Introduction: Navigating the Global Market for dental implant healing cap

In the rapidly evolving landscape of dental care, the dental implant healing cap stands as a pivotal component in ensuring successful implant procedures and optimal patient outcomes. With an estimated market value poised to reach $2.8 billion by 2033, driven by increasing tooth loss and advancements in implant technology, understanding the nuances of this product is crucial for B2B buyers. Healing caps not only facilitate the healing process but also play a significant role in the overall aesthetic and functional success of dental implants.

This guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe, with comprehensive insights into the dental implant healing cap market. We delve into various types and materials available, including metal and biocompatible plastic options, and explore the intricacies of manufacturing and quality control processes that ensure product reliability. Additionally, we provide a thorough overview of suppliers and cost considerations, empowering buyers to make informed sourcing decisions.

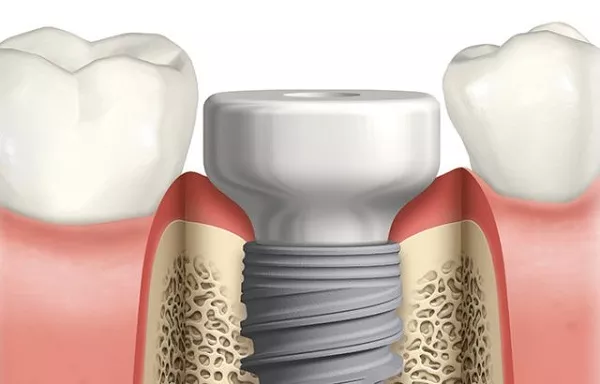

Illustrative Image (Source: Google Search)

Furthermore, this guide addresses common FAQs, enhancing your understanding of market dynamics and product specifications. By leveraging the insights provided, B2B buyers can navigate the complexities of the global market with confidence, ensuring they select the best solutions that meet the needs of their dental practices and patients alike.

Understanding dental implant healing cap Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Healing Caps | Durable, strong, and typically made from titanium | Hospitals, specialty clinics | Pros: Cost-effective, strong. Cons: Less aesthetic appeal. |

| Plastic Healing Caps | Made from biocompatible materials like PEEK | Dental laboratories, private practices | Pros: Aesthetic, lightweight. Cons: Less durable than metal. |

| Customized Healing Caps | Tailored using CAD/CAM technology | Specialty clinics, dental labs | Pros: Enhanced comfort, precise fit. Cons: Higher cost, longer lead time. |

| Antimicrobial Healing Caps | Incorporate antimicrobial agents | Hospitals, specialty clinics | Pros: Reduced infection risk, improved healing. Cons: Limited availability. |

| Temporary Healing Caps | Designed for short-term use during healing | General dental practices | Pros: Easy to replace, cost-effective. Cons: Not suitable for long-term use. |

Metal Healing Caps

Metal healing caps, primarily composed of titanium, are the most prevalent type due to their durability and strength. They are ideal for hospitals and specialty clinics where robust solutions are essential. When considering metal caps, buyers should evaluate their cost-effectiveness and longevity, though they may lack aesthetic appeal compared to plastic options. The primary B2B purchasing consideration is the balance between durability and patient comfort.

Plastic Healing Caps

Plastic healing caps, often made from materials like PEEK, are gaining traction for their biocompatibility and aesthetic qualities. These caps are particularly suitable for dental laboratories and private practices that prioritize patient comfort and appearance. While they offer a lightweight alternative, buyers should be aware of their lower durability compared to metal caps. Key purchasing considerations include material properties and the specific needs of the patient demographic.

Customized Healing Caps

Customized healing caps utilize advanced CAD/CAM technology to create precisely fitting solutions tailored to individual patient needs. They are primarily used in specialty clinics and dental labs where personalized care is paramount. Although they provide enhanced comfort and reduced complications, the costs can be significantly higher, and lead times may be longer. B2B buyers should weigh the benefits of customization against budget constraints and operational timelines.

Antimicrobial Healing Caps

Antimicrobial healing caps are designed to minimize infection risks during the healing process by incorporating antimicrobial agents. These caps are particularly valuable in hospitals and specialty clinics where infection control is critical. While they offer significant advantages in terms of improved healing outcomes, their availability may be limited. Buyers need to consider the regulatory compliance of these products and their potential impact on patient recovery times.

Temporary Healing Caps

Temporary healing caps are designed for short-term use during the initial healing phase of dental implants. These caps are commonly used in general dental practices due to their ease of replacement and cost-effectiveness. However, they are not suitable for long-term applications. B2B buyers should assess the specific healing timelines of their patients to determine the appropriate use of temporary caps, ensuring they align with overall treatment plans.

Related Video: Dental Implant Healing Cap Placement Part 6 | Dr. John Paul Gallardo | Miami, FL

Key Industrial Applications of dental implant healing cap

| Industry/Sector | Specific Application of dental implant healing cap | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Used during the healing phase post-implantation | Enhances patient recovery and satisfaction, leading to repeat business and referrals | Quality certifications (e.g., CE Mark), material biocompatibility, and cost-effectiveness |

| Hospitals | Employed in surgical procedures involving implants | Reduces the risk of complications, improving patient outcomes and hospital ratings | Compliance with medical regulations, bulk purchasing options, and reliable delivery times |

| Dental Laboratories | Utilized for customizing implant solutions | Enables tailored solutions for specific patient needs, fostering client loyalty | Access to advanced manufacturing technologies (e.g., CAD/CAM), material specifications, and innovation capabilities |

| Specialty Dental Practices | Integrated in minimally invasive surgeries | Facilitates faster recovery times, attracting more patients seeking advanced care | Training and support for staff on product use, along with ongoing product updates |

| Research Institutions | Used in clinical studies to evaluate new materials | Contributes to advancements in dental implant technology, enhancing institutional reputation | Availability of prototypes, research partnerships, and adherence to ethical standards |

Dental Clinics

In dental clinics, healing caps are critical during the post-implantation phase. They protect the implant site, allowing for optimal healing while preventing complications such as infections. For international B2B buyers, particularly in regions like Africa and South America, sourcing high-quality healing caps that meet local regulatory standards is essential. Buyers should prioritize products with strong biocompatibility and certifications, as these factors directly influence patient satisfaction and clinic reputation.

Hospitals

Hospitals utilize dental implant healing caps in surgical procedures to ensure effective healing. By minimizing the risk of complications, these caps can significantly enhance patient outcomes, which is vital for maintaining high hospital ratings. B2B buyers in the Middle East and Europe should consider sourcing from suppliers who offer reliable delivery and compliance with stringent medical regulations. This ensures that hospitals can maintain high standards of care without facing supply chain disruptions.

Dental Laboratories

Dental laboratories rely on healing caps to create customized implant solutions for various patient needs. The ability to tailor these caps enhances the laboratory’s offerings, leading to increased client loyalty. Buyers from Europe and South America should focus on suppliers that leverage advanced manufacturing technologies, such as CAD/CAM systems, to ensure precision and quality. Material specifications and innovation capabilities are also crucial to meet diverse client requirements.

Specialty Dental Practices

Specialty dental practices incorporate healing caps in minimally invasive surgeries, which have become increasingly popular among patients seeking quicker recovery times. These practices can attract more patients by offering advanced care solutions. B2B buyers should ensure that their suppliers provide adequate training and ongoing support to staff on the use of these products, as well as regular updates on innovations in healing cap technology to stay competitive in the market.

Research Institutions

Research institutions use dental implant healing caps in clinical studies to evaluate new materials and techniques. This application not only contributes to advancements in dental implant technology but also enhances the institution’s reputation as a leader in dental research. For international buyers, securing prototypes and establishing research partnerships are vital for successful outcomes. Adherence to ethical standards in sourcing and usage is also essential in maintaining credibility within the academic community.

Related Video: Dental Cap Procedure — Tooth Caps

Strategic Material Selection Guide for dental implant healing cap

When selecting materials for dental implant healing caps, it’s essential to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. Here, we analyze four common materials used in the manufacturing of healing caps: titanium alloys, PEEK (Polyether Ether Ketone), stainless steel, and biocompatible plastics.

Titanium Alloys

Key Properties: Titanium alloys are known for their excellent strength-to-weight ratio, high corrosion resistance, and biocompatibility. They can withstand high temperatures and pressures, making them suitable for various dental applications.

Pros & Cons: The durability of titanium alloys makes them a preferred choice for healing caps. They are relatively expensive compared to other materials, which can affect overall product pricing. Manufacturing complexity is moderate, as titanium requires specialized machining and processing techniques. Their suitability for end products is high due to their proven track record in dental applications.

Impact on Application: Titanium alloys are compatible with a wide range of dental implant systems and promote osseointegration, which is crucial for successful implant procedures.

Specific Considerations for International Buyers: Compliance with standards such as ASTM F136 for titanium alloys is essential. Buyers from regions like Europe and the Middle East should ensure that products meet CE Mark requirements. In Africa and South America, awareness of local regulations is crucial to avoid compliance issues.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance thermoplastic known for its excellent mechanical properties, chemical resistance, and biocompatibility. It can operate effectively in high-temperature environments.

Pros & Cons: PEEK offers a unique combination of durability and flexibility, making it suitable for customized healing caps. While it is generally less expensive than titanium, its manufacturing can be complex due to the need for advanced processing techniques. PEEK is highly suitable for aesthetic applications due to its tooth-like color.

Impact on Application: PEEK’s chemical resistance ensures compatibility with various dental materials and media, reducing the risk of adverse reactions.

Specific Considerations for International Buyers: Buyers should look for compliance with ISO 10993 for biocompatibility. In regions like Europe, adherence to the REACH regulation is critical. Buyers in Africa and South America may benefit from understanding local material sourcing capabilities.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and affordability. It can withstand significant mechanical stress and is relatively easy to fabricate.

Pros & Cons: The cost-effectiveness of stainless steel makes it a popular choice for healing caps. However, its lower biocompatibility compared to titanium and PEEK can be a drawback. Manufacturing is straightforward, which can lead to faster production times.

Impact on Application: Stainless steel is suitable for temporary healing caps but may not be ideal for long-term applications due to potential corrosion and bioactivity issues.

Specific Considerations for International Buyers: Compliance with ASTM F899 is necessary for stainless steel products. Buyers in Europe should ensure that products meet the CE Mark standards, while those in Africa and South America should verify local regulations regarding medical devices.

Biocompatible Plastics

Key Properties: Biocompatible plastics, such as polycarbonate and polyamide, offer good mechanical properties and are lightweight. They are designed to minimize adverse biological reactions.

Pros & Cons: These materials are generally less expensive and easier to manufacture than metals. However, they may not offer the same durability and long-term stability as titanium or PEEK. Their suitability for aesthetic applications is high, as they can be produced in various colors.

Impact on Application: Biocompatible plastics are ideal for short-term healing caps and can be used in combination with other materials for enhanced performance.

Specific Considerations for International Buyers: Buyers should ensure compliance with relevant standards, such as ISO 10993 for biocompatibility. In Europe, adherence to the CE Mark is essential, while buyers in Africa and South America should be aware of local certification requirements.

Summary Table

| Material | Typical Use Case for dental implant healing cap | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium Alloys | Long-term healing caps | Excellent strength and biocompatibility | High cost and complex manufacturing | High |

| PEEK | Customized healing caps | Durable and flexible | Complex manufacturing processes | Medium |

| Stainless Steel | Temporary healing caps | Cost-effective and easy to fabricate | Lower biocompatibility and corrosion risk | Low |

| Biocompatible Plastics | Short-term healing caps | Lightweight and inexpensive | Lower durability compared to metals | Low |

This analysis provides valuable insights for international B2B buyers, helping them make informed decisions regarding material selection for dental implant healing caps based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implant healing cap

The manufacturing of dental implant healing caps involves several critical stages, each designed to ensure that the final product meets the stringent requirements of safety, efficacy, and patient comfort. For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

Manufacturing Process Overview

The manufacturing process for dental implant healing caps can be broadly divided into four main stages:

1. Material Preparation

The first step involves selecting the appropriate materials, typically metals like titanium or polymers such as PEEK (Polyether Ether Ketone). The choice of material is crucial, as it affects both the biocompatibility and durability of the healing cap.

- Material Selection: Metals are favored for their strength, while plastics are increasingly popular for their lightweight and biocompatibility.

- Pre-treatment Processes: Materials may undergo cleaning, sterilization, and surface treatment to enhance adhesion and biocompatibility.

2. Forming

Once materials are prepared, they are shaped into the desired form using various techniques:

- Machining: Traditional methods such as CNC machining are used to achieve precise dimensions and tolerances.

- Injection Molding: Commonly used for plastic caps, this process allows for high-volume production and intricate designs.

- 3D Printing: This innovative technique is gaining traction for custom or complex geometries, offering significant advantages in personalization and rapid prototyping.

3. Assembly

After forming, the components of the healing cap are assembled. This may include attaching any internal mechanisms or features that enhance functionality.

- Automated Assembly: Utilizing robotic systems can improve efficiency and consistency in the assembly process.

- Manual Assembly: In cases requiring precision, skilled technicians may perform assembly to ensure quality.

4. Finishing

The final stage involves surface finishing and quality checks to ensure that the caps meet industry standards.

- Surface Treatments: Techniques such as anodizing or coating may be applied to enhance corrosion resistance or improve aesthetics.

- Final Inspection: Each healing cap undergoes a thorough inspection to ensure compliance with specifications.

Quality Assurance Practices

Quality assurance is a critical aspect of manufacturing dental implant healing caps, ensuring that products are safe, effective, and compliant with international standards.

Relevant International Standards

B2B buyers should be aware of the following quality standards applicable to dental implant healing caps:

- ISO 9001: This international standard specifies requirements for a quality management system (QMS) and is fundamental for manufacturers seeking to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- FDA Regulations: For markets in the United States, compliance with FDA standards is crucial, particularly for medical devices.

Quality Control Checkpoints

Quality control (QC) checkpoints should be integrated throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive testing of the finished product before it is packaged and shipped.

Common Testing Methods

Various testing methods are employed to validate the quality and performance of dental implant healing caps:

- Mechanical Testing: Assessing tensile strength, fatigue resistance, and hardness.

- Biocompatibility Testing: Ensuring that materials do not elicit an adverse reaction in biological tissues.

- Sterility Testing: Confirming that the product is free from viable microorganisms.

Verifying Supplier Quality Control

For B2B buyers, particularly those in emerging markets, verifying the quality control processes of suppliers is essential to ensure product reliability. Here are some actionable steps:

- Conduct Audits: Regular audits of supplier facilities can help assess their compliance with quality standards and operational practices.

- Request Quality Reports: Suppliers should provide documentation detailing their QC processes, including test results and compliance certifications.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased evaluation of a supplier’s manufacturing processes and quality assurance practices.

Quality Control and Certification Nuances

Understanding the nuances of quality control and certification is vital for international B2B buyers. Here are key considerations:

- Regulatory Differences: Compliance requirements can vary significantly between regions. For example, while the CE mark is essential for European markets, the FDA’s premarket approval is critical for the U.S. market.

- Cultural and Economic Factors: Buyers from Africa and South America may encounter different challenges, such as varying levels of regulatory enforcement and market maturity, which can affect supplier reliability.

- Documentation and Traceability: Ensure that suppliers maintain comprehensive documentation and traceability for all products, facilitating accountability and compliance with international standards.

Conclusion

The manufacturing processes and quality assurance for dental implant healing caps are complex and multifaceted, emphasizing the importance of selecting reliable suppliers who adhere to stringent quality standards. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, a thorough understanding of these processes will help ensure the procurement of high-quality products that meet the needs of dental professionals and their patients. By focusing on material selection, manufacturing techniques, and robust quality assurance practices, buyers can make informed decisions that align with their operational goals and regulatory requirements.

Comprehensive Cost and Pricing Analysis for dental implant healing cap Sourcing

The B2B cost structure and pricing analysis for dental implant healing caps are crucial for international buyers, particularly those from Africa, South America, the Middle East, and Europe. Understanding these components will aid in making informed sourcing decisions.

Cost Components

-

Materials:

– The choice of materials significantly influences the overall cost. Metal healing caps, typically made from titanium or alloys, are favored for their durability but come at a higher price point. Plastic options, such as PEEK, offer biocompatibility and lower costs, making them an attractive alternative. -

Labor:

– Labor costs can vary widely based on the manufacturing location. Regions with higher labor costs may impact the price of healing caps, while lower-cost regions may offer competitive pricing but could raise concerns about quality. -

Manufacturing Overhead:

– This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help lower overhead, thus reducing the final price of the healing caps. -

Tooling:

– Initial investment in tooling is necessary for producing customized or specialized caps. This upfront cost can be amortized over larger production runs, making it more economical for bulk orders.

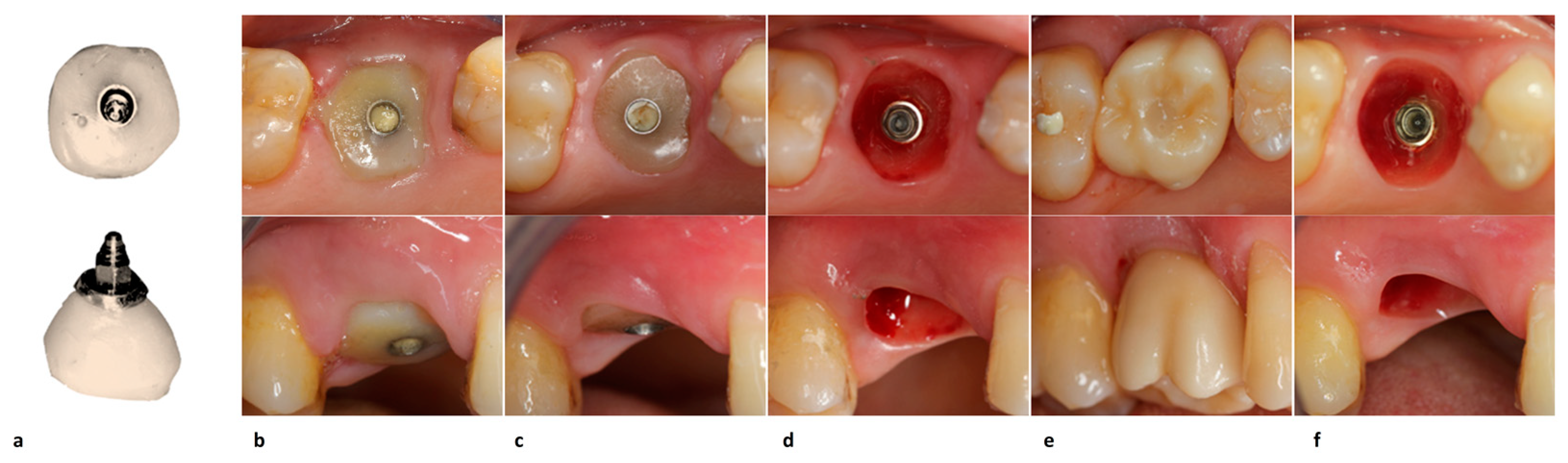

Illustrative Image (Source: Google Search)

-

Quality Control (QC):

– Stringent quality control processes are essential, especially for medical devices. The costs associated with QC can add to the overall price but are necessary to ensure compliance with regulatory standards. -

Logistics:

– Shipping and handling costs can significantly affect pricing, especially for international transactions. Factors like distance, shipping method, and local tariffs play a critical role in determining logistics expenses. -

Margin:

– Suppliers will factor in their desired profit margin, which varies depending on market conditions and competition. Understanding typical margins in the industry can help buyers negotiate better deals.

Price Influencers

- Volume/MOQ:

-

Ordering in larger quantities often leads to significant discounts. Suppliers may have a minimum order quantity (MOQ), which should be considered when planning purchases.

-

Specifications/Customization:

-

Custom specifications can increase costs due to the need for specialized manufacturing processes. However, customized solutions can enhance patient outcomes and satisfaction.

-

Materials and Quality/Certifications:

-

Higher-quality materials and certifications can lead to increased costs but are crucial for ensuring product reliability and compliance with health regulations.

-

Supplier Factors:

-

The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms:

- Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers in shipping and delivery, directly impacting the overall cost.

Buyer Tips

- Negotiation:

-

Engage suppliers in discussions about pricing, especially when placing large orders. Leverage relationships and past purchases to negotiate better terms.

-

Cost-Efficiency:

-

Consider the Total Cost of Ownership (TCO), which includes purchase price, shipping, handling, and potential costs associated with product failure or replacements.

-

Pricing Nuances:

-

International buyers should be aware of currency fluctuations, import duties, and local taxes that can affect the final cost.

-

Market Research:

- Conduct thorough research on different suppliers and their offerings. Compare prices, quality, and delivery times to make an informed decision.

Disclaimer

Prices for dental implant healing caps can vary widely based on the factors outlined above. Buyers should always seek multiple quotes and consider both direct and indirect costs when making sourcing decisions.

Spotlight on Potential dental implant healing cap Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dental implant healing cap’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dental implant healing cap

To successfully navigate the dental implant healing cap market, international B2B buyers must understand essential technical properties and common trade terminology. This knowledge is crucial for making informed purchasing decisions, ensuring compliance, and maximizing the effectiveness of the products they procure.

Essential Technical Properties

-

Material Grade

– Dental implant healing caps are primarily made from materials such as titanium, PEEK (Polyether Ether Ketone), and various polymers. Titanium is favored for its strength and biocompatibility, while PEEK offers excellent mechanical properties and comfort. Understanding material grades helps buyers choose products that meet specific regulatory standards and patient needs. -

Tolerance

– Tolerance refers to the allowable deviation in dimensions during manufacturing. For healing caps, precise tolerances ensure that the caps fit securely on implants, minimizing the risk of complications. Buyers should prioritize suppliers that adhere to stringent tolerances to enhance patient outcomes and reduce the need for adjustments. -

Surface Treatment

– The surface treatment of healing caps plays a significant role in osseointegration—the process by which the implant integrates with the surrounding bone. Treatments may include anodization or coatings that promote cell attachment and reduce infection risk. Buyers should seek detailed information on surface treatments to ensure they are selecting products that enhance healing. -

Sterilization Standards

– Healing caps must be sterilized before use to prevent infections. Understanding the sterilization methods (such as gamma radiation or ethylene oxide) and their respective standards is vital for buyers to ensure compliance with health regulations and to maintain patient safety. -

Design Features

– Innovative design features, such as antimicrobial properties or ergonomic shapes, can significantly impact the usability and effectiveness of healing caps. Buyers should evaluate these features as they can enhance patient comfort and healing times, which are critical for successful dental procedures.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components or products that are then marketed and sold by another company under its brand name. Understanding the OEM landscape can help buyers identify reputable suppliers and assess product quality. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for inventory management and cost control, especially when dealing with specialized products like healing caps. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers to request pricing and other information for specific products. Buyers should utilize RFQs to compare multiple suppliers, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized trade terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps buyers understand shipping costs, risk management, and logistical responsibilities. -

CE Mark

– The CE Mark indicates that a product meets European health, safety, and environmental protection standards. For buyers in Europe, verifying the CE Mark on healing caps is essential for regulatory compliance and market access. -

Biocompatibility

– Biocompatibility refers to the ability of a material to perform with an appropriate host response when applied in a medical context. For healing caps, biocompatibility is critical to ensure patient safety and reduce the risk of adverse reactions. Buyers should prioritize products that have documented biocompatibility testing.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ultimately improve patient care in the dental implant sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implant healing cap Sector

The dental implant healing cap market is poised for significant growth, driven by a variety of global factors. With the increasing prevalence of tooth loss, particularly among aging populations, the demand for dental implants is rising. Technological advancements in implant design and materials are enhancing the effectiveness and comfort of healing caps, which facilitate the healing process post-implantation. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Key Trends Influencing the Market:

-

Technological Innovation: The integration of CAD/CAM technology allows for the production of customized healing caps, improving fit and comfort for patients. This trend is particularly relevant for dental practices looking to offer personalized solutions.

-

Materials Development: While metal healing caps remain dominant due to their durability, the growing preference for biocompatible plastic materials, such as PEEK, is noteworthy. These materials not only enhance comfort but also reduce the risk of adverse reactions.

-

Minimally Invasive Techniques: There is a rising trend toward minimally invasive dental procedures, which often utilize advanced healing caps. This shift is crucial for clinics aiming to attract patients seeking less painful and quicker recovery options.

-

Global Market Dynamics: North America and Europe currently lead in market share, but the Asia-Pacific region is rapidly expanding due to increased dental awareness and rising disposable incomes. B2B buyers should consider emerging markets as potential sources for both supplies and partnerships.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a key consideration in the dental implant healing cap sector. The environmental impact of manufacturing processes, including waste generation and resource depletion, has prompted many buyers to seek out eco-friendly alternatives. Ethical sourcing practices are not only beneficial for the planet but also enhance brand reputation and customer loyalty.

Importance of Ethical Supply Chains:

-

Transparency: Buyers are increasingly prioritizing suppliers that provide transparency regarding their sourcing practices and the environmental impact of their products.

-

Certifications: Look for suppliers with ‘green’ certifications, such as ISO 14001, which signify adherence to environmental management standards. These certifications can be pivotal in making informed purchasing decisions.

-

Biocompatible Materials: The shift toward biocompatible and recyclable materials is gaining momentum. Materials that are both effective and sustainable can provide a competitive edge in the market.

Brief Evolution/History

The dental implant healing cap has evolved significantly since its inception. Initially, healing caps were rudimentary, primarily serving a protective function during the osseointegration process. Over the years, advancements in materials science and design have transformed healing caps into sophisticated devices that enhance patient comfort, reduce healing times, and minimize complications. Today’s healing caps are designed with both functionality and aesthetics in mind, reflecting the broader trends in dental care towards personalized and patient-centered solutions. For B2B buyers, understanding this evolution is essential for making informed sourcing decisions that align with contemporary market demands.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Frequently Asked Questions (FAQs) for B2B Buyers of dental implant healing cap

-

What key factors should I consider when vetting suppliers for dental implant healing caps?

When vetting suppliers, prioritize their certifications (e.g., ISO, CE Mark), which demonstrate compliance with international quality standards. Investigate their manufacturing capabilities, including technology and materials used, to ensure they can meet your specifications. Assess their reputation through customer reviews and industry references. Additionally, inquire about their experience in exporting to your region, as familiarity with local regulations and customs can facilitate smoother transactions. -

Can I customize dental implant healing caps to meet specific requirements?

Yes, many manufacturers offer customization options for dental implant healing caps. This can include variations in size, material (metal or plastic), and design features that enhance patient comfort or biocompatibility. Discuss your specific needs with potential suppliers to understand their capabilities and the extent of customization they can provide. Ensure that the customization process aligns with your project timelines and budget. -

What are the typical minimum order quantities (MOQs) and lead times for dental implant healing caps?

MOQs for dental implant healing caps can vary significantly based on the supplier and the level of customization required. Generally, you might expect MOQs to range from 100 to 1,000 units. Lead times can also vary; standard orders may take 4-6 weeks, while customized products could extend to 8-12 weeks. Always confirm these details with your supplier early in the negotiation process to align with your inventory needs. -

What payment options are commonly available when sourcing dental implant healing caps internationally?

Most suppliers offer several payment options, including bank transfers, letters of credit, and PayPal. It’s essential to clarify payment terms upfront, including deposits required before production and the timeline for final payments. Be aware of any potential currency exchange risks if you’re dealing with international suppliers. Establishing clear payment terms can help prevent disputes later in the transaction. -

How can I ensure quality assurance (QA) and certifications for the products I source?

To ensure quality assurance, request detailed documentation from suppliers regarding their quality control processes and any relevant certifications (like ISO 13485 for medical devices). It’s beneficial to conduct on-site inspections or third-party audits to verify compliance with production standards. Additionally, ask about their policies on product testing and how they handle defective items to safeguard your investment. -

What logistics considerations should I keep in mind when importing dental implant healing caps?

Logistics is crucial when importing dental implant healing caps. Consider the shipping methods (air vs. sea freight) based on urgency and cost. Evaluate the supplier’s ability to handle customs documentation and compliance with import regulations in your country. Additionally, factor in potential import duties and taxes, which can affect overall costs. Building a relationship with a reliable freight forwarder can streamline the logistics process. -

What should I do in case of a dispute with my supplier?

In case of a dispute, start by reviewing the contract terms to clarify the obligations of both parties. Communicate directly with the supplier to address the issue and seek a resolution amicably. If the dispute escalates, consider involving a third-party mediator to facilitate discussions. Having clear contracts that outline dispute resolution processes can significantly aid in resolving issues efficiently. -

What emerging trends should I be aware of in the dental implant healing cap market?

Emerging trends in the dental implant healing cap market include the increasing demand for biocompatible materials and the integration of antimicrobial properties to enhance patient safety. There is also a growing preference for customized solutions made possible by advancements in CAD/CAM technology. Staying informed about these trends can help you align your sourcing strategies with market demands and offer competitive solutions to your clients.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implant healing cap

The dental implant healing cap market is poised for significant growth, driven by rising global demand for dental solutions and technological advancements. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing is essential. Key takeaways include the importance of understanding market dynamics, including the dominance of metal caps and the rising popularity of biocompatible materials like PEEK. Buyers should prioritize suppliers that demonstrate innovation and compliance with international regulatory standards to ensure product quality and safety.

Investing in partnerships with manufacturers that leverage digital technologies, such as CAD/CAM systems, can enhance customization and patient satisfaction. Moreover, as the market evolves, the integration of antimicrobial properties in healing caps will become increasingly vital in preventing complications, offering further value to end-users.

Looking ahead, the potential for market expansion in emerging regions highlights the need for proactive sourcing strategies. B2B buyers should remain vigilant and adaptable, seeking out innovative solutions and reliable suppliers to stay competitive in this dynamic landscape. Engage with industry experts and participate in relevant trade shows to foster connections that can lead to fruitful partnerships and growth opportunities.