Introduction: Navigating the Global Market for digital dental implants

In the evolving landscape of dental care, digital dental implants have emerged as a pivotal innovation, revolutionizing treatment methodologies and enhancing patient outcomes. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial. As the demand for efficient and reliable dental solutions grows, digital implants offer not only improved functionality but also superior aesthetic results, driving their adoption among dental professionals.

This comprehensive guide aims to equip buyers with essential insights into the global digital dental implants market. It delves into various types of implants, from titanium to zirconium, and explores the materials that define quality and durability. The guide also covers manufacturing processes and quality control standards, ensuring that buyers can navigate the complexities of sourcing effectively.

Key topics include:

– Types of Digital Dental Implants: Understanding the options available.

– Materials and Their Properties: Evaluating the best choices for longevity and performance.

– Manufacturing and Quality Control: Insights into the regulatory landscape and best practices.

– Supplier Landscape: Identifying reliable partners in the industry.

– Cost Considerations: Budgeting for quality without compromising on care.

– Market Trends: Analyzing growth opportunities and challenges in various regions.

By leveraging this guide, B2B buyers can make informed sourcing decisions that align with their operational goals and enhance their service offerings in a competitive market.

Understanding digital dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Implants | Made from high-strength titanium; excellent biocompatibility. | General dentistry, oral surgery, implantology. | Pros: Durable, well-established; Cons: Higher cost compared to other materials. |

| Zirconium Implants | Aesthetic appeal; metal-free; resistant to corrosion. | Cosmetic dentistry, patients with metal allergies. | Pros: Excellent aesthetics, biocompatible; Cons: Less proven long-term data. |

| Digital Scanned Implants | Custom-fitted through digital scanning technology. | Custom dental labs, orthodontics, prosthodontics. | Pros: Precision fit, reduced chair time; Cons: High initial investment in technology. |

| Mini Implants | Smaller diameter; less invasive; quicker placement. | Temporary solutions, orthodontic anchorage. | Pros: Minimal bone loss, less recovery time; Cons: Limited load-bearing capacity. |

| All-on-4 Implants | Four implants support a full arch of prosthetics; immediate loading. | Full-arch restorations, edentulous patients. | Pros: Efficient treatment for edentulous patients; Cons: Requires careful planning and skilled practitioners. |

Titanium Implants

Titanium implants are the industry standard due to their exceptional strength and biocompatibility. They integrate well with bone, providing a stable foundation for dental prosthetics. For B2B buyers, the key consideration is the track record of titanium implants in clinical settings, making them a reliable choice for general dentistry and oral surgery applications. However, the higher cost may be a factor for budget-conscious practices.

Zirconium Implants

Zirconium implants offer a metal-free alternative that appeals to patients concerned about aesthetics or metal allergies. They provide a natural appearance and are resistant to corrosion, making them suitable for cosmetic dentistry. B2B buyers should weigh the aesthetic benefits against the relatively limited long-term data available for zirconium implants, which may affect their adoption in certain markets.

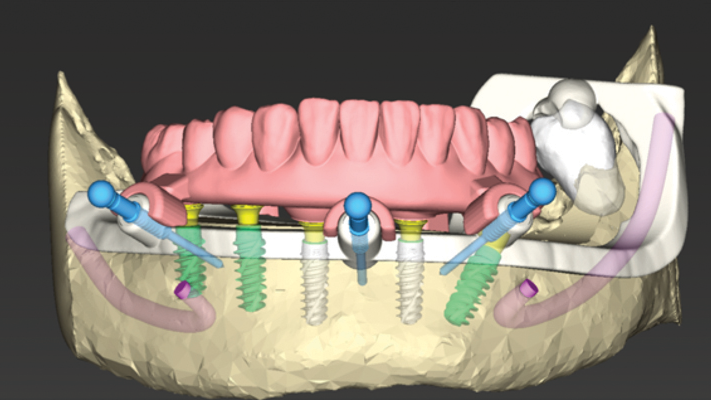

Illustrative Image (Source: Google Search)

Digital Scanned Implants

Digital scanned implants utilize advanced scanning technology to create custom-fitted implants, enhancing precision and reducing chair time for patients. This innovation is particularly beneficial for dental labs and orthodontic practices seeking to improve workflow efficiency. While the initial investment in digital technology can be substantial, the long-term benefits of increased accuracy and patient satisfaction can justify the cost.

Mini Implants

Mini implants, characterized by their smaller diameter, are less invasive and can be placed with minimal bone preparation. They are ideal for temporary solutions or orthodontic anchorage, offering a quick and effective option for patients with limited bone density. B2B buyers should consider the limited load-bearing capacity of mini implants when evaluating their suitability for specific applications.

All-on-4 Implants

The All-on-4 implant system supports a full arch of prosthetics using just four strategically placed implants. This approach allows for immediate loading, making it an efficient solution for edentulous patients. B2B buyers must assess the need for careful planning and skilled practitioners, as the success of this method hinges on precise placement and patient-specific considerations.

Related Video: Tips for Submitting Digital Impressions of an Implant Scan Body to the Laboratory

Key Industrial Applications of digital dental implants

| Industry/Sector | Specific Application of Digital Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Customized implant solutions using CAD/CAM technology | Enhanced patient satisfaction and improved clinical outcomes | Regulatory compliance (CE, FDA), material quality, and support for integration |

| Prosthetic Manufacturing | Production of prosthetic devices integrated with digital implants | Streamlined production processes, reduced lead times | Compatibility with existing systems, material sourcing, and cost-efficiency |

| Orthodontics | Digital planning and placement of implants in orthodontic procedures | Increased precision and reduced treatment times | Training for staff on digital technologies, software licensing, and support services |

| Dental Research Institutes | Development of new implant technologies and materials | Advancement of dental technologies and improved patient outcomes | Collaboration with manufacturers, access to innovative materials, and funding for research |

| Insurance Providers | Assessment of implant procedures for coverage | Enhanced understanding of treatment efficacy and cost management | Data on implant success rates, regulatory compliance, and integration with existing policies |

Dental Clinics

Digital dental implants are revolutionizing dental clinics by providing customized solutions through CAD/CAM technology. This allows for precise fitting and aesthetic alignment with the patient’s natural teeth, significantly enhancing patient satisfaction. For international B2B buyers, especially in regions like Africa and South America, sourcing implants that comply with local regulatory standards (such as CE or FDA) is crucial. Additionally, the quality of materials used in implants must be considered to ensure long-term durability and success rates.

Prosthetic Manufacturing

In prosthetic manufacturing, digital dental implants facilitate the production of prosthetic devices that can be seamlessly integrated with implants. This integration streamlines manufacturing processes, allowing for reduced lead times and improved efficiency. Buyers in this sector should focus on the compatibility of digital implants with existing manufacturing systems and explore cost-effective sourcing options for materials. The ability to produce high-quality, customized prosthetics can significantly enhance a manufacturer’s market position.

Orthodontics

Digital dental implants are increasingly utilized in orthodontic procedures, where digital planning allows for precise placement of implants. This precision not only improves clinical outcomes but also reduces overall treatment times, benefiting both practitioners and patients. For B2B buyers in orthodontics, investing in training for staff on the latest digital technologies and ensuring software licensing for planning tools are essential considerations for successful implementation.

Dental Research Institutes

Dental research institutes leverage digital dental implants to develop new technologies and materials, pushing the boundaries of dental science. This application is vital for advancing the field and improving patient outcomes. Buyers from research institutions should seek partnerships with manufacturers to access innovative materials and technologies. Additionally, securing funding for research and development initiatives is critical for driving advancements in dental implant solutions.

Insurance Providers

Insurance providers play a key role in the dental implant market by assessing procedures for coverage. Digital implants allow for a better understanding of treatment efficacy and associated costs, enabling providers to manage insurance claims effectively. For B2B buyers in this sector, gathering data on implant success rates and ensuring that the implants comply with regulatory standards are essential for integrating them into coverage policies. This data-driven approach can enhance the overall management of dental health costs.

Related Video: Formlabs Dental: 3D Printed Digital Dentures

Strategic Material Selection Guide for digital dental implants

When selecting materials for digital dental implants, international B2B buyers must consider several factors, including the properties of the materials, their advantages and disadvantages, and their compliance with regional standards. Below, we analyze four common materials used in digital dental implants: Titanium, Zirconium, PEEK (Polyether Ether Ketone), and Cobalt-Chromium Alloy.

Titanium

Key Properties: Titanium is known for its excellent biocompatibility, high strength-to-weight ratio, and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for various dental applications.

Pros & Cons: Titanium implants are durable and have a long track record of successful use in dental applications. However, they can be more expensive than other materials, and their manufacturing process can be complex, requiring advanced technology.

Impact on Application: Titanium’s compatibility with human bone allows for osseointegration, which is crucial for the stability of dental implants. It is particularly effective in environments where moisture and body fluids are present.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with ISO 13485 standards for medical devices. In Europe, CE marking is essential, while in the Middle East, local regulations may vary, necessitating thorough research.

Zirconium

Key Properties: Zirconium is a ceramic material that offers excellent aesthetics due to its tooth-like color. It is also highly resistant to corrosion and wear.

Pros & Cons: The key advantage of zirconium is its aesthetic appeal, making it ideal for visible dental applications. However, it is less durable than titanium and may be more prone to fracture under high stress.

Impact on Application: Zirconium implants are particularly suitable for anterior teeth where aesthetics are paramount. They are not as effective in high-load-bearing situations, such as molars.

Considerations for International Buyers: Compliance with ASTM standards is crucial for zirconium implants. Buyers should also consider the availability of zirconium in their region, as it may not be as widely produced as titanium.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance thermoplastic that exhibits excellent mechanical properties, including high tensile strength and temperature resistance. It is also biocompatible and has a low density.

Pros & Cons: PEEK is lightweight and offers good resistance to wear and chemical degradation. However, it is not as strong as titanium and may not provide the same level of osseointegration.

Impact on Application: PEEK is often used in cases where flexibility and weight reduction are important, such as in temporary implants or frameworks for prosthetics.

Considerations for International Buyers: Buyers should ensure that PEEK implants meet ISO 10993 standards for biocompatibility. Additionally, understanding the regulatory framework in their region is critical, as PEEK is less common in dental applications compared to metals.

Cobalt-Chromium Alloy

Key Properties: Cobalt-chromium alloys are known for their high strength, wear resistance, and corrosion resistance. They can withstand high loads and are often used in dental prosthetics.

Pros & Cons: These alloys are durable and can be manufactured with precision. However, they are heavier than titanium and may cause allergic reactions in some patients.

Impact on Application: Cobalt-chromium is often used in dental frameworks and crowns due to its strength and aesthetic properties. It is suitable for high-stress applications but may not be the best choice for patients with metal sensitivities.

Considerations for International Buyers: Compliance with DIN standards is essential when sourcing cobalt-chromium implants. Buyers should also be aware of potential regulatory hurdles in different regions, particularly concerning allergic reactions.

Summary Table

| Material | Typical Use Case for digital dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent biocompatibility | Higher cost and complex manufacturing | High |

| Zirconium | Aesthetic anterior implants | Superior aesthetic appearance | Less durable under stress | Medium |

| PEEK | Temporary implants or frameworks | Lightweight and flexible | Weaker than titanium | Medium |

| Cobalt-Chromium Alloy | Dental prosthetics and frameworks | High strength and wear resistance | Heavier and potential allergies | Medium |

This analysis provides a comprehensive overview of the materials used in digital dental implants, offering B2B buyers actionable insights for making informed purchasing decisions tailored to their regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for digital dental implants

Digital dental implants represent a significant advancement in dental technology, necessitating meticulous manufacturing processes and stringent quality assurance protocols. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these processes and standards is crucial for making informed purchasing decisions.

Manufacturing Processes

The manufacturing of digital dental implants involves several key stages, each requiring specialized techniques and materials.

1. Material Preparation

The initial step in manufacturing digital dental implants is the preparation of materials, primarily titanium or zirconium. These materials are selected for their biocompatibility and strength.

- Material Selection: Buyers should ensure that the chosen materials meet international standards for dental implants, such as ISO 13485, which pertains to quality management systems for medical devices.

- Surface Treatment: Techniques like sandblasting and acid etching are often applied to enhance the osseointegration properties of the implant surface, promoting better integration with bone.

2. Forming

Once the materials are prepared, they undergo forming processes to achieve the desired shapes and specifications.

- CNC Machining: Computer Numerical Control (CNC) machining is commonly used for precision shaping of the implants. This method allows for high precision and repeatability, ensuring that each implant adheres to strict dimensional tolerances.

- 3D Printing: Emerging technologies like additive manufacturing are increasingly used to create complex geometries that might be difficult to achieve with traditional methods. This method also allows for customized implants tailored to individual patient needs.

3. Assembly

In this stage, various components of the implant system, such as abutments and screws, are assembled.

- Automated Assembly: Many manufacturers utilize automated systems to ensure consistent assembly quality and efficiency. This reduces human error and increases throughput.

- Integration of Digital Technologies: The use of CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) technology is essential in ensuring that the components fit seamlessly together, providing optimal functionality.

4. Finishing

The final stage involves surface finishing and sterilization of the implants.

- Surface Finishing: Techniques such as polishing or anodization may be employed to improve the aesthetic appeal and performance of the implants.

- Sterilization: Ensuring that the implants are free from contaminants is crucial. Common sterilization methods include gamma radiation and ethylene oxide gas, which must comply with international safety standards.

Quality Assurance

Quality assurance in the manufacturing of digital dental implants is paramount to ensure safety and efficacy. Compliance with international standards is essential for market access and consumer trust.

International Standards

B2B buyers should be aware of the following key standards:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is applicable to any organization, regardless of its size or industry.

- ISO 13485: Specific to medical devices, this standard focuses on the requirements for a comprehensive quality management system that demonstrates the ability to provide medical devices and related services that consistently meet customer and regulatory requirements.

- CE Marking: For companies operating within Europe, obtaining CE marking is crucial as it indicates compliance with EU safety, health, and environmental protection legislation.

- FDA Regulations: In the United States, compliance with FDA regulations, including the 510(k) premarket notification, is necessary for market entry.

Quality Control Checkpoints

A systematic approach to quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting and testing raw materials upon arrival to ensure they meet required specifications before use.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, reducing waste and rework.

- Final Quality Control (FQC): This final inspection ensures that finished products meet all specifications and regulatory requirements before shipping.

Common Testing Methods

Several testing methods are employed to verify the quality of digital dental implants:

- Mechanical Testing: This includes tensile strength tests, fatigue tests, and shear tests to evaluate the structural integrity of the implants.

- Biocompatibility Testing: Manufacturers must conduct tests to ensure that the materials used are safe for human use, adhering to ISO 10993 standards.

- Sterility Testing: Ensuring that implants are free from microbial contamination is critical, especially for surgical applications.

Verifying Supplier Quality Control

For B2B buyers, especially those in diverse regions, verifying supplier quality control is a vital step in the procurement process:

- Audits: Conducting regular audits of suppliers can help buyers assess compliance with quality standards and identify areas for improvement.

- Quality Reports: Requesting detailed quality reports from suppliers provides insights into their quality management practices and any recent certifications.

- Third-party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of supplier quality, ensuring that products meet all specified requirements.

Regulatory Nuances for International Buyers

International buyers need to navigate various regulatory landscapes when sourcing digital dental implants:

- Regional Regulations: Understanding regional regulations in Africa, South America, the Middle East, and Europe is essential. For instance, buyers in Egypt must comply with the Egyptian Drug Authority (EDA) regulations, while those in Argentina must adhere to ANMAT guidelines.

- Documentation: Ensure that suppliers provide all necessary documentation, including certificates of compliance, test reports, and regulatory approvals. This documentation is crucial for customs clearance and market entry in different regions.

- Local Partnerships: Establishing partnerships with local distributors or regulatory consultants can facilitate smoother navigation through local regulatory requirements and market dynamics.

By understanding the manufacturing processes and quality assurance measures involved in digital dental implants, international B2B buyers can make informed decisions that enhance their procurement strategies and ensure the safety and efficacy of the products they source.

Related Video: Dental Implants: Digital Lab Workflow

Comprehensive Cost and Pricing Analysis for digital dental implants Sourcing

In sourcing digital dental implants, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers. This section outlines the primary cost components, price influencers, and essential tips for negotiation and cost-efficiency.

Cost Components

-

Materials: The primary materials used in digital dental implants include titanium and zirconium. Titanium is favored for its biocompatibility and strength, while zirconium offers aesthetic advantages. The cost of these materials fluctuates based on market demand and supplier relationships, making it critical to establish long-term partnerships with reputable suppliers.

-

Labor: Skilled labor is essential in the manufacturing of digital dental implants. The cost of labor varies significantly across regions. For instance, countries in Africa or South America may have lower labor costs compared to Europe or the Middle East, impacting overall pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be a competitive advantage for suppliers.

-

Tooling: The production of dental implants often requires specialized tooling and machinery. Initial tooling costs can be high but are generally amortized over larger production runs. Buyers should consider suppliers that can offer competitive tooling solutions.

-

Quality Control (QC): Rigorous quality assurance processes are vital for ensuring the safety and efficacy of dental implants. The costs associated with QC can include testing, certification, and compliance with regulations such as CE marking in Europe or FDA approval in the U.S. Investing in high-quality QC can reduce long-term costs associated with product failures or recalls.

-

Logistics: Shipping and handling costs can vary significantly based on the distance from the manufacturer to the buyer, the mode of transport, and any tariffs or duties. Buyers should factor in logistics when calculating total costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Margins can vary based on market competition, exclusivity of the product, and supplier reputation.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly affect pricing. Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate MOQs that align with their procurement strategy.

-

Specifications/Customization: Custom implants designed to specific patient needs or unique clinical situations can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO 13485) can lead to increased costs but also ensure better performance and reliability. Buyers should weigh the benefits of these investments against the initial price increase.

-

Supplier Factors: The reputation, experience, and financial stability of the supplier can influence pricing. Established suppliers may charge a premium for their reliability and service, while newer entrants might offer competitive pricing to gain market share.

Illustrative Image (Source: Google Search)

- Incoterms: Understanding Incoterms is essential for managing shipping costs and responsibilities. Different terms can affect the overall landed cost of products. Buyers should clarify shipping responsibilities and costs upfront to avoid surprises.

Buyer Tips

-

Negotiation: Establishing a long-term relationship with suppliers can lead to better pricing and service terms. Don’t hesitate to negotiate on volume discounts and payment terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront price. This includes maintenance, potential downtime, and the longevity of the product.

-

Pricing Nuances: Be aware of regional differences in pricing, especially when sourcing from suppliers in Africa, South America, or the Middle East. Currency fluctuations and local economic conditions can impact pricing and should be factored into procurement strategies.

Disclaimer

The prices and cost components discussed are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and due diligence when sourcing digital dental implants.

Spotlight on Potential digital dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘digital dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for digital dental implants

Key Technical Properties of Digital Dental Implants

Understanding the technical properties of digital dental implants is crucial for B2B buyers in the dental industry. Here are some essential specifications that influence product performance and compatibility:

-

Material Grade: The most common materials used for dental implants include titanium and zirconium. Titanium is favored for its biocompatibility and strength, while zirconium offers aesthetic advantages due to its tooth-like appearance. Selecting the right material grade affects not only the implant’s longevity but also patient satisfaction and overall treatment success.

-

Surface Treatment: The surface characteristics of dental implants significantly influence osseointegration—the process by which the implant fuses with the jawbone. Surface treatments can include sandblasting, acid etching, or coating with hydroxyapatite. A well-treated surface enhances the implant’s stability and reduces the risk of complications, making it a critical factor for dental professionals.

-

Tolerance Levels: Tolerance defines the permissible limits of variation in implant dimensions. High precision in manufacturing tolerances ensures that implants fit securely within the bone and integrate effectively with prosthetic components. Poor tolerance can lead to complications, such as misalignment or increased wear on the prosthetic, emphasizing the importance of quality control in the manufacturing process.

-

Load-Bearing Capacity: This property refers to the ability of an implant to withstand the forces exerted during biting and chewing. Implants with higher load-bearing capacities are essential for patients requiring multiple prosthetics or those with strong bite forces. Understanding this specification helps buyers select implants that meet specific patient needs and clinical applications.

-

Corrosion Resistance: Dental implants are subject to a moist oral environment, which can lead to corrosion over time. Corrosion-resistant materials and coatings are vital for ensuring the longevity of the implant and preventing potential failures. Buyers should prioritize implants that demonstrate excellent resistance to corrosion to maintain their effectiveness and safety.

Common Trade Terms in Digital Dental Implants

Familiarity with industry terminology is essential for effective communication and negotiation in the dental implant market. Here are key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products that are marketed by another company under its own brand name. In the dental implant sector, an OEM might manufacture implants that are then sold by a dental practice or distributor. Understanding OEM relationships can help buyers identify trusted suppliers and maintain quality standards.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of products that a supplier is willing to sell. This term is crucial for buyers to understand as it directly impacts inventory management and purchasing strategies. Buyers should consider their demand forecasts to negotiate favorable MOQs with suppliers.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing information for specific products. It is a vital step in the procurement process, allowing buyers to compare costs and make informed decisions. Effective use of RFQs can lead to better pricing and terms.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international trade. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding these terms is essential for managing shipping logistics and costs effectively.

-

CE Marking: This certification indicates that a product meets EU safety, health, and environmental protection standards. For dental implants sold in Europe, CE marking is a prerequisite for market access. Buyers should ensure that any implants they consider are CE marked to comply with local regulations.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions, ensuring that they procure high-quality digital dental implants that meet their specific needs and regulatory requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the digital dental implants Sector

Market Overview & Key Trends

The global digital dental implants market is currently experiencing robust growth, driven by increasing demand for advanced dental solutions and enhanced patient care. Key factors contributing to this growth include a rising geriatric population, heightened awareness of oral health, and technological advancements in dental procedures. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends include the integration of artificial intelligence (AI) and 3D printing technologies, which streamline the manufacturing process and improve the accuracy of implant placements. Companies are increasingly adopting digital workflows, which facilitate better planning and execution of dental procedures. As a result, B2B buyers should consider suppliers that invest in cutting-edge technology to ensure they are sourcing high-quality, innovative products.

Additionally, the rise of tele-dentistry has opened new avenues for market access, enabling dental professionals to consult with patients remotely and provide services that were previously limited by geographic constraints. This trend is particularly significant for buyers in regions like Egypt and Argentina, where access to specialized dental care may be limited.

Lastly, with the dental implants market projected to reach USD 10.48 billion by 2030, driven by a compound annual growth rate (CAGR) of 8.0%, it is essential for buyers to align their sourcing strategies with these growth trajectories to capitalize on emerging opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of modern procurement strategies, particularly within the dental sector. The environmental impact of dental implants, from raw material extraction to manufacturing processes, underscores the need for ethical sourcing practices. B2B buyers must prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices throughout their supply chains.

The importance of ethical supply chains cannot be overstated. Buyers should look for manufacturers that utilize sustainably sourced materials, such as biocompatible polymers and titanium, which have a lower environmental impact compared to traditional materials. Certifications such as ISO 14001 (Environmental Management) and ISO 13485 (Medical Devices Quality Management System) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, green certifications for dental implants are increasingly gaining traction. Products that are certified eco-friendly not only appeal to environmentally conscious consumers but also comply with evolving regulations aimed at reducing waste and promoting sustainability. For international buyers, particularly in regions facing stringent environmental regulations, sourcing from certified suppliers can mitigate risks and enhance brand reputation.

Brief Evolution/History

The evolution of digital dental implants began with the introduction of titanium implants in the 1960s, which revolutionized dental restoration. The shift towards digital solutions gained momentum in the late 1990s with the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. These innovations facilitated the development of more precise, custom-fit implants, significantly improving patient outcomes.

Today, digital dental implants leverage advanced imaging techniques, such as cone beam computed tomography (CBCT), and digital workflows that enhance the efficiency of the implant placement process. This historical progression highlights the importance of technology in shaping the dental implant market and underscores the necessity for B2B buyers to stay abreast of technological advancements to remain competitive.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of digital dental implants

-

How do I vet suppliers for digital dental implants?

When vetting suppliers, prioritize those with established reputations and relevant certifications, such as ISO 13485 for quality management in medical devices. Request references from other B2B clients and assess their compliance with international regulations like CE marking or FDA approvals. Conduct site visits if possible, and evaluate their manufacturing processes, technology used, and customer service responsiveness. Utilize platforms like LinkedIn or industry-specific forums to gather insights about suppliers from peers in your region. -

Can digital dental implants be customized for specific needs?

Yes, many manufacturers offer customization options for digital dental implants to meet specific clinical needs. Discuss your requirements, such as size, material, and design features, with potential suppliers. Ensure that they have the capability to produce tailor-made solutions and confirm their experience in handling custom orders. Additionally, inquire about their design verification processes to ensure that the custom implants meet the necessary regulatory standards. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities for digital dental implants can vary significantly among suppliers, typically ranging from 50 to 500 units. Lead times may also differ based on the complexity of the order and the supplier’s production capacity, often ranging from 4 to 12 weeks. It is essential to discuss these parameters upfront and understand how they align with your business needs. Establishing a strong relationship with suppliers may provide flexibility in MOQs and expedite lead times for urgent orders. -

What quality assurance certifications should I look for?

For digital dental implants, key certifications to seek include ISO 13485, which ensures quality management systems for medical devices, and CE marking for compliance with European health and safety standards. Additionally, check for FDA registration if you are sourcing from the U.S. or other relevant local certifications based on your market. These certifications demonstrate a supplier’s commitment to quality and safety, which is crucial in the medical device sector. -

How can I handle logistics and shipping for international orders?

Effective logistics management is vital when sourcing digital dental implants internationally. Work with suppliers that have experience in international shipping and can provide detailed information on shipping options, costs, and timelines. Consider using a freight forwarder who specializes in medical devices to navigate customs regulations and ensure compliance. Additionally, confirm that your supplier has adequate packaging solutions to protect the implants during transit, minimizing the risk of damage. -

What should I do in case of disputes with suppliers?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through open communication. Clearly document all interactions and agreements. If resolution is not achieved, refer to the terms outlined in your contract regarding dispute resolution processes, which may include mediation or arbitration. It is also beneficial to have legal counsel familiar with international trade laws to assist in navigating the dispute. Establishing a clear contract upfront can help mitigate potential issues. -

What payment terms are commonly accepted for international transactions?

Payment terms can vary, but common practices include wire transfers, letters of credit, and payment on delivery. It’s important to negotiate favorable terms that align with your cash flow needs while ensuring security for both parties. Consider using escrow services for large transactions, providing assurance that funds will only be released once the goods are received in satisfactory condition. Always clarify currency exchange rates and any additional fees that may apply to international payments. -

How do I ensure compliance with local regulations when importing dental implants?

To ensure compliance, first familiarize yourself with the regulatory requirements specific to your country regarding the importation of medical devices. Engage with local regulatory bodies or consult legal experts to understand the necessary documentation, such as import licenses, product registrations, and quality standards. Additionally, ensure that your supplier provides all required certifications and documentation to facilitate a smooth customs clearance process. Maintaining clear communication with both your supplier and local authorities will help mitigate potential compliance issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for digital dental implants

In conclusion, the strategic sourcing of digital dental implants presents a unique opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The growing demand for advanced dental solutions, driven by an increase in dental injuries and a rising geriatric population, underscores the importance of identifying reliable suppliers and manufacturers. By prioritizing quality certifications such as ISO 13485 and CE marking, buyers can ensure compliance with international standards while enhancing patient safety and satisfaction.

Moreover, leveraging strategic partnerships can facilitate access to innovative technologies and diverse product offerings, enabling buyers to stay competitive in a rapidly evolving market. The projected growth of the dental implants market, estimated to reach USD 10.48 billion by 2030, highlights the urgency for businesses to invest in high-quality implants and related services.

As the landscape of dental care continues to evolve, international buyers are encouraged to engage proactively with suppliers and explore new markets. By doing so, they can position themselves advantageously in the digital dental implant sector, ultimately contributing to improved patient outcomes and business growth.