Introduction: Navigating the Global Market for difference between dental implants and dentures

In the rapidly evolving global dental market, the distinction between dental implants and dentures is not merely academic; it is a critical factor influencing the decisions of B2B buyers. Understanding these two solutions is essential for dental suppliers, clinics, and manufacturers looking to meet the diverse needs of patients across continents, particularly in regions like Africa, South America, the Middle East, and Europe. Each option presents unique benefits, challenges, and market dynamics that can significantly impact sourcing decisions and patient satisfaction.

This guide delves into the comprehensive differences between dental implants and dentures, exploring various types, materials, manufacturing processes, quality control measures, and supplier landscapes. Buyers will gain insights into the cost implications associated with each solution, enabling them to make informed decisions that align with budgetary constraints while ensuring high standards of care.

Additionally, the guide addresses frequently asked questions that often arise during the sourcing process, offering clarity and confidence to international buyers. By empowering stakeholders with actionable insights, this resource aims to facilitate strategic partnerships and enhance competitive advantage in the global dental marketplace. Whether you are sourcing in Nigeria, Mexico, or elsewhere, understanding these fundamental differences will enable you to navigate the complexities of dental procurement with greater ease and efficacy.

Understanding difference between dental implants and dentures Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dental Implants | Titanium posts surgically placed in the jawbone. | Long-term tooth replacement solutions. | Pros: Durable, natural appearance. Cons: Higher initial cost, requires surgery. |

| Complete Dentures | Removable prosthetics covering entire arch. | Immediate tooth loss solutions. | Pros: Lower cost, non-invasive. Cons: Less stability, may require frequent adjustments. |

| Partial Dentures | Removable devices for patients with some natural teeth. | Cost-effective solution for tooth gaps. | Pros: Affordable, easy to adjust. Cons: Less stable than implants, may affect speech. |

| All-on-4 Implants | Fixed implant-supported prosthesis using 4 implants. | Comprehensive solution for edentulous patients. | Pros: Quick recovery, fixed solution. Cons: Higher upfront investment, surgical risks. |

| Snap-In Dentures | Dentures that clip onto implants for stability. | Hybrid approach for improved comfort. | Pros: Better stability than traditional dentures. Cons: Requires implants, higher cost than standard dentures. |

Dental Implants

Dental implants are titanium posts that are surgically inserted into the jawbone, serving as artificial tooth roots. They are ideal for buyers looking for a long-term solution to tooth loss, particularly in markets where durability and aesthetics are prioritized. When purchasing dental implants, consider the quality of materials, the expertise of the dental professionals, and the potential need for follow-up care. The initial investment is higher compared to dentures, but their longevity and natural appearance often justify the cost.

Complete Dentures

Complete dentures are removable prosthetic devices designed to replace all teeth in an arch. They are particularly suitable for patients who have lost all their teeth and seek a cost-effective and non-invasive solution. B2B buyers should evaluate the quality of materials used, as well as the customization options available to ensure a comfortable fit. While the lower cost is attractive, it’s essential to consider that complete dentures may require frequent adjustments and can be less stable than implants.

Partial Dentures

Partial dentures cater to patients with remaining natural teeth, filling gaps left by missing teeth. They are an affordable option for buyers looking to restore functionality without the need for extensive surgery. When considering partial dentures, assess the ease of adjustment and the potential impact on the patient’s speech and comfort. While they offer a quick solution, their stability compared to implants may be a drawback for some users, making patient education crucial.

All-on-4 Implants

All-on-4 implants are a revolutionary solution for patients who have lost most or all of their teeth, utilizing just four implants to support a full arch of teeth. This approach is particularly advantageous for B2B buyers seeking a comprehensive and fixed solution with a quicker recovery time. Key considerations include the upfront investment and the need for skilled professionals for the surgical procedure. The benefits often outweigh the costs for patients seeking a permanent solution to tooth loss.

Snap-In Dentures

Snap-in dentures are a hybrid solution that combines traditional dentures with the stability of implants. These dentures clip onto implants, providing enhanced comfort and security for patients. B2B buyers should consider the dual benefits of affordability and improved stability when evaluating this option. However, the requirement for implant surgery means that costs can be higher than for standard dentures. This solution is ideal for patients who desire a removable option without sacrificing stability.

Related Video: Comparing All-on-4 vs Dental Implants vs Dentures

Key Industrial Applications of difference between dental implants and dentures

| Industry/Sector | Specific Application of difference between dental implants and dentures | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Offering comprehensive treatment options for patients | Attracts a wider patient base and enhances service quality | Supplier reliability, quality of materials, and regulatory compliance |

| Dental Laboratories | Producing custom prosthetics based on patient needs | Increases operational efficiency and patient satisfaction | Access to advanced technology, material sourcing, and turnaround time |

| Health Insurance Providers | Developing coverage plans for dental procedures | Enhances customer satisfaction and retention | Understanding regional regulations, competitive pricing, and network of providers |

| Medical Equipment Suppliers | Supplying tools for implant placement versus denture fitting | Expands product offerings and improves market competitiveness | Quality certification, compatibility with existing systems, and after-sales support |

| Educational Institutions | Training future dentists on implants vs. dentures | Improves curriculum relevance and attracts students | Collaboration with dental industry professionals and access to updated materials |

Detailed Applications

Dental Clinics

Dental clinics can leverage the difference between dental implants and dentures to provide tailored treatment options that meet diverse patient needs. By understanding the advantages of each solution—such as the durability of implants versus the affordability of dentures—clinics can attract a broader patient base. This is particularly relevant in regions like Africa and South America, where economic factors heavily influence dental care choices. International buyers must consider supplier reliability and the quality of materials used in these procedures to ensure patient safety and satisfaction.

Dental Laboratories

In dental laboratories, the distinction between implants and dentures plays a crucial role in producing custom prosthetics. Laboratories can streamline their operations by offering specialized services for each type, thereby enhancing patient satisfaction through personalized care. Buyers in this sector should prioritize suppliers that provide advanced manufacturing technologies and high-quality materials, as these factors directly impact turnaround times and the final product quality. This is especially vital in competitive markets across Europe and the Middle East.

Health Insurance Providers

Health insurance providers can capitalize on the differences between dental implants and dentures when designing coverage plans. By offering comprehensive dental plans that include both options, they can enhance customer satisfaction and retention rates. Understanding regional regulations and market needs is essential for creating competitive offerings that cater to the unique demographics of international markets, particularly in emerging economies like Nigeria and Mexico.

Medical Equipment Suppliers

Medical equipment suppliers can expand their product offerings by supplying specialized tools for the placement of dental implants versus the fitting of dentures. This differentiation allows suppliers to target specific segments of the dental market, enhancing their competitiveness. Key sourcing considerations include ensuring that the equipment meets quality certification standards and is compatible with existing dental systems, which is crucial for international buyers navigating diverse regulatory landscapes.

Educational Institutions

Educational institutions focusing on dentistry can incorporate the differences between dental implants and dentures into their curriculum to better prepare students for real-world challenges. By collaborating with industry professionals, these institutions can ensure their training programs remain relevant and attractive to prospective students. Access to updated materials and technologies is vital for providing a comprehensive educational experience that aligns with the current needs of the dental industry, particularly in rapidly developing regions.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Strategic Material Selection Guide for difference between dental implants and dentures

When selecting materials for dental implants and dentures, understanding the properties, advantages, and limitations of each material is crucial for international B2B buyers. This guide analyzes four common materials used in these dental solutions: titanium, zirconia, acrylic resin, and porcelain. Each material has unique characteristics that influence product performance, manufacturing complexity, and suitability for specific applications.

Titanium

Key Properties:

Titanium is renowned for its excellent strength-to-weight ratio, high corrosion resistance, and biocompatibility. It can withstand significant temperature and pressure variations, making it ideal for long-term use in dental applications.

Pros & Cons:

The durability of titanium implants is one of their greatest advantages, often lasting a lifetime with proper care. However, they are generally more expensive than other materials, which can be a barrier for some markets. The manufacturing process is complex, requiring specialized equipment and expertise.

Impact on Application:

Titanium is compatible with various biological environments, reducing the risk of rejection by the body. Its strength allows for the creation of narrow implants, which can be advantageous in cases with limited bone density.

Considerations for International Buyers:

Buyers from regions like Africa and South America should be aware of compliance with international standards such as ASTM F136 for titanium implants. Understanding local regulations regarding biocompatibility and material sourcing is essential.

Zirconia

Key Properties:

Zirconia is a ceramic material known for its high strength, aesthetic appeal, and excellent wear resistance. It is less prone to chipping compared to other ceramics, making it suitable for dental applications.

Pros & Cons:

The aesthetic quality of zirconia is a significant advantage, as it closely resembles natural teeth. However, its brittleness can be a limitation in certain applications, and the cost is typically higher than acrylic alternatives.

Impact on Application:

Zirconia is particularly suited for anterior implants due to its natural appearance. However, its performance in high-stress environments may be less reliable compared to titanium.

Considerations for International Buyers:

Compliance with standards such as ISO 6872 is crucial for zirconia products. Buyers should also consider the availability of zirconia in local markets, as sourcing can be challenging in some regions.

Acrylic Resin

Key Properties:

Acrylic resin is lightweight, easy to mold, and can be produced in various colors. It offers good impact resistance but is less durable than metals or ceramics.

Pros & Cons:

The primary advantage of acrylic resin is its affordability and ease of manufacturing, making it a popular choice for temporary dentures. However, it is less durable and may require frequent replacements, which can increase long-term costs.

Impact on Application:

Acrylic is suitable for removable dentures and is often used in immediate denture applications. Its compatibility with various dental adhesives makes it versatile.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of acrylic materials in dental applications. Standards like ISO 1567 for dental polymers should be considered to ensure product quality.

Porcelain

Key Properties:

Porcelain is a ceramic material known for its aesthetic qualities and resistance to wear and staining. It is often used in conjunction with metal frameworks for added strength.

Pros & Cons:

The aesthetic appeal of porcelain makes it a preferred choice for visible dental restorations. However, it can be brittle and may chip under excessive force, limiting its use in certain applications.

Impact on Application:

Porcelain is ideal for crowns and veneers, providing a natural look. Its compatibility with metal frameworks enhances its strength but can complicate the manufacturing process.

Considerations for International Buyers:

Compliance with standards such as ISO 6872 is essential when sourcing porcelain products. Buyers should also consider the availability and cost of porcelain in their local markets, as these can vary significantly.

Summary Table

| Material | Typical Use Case for difference between dental implants and dentures | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent durability and biocompatibility | High cost and complex manufacturing | High |

| Zirconia | Anterior dental implants | Aesthetic appeal | Brittleness in high-stress situations | High |

| Acrylic Resin | Temporary and removable dentures | Cost-effective and easy to mold | Less durable, frequent replacements | Low |

| Porcelain | Crowns and veneers | Natural appearance | Brittle, can chip under stress | Medium |

This guide provides a comprehensive overview of the strategic material selection for dental implants and dentures, ensuring that international B2B buyers can make informed decisions based on their specific market needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for difference between dental implants and dentures

Understanding Manufacturing Processes for Dental Implants and Dentures

The production of dental implants and dentures involves distinct manufacturing processes that reflect their functional and material differences. For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes is crucial for informed purchasing decisions.

Manufacturing Processes Overview

-

Material Preparation

– Dental Implants: Typically made from titanium or zirconia, which are biocompatible materials. The manufacturing begins with the selection of high-quality raw materials, followed by sterilization processes to eliminate contaminants.

– Dentures: Often composed of acrylic resin, metal, or a combination of both. The first step involves sourcing dental-grade polymers and metal alloys, ensuring they meet specific safety and performance standards. -

Forming

– Dental Implants: Techniques such as CNC (Computer Numerical Control) machining are employed to create precise implant shapes. Advanced processes like additive manufacturing (3D printing) are increasingly used for custom implants.

– Dentures: The forming stage includes techniques like injection molding and heat curing. These methods enable manufacturers to produce dentures that are both lightweight and durable, conforming to the unique anatomical features of patients. -

Assembly

– Dental Implants: This stage involves the integration of various components, such as the implant body, abutment, and crown. Each component must fit precisely to ensure optimal performance and longevity.

– Dentures: Assembly typically includes attaching the denture base to the denture teeth. This requires careful alignment and adhesion to ensure functionality and aesthetics. -

Finishing

– Dental Implants: The finishing process may include surface treatments to enhance osseointegration, such as sandblasting or acid etching. These treatments increase the implant’s surface area for better integration with the bone.

– Dentures: Finishing involves polishing and coloring to achieve a natural appearance. This is essential for patient satisfaction and acceptance.

Quality Assurance in Dental Manufacturing

Quality assurance (QA) is critical in the dental industry, where product safety and effectiveness are paramount. B2B buyers should be aware of the following key aspects of QA in the context of dental implants and dentures.

International Standards and Certifications

- ISO 9001: This standard ensures that manufacturers have a quality management system in place, focusing on continuous improvement and customer satisfaction.

- CE Marking: In Europe, dental products must comply with the Medical Devices Regulation (MDR) to obtain CE marking, indicating they meet safety and performance requirements.

- API (Active Pharmaceutical Ingredient): For manufacturers producing bioactive components, compliance with API regulations is essential for ensuring product safety and efficacy.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to verify that they meet specified standards. This step is critical to prevent defects in the final product. -

In-Process Quality Control (IPQC)

– Continuous monitoring during manufacturing ensures that processes remain within defined parameters. This includes regular checks on machinery calibration and environmental conditions. -

Final Quality Control (FQC)

– Finished products undergo rigorous testing to ensure they meet all specifications. This may involve mechanical testing, biocompatibility assessments, and aesthetic evaluations.

Common Testing Methods

- Mechanical Testing: Assesses the strength and durability of implants and dentures under simulated stress conditions.

- Biocompatibility Testing: Ensures that materials do not provoke an adverse reaction when in contact with human tissue.

- Sterilization Validation: Confirms that sterilization processes effectively eliminate pathogens, ensuring safety for end-users.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are some actionable insights:

-

Supplier Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing processes and quality assurance practices. Look for compliance with international standards and internal protocols.

-

Quality Reports: Request detailed quality assurance reports, including testing results and compliance certifications. These documents should outline the supplier’s adherence to relevant standards.

-

Third-Party Inspections: Engage independent organizations to perform audits and inspections. Third-party verification can provide an unbiased assessment of a supplier’s quality control systems.

Quality Control Nuances for International Buyers

International B2B buyers face unique challenges regarding quality control. Here are some considerations:

-

Regulatory Variations: Different countries have varying regulations and standards. Buyers should familiarize themselves with local requirements in their respective markets, such as ANVISA in Brazil or the South African Health Products Regulatory Authority (SAHPRA).

-

Cultural Differences: Understanding cultural nuances can enhance communication with suppliers. Buyers from Africa, South America, the Middle East, and Europe may have different expectations regarding product specifications and quality standards.

-

Supply Chain Considerations: The global supply chain can affect the availability and quality of materials. Buyers should assess the reliability of suppliers’ sourcing practices and their ability to maintain quality throughout the supply chain.

Conclusion

Understanding the manufacturing processes and quality assurance practices for dental implants and dentures is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can make informed decisions that ensure they source high-quality dental products. With a proactive approach to verifying supplier quality, businesses can enhance their competitive advantage in the global dental market.

Comprehensive Cost and Pricing Analysis for difference between dental implants and dentures Sourcing

In the realm of dental solutions, understanding the cost structure and pricing dynamics between dental implants and dentures is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and practical buyer tips tailored specifically for stakeholders from Africa, South America, the Middle East, and Europe.

Cost Components

When sourcing dental implants and dentures, several key cost components come into play:

-

Materials: The choice of materials significantly affects costs. Dental implants typically involve higher-quality materials like titanium, which are more expensive than the acrylic or metal used in dentures.

-

Labor: Skilled labor is essential in the manufacturing of both products. The complexity of dental implants often requires more specialized skills, leading to higher labor costs compared to the relatively simpler fabrication of dentures.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment. Dental implants may incur higher overhead due to the advanced technology and stringent manufacturing processes involved.

-

Tooling: Custom tooling is often necessary for dental implants, which can add to the initial costs. Conversely, dentures may require less specialized tooling, making them more cost-effective in this regard.

-

Quality Control (QC): Given the regulatory landscape surrounding dental products, QC processes can be more intensive for implants, impacting overall costs. Dentures, while still requiring QC, may not face the same level of scrutiny.

-

Logistics: Transportation costs can vary based on the product type. Implants, being smaller but often requiring expedited shipping due to demand, can incur higher logistics costs.

-

Margin: Supplier margins will vary based on the product type and market demand. Dental implants often carry higher margins due to their perceived value and complexity.

Price Influencers

Several factors influence the pricing of dental implants versus dentures:

-

Volume/MOQ (Minimum Order Quantity): Buyers who can commit to larger orders often benefit from volume discounts. This is particularly relevant in regions with burgeoning dental markets, such as Nigeria and Mexico.

-

Specifications/Customization: Customized solutions for dental implants can lead to increased costs. Buyers should evaluate the need for customization against potential cost savings.

-

Materials and Quality/Certifications: The quality of materials used and the certifications obtained can significantly impact pricing. Higher quality and certified materials justify higher prices but are essential for compliance and patient safety.

-

Supplier Factors: Established suppliers with a proven track record may charge a premium. However, their reliability can offset potential risks associated with lower-cost suppliers.

-

Incoterms: The chosen Incoterms can also influence pricing by determining who bears the transportation costs and risks. Understanding these terms is crucial for accurate cost estimations.

Buyer Tips

For B2B buyers, particularly in emerging markets, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Understanding their cost components can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Beyond initial costs, consider the TCO, which includes maintenance, replacement, and potential downtime. Implants may have a higher upfront cost but could result in lower long-term expenses due to durability.

-

Pricing Nuances: Be aware of regional pricing variations. Suppliers may adjust prices based on local market conditions, which can be advantageous for buyers in developing regions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service terms. Long-term partnerships often result in improved support and potential discounts.

Disclaimer

Pricing in the dental market can fluctuate based on various factors, including economic conditions, material availability, and regulatory changes. This analysis provides indicative pricing insights but should not be viewed as definitive. Buyers are encouraged to conduct thorough market research and seek quotes from multiple suppliers to ensure competitive pricing.

Essential Technical Properties and Trade Terminology for difference between dental implants and dentures

Understanding the essential technical properties and trade terminology related to dental implants and dentures is crucial for B2B buyers navigating the dental health market. This knowledge can assist in making informed purchasing decisions, evaluating supplier offers, and ensuring compliance with regional health standards.

Key Technical Properties

- Material Composition

– Definition: Dental implants are typically made from titanium or zirconia, while dentures are often crafted from acrylic resin or metal frameworks.

– B2B Importance: The choice of material affects durability, biocompatibility, and patient comfort. Buyers should evaluate the long-term performance and potential health implications of materials used in products.

Illustrative Image (Source: Google Search)

-

Tensile Strength

– Definition: This refers to the maximum amount of tensile (pulling) stress that a material can withstand without breaking.

– B2B Importance: High tensile strength in implants is crucial for supporting chewing forces. Understanding this property helps buyers select products that can withstand daily use and reduce the risk of failure. -

Surface Treatment

– Definition: Surface treatments can include coatings or textures applied to implants to enhance osseointegration, the process by which the implant fuses with the jawbone.

– B2B Importance: Advanced surface treatments can improve implant success rates. Buyers should inquire about these treatments to ensure they are investing in high-quality products that promote better patient outcomes. -

Porosity

– Definition: This refers to the presence of tiny holes or voids in a material that can affect its strength and ability to integrate with bone.

– B2B Importance: For implants, optimal porosity is essential for bone growth. Buyers should assess porosity levels to ensure they are choosing implants that will promote long-term stability. -

Fit and Tolerance

– Definition: Tolerance refers to the allowable deviation from a specified dimension in the manufacturing of dental products.

– B2B Importance: Precise fit is critical for both implants and dentures to ensure comfort and functionality. Buyers must prioritize suppliers who adhere to strict manufacturing tolerances to avoid complications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify quality manufacturers and establish partnerships that ensure product reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is vital for budgeting and inventory planning. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and details on specific products.

– Importance: An RFQ helps buyers gather competitive offers and ensures they receive the best pricing based on their specifications. It’s an essential tool for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Familiarity with Incoterms is critical for international transactions, as they clarify shipping responsibilities, risk transfer, and cost allocation, ensuring smoother cross-border trade. -

CE Marking

– Definition: A certification mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– Importance: For B2B buyers in Europe, understanding CE marking is essential for compliance and market access. It assures buyers that products meet EU regulations.

By grasping these technical properties and industry terminology, B2B buyers can enhance their procurement strategies, improve supplier negotiations, and ultimately deliver better outcomes for their clients in the dental health sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the difference between dental implants and dentures Sector

Market Overview & Key Trends

The global dental implants and dentures market is experiencing significant transformation driven by advancements in technology, increasing demand for aesthetic dental solutions, and an aging population. Key drivers include the rise in dental tourism, particularly in regions like South America and Europe, where cost-effective solutions attract international patients. In Africa and the Middle East, there’s a growing awareness of oral health, leading to increased investments in dental care infrastructure.

Emerging B2B tech trends include the integration of 3D printing technologies and digital dentistry, which streamline the production and customization of dental implants and dentures. This not only reduces lead times but also enhances precision, catering to the unique anatomical needs of patients. Additionally, the rise of tele-dentistry platforms is reshaping how dental professionals engage with patients, allowing for remote consultations and follow-ups, which is particularly beneficial in regions with limited access to dental care.

For international B2B buyers, understanding market dynamics is crucial. The competition between dental implants and dentures is intensifying, with implants often seen as a long-term solution, while dentures provide a more affordable and immediate option. Buyers must assess local market preferences and regulatory environments, which can vary significantly between regions such as Nigeria, Mexico, and European countries. Moreover, sourcing strategies are evolving, with many buyers looking to establish partnerships with manufacturers who can provide both traditional and innovative solutions, balancing cost, quality, and delivery timelines.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a cornerstone of business strategy, the dental industry is not exempt from this shift. The environmental impact of dental products, particularly in terms of materials used and waste generated, is a growing concern. For B2B buyers, prioritizing suppliers who adopt sustainable practices is essential. This includes sourcing materials that are biocompatible and recyclable, thereby reducing the ecological footprint of dental implants and dentures.

Ethical supply chains play a pivotal role in the sourcing process. Buyers should seek manufacturers that adhere to rigorous ethical standards, ensuring that labor practices are fair and that environmental regulations are met. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are indicators of a supplier’s commitment to sustainability. Furthermore, using ‘green’ materials—such as bioactive glass or plant-based polymers—can enhance the appeal of dental products to environmentally conscious consumers.

By integrating sustainability into procurement strategies, B2B buyers can not only comply with increasing regulations but also enhance their brand reputation and appeal to a broader customer base, particularly in regions where eco-friendly practices are highly valued.

Brief Evolution/History

The evolution of dental implants and dentures can be traced back thousands of years, with early forms of dentures made from materials such as ivory and animal teeth. The modern dental implant, developed in the 1960s by Dr. Per-Ingvar Brånemark, marked a significant advancement, utilizing titanium for its biocompatibility and strength. Over the decades, both implants and dentures have undergone substantial innovations, including the development of mini implants and advanced denture materials that enhance comfort and aesthetics.

For B2B buyers, understanding this historical context provides insight into current trends and future directions in the dental market. As technology continues to evolve, buyers must stay informed about emerging materials and techniques that can improve product offerings and meet changing consumer demands.

Related Video: Full Mouth Dental Implants: Everything You Need to Know and Cost

Frequently Asked Questions (FAQs) for B2B Buyers of difference between dental implants and dentures

-

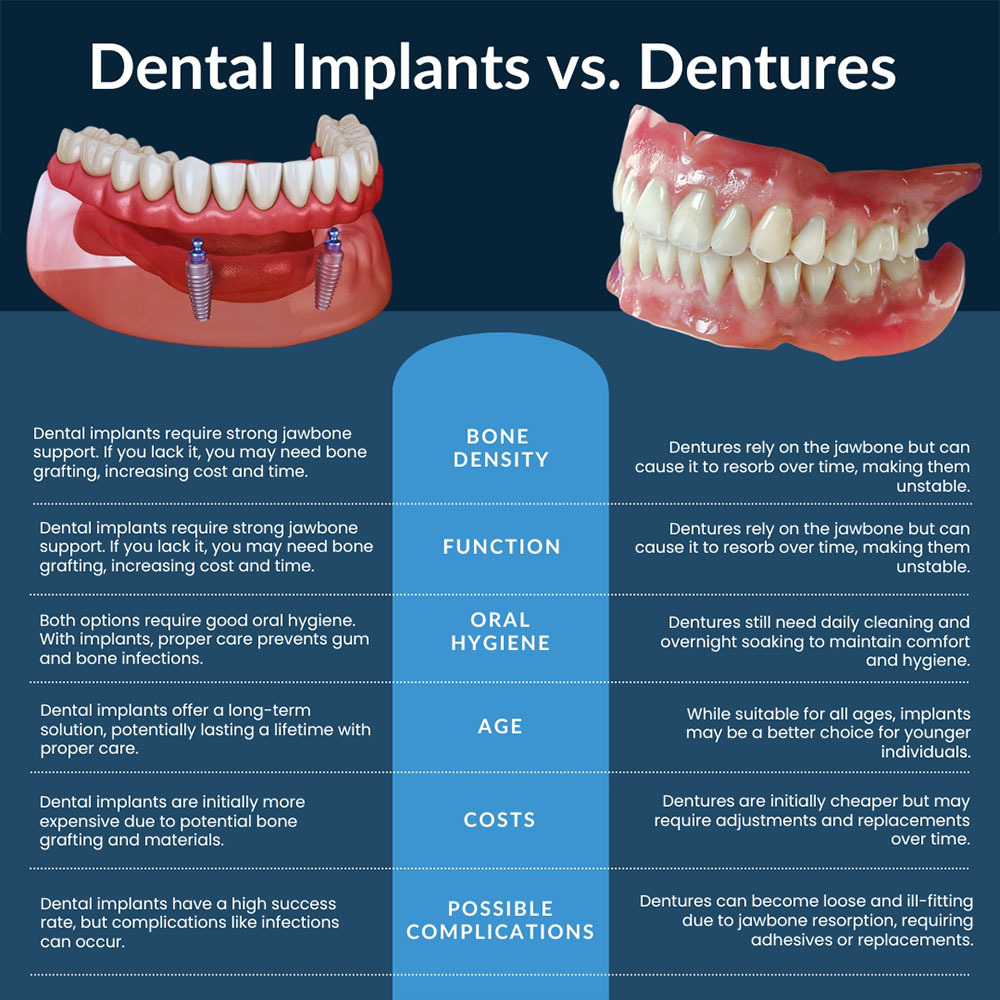

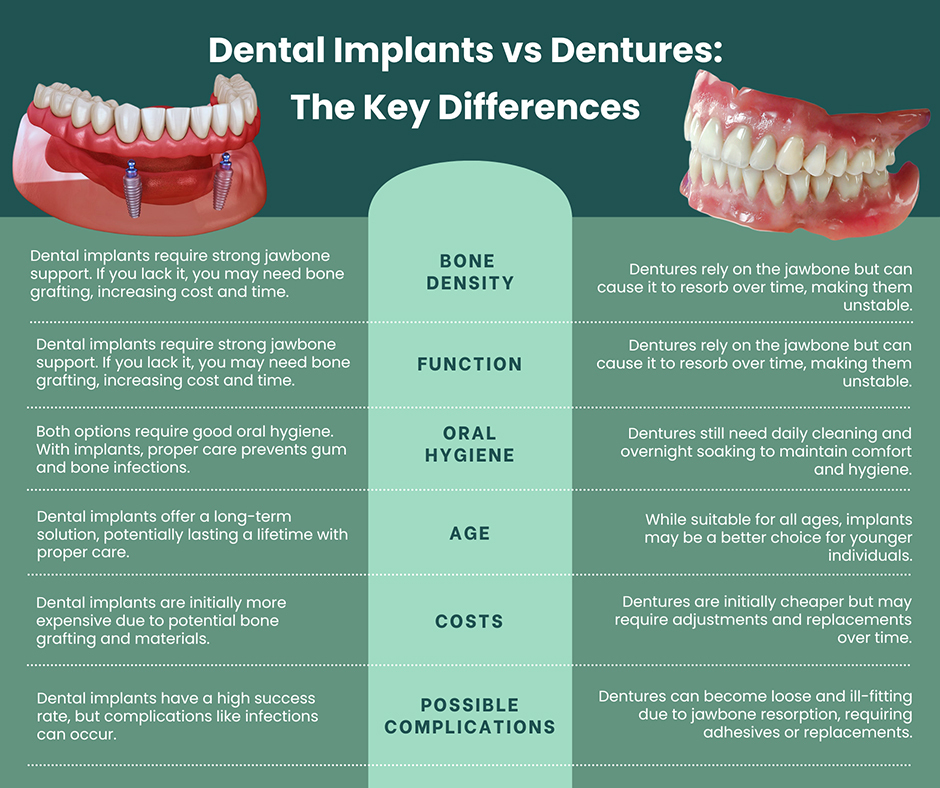

What are the key differences between dental implants and dentures?

Dental implants are permanent fixtures that involve surgically placing a titanium post into the jawbone, serving as a root for artificial teeth. In contrast, dentures are removable prosthetics that replace missing teeth without the need for surgery. For B2B buyers, understanding these differences is crucial for making informed decisions about product offerings and potential markets, especially in regions with varying dental health needs. -

How can I vet suppliers of dental implants and dentures?

When sourcing suppliers, prioritize those with verified credentials, including ISO certification and compliance with local health regulations. Conduct background checks to assess their reputation and financial stability. Engage in direct communication to evaluate their responsiveness and ability to customize products for different markets, particularly for regions like Africa and South America where dental health needs may vary significantly. -

What customization options should I look for in dental implants and dentures?

Customization is vital to meet diverse patient needs across international markets. Look for suppliers that offer various sizes, shapes, and materials for implants and dentures. Additionally, inquire about the possibility of bespoke designs that cater to local preferences or specific dental conditions prevalent in regions like the Middle East or Europe. A flexible supplier can help you stay competitive in diverse markets.

Illustrative Image (Source: Google Search)

-

What are typical minimum order quantities (MOQs) and lead times for dental products?

MOQs for dental implants and dentures can vary widely based on the supplier and the product line. Typically, dental implant manufacturers may have higher MOQs due to the specialized nature of their products. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s production capacity. Always clarify these details upfront to manage inventory and fulfill customer demands efficiently. -

How important are quality assurance certifications for dental products?

Quality assurance certifications are essential indicators of product reliability and safety. Look for suppliers with certifications from recognized bodies such as the FDA, CE marking, or ISO standards. These certifications not only ensure compliance with regulatory requirements but also enhance the credibility of your offerings in international markets, reassuring customers about the quality of dental implants and dentures. -

What logistics considerations should I keep in mind when importing dental products?

Logistics plays a crucial role in the timely delivery of dental products. Consider factors such as shipping methods, customs regulations, and potential tariffs in your target markets. Partnering with a logistics provider experienced in handling medical devices can streamline the process. Additionally, be aware of the shelf life of dental products and ensure that your supply chain can accommodate any specific storage requirements. -

How can I address potential disputes with suppliers?

Establishing clear terms and conditions in your contracts is vital for minimizing disputes. Include clauses that define quality expectations, delivery timelines, and payment terms. In the event of a disagreement, maintain open communication with your supplier to seek amicable resolutions. Consider mediation or arbitration as alternatives to litigation, especially when dealing with international suppliers, to save time and resources. -

What payment options are commonly available for international purchases of dental products?

Payment options can vary by supplier and region. Common methods include letters of credit, wire transfers, and payment platforms like PayPal or Escrow services. Evaluate the security and fees associated with each method, and consider negotiating terms that protect both parties, such as partial upfront payments and milestone payments tied to production stages. Understanding these options can help you manage cash flow and reduce financial risks in international transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for difference between dental implants and dentures

In the evolving landscape of dental solutions, understanding the distinctions between dental implants and dentures is crucial for international B2B buyers. Dental implants offer a permanent, stable solution that mimics natural teeth, making them a preferred choice among patients who seek longevity and functionality. Conversely, dentures provide a more immediate, cost-effective alternative, catering to a different segment of the market that may prioritize affordability over permanence.

Key Takeaways:

– Market Demand: Recognize the growing demand for both dental implants and dentures across various regions, driven by increasing awareness of oral health.

– Strategic Sourcing: Establishing strong relationships with reliable suppliers can ensure access to high-quality products, essential for maintaining competitiveness in the dental market.

– Customization Opportunities: Tailoring solutions to meet the unique needs of diverse populations in Africa, South America, the Middle East, and Europe can enhance customer satisfaction and loyalty.

As the dental industry continues to innovate, now is the time for B2B buyers to assess their sourcing strategies. By leveraging data-driven insights and fostering partnerships with manufacturers, businesses can not only optimize their offerings but also position themselves for future growth. Embrace the potential of this market and make informed decisions that will drive success in the ever-evolving dental landscape.