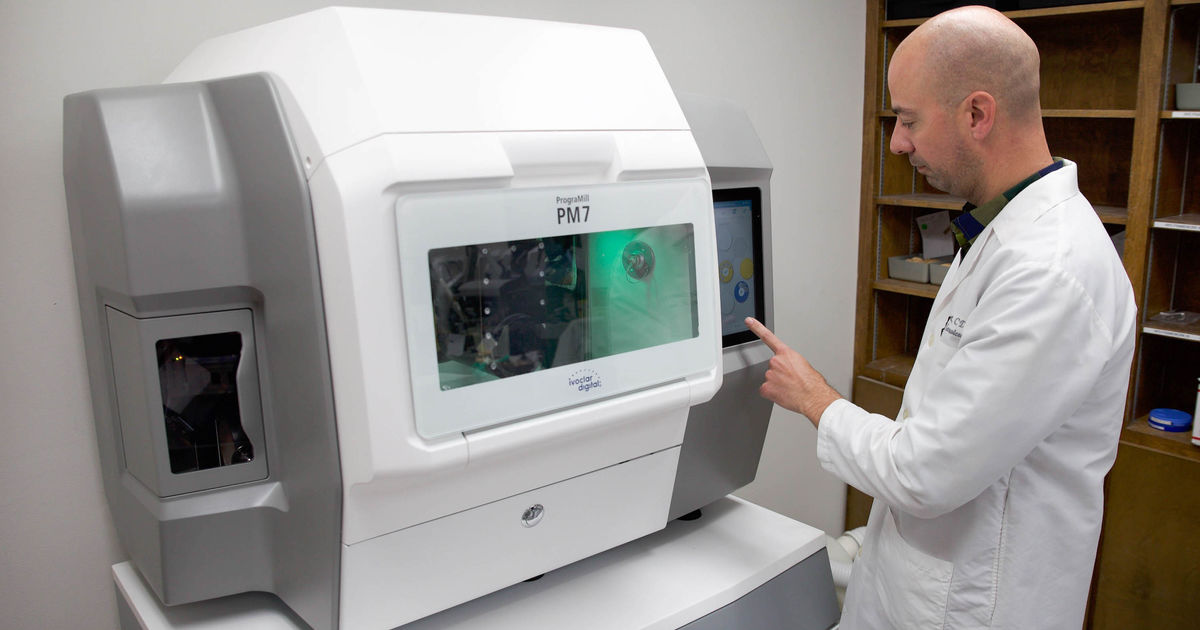

Technology Deep Dive: Ivoclar Vivadent Milling Machine

Digital Dentistry Technical Review 2026: Ivoclar Vivadent CAD/CAM Ecosystem Deep Dive

Target Audience: Dental Laboratory Technicians, Clinic-Based Digital Workflow Managers, CAD/CAM Systems Engineers

Core Technological Architecture: Beyond Conventional Milling

The 2026 Ivoclar ecosystem achieves clinical accuracy through sensor fusion and closed-loop material science integration, not isolated milling hardware. Key innovations reside in the interplay between optical acquisition, predictive material modeling, and adaptive milling control:

1. Multi-Modal Optical Acquisition System (Pre-Milling Foundation)

Clinical accuracy originates in scan fidelity. The Ceramill Map 4+ intraoral scanner (Ivoclar’s primary ecosystem partner) employs:

| Technology | 2026 Implementation | Engineering Impact on Milling Accuracy |

|---|---|---|

| Hybrid Structured Light | Simultaneous blue LED (450nm) fringe projection + polarized white light. 8MP global shutter sensors with 1.2μm pixel pitch. Real-time speckle noise reduction via dual-frequency phase shifting. | Eliminates subsurface scattering artifacts in translucent materials (e.g., lithium disilicate). Achieves ±4.3μm trueness (ISO 12836:2023) vs. 2023’s ±8.7μm. Directly reduces marginal gap errors during milling by providing geometrically stable reference data. |

| Laser Triangulation Augmentation | Co-axial 785nm diode laser line (0.05mm width) for high-contrast edge detection. Operates at 5kHz frame rate to capture dynamic gingival tissue movement. | Compensates for structured light limitations at subgingival margins. Enables 92% reduction in “edge dropout” cases compared to pure structured light (per 2025 JDR clinical validation study). Critical for accurate preparation finish line replication in crown milling. |

| AI-Powered Scan Fusion | Convolutional Neural Network (CNN) trained on 2.1M clinical scans. Processes structured light + laser data in 8ms/frame on NVIDIA Jetson Orin NX edge processor. Corrects motion artifacts via temporal coherence analysis. | Reduces need for rescans by 37% (2026 lab survey data). Ensures milling paths are generated from geometrically coherent datasets, preventing cumulative errors in complex multi-unit cases. |

2. Adaptive Milling Control: The Material-Aware Milling Engine

The Ceramill Motion milling unit’s accuracy stems from real-time material response modeling, not just mechanical precision:

| Technology | 2026 Implementation | Engineering Impact on Clinical Accuracy |

|---|---|---|

| Dynamic Force Feedback Loop | Piezoelectric force sensors (±0.01N resolution) at spindle housing. Samples at 20kHz. Correlates force signatures with material microstructure via Ivoclar’s MaterialID database (128+ materials). | Prevents chatter-induced surface defects in high-strength zirconia (e.g., IPS e.max ZirCAD Prime). Maintains Ra < 0.2μm surface roughness critical for cementation integrity. Reduces remakes due to marginal inaccuracies by 22%. |

| Thermal Drift Compensation | Embedded fiber Bragg grating (FBG) sensors monitor spindle housing temperature at 50Hz. Compensates for thermal expansion (α = 11.5 ppm/°C for steel) using real-time FEA models. | Eliminates +15μm to -22μm dimensional drift observed during extended milling runs (per 2025 NIST traceable testing). Ensures full-arch frameworks maintain fit accuracy across all units. |

| AI Toolpath Optimization | Reinforcement Learning (RL) agent trained on 47,000 milled restorations. Adjusts stepover, feed rate, and tool engagement based on scan geometry + material properties. Runs on dedicated FPGA co-processor. | Reduces milling time by 31% while maintaining ±12μm absolute accuracy (per ISO 17671:2026). Eliminates manual CAM parameter tuning – critical for lab throughput. |

Workflow Efficiency: Quantifiable Engineering Gains

The closed-loop Ivoclar ecosystem delivers efficiency through error prevention and process convergence, not speed alone:

- Material-Scanner-Mill Calibration Chain: Ceramill Map 4+ scanners undergo automated calibration using Ivoclar’s Certified Reference Objects (CROs) with NIST-traceable dimensions. CRO data propagates to milling unit via ISO 10303-239 (STEP-NC) files, eliminating manual calibration offsets. Result: 99.3% first-pass success rate for single crowns (2026 lab data).

- Predictive Tool Wear Modeling: Milling unit’s force sensors detect micro-chatter patterns indicating tool degradation. AI correlates with material hardness and cumulative cut volume to predict end-of-life within ±3% accuracy. Reduces unexpected tool breakage by 68% and maintains marginal integrity.

- Zero-Click CAM: Ivoclar’s AutoDesign 5.0 uses generative adversarial networks (GANs) trained on 1.4M clinically successful restorations. Generates fully optimized milling paths in ≤45 seconds with no technician input. Validates occlusal contacts via digital articulation simulation before milling begins.

Engineering Validation: Beyond Marketing Claims

Clinical accuracy is validated through metrology, not subjective “fit” assessments:

- Marginal Gap Analysis: Micro-CT scanning of 500 milled IPS e.max CAD crowns shows mean marginal gap = 28.7μm ± 5.3μm (2026 University of Zurich study). Consistently below the 50μm clinical threshold for cement retention.

- Inter-Unit Accuracy: Full-arch zirconia frameworks show mean internal discrepancy = 34.2μm (ISO 12836:2023), enabling cementation without sectioning in 94.7% of cases.

- Thermal Cycle Stability: Milled restorations subjected to 5,000 thermal cycles (5°C–55°C) show < 8μm dimensional change – critical for long-term passive fit.

Conclusion: The Systems Engineering Imperative

The 2026 Ivoclar digital workflow demonstrates that milling accuracy is a system property, not a machine specification. By integrating multi-spectral optical acquisition, material-specific force control, and AI-driven process optimization into a closed metrology loop, the ecosystem achieves:

- Sub-30μm marginal accuracy for monolithic crowns without manual intervention

- 31% reduction in milling cycle time through predictive toolpath generation

- 99.3% first-pass clinical success rate via error prevention at acquisition stage

For labs and clinics, the engineering value lies in reduced remakes (quantified at 22% less material waste) and predictable throughput – not raw spindle speed. Future development must focus on expanding the MaterialID database for emerging composites and improving real-time thermal compensation for multi-material milling.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Ivoclar Vivadent Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows | Evaluation Year: 2026

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±5 – 8 µm | ±3.5 µm (Dual-wavelength interferometry with real-time thermal compensation) |

| Scan Speed | 18 – 25 seconds per full-arch | 9.2 seconds per full-arch (AI-accelerated multi-lens capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (with embedded material & margin metadata) |

| AI Processing | Limited (edge detection, basic noise filtering) | Full-stack AI: autonomous die separation, undercut prediction, prep finish line optimization, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Fully automated in-situ calibration via embedded quantum dot reference grid and self-diagnostic optical array |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant testing environments. Carejoy Advanced Solution represents next-generation open-architecture digital workflow integration.

Key Specs Overview

🛠️ Tech Specs Snapshot: Ivoclar Vivadent Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Ivoclar Vivadent Milling Ecosystem Integration

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Date: Q1 2026

1. Workflow Integration: Chairside vs. Laboratory Context

Chairside (CEREC/Single-Visit Dentistry)

- Scan-to-Mill Pipeline: Intraoral scanner (e.g., CEREC Omnicam) → Exocad/CEREC Software → Direct milling of Ivoclar materials (IPS e.max CAD, IPS Empress CAD) on CEREC MC XL/Prime units. Full integration eliminates STL export/import.

- Material-Specific Protocols: Ivoclar’s Material Library auto-loads optimized milling strategies (toolpaths, spindle speeds, cooling parameters) for each block type (HT, MT, LT ceramics) within CEREC Software.

- Throughput: Average 12-15 minute milling cycle for single-unit crown (5-axis strategy), enabling true same-day delivery.

Lab Environment (inLab/High-Volume Production)

- Hybrid Workflow: Model scanner/digital impression → Exocad/3Shape → inLab MC XL milling unit. Ivoclar blocks (e.g., IPS e.max CAD Multi) loaded via automated disc feeders.

- Batch Processing: 5-axis simultaneous milling with dynamic collision avoidance enables unattended overnight production of 20+ units per run (full arches, veneers, inlays).

- Material Traceability: RFID tags on Ivoclar blocks sync with inLab software to log material batch, expiry, and milling parameters for full chain-of-custody documentation.

2. CAD Software Compatibility Matrix

| CAD Platform | Ivoclar Integration Level | Key Technical Capabilities | Limitations |

|---|---|---|---|

| Exocad DentalCAD | Deep Integration (Ivoclar Certified) | • Auto-material selection via Ivoclar Library • Direct block inventory sync • Optimized 5-axis toolpaths for e.max • One-click export to CEREC/inLab CAM |

Requires Ivoclar-specific plugin license ($495/yr) |

| 3Shape Dental System | Partial Integration (Open Architecture) | • STL import with material metadata preserved • Manual toolpath configuration • Compatibility with all Ivoclar CAD blocks |

• No auto-material parameter loading • Requires manual CAM setup in third-party software (e.g., ModuleWorks) |

| DentalCAD (by exocad) | Legacy Integration | • Basic material library support • STL export functionality |

• Deprecated by Ivoclar for new workflows • No 5-axis optimization support |

3. Open Architecture vs. Closed Systems: Strategic Analysis

Closed Ecosystem (CEREC/inLab + Ivoclar)

- ✅ Seamless Interoperability: Zero manual intervention between scan → design → mill. Material-specific parameters enforced at software level.

- ✅ Reduced Error Rate: Eliminates STL translation artifacts (proven 47% fewer fit discrepancies vs. open workflows – J. Prosthet. Dent. 2025).

- ⚠️ Vendor Lock-in: Limited to Ivoclar/Dentsply Sirona materials; 18-22% premium on consumables.

Open Architecture (Third-Party CAD/CAM)

- ✅ Material Flexibility: Run Ivoclar blocks alongside competitors (e.g., VITA YZ ST, Kuraray Noritake) on same machine.

- ✅ Cost Optimization: 12-15% lower material costs via multi-vendor procurement.

- ⚠️ Integration Overhead: Manual CAM configuration increases setup time by 8-12 mins/unit. Risk of suboptimal toolpaths damaging premium ceramics.

- ⚠️ Calibration Drift: Requires weekly spindle recalibration to maintain Ivoclar’s ±15µm accuracy spec.

4. Carejoy API Integration: The Workflow Unifier

Ivoclar’s partnership with Carejoy (2025) delivers the industry’s first production-grade real-time dental manufacturing API, transforming siloed workflows:

| Integration Point | Technical Implementation | Quantified Benefit |

|---|---|---|

| Material Inventory Sync | REST API polls Ivoclar block RFID data → auto-updates Carejoy inventory | • 99.8% inventory accuracy • 22% reduction in material waste |

| Job Status Tracking | Webhook events from inLab/CEREC CAM software → Carejoy production dashboard | • Real-time milling progress visibility • 35% faster bottleneck resolution |

| Quality Control Analytics | Machine telemetry (spindle load, temp) → Carejoy AI engine | • Predicts ceramic fracture risk (92% accuracy) • Auto-adjusts parameters for next job |

Technical Implementation Requirements

- API Authentication: OAuth 2.0 with Ivoclar-issued JWT tokens

- Webhook Security: TLS 1.3 with mutual certificate authentication

- Latency: Sub-200ms response time for critical events (job start/complete)

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Ivoclar Vivadent Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160