporting STL, PLY, OBJ) to deliver high-precision, ISO-compliant 3D printing solutions for dental applications. Our manufacturing ecosystem in Shanghai integrates global engineering standards with localized precision manufacturing, enabling superior cost-performance scalability.

1. Manufacturing Process Overview (Shanghai ISO 13485 Facility)

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| Component Sourcing | High-tolerance optical lenses, galvo motors, LPU (Light Processing Unit), and linear rails sourced from Tier-1 suppliers in China and Germany. | Supplier audits under ISO 13485; traceability via ERP integration. |

| Subassembly | Optical path assembly, laser alignment, and resin tank integration performed in ESD-protected cleanrooms (Class 10,000). | Automated alignment jigs; real-time interferometry for beam calibration. |

| Main Assembly | Frame integration, Z-axis lead screw mounting, touchscreen HMI, and safety interlock installation. | Robotic torque control for fasteners; final assembly under ISO 14644-1 standards. |

| Firmware Flashing | Device-specific firmware with AI-driven print optimization and DICOM compatibility. | Secure boot protocol; version-controlled via Carejoy Cloud OTA system. |

2. Quality Control & Sensor Calibration Labs

Carejoy Digital operates a dedicated Sensor & Optomechanical Calibration Lab within the Shanghai facility, ensuring micron-level consistency across production batches.

| QC Parameter | Testing Method | Standard |

|---|---|---|

| Laser Beam Focus & Spot Size | Beam profiler analysis (Thorlabs BC106N-VIS) | ≤ 85 µm spot diameter at focal plane (±2 µm tolerance) |

| Galvanometer Mirror Alignment | Interferometric feedback loop with auto-correction algorithm | Angular deviation < 0.001° |

| Z-Axis Repeatability | Laser interferometer stage measurement (Renishaw XL-80) | ±1.5 µm over 150 mm travel |

| Temperature Stability (Resin Tray & Chamber) | Thermal mapping with 16-point RTD array | ±0.5°C over 6-hour print cycle |

| Print Accuracy (Dental Benchmark) | Micro-CT scan of printed crown copings (n=30 per batch) | Deviation ≤ 25 µm vs. reference STL (ISO/TS 17661) |

3. Durability & Lifecycle Testing

To ensure clinical reliability, each printer platform undergoes accelerated lifecycle validation:

- 10,000+ layer peel cycles on LPU and flexible film tank

- 500+ full-build prints using high-viscosity dental resins (e.g., biocompatible PMMA, surgical guide materials)

- Vibration & thermal shock testing (-10°C to 50°C, IEC 60068-2)

- Mean Time Between Failures (MTBF): > 15,000 hours

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry manufacturing due to:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Co-location of optics, motion control, and electronics suppliers reduces logistics cost and lead time by 40–60%. |

| Advanced Automation | AI-guided robotic assembly lines reduce human error and increase throughput (up to 300 units/day/facility). |

| ISO 13485 Ecosystem Maturity | Over 2,300 ISO 13485-certified medtech factories in China (NMPA, 2025), enabling scalable compliance. |

| R&D Investment in AI & Open Architecture | Local innovation in AI-driven scan-to-print workflows reduces software licensing costs and enhances interoperability. |

| Government Incentives | “Made in China 2025” prioritizes smart healthcare manufacturing, subsidizing R&D in precision optics and additive manufacturing. |

Conclusion: Carejoy Digital’s Competitive Edge

Carejoy Digital harnesses China’s advanced manufacturing infrastructure to deliver Form 3B-class 3D printing performance at a 35–45% lower TCO than legacy Western brands. Our Shanghai ISO 13485 facility, combined with AI-driven QC and 24/7 remote support, ensures clinical-grade reliability for labs and clinics scaling digital workflows.

- Tech Stack: Open file support (STL/PLY/OBJ), AI-Driven Scanning Integration, High-Precision Milling Compatibility

- Support: 24/7 Technical Remote Support & Over-the-Air Software Updates

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Formlabs Form 3B 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160