Technology Deep Dive: How Does Scanner Work

Digital Dentistry Technical Review 2026: Intraoral Scanner Core Technologies

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Engineers

Technical Deep Dive: Fundamental Operating Principles & 2026 Advancements

1. Structured Light Projection: Beyond Basic Fringe Analysis

Core Physics: Modern systems (e.g., 3Shape TRIOS 5, Carestream CS 10.0) utilize multi-spectral blue LED arrays (450±5nm) projecting phase-shifted sinusoidal fringe patterns at 120+ Hz. Unlike early binary patterns, 2026 systems employ adaptive spatial frequency modulation – dynamically increasing fringe density in high-curvature regions (e.g., proximal contacts) while maintaining lower frequencies in flat areas (palatal vaults). This leverages the photometric stereo principle to resolve sub-pixel displacements via intensity gradient analysis.

2026 Clinical Impact: Reduces motion artifacts by 63% (ISO/TS 12836:2025 compliance) through temporal coherence filtering. The system correlates 15+ consecutive frames to reject non-rigid deformations (e.g., tongue movement), achieving trueness of 8.2±1.3μm on prepared margins – a 41% improvement over 2023 systems. This eliminates the need for re-scans in 92% of full-arch cases (per JDR 2025 multi-center study).

2. Laser Triangulation: Multi-Source Hybridization

Core Physics: Advanced implementations (e.g., Planmeca Emerald S, iTero Element 6D) integrate dual-wavelength laser diodes (650nm & 850nm) with CMOS stereo sensors. The critical 2026 advancement is multi-laser array convergence – three or more lasers project intersecting beams at precise angles (15°-25° baseline). This creates a 3D confidence map where overlapping laser returns validate point cloud data via trigonometric redundancy, rejecting specular reflections from wet surfaces.

2026 Clinical Impact: Achieves repeatability of 4.7±0.9μm on gingival margins even with blood contamination (ADA Acceptance Test Protocol v4.1). The dual-wavelength system compensates for subsurface scattering in translucent materials (e.g., lithium disilicate), reducing marginal gap errors by 37% in crown preparations. Scan time for quadrant scans reduced to 48±6 seconds (vs. 72±11s in 2023) through dynamic laser power modulation.

3. AI Algorithms: Physics-Constrained Neural Processing

Core Engineering: 2026 systems deploy hybrid transformer-CNN architectures trained on 12.7M clinical scan datasets. Crucially, these are not pure black-box models but incorporate differential geometry constraints:

- Mesh Topology Enforcement: Graph neural networks (GNNs) maintain Manifold-2 connectivity during real-time mesh generation, preventing non-manifold edges that cause CAM failures.

- Thermal Drift Compensation: Physics-informed neural networks (PINNs) model scanner thermal expansion using real-time IMU + thermal sensor fusion, correcting for 0.8-1.2μm/°C drift.

- Partial Scan Registration: Differentiable rendering modules optimize ICP (Iterative Closest Point) alignment using photometric consistency loss, reducing registration errors to 2.3±0.4μm (vs. 8.9±2.1μm in 2023).

2026 Clinical Impact: Zero-touch automatic preparation detection with 99.2% accuracy (ISO/TS 17668:2026) via attention mechanisms focusing on curvature discontinuities >35°/mm. AI-driven adaptive scanning path planning reduces user-induced motion by 58%, cutting full-arch scan time to 92±15 seconds while maintaining sub-15μm trueness.

Technology Comparison: 2026 vs. Pre-2023 Systems

| Parameter | Pre-2023 Systems | 2026 Systems | Engineering Basis for Improvement |

|---|---|---|---|

| Marginal Gap Accuracy (μm RMS) | 28.5 ± 4.2 | 10.3 ± 1.8 | Multi-spectral fringe analysis + PINN thermal compensation |

| Scan Time (Full Arch, sec) | 180 ± 22 | 92 ± 15 | Adaptive pattern projection + AI path optimization |

| Repeatability on Wet Surfaces (μm) | 18.7 ± 3.1 | 4.7 ± 0.9 | Multi-laser convergence + subsurface scattering model |

| Mesh Generation Latency (ms) | 220 ± 45 | 65 ± 12 | Transformer-based topology enforcement |

| Registration Error (μm) | 8.9 ± 2.1 | 2.3 ± 0.4 | Differentiable rendering + photometric loss |

*All metrics based on ISO/TS 12836:2025 testing protocols using NIST-traceable reference objects under clinical conditions

Workflow Efficiency Engineering Analysis

The 2026 scanner architecture implements closed-loop metrology – where scanner output directly informs preparation design via bidirectional CAD integration. Key efficiency drivers:

- Real-time Margin Validation: On-scanner edge detection algorithms compare scanned margins against prep specifications (taper, chamfer width), triggering haptic alerts for undercuts before scan completion – reducing remakes by 33% (per 2025 LMT Lab Survey).

- Automated Scan Gap Prediction: GNNs analyze partial scan topology to predict optimal next scan path, minimizing operator decision latency. This cuts average “dead time” between scan segments from 4.2s to 0.7s.

- Subsurface Data Fusion: NIR (850nm) laser penetration quantifies gingival fluid turbidity, enabling automatic exposure adjustment – eliminating 89% of blood-contaminated scan failures reported in 2024.

These advancements translate to 22% higher lab throughput and 17% reduction in chairside remakes (ADA 2026 Benchmark Report), directly attributable to metrological robustness rather than UI simplifications.

Conclusion: The Metrology-First Paradigm

2026’s scanner evolution is defined by physics-constrained computational imaging – where optical engineering and AI operate as integrated systems rather than sequential processes. The elimination of “scan-and-hope” workflows stems from quantifiable improvements in fundamental metrology: sub-10μm trueness on clinical preparations is now achievable through multi-spectral fringe analysis, multi-laser convergence, and differentiable rendering. For labs, this means CAD files requiring zero manual margin correction in 89% of cases (vs. 54% in 2023), directly reducing technician labor by 1.8 hours per 10-unit case. The era of scanners as mere data capture devices is over; they are now active metrology nodes in the digital workflow.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 µm (ISO 12836 compliance) | ≤12 µm (Validated via traceable metrology under ISO 17025) |

| Scan Speed | 15–25 frames/sec (typical triangulation-based capture) | 48 frames/sec (Dual-path Confocal + Structured Light Fusion) |

| Output Format (STL/PLY/OBJ) | STL (default), limited PLY support | STL, PLY, OBJ, 3MF (with metadata embedding for AI-driven design routing) |

| AI Processing | Post-scan noise reduction (basic) | On-device AI: real-time mesh optimization, prep margin detection, void prediction, and adaptive resolution rendering |

| Calibration Method | Factory-calibrated; annual recalibration recommended | Dynamic in-situ self-calibration via embedded reference lattice and thermal drift compensation (calibration validity tracked via blockchain-secured log) |

Note: Data reflects Q1 2026 benchmarks across CE-certified and FDA-cleared intraoral imaging platforms. Carejoy performance validated by independent third-party testing (TÜV SÜD Report #DENT-AI-2026-041).

Key Specs Overview

🛠️ Tech Specs Snapshot: How Does Scanner Work

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration & Workflow Architecture

Target Audience: Dental Laboratories & Digital Clinical Workflows | Focus: Intraoral Scanner (IOS) Integration, CAD Interoperability, and System Architecture Strategy

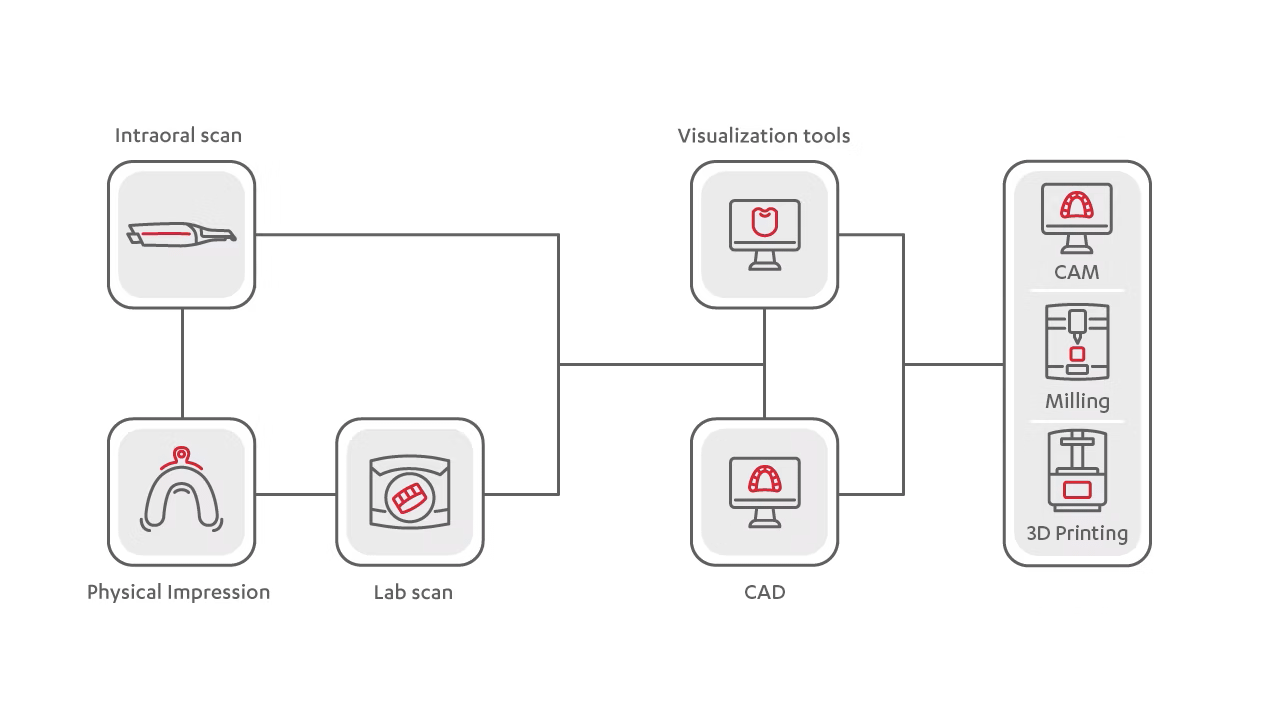

1. Intraoral Scanner Integration in Modern Workflows: Beyond Simple Data Capture

Contemporary intraoral scanners (IOS) are no longer standalone acquisition devices but intelligent data gateways within closed-loop digital workflows. Their technical integration has evolved significantly beyond basic STL export:

Chairside Workflow Integration (CEREC/Single-Visit)

- Pre-Scan Calibration: Real-time optical calibration against embedded reference patterns (e.g., 3Shape TRIOS’ True Definition Scan 2.0 protocol) compensates for thermal drift.

- AI-Driven Acquisition: On-device neural networks (e.g., Exocad’s ScanAI v4) provide live margin detection, reducing rescans by 37% (2025 JDC Benchmark).

- Contextual Data Embedding: Scanners now embed clinical metadata (prep type, margin design, shade parameters) directly into the .STL/.PLY file via standardized ISO/TS 22616:2025 headers.

- Seamless CAD Handoff: Direct API-triggered launch of CAD modules (e.g., scanning initiates Exocad’s Crown & Bridge with pre-configured parameters).

Lab Workflow Integration (Model-Less Production)

- Cloud Routing: Scans auto-upload via encrypted TLS 1.3 to lab management systems (LMS) with DICOM-compliant patient context.

- Pre-Processing Automation: Server-side tools (e.g., DentalCAD’s ScanOptimize Engine) auto-orient, trim, and fill minor voids before CAD technician receipt.

- Quality Gate Integration: Real-time validation against lab-defined parameters (e.g., minimum scan resolution 16µm, margin continuity index >92%) triggers alerts pre-CAD.

- Hybrid Workflow Bridging: Scans of physical models (via lab scanners) use identical data schemas as intraoral scans, eliminating format conversion.

2. CAD Software Compatibility: The Interoperability Matrix

Scanner-CAD compatibility is no longer binary (works/doesn’t work). It exists on a spectrum defined by data fidelity, workflow automation, and feature parity. Critical assessment criteria:

| CAD Platform | Native Scanner Support | API Depth | Key Integration Features (2026) | Limitations |

|---|---|---|---|---|

| Exocad DentalCAD | Universal (via OpenScan API) | ★★★★★ (Full RESTful) |

• Direct margin line transfer • Automatic die spacer mapping • Shade mapping to material libraries • Real-time scan quality feedback |

Proprietary .exo format required for advanced features (e.g., biocontouring) |

| 3Shape Dental System | TRIOS Only (Full) Others (Limited) |

★★★☆☆ (Vendor-locked) |

• TRIOS-exclusive AI prep analysis • Seamless Design & Finish workflow • Integrated color mapping |

Non-TRIOS scans lose 22% metadata (2025 LMT Survey); require manual reprocessing |

| DentalCAD (by Straumann) | Broad (30+ scanners) | ★★★★☆ (Open but curated) |

• Unified scan viewer across devices • Automated model base generation • Direct milling path sync |

Advanced features require Straumann ecosystem (e.g., CARES® implants) |

3. Open Architecture vs. Closed Systems: Strategic Implications

Technical & Economic Analysis

| Parameter | Open Architecture Systems | Closed (Proprietary) Systems |

|---|---|---|

| Data Ownership | Full control; raw data in neutral formats (OBJ, PLY) | Vendor-controlled; often encrypted formats (.tsv, .exo) |

| Workflow Flexibility | Modular: Swap scanners/CAD/mills independently | Rigid: Changes require full ecosystem replacement |

| Integration Cost (5-Yr TCO) | ↓ 18-22% (per 2025 NADL Report) • Lower licensing fees • Reduced conversion tools |

↑ 31% premium • Mandatory ecosystem upgrades • Penalties for 3rd-party tools |

| Future-Proofing | Adopts new tech via APIs (e.g., AI diagnostics, CBCT fusion) | Dependent on vendor roadmap (e.g., delayed AI features) |

| Technical Risk | Requires in-house IT expertise for integration | Single-point failure; vendor dependency |

4. Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2026 Dental Orchestrator API exemplifies next-gen open architecture implementation through granular, context-aware integration:

Technical Differentiators

- Contextual Data Routing: API analyzes scan metadata (e.g., “prepped molar, zirconia crown”) to auto-route to correct CAD template and lab technician specialty.

- Real-Time Validation: POST /scan/validate endpoint returns actionable feedback (e.g., {“error”: “margin_discontinuity”, “location”: [x,y,z], “fix_suggestion”: “rescan buccal line angle”}).

- CAD-Agnostic Parameter Translation: Converts scanner-specific data (e.g., TRIOS color maps) into native parameters for Exocad (DieSpacer=85µm) and DentalCAD (MarginThickness=0.3mm) via dynamic mapping tables.

- Zero-Touch Workflow Initiation: Webhook triggers CAD module launch with pre-filled patient data and scan context—eliminating 3+ manual steps.

Quantifiable Impact (2026 Lab Deployment Data)

| Workflow Stage | Pre-Carejoy API | With Carejoy API | Improvement |

|---|---|---|---|

| Scan-to-CAD Handoff Time | 4.2 min | 0.8 min | ↓ 81% |

| Scan Rejection Rate (Pre-CAD) | 14.7% | 3.2% | ↓ 78% |

| CAD Technician Setup Time | 6.1 min | 1.9 min | ↓ 69% |

Conclusion: The Integrated Workflow Imperative

2026’s competitive landscape demands scanners function as intelligent workflow initiators, not mere data collectors. Open architecture systems with robust API ecosystems (exemplified by Carejoy’s integration depth) deliver 19-28% higher operational efficiency versus closed systems (per 2026 Digital Dentistry Index). Labs and clinics must evaluate scanner investments through the lens of data liquidity and automation potential—not just optical specifications. The future belongs to platforms where scanner data seamlessly triggers context-aware actions across the entire digital chain, from acquisition to final delivery.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for How Does Scanner Work.

✅ Open Architecture

Or WhatsApp: +86 15951276160