Introduction: Navigating the Global Market for dental implant torque wrench

In the rapidly evolving dental industry, the significance of precision cannot be overstated, particularly when it comes to dental implant procedures. The dental implant torque wrench is an essential tool that ensures the optimal application of torque during the placement of implants, directly influencing the longevity and success of these intricate procedures. For B2B buyers, understanding the nuances of this tool is critical for making informed purchasing decisions that impact patient outcomes and operational efficiency.

This comprehensive guide delves into the multifaceted world of dental implant torque wrenches, offering insights into various types, materials, and manufacturing quality control practices. It aims to equip international buyers, especially from regions like Africa, South America, the Middle East, and Europe, with the knowledge necessary to navigate the global market effectively.

Key components of the guide include an analysis of leading suppliers, a breakdown of costs, and an overview of market trends that can influence purchasing strategies. Additionally, it addresses frequently asked questions that can help demystify the selection process. By empowering buyers with this essential information, the guide not only enhances sourcing decisions but also fosters partnerships that can elevate dental practices across diverse markets. As you explore this resource, prepare to transform your approach to procuring dental implant torque wrenches, ensuring you secure the best tools for optimal clinical outcomes.

Understanding dental implant torque wrench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Torque Wrench | Mechanical operation, no battery required | General dental practices | Pros: Cost-effective, simple to use. Cons: Limited torque precision. |

| Digital Torque Wrench | Electronic display, programmable settings | Advanced dental surgeries | Pros: High accuracy, easy to read. Cons: Higher cost, requires battery. |

| Ratchet Torque Wrench | Gear mechanism allows for continuous turning | Implant placements in tight spaces | Pros: Efficient in confined areas. Cons: Can be bulkier than other types. |

| Click Torque Wrench | Auditory click when set torque is reached | Routine dental procedures | Pros: Ensures proper torque application. Cons: May require recalibration. |

| Torque Control System | Integrated with dental units, real-time monitoring | High-volume dental facilities | Pros: Streamlined workflow, data tracking. Cons: Higher initial investment. |

Manual Torque Wrench

Manual torque wrenches are the most basic type, relying solely on mechanical mechanisms to apply torque without the need for batteries or electronic components. They are particularly suitable for general dental practices where cost efficiency is a priority. Buyers should consider the torque range and ease of use, as well as the maintenance requirements, which tend to be minimal. While they are cost-effective, the precision might not meet the needs of more complex dental implant procedures.

Digital Torque Wrench

Digital torque wrenches offer enhanced precision through electronic displays and programmable settings. They are ideal for advanced dental surgeries where accurate torque application is critical. B2B buyers should focus on features such as battery life, ease of calibration, and the range of torque settings. Although they come with a higher price tag, the investment can significantly improve outcomes in complex procedures, making them a valuable addition for practices aiming for precision.

Ratchet Torque Wrench

Ratchet torque wrenches employ a gear mechanism that allows continuous turning, making them particularly useful in tight spaces where traditional wrenches may struggle. They are commonly used in implant placements, where maneuverability is essential. Buyers should assess the size and weight of the wrench, as well as its torque range. The convenience of this type can outweigh the bulkiness, especially in specialized dental environments.

Click Torque Wrench

Click torque wrenches provide an auditory signal when the preset torque level is achieved, ensuring that dental professionals can apply the correct amount of force. They are suitable for routine dental procedures where consistent torque application is necessary. B2B buyers should consider the calibration requirements and overall durability of the wrench. While they are user-friendly and promote accuracy, they may require periodic recalibration, which could be a factor for practices with high turnover.

Torque Control System

Torque control systems are advanced tools integrated with dental units, providing real-time monitoring and data tracking capabilities. They are particularly beneficial for high-volume dental facilities looking to streamline their workflow. Buyers should evaluate the system’s compatibility with existing equipment, as well as the potential for long-term cost savings through improved efficiency. Although the initial investment is higher, the benefits of enhanced workflow and data management can justify the cost for larger practices.

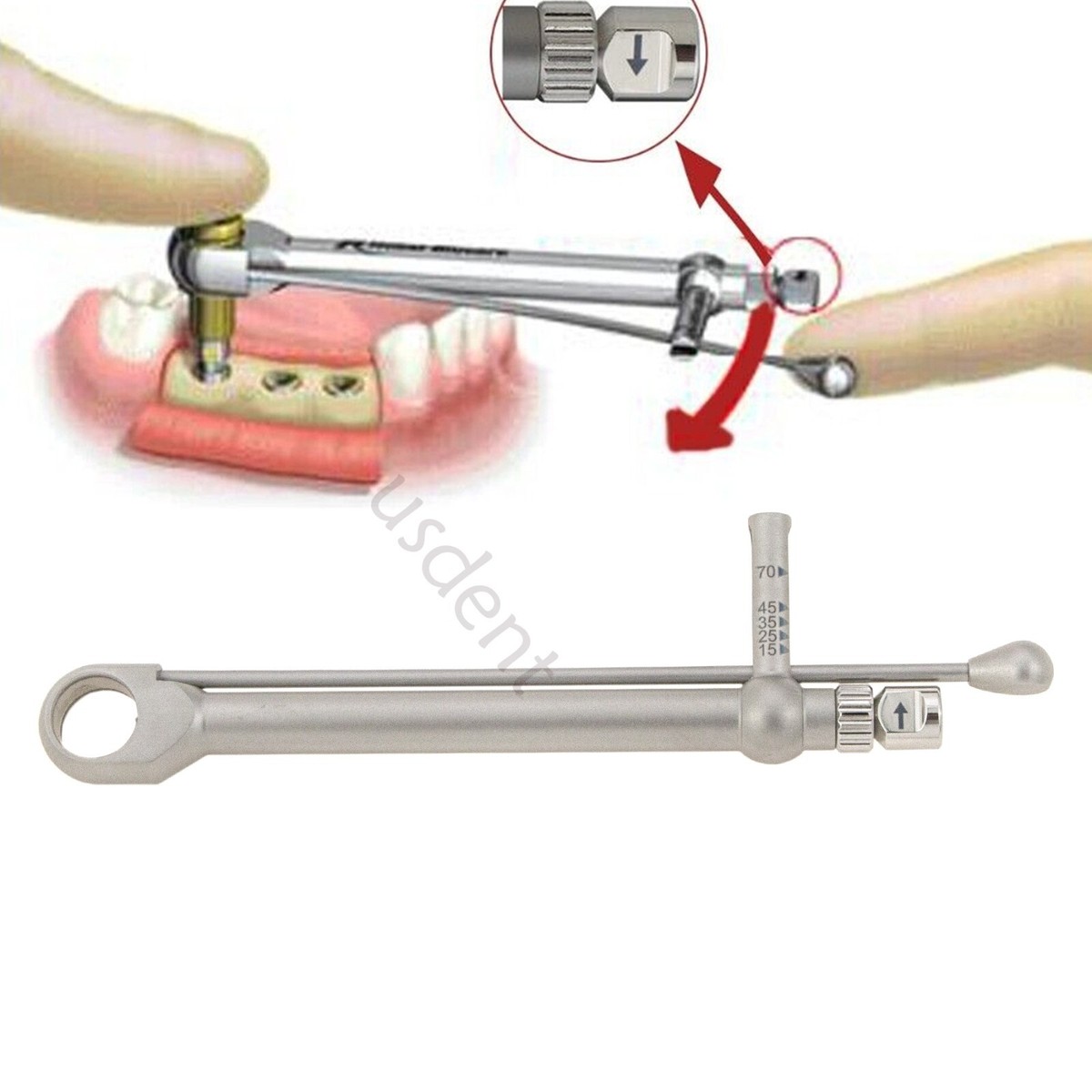

Related Video: What is a dental torque wrench? One of the most important tools used to put a tooth on an implant.

Key Industrial Applications of dental implant torque wrench

| Industry/Sector | Specific Application of dental implant torque wrench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Ensuring optimal torque during dental implant procedures | Enhances patient safety and treatment outcomes | Look for precision calibration and ergonomic design |

| Dental Laboratories | Research and development of implant prototypes | Improves accuracy in testing and product development | Ensure compatibility with various implant designs |

| Dental Equipment Manufacturers | Quality control in manufacturing dental implants | Reduces the risk of product failure and recalls | Source from manufacturers with ISO certifications |

| Educational Institutions | Training dental professionals on implant procedures | Promotes best practices and enhances skill development | Consider suppliers that provide training and support materials |

| Dental Supply Distributors | Retailing torque wrenches to dental professionals | Expands product offerings and meets demand | Evaluate supplier reliability and after-sales support |

Dental Clinics

In dental clinics, a torque wrench is crucial during the installation of dental implants. It ensures that the screws are tightened to the manufacturer’s specified torque, which is essential for the stability and longevity of the implant. This reduces the risk of implant failure and enhances patient safety. For international buyers, particularly from regions like Africa and the Middle East, it’s important to source wrenches that are not only precise but also ergonomically designed to minimize strain during procedures.

Dental Laboratories

Dental laboratories utilize torque wrenches during the research and development of implant prototypes. By applying consistent torque, they can test the durability and effectiveness of new designs under controlled conditions. This application is vital for ensuring that products meet both safety standards and market demands. Buyers from South America and Europe should consider wrenches that can accommodate various sizes and types of implants, as well as those that provide reliable calibration.

Dental Equipment Manufacturers

In the manufacturing sector, torque wrenches play a pivotal role in quality control processes. By ensuring that each dental implant is produced with the correct torque specifications, manufacturers can significantly reduce the risk of product failures and recalls. For businesses in Europe and Africa, sourcing high-quality torque wrenches that adhere to ISO certifications is critical to maintaining compliance and ensuring product reliability.

Educational Institutions

Educational institutions use dental implant torque wrenches as part of their training programs for dental professionals. By providing hands-on experience with these tools, schools can instill best practices in torque application, which is essential for successful implant procedures. Buyers from the Middle East should look for suppliers that not only offer high-quality tools but also provide training materials and support to enhance the educational experience.

Dental Supply Distributors

Dental supply distributors benefit from retailing torque wrenches to dental professionals. Offering a range of high-quality torque wrenches can help distributors meet the growing demand for reliable dental tools. For international buyers, especially in South America, evaluating the reliability of suppliers and the availability of after-sales support is crucial to ensure customer satisfaction and repeat business.

Strategic Material Selection Guide for dental implant torque wrench

When selecting materials for dental implant torque wrenches, international B2B buyers must consider several factors that influence performance, durability, and compliance with industry standards. Here, we analyze four common materials used in the manufacturing of these essential tools: stainless steel, aluminum, titanium, and carbon fiber.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high tensile strength. It can withstand a wide range of temperatures and pressures, making it suitable for various applications in dental settings.

Pros & Cons: The durability of stainless steel is one of its primary advantages, as it can endure repeated use without significant wear. However, the cost can be relatively high compared to other materials, and manufacturing can be complex due to the need for precise machining to achieve the desired torque specifications.

Impact on Application: Stainless steel is compatible with various dental media, including saline and other sterilizing agents. Its resistance to corrosion ensures longevity and reliability in clinical environments.

Considerations for International Buyers: Buyers from regions like Europe and South Africa should ensure compliance with ASTM and DIN standards for stainless steel grades. The availability of certified suppliers can affect procurement decisions, particularly in regions with stringent regulatory requirements.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it a popular choice for dental tools that require frequent handling.

Pros & Cons: The primary advantage of aluminum is its low weight, which enhances maneuverability during procedures. However, it is less durable than stainless steel and can be prone to deformation under high torque. Additionally, the manufacturing process is generally simpler and less costly.

Impact on Application: Aluminum’s compatibility with dental applications is strong, but care must be taken to avoid exposure to harsh chemicals that could compromise its integrity.

Considerations for International Buyers: In regions like South America and the Middle East, buyers should consider local manufacturing capabilities and the availability of aluminum alloys that meet international standards. Compliance with JIS standards is particularly relevant in these markets.

Titanium

Key Properties: Titanium is renowned for its exceptional strength-to-weight ratio and outstanding corrosion resistance, especially in saline environments.

Pros & Cons: The key advantage of titanium is its biocompatibility, making it ideal for dental applications. However, it is more expensive and can be challenging to machine, which may lead to higher manufacturing costs.

Impact on Application: Titanium’s properties make it suitable for use in environments where exposure to bodily fluids is common. It is also less likely to cause allergic reactions, enhancing patient safety.

Considerations for International Buyers: Buyers in Europe and Africa should be aware of the specific titanium grades that comply with ISO standards. The higher cost may be justified in markets where quality and safety are paramount.

Carbon Fiber

Key Properties: Carbon fiber offers a unique combination of lightweight characteristics and high strength, along with excellent resistance to fatigue.

Pros & Cons: The main advantage of carbon fiber is its lightweight nature, which facilitates ease of use. However, it is generally more expensive than metals and may not provide the same level of torque accuracy due to its flexibility.

Impact on Application: Carbon fiber is suitable for applications where weight savings are critical, but its compatibility with certain dental media must be assessed to avoid degradation.

Considerations for International Buyers: In regions like South America and the Middle East, buyers should evaluate the availability of carbon fiber suppliers and ensure that products meet relevant ASTM standards. The higher cost may limit its adoption in price-sensitive markets.

Summary Table

| Material | Typical Use Case for dental implant torque wrench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General use in dental practices | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight tools for frequent handling | Low weight enhances maneuverability | Less durable under high torque | Medium |

| Titanium | High-end applications requiring biocompatibility | Exceptional strength and corrosion resistance | Expensive and challenging to machine | High |

| Carbon Fiber | Specialized applications prioritizing weight | Lightweight and fatigue-resistant | Higher cost and potential torque inaccuracies | High |

Understanding these materials’ properties, advantages, and limitations will help international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implant torque wrench

Understanding the Manufacturing Process of Dental Implant Torque Wrenches

The manufacturing of dental implant torque wrenches involves several critical stages, each designed to ensure precision and reliability. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence purchasing decisions and supplier evaluations.

Material Preparation

The first stage in the manufacturing process is material preparation. High-grade materials such as stainless steel or titanium alloys are typically selected for their strength, corrosion resistance, and biocompatibility.

- Material Selection: Buyers should inquire about the specific alloys used and their certifications.

- Heat Treatment: This process is often employed to enhance the mechanical properties of the materials, ensuring the wrench can withstand the stresses encountered during use.

Forming

Once the materials are prepared, the forming stage begins. This includes machining and shaping the raw materials into the desired specifications.

- CNC Machining: Computer Numerical Control (CNC) machines are commonly utilized for their precision. They allow manufacturers to create intricate designs and maintain tight tolerances, which are crucial for torque wrenches.

- Forging and Casting: Some manufacturers may also use forging or casting techniques, which can enhance the strength and durability of the final product.

Assembly

The assembly phase involves integrating various components of the torque wrench. Each component must be assembled with precision to ensure functionality.

- Component Integration: This includes the handle, socket, and measurement mechanism. Each part must fit together seamlessly to ensure accurate torque readings.

- Calibration: Calibration is essential in this stage to ensure that the wrench provides accurate torque measurements. Buyers should ensure that suppliers have robust calibration processes in place.

Finishing

The finishing stage enhances the aesthetics and functionality of the torque wrenches.

- Surface Treatment: Techniques such as anodizing or passivation are often employed to improve corrosion resistance and provide a smoother finish.

- Quality Inspection: After finishing, wrenches undergo a final inspection to ensure they meet all specifications before packaging.

Quality Assurance Standards

Quality assurance is critical in the manufacturing of dental implant torque wrenches, given their application in surgical environments. International standards such as ISO 9001 and industry-specific certifications like CE marking and API standards play a crucial role in this process.

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system, ensuring that manufacturers meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In some regions, particularly in the oil and gas sector, API standards may also apply, ensuring the tools meet rigorous safety and performance requirements.

Quality Control Checkpoints

To maintain high-quality standards, manufacturers implement several quality control checkpoints throughout the production process:

- Incoming Quality Control (IQC): This checkpoint verifies the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Quality is monitored during the manufacturing process to identify any issues in real time.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications and standards before it is shipped.

Common Testing Methods

Several testing methods are employed to ensure the torque wrenches function correctly and reliably:

- Torque Calibration Tests: These tests measure the accuracy of the wrench’s torque settings.

- Durability Testing: This assesses the tool’s ability to withstand repeated use without failure.

- Corrosion Resistance Tests: Conducted to ensure the materials used can withstand harsh environments, particularly in regions with high humidity or saline conditions.

Verifying Supplier Quality Control

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures.

- Quality Reports: Requesting detailed quality reports and certifications can help verify compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance processes.

QC and Certification Nuances for International Buyers

B2B buyers must be aware of the nuances in quality control and certification relevant to their specific regions. For instance:

- Regional Regulations: Different countries may have varying requirements for medical devices, including dental tools. Buyers should familiarize themselves with local regulations in their markets.

- Cultural Considerations: Understanding cultural attitudes towards quality and compliance can also affect supplier relationships and negotiations.

Conclusion

Understanding the manufacturing processes and quality assurance measures for dental implant torque wrenches is crucial for international B2B buyers. By focusing on material selection, manufacturing techniques, and stringent quality control protocols, buyers can ensure they procure reliable and high-quality tools that meet their specific needs.

Related Video: Assembly and Use of a Straumann Torque Wrench

Comprehensive Cost and Pricing Analysis for dental implant torque wrench Sourcing

Understanding the cost structure and pricing dynamics of dental implant torque wrenches is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will help buyers make informed decisions while sourcing these critical tools.

Cost Components

- Materials: The primary materials used in manufacturing dental implant torque wrenches include high-grade stainless steel and aluminum alloys. The quality of these materials directly influences the durability and performance of the tool, thus impacting overall cost.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary significantly based on geographic location and the skill level required for manufacturing. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help mitigate these costs, allowing suppliers to offer better pricing.

-

Tooling: Initial tooling costs can be substantial, especially for customized wrenches. This is a one-time expense but can affect pricing in the short term. Buyers should be aware that larger orders can spread these costs over more units, reducing the per-unit price.

-

Quality Control (QC): Ensuring the quality of dental torque wrenches through rigorous QC processes incurs additional costs. However, these costs are crucial for maintaining safety and compliance standards, particularly in the medical field.

-

Logistics: Shipping and handling fees can vary widely based on the shipping method, distance, and Incoterms agreed upon. Buyers must consider these costs as part of the total expenditure.

-

Margin: Suppliers typically mark up prices to cover operational expenses and achieve profit. Understanding the standard margins in different regions can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: The quantity ordered can significantly affect pricing. Suppliers often provide discounts for larger orders, making it beneficial for buyers to consolidate purchases when possible.

-

Specifications/Customization: Customized torque wrenches tailored to specific requirements may incur higher costs due to the complexities involved in production. Buyers should assess whether customization is necessary versus off-the-shelf solutions.

-

Materials: The choice of materials affects both the cost and performance of the wrench. Higher-quality materials may lead to higher initial costs but can result in lower long-term maintenance expenses.

-

Quality/Certifications: Products with certifications such as ISO or CE may command a premium price. However, they often offer better reliability and compliance with international standards, making them a worthwhile investment.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with proven track records may charge higher prices due to their reliability and service quality.

-

Incoterms: The terms of shipping and delivery can impact overall costs significantly. Understanding Incoterms helps buyers manage risk and predict additional expenses related to logistics.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term contracts to negotiate better pricing. Suppliers are often open to discussions, especially for repeat business.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes acquisition cost, maintenance, and potential downtime. Investing in higher-quality tools may reduce long-term expenses.

-

Pricing Nuances: Be aware of regional pricing differences, especially between developed and emerging markets. Buyers from Africa and South America may find that local suppliers offer more competitive pricing compared to European counterparts.

-

Research and Compare: Before committing to a supplier, conduct thorough market research to compare prices, quality, and service levels. Utilize trade shows and online platforms to gather insights and identify potential suppliers.

Disclaimer

Prices for dental implant torque wrenches can fluctuate based on market conditions, currency exchange rates, and supplier negotiations. It is advisable for buyers to request quotes and confirm pricing prior to finalizing any purchase agreements.

Spotlight on Potential dental implant torque wrench Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dental implant torque wrench’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dental implant torque wrench

When considering the procurement of a dental implant torque wrench, understanding its technical properties and trade terminology is crucial for making informed purchasing decisions. Here, we outline essential specifications and commonly used terms that every B2B buyer should be familiar with.

Key Technical Properties

-

Material Grade

– Definition: The material grade refers to the type of materials used in the construction of the torque wrench, such as stainless steel or aluminum.

– Importance: High-grade materials ensure durability, corrosion resistance, and longevity, which are vital in medical applications. Selecting the right material can affect the wrench’s performance and lifespan, directly impacting the cost of ownership. -

Torque Range

– Definition: This indicates the minimum and maximum torque levels that the wrench can accurately apply, usually measured in Newton-meters (Nm).

– Importance: A torque wrench with a suitable torque range is essential for the precise installation of dental implants, as incorrect torque can lead to implant failure. Buyers must ensure that the wrench meets the specific torque requirements of the implants they are using. -

Accuracy and Calibration

– Definition: Accuracy refers to how close the torque wrench’s readings are to the actual torque applied, while calibration ensures that the tool provides reliable measurements over time.

– Importance: High accuracy is critical in dental procedures to prevent complications. Regular calibration is necessary to maintain the tool’s reliability, making it essential to consider the manufacturer’s calibration standards and recommendations. -

Tolerance

– Definition: Tolerance specifies the allowable deviation from a specified value, indicating how precise the tool’s measurements are.

– Importance: Low tolerance levels are crucial in medical applications to ensure consistent and safe outcomes. Understanding the tolerance specifications helps buyers gauge the reliability of the tool in clinical settings. -

Ergonomics and Design

– Definition: This refers to how the tool is designed for ease of use, including handle grip and weight distribution.

– Importance: Ergonomically designed tools reduce user fatigue and increase precision, which is particularly important during lengthy procedures. Buyers should evaluate the design for comfort and usability in a clinical environment.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding whether a torque wrench is sourced from an OEM can provide insights into quality and reliability. Buyers often prefer OEM products for their consistency and adherence to industry standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory management. Buyers should evaluate their needs against the MOQ to avoid overstocking or underordering. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to request pricing and availability for specific products.

– Importance: Utilizing RFQs allows buyers to compare prices and terms from multiple suppliers, enabling better negotiation and cost management. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Importance: Familiarity with Incoterms helps buyers understand their responsibilities and risks in the shipping process, including shipping costs, insurance, and delivery obligations. -

Lead Time

– Definition: Lead time is the time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is critical for planning and inventory management. Buyers should consider lead times when evaluating suppliers to ensure timely delivery aligns with project timelines.

By familiarizing themselves with these technical specifications and trade terms, international B2B buyers can make more informed decisions when sourcing dental implant torque wrenches, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implant torque wrench Sector

Market Overview & Key Trends

The dental implant torque wrench sector is witnessing significant transformation driven by technological advancements, increasing demand for dental implants, and a growing emphasis on precision in dental procedures. Key global drivers include an aging population, rising disposable incomes, and greater awareness of dental health. These factors are particularly relevant in regions like Africa and South America, where dental care access is improving, and in Europe and the Middle East, where advanced dental technologies are being adopted rapidly.

Emerging trends in sourcing include a shift towards digital procurement solutions that streamline the purchasing process. International B2B buyers are increasingly leveraging platforms that offer real-time pricing, inventory management, and supplier ratings, enhancing decision-making efficiency. Additionally, the rise of automation and robotics in manufacturing is influencing sourcing strategies, as companies look for suppliers that can provide innovative, tech-driven solutions. Buyers in regions such as South Africa and France should consider suppliers who not only offer high-quality torque wrenches but also demonstrate adaptability to new technologies.

Market dynamics are also affected by geopolitical factors and trade agreements, which can impact pricing and availability. For example, tariffs and regulations may affect sourcing from specific countries, necessitating a thorough understanding of the global supply chain landscape. Buyers are encouraged to build relationships with multiple suppliers across different regions to mitigate risks associated with market fluctuations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the dental implant torque wrench sector, as environmental awareness grows among consumers and regulatory bodies. The environmental impact of dental manufacturing processes, including waste generation and energy consumption, has prompted buyers to seek out suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials and energy-efficient production methods.

Ethical sourcing is increasingly important, particularly in regions like Africa and South America, where supply chain transparency can be an issue. Buyers should prioritize suppliers who adhere to ethical labor practices and can demonstrate compliance with international standards. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are valuable indicators of a supplier’s commitment to sustainable practices.

Furthermore, the adoption of ‘green’ materials in the manufacturing of dental tools, including torque wrenches, is gaining traction. Materials that are recyclable or derived from sustainable sources not only reduce environmental impact but also appeal to a growing segment of environmentally conscious dental professionals. Buyers should actively inquire about the sustainability credentials of their suppliers to ensure alignment with their own corporate social responsibility goals.

Brief Evolution/History

The dental implant torque wrench has evolved significantly since its inception. Initially designed for manual use, modern torque wrenches now incorporate digital technology that provides precise torque measurements, enhancing the accuracy and safety of dental implant procedures. Over the past few decades, as dental implantology has advanced, the demand for reliable torque wrenches has surged, leading to innovations in design and functionality.

As the market continues to evolve, B2B buyers must stay informed about these advancements and consider how they can leverage new technologies and sustainable practices to enhance their procurement strategies. Understanding the historical context of the products they source can provide valuable insights into future trends and opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of dental implant torque wrench

-

What key factors should I consider when vetting suppliers for dental implant torque wrenches?

When vetting suppliers, prioritize their industry experience, product quality certifications (such as ISO 13485), and customer reviews. Evaluate their manufacturing capabilities and ensure they adhere to international standards. Additionally, assess their ability to provide post-sale support and training, which is crucial for ensuring the proper use of torque wrenches in dental applications. Consider requesting references from other international buyers to gauge reliability and responsiveness. -

Can dental implant torque wrenches be customized to meet specific needs?

Yes, many suppliers offer customization options for dental implant torque wrenches, including adjustments in torque settings, handle design, and materials used. When discussing customization, clearly communicate your requirements and expectations. Ensure that the supplier can produce prototypes and validate them through testing to meet your specific application needs. This can help differentiate your offerings in competitive markets. -

What are the typical minimum order quantities (MOQs) and lead times for dental implant torque wrenches?

MOQs for dental implant torque wrenches can vary widely based on the supplier and the complexity of the product. Generally, MOQs range from 50 to 500 units. Lead times can range from 4 to 12 weeks, depending on production schedules and shipping logistics. When negotiating, clarify these terms upfront and consider potential delays in international shipping, especially during peak seasons or due to customs processes.

Illustrative Image (Source: Google Search)

-

What payment options should I expect when sourcing from international suppliers?

International suppliers typically offer various payment options, including wire transfers, letters of credit, and PayPal. It’s essential to discuss payment terms early in negotiations, including deposits and final payments. Consider using secure payment methods that offer buyer protection, especially for first-time transactions. Establishing clear payment terms can help build trust and ensure smoother transactions throughout the procurement process. -

What quality assurance processes should I look for in a supplier?

A reputable supplier should have stringent quality assurance (QA) processes in place, including regular inspections and testing of their products. Look for certifications like CE marking for European markets and compliance with FDA regulations in the U.S. Request documentation of their QA processes and any test results for the torque wrenches. This will ensure that the products meet your required standards and reduce the risk of defects. -

How can I effectively manage logistics when importing dental implant torque wrenches?

Managing logistics involves selecting reliable freight forwarders and understanding shipping terms (Incoterms). Ensure that your supplier provides clear shipping timelines and tracking information. Familiarize yourself with customs regulations in your country to avoid delays. Consider using a logistics partner experienced in medical devices to streamline the import process and handle any potential issues that may arise during transit. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Keep records of all correspondences and agreements. If resolution fails, refer to the terms outlined in your contract regarding dispute resolution processes, such as mediation or arbitration. Engaging a legal professional familiar with international trade can also provide guidance on the best course of action to protect your interests. -

Are there specific certifications or regulations I need to be aware of when sourcing dental implant torque wrenches?

Yes, specific certifications are crucial when sourcing dental implant torque wrenches, particularly in regions like Europe and North America. In Europe, ensure compliance with the Medical Devices Regulation (MDR) and obtain CE marking. In other markets, verify any local regulations or standards applicable to dental equipment. Request documentation from suppliers to confirm compliance, as this can influence your ability to market and sell the products in your region.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implant torque wrench

In conclusion, the strategic sourcing of dental implant torque wrenches is essential for international B2B buyers seeking to enhance their dental practices and ensure patient safety. Key takeaways emphasize the importance of selecting high-quality tools that meet industry standards, as well as the need for suppliers who can provide reliable support and training. Establishing partnerships with manufacturers who prioritize innovation can lead to significant long-term benefits, including improved operational efficiency and reduced costs.

Moreover, buyers from regions such as Africa, South America, the Middle East, and Europe should leverage their unique market insights to negotiate better terms and access tailored solutions. Investing in advanced torque wrench technology not only improves clinical outcomes but also positions businesses as leaders in a competitive marketplace.

As the dental industry continues to evolve, staying abreast of emerging trends and technologies will be critical. We encourage international B2B buyers to actively engage with suppliers, seek out educational resources, and participate in industry forums to ensure they are making informed sourcing decisions. The future of dental implant procedures hinges on the strategic choices made today; now is the time to act and secure the best tools for tomorrow’s success.