Introduction: Navigating the Global Market for zygomatic dental implants

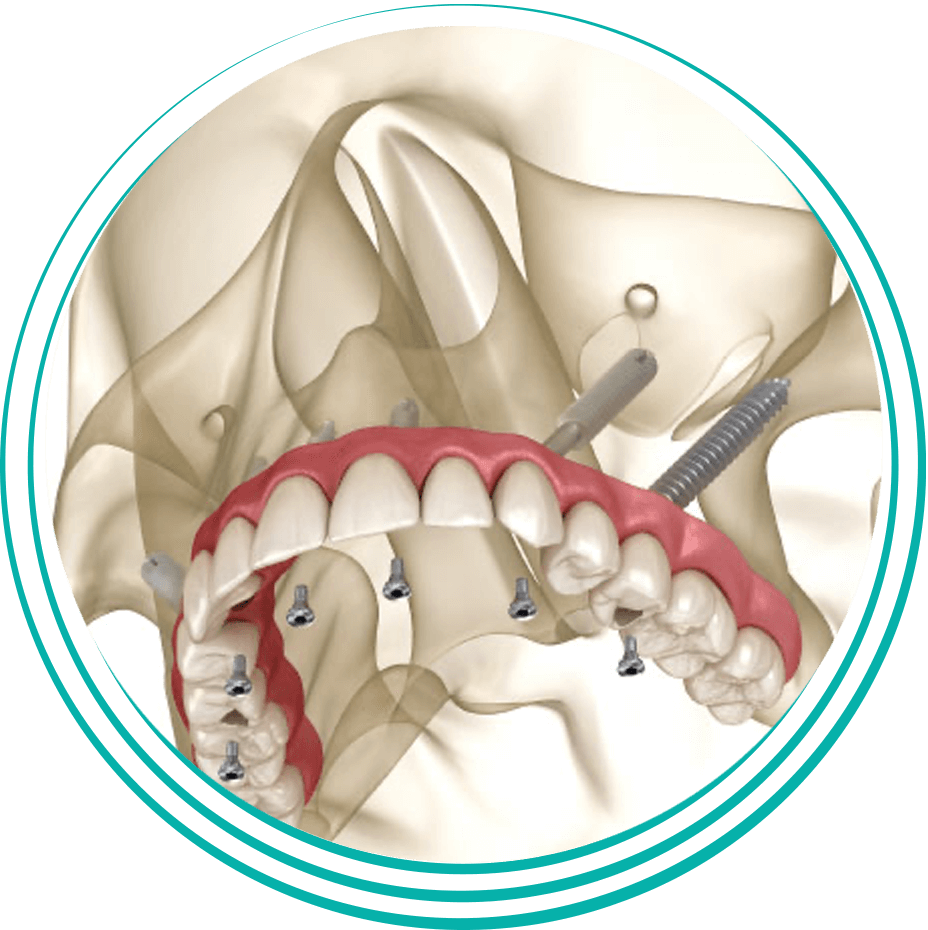

Navigating the complex landscape of zygomatic dental implants is essential for international B2B buyers seeking innovative solutions for patients with severe maxillary bone loss. These implants, which anchor securely into the zygomatic bone, offer a groundbreaking alternative to traditional implants, eliminating the need for bone grafting and significantly reducing treatment time. As a result, zygomatic implants have emerged as a critical component in the full-mouth rehabilitation toolkit, providing patients with effective restoration options that were previously unattainable.

This guide serves as a comprehensive resource, covering a wide array of topics crucial for informed decision-making. You will find detailed insights on various types of zygomatic implants, the materials used in their construction, and the quality control processes employed by leading manufacturers. We will also explore prominent suppliers, cost considerations, and market trends that impact the procurement of these innovative dental solutions.

Moreover, the guide addresses common FAQs, empowering you to navigate challenges and seize opportunities in the zygomatic implant market. Whether you are a distributor in Brazil, a dental clinic in Kenya, or a procurement officer in the Middle East, this guide equips you with the knowledge necessary to make strategic sourcing decisions that enhance patient care while optimizing your operational efficiency.

Understanding zygomatic dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Zygomatic Implants | Longer implants designed to anchor into the zygoma; typically used in severe bone loss cases. | Full-arch restorations for patients with significant maxillary atrophy. | Pros: Quick recovery, no bone grafting. Cons: Requires skilled surgical expertise. |

| Short Zygomatic Implants | Shorter than standard implants, used in cases with limited zygomatic bone height. | Suitable for patients with moderate bone loss or anatomical constraints. | Pros: Less invasive, lower risk of complications. Cons: May not provide as much stability in extreme cases. |

| Zygomatic-Implant Hybrid Systems | Combines zygomatic implants with traditional implants for enhanced stability. | Ideal for complex cases requiring a mix of support types. | Pros: Greater versatility, improved load distribution. Cons: Higher complexity and cost of treatment. |

| Immediate Load Zygomatic Implants | Allows for immediate placement of prosthetics post-surgery. | Patients needing quick restoration of function and aesthetics. | Pros: Fast results, enhanced patient satisfaction. Cons: Requires meticulous planning and execution. |

| Custom Zygomatic Implants | Tailored implants designed based on individual patient anatomy using advanced imaging. | Personalized solutions for unique anatomical challenges. | Pros: Optimized fit and function, potentially better outcomes. Cons: Increased costs and longer lead times for manufacturing. |

Standard Zygomatic Implants

Standard zygomatic implants are the most commonly used type for patients with severe maxillary bone loss. Their length allows them to anchor securely into the zygomatic bone, providing a robust foundation for dental prosthetics. B2B buyers should consider the expertise of the surgical team, as the success of these implants heavily relies on precise placement. They eliminate the need for bone grafting, making them a cost-effective solution for full-arch restorations.

Short Zygomatic Implants

Short zygomatic implants cater to patients with limited zygomatic bone height but still require substantial support. These implants are less invasive compared to their standard counterparts, reducing the risk of complications. For B2B buyers, understanding the anatomical constraints of potential patients is crucial when considering this option. While they can be a suitable solution for moderate cases, their stability may not match that of longer implants in extreme situations.

Zygomatic-Implant Hybrid Systems

Hybrid systems that combine zygomatic and traditional implants offer enhanced stability and load distribution. These systems are particularly beneficial for complex cases where a mix of support types is necessary. B2B buyers should evaluate the potential for increased treatment complexity and costs, but also recognize the value in providing versatile solutions to patients. These hybrids can lead to improved patient outcomes when designed and executed correctly.

Immediate Load Zygomatic Implants

Immediate load zygomatic implants allow for the placement of temporary prosthetics right after surgery, facilitating a quicker restoration of function and aesthetics. This type is particularly appealing for patients seeking fast results. B2B buyers must ensure that their dental teams are well-equipped and trained for meticulous planning, as the success of immediate loading depends on the quality of the surgical procedure and post-operative care.

Custom Zygomatic Implants

Custom zygomatic implants are designed using advanced imaging techniques, tailored to the unique anatomy of each patient. This personalization can lead to optimized fit and function, potentially improving surgical outcomes. B2B buyers should consider the additional costs and longer lead times associated with custom implants. However, for patients with unique anatomical challenges, the benefits of a tailored solution can justify the investment, leading to enhanced patient satisfaction and success rates.

Related Video: Zygomatic Dental Implants Procedure

Key Industrial Applications of zygomatic dental implants

| Industry/Sector | Specific Application of zygomatic dental implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Full-mouth rehabilitation for patients with severe maxillary atrophy | Expands service offerings, attracting more patients | Ensure implants are CE/FDA certified; consider training support for staff |

| Oral Surgery Centers | Immediate loading solutions for complex cases | Reduces patient waiting time, improving patient satisfaction | Verify the surgical techniques used; assess post-operative care protocols |

| Dental Laboratories | Custom prosthetics for zygomatic implants | Enhances product range, improving competitiveness | Source high-quality materials; ensure compatibility with various implant systems |

| Medical Tourism Providers | Facilitation of international patients seeking zygomatic implants | Increases revenue streams; attracts global clientele | Partner with reputable clinics; ensure compliance with local regulations |

| Insurance Companies | Coverage for zygomatic implant procedures | Expands policy offerings, catering to a broader patient base | Assess the cost-effectiveness of procedures; understand patient demographics |

Detailed Applications of Zygomatic Dental Implants

Dental Clinics

Zygomatic dental implants are increasingly used in dental clinics for full-mouth rehabilitation, particularly for patients suffering from severe maxillary atrophy. This innovative solution allows clinics to attract patients who have been previously deemed unsuitable for traditional implants. By offering zygomatic implants, clinics can enhance their service portfolio, leading to increased patient footfall and revenue. International buyers should ensure that the implants sourced are CE or FDA certified and look for suppliers that provide training support for their staff to ensure procedural success.

Oral Surgery Centers

In oral surgery centers, zygomatic implants facilitate immediate loading solutions for complex cases, significantly reducing patient waiting times. This capability not only improves operational efficiency but also enhances patient satisfaction, as individuals are able to receive prosthetics sooner. For international buyers, it is crucial to verify the surgical techniques employed by the center and to assess post-operative care protocols to ensure optimal outcomes for patients.

Dental Laboratories

Dental laboratories can leverage zygomatic implants by creating custom prosthetics tailored for these implants. This application enhances the laboratory’s product range, making it more competitive in the market. Laboratories should prioritize sourcing high-quality materials to ensure durability and aesthetics in prosthetics. Additionally, compatibility with various implant systems is essential for meeting diverse client needs, especially for international buyers who may be working with different implant brands.

Medical Tourism Providers

Medical tourism providers can capitalize on the growing demand for zygomatic implants by facilitating international patients seeking these advanced dental solutions. This application can significantly increase revenue streams while attracting a global clientele. Providers should partner with reputable dental clinics known for their expertise in zygomatic implants and ensure compliance with local regulations to provide a seamless experience for patients traveling for treatment.

Insurance Companies

Insurance companies can expand their policy offerings by including coverage for zygomatic implant procedures. This move caters to a broader patient base, especially as awareness of zygomatic implants grows. To effectively include these procedures in insurance plans, companies should assess the cost-effectiveness of the procedures and understand the demographics of patients who may seek this solution, particularly in regions with higher incidences of maxillary bone loss.

Related Video: Guided Zygomatic Implants

Strategic Material Selection Guide for zygomatic dental implants

Zygomatic dental implants are a specialized solution designed to provide stability and support for dental prosthetics in patients with severe maxillary bone loss. The selection of materials for these implants is crucial, as it directly influences performance, durability, and patient outcomes. Here, we analyze four common materials used in the manufacturing of zygomatic dental implants, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Titanium

Key Properties: Titanium is renowned for its excellent strength-to-weight ratio and biocompatibility. It exhibits high corrosion resistance, making it suitable for long-term use in the human body. Titanium implants can withstand significant mechanical loads, which is vital for zygomatic applications.

Pros & Cons: The primary advantage of titanium is its durability and ability to integrate with bone through osseointegration, leading to long-lasting results. However, titanium implants can be more expensive than other materials, and their manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Titanium’s compatibility with various media, including saliva and blood, ensures that it performs well in the oral environment. Its strength allows for immediate loading, which is beneficial for patients requiring rapid restoration.

Considerations for International Buyers: Buyers should ensure that titanium implants comply with international standards such as ASTM F136 for titanium alloys. Awareness of local regulations and certifications is essential, particularly in regions like Africa and South America, where compliance may vary.

Zirconia

Key Properties: Zirconia is a ceramic material known for its high strength and aesthetic appeal. It offers excellent fracture toughness and is highly resistant to wear and corrosion, making it suitable for dental applications.

Pros & Cons: One of the main advantages of zirconia is its tooth-like appearance, which is particularly appealing for aesthetic restorations. However, zirconia implants are generally less flexible than titanium, which can lead to brittleness in certain applications. The manufacturing process can also be more complex, potentially increasing costs.

Impact on Application: Zirconia’s compatibility with oral tissues and its resistance to staining make it an excellent choice for visible areas. However, its brittleness may limit its use in load-bearing applications unless designed correctly.

Considerations for International Buyers: Buyers should verify that zirconia implants meet standards such as ISO 13356 for zirconia ceramics. In regions like the Middle East, where aesthetic considerations are paramount, zirconia may be preferred despite its higher cost.

Cobalt-Chromium Alloys

Key Properties: Cobalt-chromium alloys are known for their high strength, wear resistance, and excellent corrosion resistance. These materials can withstand high loads, making them suitable for dental implants.

Pros & Cons: The primary advantage of cobalt-chromium alloys is their durability and ability to resist deformation under stress. However, they can be more challenging to manufacture and may have a higher cost compared to titanium. Additionally, their biocompatibility is not as well-established as titanium.

Impact on Application: Cobalt-chromium alloys are particularly effective in applications requiring high strength and resistance to wear. However, their use may be limited in patients with metal allergies.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards, such as ASTM F75 for cobalt-chromium alloys. Understanding regional preferences and regulations is crucial, especially in Europe, where stricter guidelines may apply.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties and biocompatibility. It is lightweight and resistant to chemicals and high temperatures.

Pros & Cons: The main advantage of PEEK is its flexibility and lower weight compared to metals, which can enhance patient comfort. However, it may not provide the same level of strength as titanium or cobalt-chromium alloys, which could limit its application in load-bearing situations.

Impact on Application: PEEK’s compatibility with various bodily fluids and its ability to be used in conjunction with other materials make it a versatile option. However, its lower mechanical strength may restrict its use in demanding applications.

Considerations for International Buyers: Buyers should confirm that PEEK implants meet standards such as ISO 10993 for biocompatibility. In regions like South America and Africa, where cost considerations are significant, PEEK may offer a more affordable alternative.

Summary Table

| Material | Typical Use Case for zygomatic dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Severe maxillary bone loss | Excellent strength-to-weight ratio | Higher cost, complex manufacturing | High |

| Zirconia | Aesthetic restorations | Tooth-like appearance | Brittle, higher manufacturing complexity | Med |

| Cobalt-Chromium Alloys | Load-bearing applications | High strength and wear resistance | Challenging to manufacture, biocompatibility concerns | Med |

| PEEK | Flexible applications | Lightweight and biocompatible | Lower mechanical strength | Low |

This analysis provides a comprehensive overview of the materials used in zygomatic dental implants, aiding international B2B buyers in making informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for zygomatic dental implants

Zygomatic dental implants are a specialized product that requires precise manufacturing and rigorous quality assurance to ensure their effectiveness and safety. For international B2B buyers, understanding the manufacturing processes and quality control measures is crucial for making informed purchasing decisions. Below is an overview of the manufacturing stages, key techniques, relevant international standards, quality checkpoints, testing methods, and how buyers can verify supplier quality.

Manufacturing Process of Zygomatic Dental Implants

The manufacturing process for zygomatic dental implants typically involves several key stages:

1. Material Preparation

The primary materials used in zygomatic implants are titanium and titanium alloys due to their biocompatibility, strength, and resistance to corrosion. The preparation phase includes:

– Material Sourcing: Suppliers must provide raw materials that comply with international standards for dental implants.

– Material Testing: Incoming materials undergo testing for purity, mechanical properties, and chemical composition to ensure they meet specifications.

2. Forming

The forming stage involves shaping the implant components through various techniques:

– CNC Machining: Computer Numerical Control (CNC) machines are often used to precisely cut and shape the implants from titanium rods.

– Additive Manufacturing: Some manufacturers are now employing 3D printing techniques to create complex geometries that enhance osseointegration and reduce weight.

3. Assembly

This stage involves the assembly of the implant components:

– Component Integration: If the implant design includes multiple parts (e.g., abutments), these components are assembled under sterile conditions to prevent contamination.

– Surface Treatment: Implants undergo surface modification processes such as sandblasting or acid etching to enhance their surface roughness, promoting better bone integration.

4. Finishing

Finishing processes are critical to ensure the final product meets aesthetic and functional standards:

– Polishing and Coating: The implants are polished and may receive bioactive coatings to improve integration with bone.

– Sterilization: Final products are sterilized using methods such as gamma irradiation or ethylene oxide to ensure they are safe for implantation.

Quality Assurance in Manufacturing

Quality assurance (QA) is paramount in the production of zygomatic dental implants. Manufacturers must comply with various international standards and implement stringent QC measures throughout the manufacturing process.

Relevant International Standards

- ISO 9001: This standard ensures that manufacturers adhere to quality management principles, emphasizing continuous improvement and customer satisfaction.

- ISO 13485: Specific to medical devices, this standard outlines the requirements for a quality management system that demonstrates the manufacturer’s ability to provide medical devices that consistently meet customer and regulatory requirements.

- CE Marking: In Europe, zygomatic implants must bear the CE mark, indicating compliance with EU safety, health, and environmental protection standards.

- FDA Approval: In the United States, implants must be approved by the FDA, ensuring they meet safety and effectiveness standards.

Quality Control Checkpoints

Quality control is integrated at multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected and tested upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, random samples are taken to ensure that processes are being followed correctly and that the products meet quality standards.

– Final Quality Control (FQC): Before packaging and shipment, final inspections are conducted to ensure each implant meets the established specifications and is free from defects.

Common Testing Methods

Manufacturers employ several testing methods to validate the quality and safety of zygomatic implants:

– Mechanical Testing: Implants undergo tensile, compressive, and fatigue testing to ensure they can withstand the forces experienced in the oral environment.

– Biocompatibility Testing: Various tests are conducted to assess the biological response to the implant materials, ensuring they do not cause adverse reactions in patients.

– Sterility Testing: Validation of the sterilization process is crucial, with tests performed to confirm that the implants are free of microbial contamination.

Verifying Supplier Quality

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality of suppliers is essential. Here are actionable insights:

Conducting Audits

- Supplier Audits: Buyers should conduct on-site audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Documentation Review: Request documentation of quality certifications, testing reports, and compliance with relevant standards.

Requesting Reports

- Quality Reports: Suppliers should provide detailed quality reports that outline the results of various testing methods, including mechanical and biocompatibility tests.

- Traceability Information: Ensure that suppliers can trace the materials used in the implants back to their source, which is crucial for accountability.

Third-Party Inspections

- Independent Verification: Consider using third-party inspection services to verify compliance with international standards and ensure that the manufacturing process meets the required quality benchmarks.

- Regulatory Compliance Checks: Ensure that suppliers are compliant with local regulations and international standards relevant to dental implants.

Quality Control Nuances for International Buyers

International B2B buyers must be aware of specific nuances regarding quality control when sourcing zygomatic dental implants:

– Cultural and Regulatory Differences: Be mindful of the differences in quality standards and regulations between regions. For instance, the standards in Europe may differ from those in Africa or South America.

– Logistics and Supply Chain Management: Understand the logistics involved in importing medical devices, including customs regulations and potential tariffs that may affect overall costs.

– Communication with Suppliers: Maintain clear communication with suppliers regarding quality expectations, delivery timelines, and any specific certifications required for your market.

By understanding the manufacturing processes, quality assurance measures, and how to verify supplier quality, B2B buyers can make informed decisions when sourcing zygomatic dental implants. This knowledge not only ensures compliance with international standards but also enhances patient safety and satisfaction, ultimately contributing to the success of dental practices.

Comprehensive Cost and Pricing Analysis for zygomatic dental implants Sourcing

Zygomatic dental implants represent a significant advancement in dental restoration, particularly for patients with severe bone loss. As an international B2B buyer, understanding the cost structure and pricing dynamics associated with sourcing these implants is essential for making informed procurement decisions.

Cost Components

The total cost of zygomatic dental implants can be broken down into several key components:

-

Materials: The primary materials include titanium or zirconia for the implants, which are chosen for their biocompatibility and durability. The quality of these materials can significantly affect the price.

-

Labor: Skilled labor is crucial in the surgical placement of zygomatic implants. Surgeons with specialized training command higher fees, impacting the overall cost structure.

-

Manufacturing Overhead: This encompasses costs related to production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help lower these overhead costs.

-

Tooling: The cost of tools and equipment necessary for implant production, including specialized drilling devices, contributes to the overall expense.

-

Quality Control (QC): Ensuring that each implant meets safety and quality standards requires a robust QC process. This may involve testing, certifications, and compliance with international regulations.

-

Logistics: Shipping costs, particularly for international transactions, can vary widely based on distance, mode of transport, and customs duties. Efficient logistics management is vital to minimize these costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure business sustainability. This margin can vary depending on the supplier’s market position and the complexity of the implants.

Price Influencers

Several factors influence the pricing of zygomatic dental implants:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounted pricing. Buyers should consider negotiating for bulk purchases to achieve cost savings.

-

Specifications/Customization: Customized implants designed for specific patient needs may incur additional costs. Standardized products generally offer better pricing due to lower production costs.

-

Materials: The choice of materials (e.g., titanium vs. zirconia) can significantly affect pricing. Higher-quality materials typically command higher prices but may offer better long-term performance.

-

Quality and Certifications: Implants certified by recognized organizations (e.g., CE or FDA) may be priced higher due to the assurance of quality and safety, which is crucial for patient trust.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers with a track record of success may charge premium prices, reflecting their expertise.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can help buyers manage total costs effectively, as these terms define responsibilities for shipping costs and risks.

Buyer Tips

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiate: Leverage your purchasing power by negotiating prices, especially for larger orders. Suppliers may be willing to adjust their prices to secure a deal.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership, which includes not just the purchase price but also logistics, potential tariffs, and after-sales support. This holistic view can lead to better long-term value.

-

Understand Pricing Nuances: Be aware of market fluctuations and currency exchange rates that can impact pricing. Establishing contracts in stable currencies may mitigate risks.

-

Investigate Supplier Backgrounds: Research potential suppliers thoroughly. Look for reviews, testimonials, and case studies to ensure they have a solid reputation in the industry.

-

Consider Long-Term Relationships: Building a long-term relationship with suppliers can lead to better pricing and support. Establishing trust can facilitate smoother negotiations and favorable terms in future transactions.

Disclaimer

The prices for zygomatic dental implants can vary widely based on numerous factors, including market conditions, supplier policies, and specific buyer requirements. It is advisable to conduct thorough market research and supplier comparisons to obtain the most accurate and relevant pricing information.

Spotlight on Potential zygomatic dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘zygomatic dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for zygomatic dental implants

Key Technical Properties of Zygomatic Dental Implants

Understanding the technical specifications of zygomatic dental implants is crucial for international B2B buyers, particularly those sourcing these products for dental practices or clinics. Here are essential properties to consider:

-

Material Composition

– Definition: Zygomatic implants are typically made from titanium or titanium alloys, known for their biocompatibility and strength.

– Importance: The choice of material affects the implant’s longevity and integration with bone. Titanium’s corrosion resistance and ability to support osseointegration make it the preferred choice in dental applications. -

Implant Length and Diameter

– Definition: Zygomatic implants are longer than conventional implants, often measuring between 30 to 50 mm in length, with diameters ranging from 4 to 6 mm.

– Importance: The unique dimensions allow for anchoring in the zygomatic bone, providing stability in cases of severe maxillary atrophy. Understanding these specifications helps in selecting the right implant for specific patient needs. -

Surface Treatment

– Definition: The surface of zygomatic implants may be treated with coatings or roughening to enhance osseointegration.

– Importance: Surface treatments can significantly improve the implant’s ability to bond with bone, reducing the risk of failure and enhancing long-term success rates. -

Load Capacity

– Definition: This refers to the amount of functional force the implant can withstand without failure.

– Importance: Knowledge of load capacity is essential for ensuring that the implants can support the intended prosthetic devices without risk of fracture or loosening, particularly in full-arch restorations. -

Tapered vs. Parallel Design

– Definition: Implants can be tapered or parallel in design, affecting how they fit into the bone structure.

– Importance: Tapered designs are often better for immediate loading and can accommodate varying bone densities, making them versatile for different clinical situations. -

Osseointegration Timeframe

– Definition: The duration required for the implant to securely integrate with the bone, typically ranging from 3 to 6 months.

– Importance: Understanding osseointegration timelines helps dental professionals plan treatment schedules and manage patient expectations effectively.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation within the dental implant market. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Sourcing from reputable OEMs ensures high-quality implants that meet safety and performance standards, critical for maintaining a clinic’s reputation. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers manage inventory costs and plan for future needs, especially in regions with fluctuating demand like Africa and South America. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request price quotations from suppliers.

– Importance: Utilizing RFQs enables buyers to compare prices and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, which is crucial for international transactions. -

Regulatory Compliance

– Definition: Adherence to laws and regulations governing medical devices in specific markets.

– Importance: Ensuring compliance with local and international regulations protects buyers from legal issues and enhances product safety for end-users. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Understanding lead times is essential for planning surgeries and managing patient care efficiently, especially in regions with longer shipping durations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding zygomatic dental implants, ultimately enhancing their offerings and improving patient care in their respective markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the zygomatic dental implants Sector

Market Overview & Key Trends

The zygomatic dental implants sector is witnessing robust growth, driven by increasing demand for advanced dental solutions, particularly among populations with significant maxillary bone loss. Key global drivers include the rising prevalence of dental diseases, an aging population, and a growing trend towards cosmetic dentistry. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial.

Emerging technologies such as 3D imaging and CAD/CAM systems are enhancing the precision of implant placements, while telemedicine is facilitating remote consultations and follow-ups, allowing clinics to cater to a broader clientele. Additionally, there is a notable trend towards immediate loading protocols, which significantly reduce treatment timelines and improve patient satisfaction.

Furthermore, buyers should be aware of regional differences in regulatory standards and patient preferences. For instance, while European markets may emphasize high-quality materials and advanced technology, African and South American markets may prioritize affordability and accessibility. This discrepancy presents both challenges and opportunities for suppliers, who must tailor their offerings to meet diverse needs.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the zygomatic dental implants sector, as B2B buyers increasingly prioritize environmentally friendly practices. The environmental impact of dental materials, particularly in terms of production and disposal, is under scrutiny. Suppliers that adopt sustainable practices not only contribute to environmental conservation but also enhance their brand reputation and appeal to ethically-minded buyers.

Illustrative Image (Source: Google Search)

The importance of ethical supply chains cannot be overstated. Buyers should seek manufacturers that adhere to strict ethical standards, ensuring fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a company’s commitment to sustainability.

Moreover, the use of biocompatible and recyclable materials in zygomatic implants is gaining traction. Suppliers that can demonstrate the use of ‘green’ materials not only comply with regulatory requirements but also cater to a growing market segment that values sustainability. Engaging in transparent communication about sourcing practices will build trust and loyalty among international buyers.

Brief Evolution/History

Zygomatic implants were first introduced in the late 1980s by Professor Per-Ingvar Brånemark, revolutionizing the field of dental implantology. Originally designed for patients with maxillary defects due to trauma or congenital issues, advancements in technology and surgical techniques have broadened their application. Today, zygomatic implants are recognized as a reliable solution for patients with severe bone loss, eliminating the need for bone grafting and enabling immediate loading of prosthetics. This evolution has not only improved patient outcomes but has also opened new avenues for international B2B partnerships in the dental sector.

Frequently Asked Questions (FAQs) for B2B Buyers of zygomatic dental implants

-

What criteria should I use to vet suppliers of zygomatic dental implants?

When vetting suppliers, focus on their industry experience, product certifications (such as CE or FDA), and client testimonials. Verify their manufacturing processes to ensure they adhere to international quality standards. Additionally, consider their reputation in the market, including any partnerships with dental professionals or institutions. Request samples to evaluate product quality and ensure that they can meet your specific needs, including customization options. -

Can zygomatic dental implants be customized for specific patient needs?

Yes, many suppliers offer customization options for zygomatic dental implants, including variations in size, shape, and surface treatment. This customization is essential to ensure the implants fit the unique anatomical requirements of patients. When sourcing implants, inquire about the supplier’s capability to provide tailored solutions and their process for collaborating with dental professionals to achieve optimal results. -

What are the typical minimum order quantities (MOQ) and lead times for zygomatic dental implants?

MOQs can vary significantly by supplier, typically ranging from 10 to 50 units per order. Lead times for production and delivery may also differ, generally falling between 4 to 12 weeks. It’s crucial to discuss your specific needs with the supplier, especially if you’re operating in regions with varying demand. Establishing a clear timeline will help ensure you have the necessary stock when required. -

What payment terms are commonly offered for international purchases of zygomatic dental implants?

Payment terms can vary, but common options include upfront payments, partial payments upon order confirmation, and balance payments upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while also ensuring supplier reliability. Additionally, consider using secure payment methods or letters of credit to mitigate risks associated with international transactions. -

How can I ensure the quality and safety of zygomatic dental implants?

To ensure quality, request certificates of conformity, such as ISO certifications, and inquire about the supplier’s quality assurance processes. Ask for documentation that demonstrates compliance with international standards. Regular audits of suppliers can also help maintain quality assurance. Furthermore, consider collaborating with suppliers that have established reputations for providing reliable products.

Illustrative Image (Source: Google Search)

-

What logistical considerations should I keep in mind when importing zygomatic dental implants?

When importing zygomatic dental implants, consider shipping methods, customs regulations, and potential tariffs. Work with experienced logistics partners who understand the medical device importation process to avoid delays. Ensure that all necessary documentation, including import permits and product certifications, is in order to facilitate smooth customs clearance. -

How should disputes regarding zygomatic dental implant orders be resolved?

To effectively resolve disputes, establish clear terms in your purchase agreement, including return policies and warranty conditions. Consider including a mediation clause that outlines the steps to resolve disagreements amicably. If disputes arise, maintain open communication with the supplier to negotiate a solution. If necessary, seek legal advice to understand your rights and obligations under international trade laws. -

What are the trends influencing the zygomatic dental implant market globally?

Current trends include the increasing demand for minimally invasive procedures and advancements in implant technology. There is also a growing focus on biocompatible materials and personalized dental solutions. Additionally, the expansion of dental tourism in regions like Turkey and Brazil is making high-quality zygomatic implants more accessible. Staying informed about these trends can help you make strategic sourcing decisions and align with market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zygomatic dental implants

Zygomatic dental implants present a transformative opportunity for dental professionals and B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. The ability to provide solutions for patients with severe bone loss without the need for invasive bone grafting not only enhances patient outcomes but also streamlines the treatment process.

Key Takeaways:

- Minimized Treatment Time: Zygomatic implants allow for immediate loading and quicker recovery, making them a desirable option for clinics aiming to optimize patient throughput.

- Market Demand: As awareness of these implants grows, so does the potential for increased demand, particularly in regions with high instances of dental issues related to bone loss.

- Strategic Sourcing: Partnering with reputable manufacturers like Nobel Biocare and Straumann ensures quality and reliability, vital for maintaining a competitive edge.

As the global dental landscape evolves, embracing zygomatic implants can position your practice at the forefront of innovation. Take action now by exploring partnerships and training opportunities to enhance your offerings. By doing so, you can not only meet but exceed the needs of your patients, paving the way for a successful and sustainable future in dental care.