Introduction: Navigating the Global Market for w&h dental implant motor

Navigating the complex landscape of dental implant technology is crucial for dental practitioners and suppliers alike, especially when it comes to high-quality equipment such as the w&h dental implant motor. This advanced tool is integral to ensuring precision and efficiency in dental procedures, which directly impacts patient outcomes and clinic productivity. As the demand for dental implants grows globally, understanding the nuances of sourcing and selecting the right w&h dental implant motor becomes essential for B2B buyers.

This comprehensive guide is designed to empower international buyers, particularly from Africa, South America, the Middle East, and Europe, with actionable insights on various aspects of the w&h dental implant motor. We will explore the different types available, the materials used in manufacturing, quality control standards, and a thorough analysis of suppliers. Additionally, we will discuss pricing structures and market trends, providing a well-rounded view that facilitates informed purchasing decisions.

By delving into frequently asked questions and addressing common concerns, this guide aims to equip you with the knowledge needed to navigate your sourcing journey confidently. Whether you are looking to enhance your practice’s capabilities or seeking reliable suppliers, understanding the intricacies of the w&h dental implant motor will enable you to make strategic choices that align with your operational needs and budgetary constraints.

Understanding w&h dental implant motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| W&H Implantmed | High torque, integrated irrigation system | Surgical implant placements | Pros: Reliable performance; Cons: Higher cost |

| W&H Synea | Lightweight design, multiple speed settings | General dental practices | Pros: Versatile; Cons: May lack advanced features |

| W&H Piezomed | Piezoelectric technology, minimal heat generation | Bone surgery, implant site preparation | Pros: Precise cuts; Cons: Requires training |

| W&H Variosurg | Adjustable power settings, compact size | Soft tissue surgeries | Pros: Easy to handle; Cons: Limited to specific tasks |

| W&H Implant Motor with LED | Integrated LED light for improved visibility | Complex implant procedures | Pros: Enhanced visibility; Cons: Bulky design |

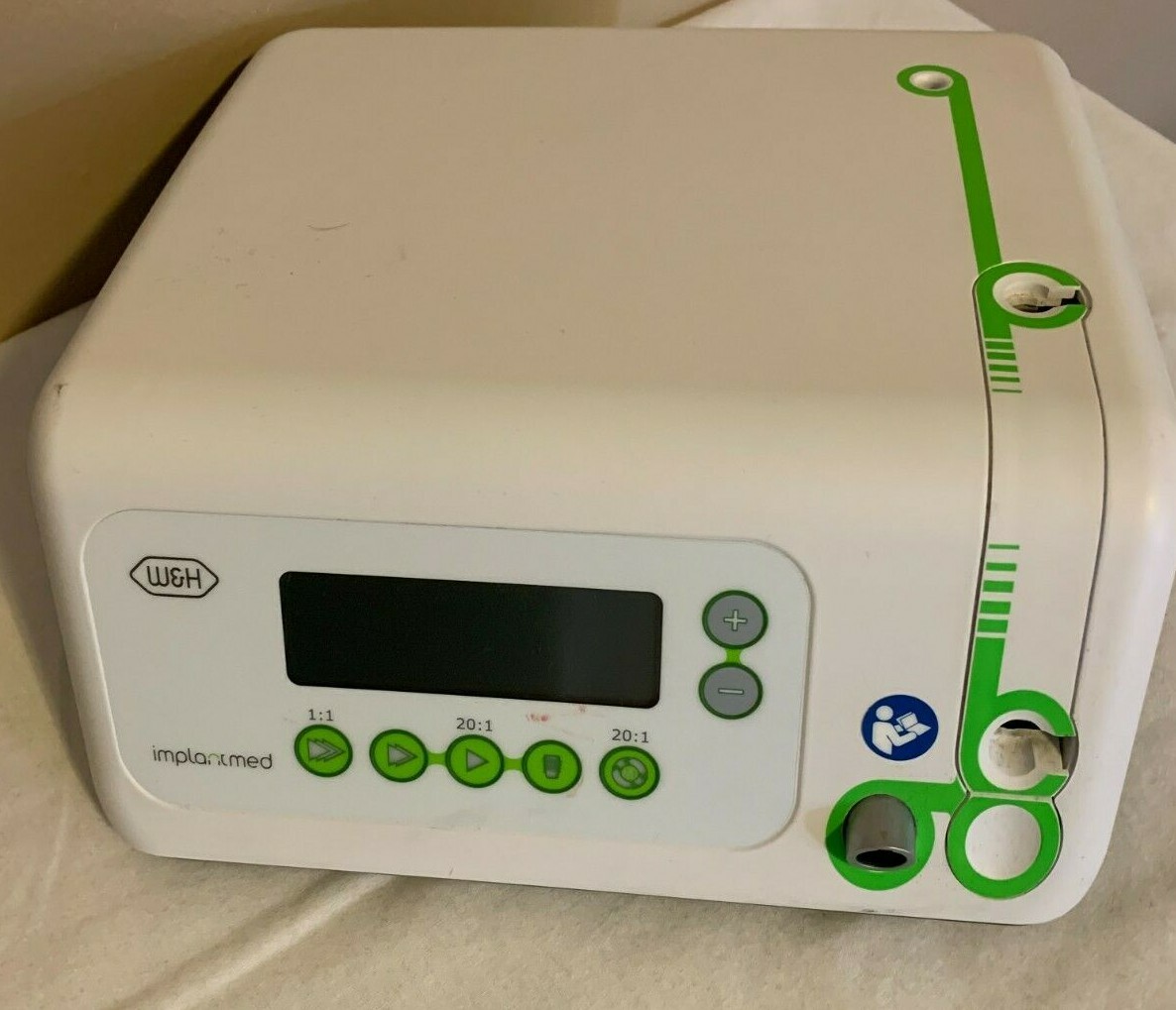

W&H Implantmed

The W&H Implantmed is engineered for high torque applications, making it ideal for surgical implant placements. Its integrated irrigation system ensures optimal cooling during procedures, enhancing both safety and precision. When considering a purchase, B2B buyers should evaluate the motor’s reliability and performance in demanding environments, as well as potential higher costs compared to other models. This motor is particularly suitable for practices focusing on advanced implantology, where consistent performance is critical.

W&H Synea

The W&H Synea stands out with its lightweight design and multiple speed settings, making it versatile for various dental applications. It is well-suited for general dental practices that require a reliable motor for routine procedures. Buyers should consider the balance between versatility and the absence of some advanced features found in other models. Its adaptability makes it an attractive option for practices looking to maximize their operational capabilities without investing in multiple devices.

W&H Piezomed

Utilizing piezoelectric technology, the W&H Piezomed minimizes heat generation during procedures, which is essential for maintaining tissue integrity. This motor is particularly advantageous for bone surgery and implant site preparation, where precision is paramount. B2B buyers should assess the need for specialized training, as the unique technology may require a learning curve. Its precision cutting capabilities make it a preferred choice for practices that prioritize delicate surgical procedures.

W&H Variosurg

The W&H Variosurg is designed for soft tissue surgeries, featuring adjustable power settings that enhance its usability. Its compact size makes it easy to handle, which is beneficial in confined surgical spaces. Buyers should weigh the motor’s ease of use against its limitations for specific tasks. This device is ideal for practices focusing on soft tissue management, offering a balance of efficiency and control.

W&H Implant Motor with LED

The W&H Implant Motor with LED integrates an LED light for improved visibility during complex implant procedures. This feature is crucial for enhancing precision and reducing the risk of errors. While the increased visibility is a significant advantage, potential buyers should consider the bulkier design and whether the benefits outweigh the space constraints in their practice. This motor is particularly suited for advanced implantology, where visibility can directly impact outcomes.

Key Industrial Applications of w&h dental implant motor

| Industry/Sector | Specific Application of w&h dental implant motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Implant placement procedures | Enhances precision in implant surgeries, reducing patient recovery time and improving outcomes. | Ensure compatibility with existing surgical tools and compliance with local regulations. |

| Dental Laboratories | Prosthetic fabrication and adjustments | Facilitates the creation of precise dental prosthetics, leading to higher patient satisfaction. | Look for motors that support various prosthetic materials and have a reliable service network. |

| Educational Institutions | Training for dental students | Provides hands-on experience with advanced dental technology, preparing students for modern practices. | Consider motors that are durable and easy to use for educational settings. |

| Cosmetic Dentistry | Aesthetic enhancement procedures | Increases efficiency in cosmetic procedures, allowing for higher patient turnover and satisfaction. | Assess the motor’s versatility for different cosmetic applications and ease of cleaning. |

| Research and Development | Clinical trials and product testing | Supports innovative dental solutions through reliable data collection and analysis. | Source from manufacturers with a strong R&D background and support for advanced applications. |

Detailed Applications

Dental Clinics

In dental clinics, the w&h dental implant motor is integral for implant placement procedures. It allows dentists to perform surgeries with enhanced precision, which not only minimizes the risk of complications but also accelerates patient recovery times. For international buyers, especially in regions like Africa and South America where dental care is evolving, sourcing a reliable motor that meets local regulatory standards is crucial. Ensuring compatibility with existing surgical instruments is also a key consideration.

Dental Laboratories

Dental laboratories utilize the w&h dental implant motor for the fabrication and adjustment of dental prosthetics. This motor enables technicians to create highly accurate prosthetics, which directly impacts patient satisfaction and clinic reputation. B2B buyers in Europe and the Middle East should focus on motors that can accommodate various prosthetic materials and offer a robust service network for maintenance, ensuring uninterrupted operations.

Educational Institutions

In educational settings, the w&h dental implant motor is used to train dental students in modern implant technologies. By providing hands-on experience with this advanced tool, institutions can better prepare students for their professional careers. Buyers from institutions in regions like Saudi Arabia and Italy should prioritize durability and ease of use when selecting motors for educational purposes, as these factors contribute to effective learning environments.

Cosmetic Dentistry

Cosmetic dentistry practices benefit from the efficiency brought by the w&h dental implant motor in aesthetic enhancement procedures. The motor allows for quicker and more precise interventions, which can lead to increased patient turnover and higher satisfaction rates. B2B buyers should evaluate the motor’s versatility and ease of cleaning, particularly in markets where hygiene standards are critical.

Research and Development

In the realm of research and development, the w&h dental implant motor plays a vital role in clinical trials and product testing. It supports innovative dental solutions by facilitating reliable data collection and analysis. International buyers engaged in R&D should source from manufacturers with a strong emphasis on innovation and support for advanced applications, ensuring that they stay at the forefront of dental technology advancements.

Related Video: US Uses B-2 Bombers and Deception in Iran Air Strikes

Strategic Material Selection Guide for w&h dental implant motor

When selecting materials for the w&h dental implant motor, it is crucial to consider various factors that influence performance, durability, and compliance with international standards. Below, we analyze several common materials used in the construction of these motors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures. It typically has a temperature rating of up to 800°C and can endure high pressure, making it suitable for various dental applications.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can withstand repeated sterilization processes without degrading. However, it can be relatively expensive compared to other materials, and its manufacturing complexity may increase production costs.

Impact on Application:

Stainless steel is compatible with a wide range of media, including saline solutions and other dental fluids, ensuring that it does not react adversely during procedures.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A276 or DIN 17440. Additionally, understanding local regulations regarding material sourcing is essential.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 200°C. It is also known for its thermal conductivity, which can be beneficial in applications requiring heat dissipation.

Pros & Cons:

The lightweight nature of aluminum allows for easier handling and maneuverability of the dental implant motor. However, it is less durable than stainless steel and may not withstand as much wear and tear, leading to a shorter lifespan in demanding environments.

Impact on Application:

Aluminum is suitable for applications where weight reduction is critical, but its lower pressure rating may limit its use in high-pressure scenarios.

Considerations for International Buyers:

Buyers should be aware of the need for anodization or other protective coatings to enhance corrosion resistance. Compliance with standards such as ASTM B221 is also important, especially in Europe.

Titanium

Key Properties:

Titanium exhibits exceptional strength-to-weight ratio and excellent corrosion resistance, particularly in saline environments. It can withstand temperatures up to 600°C, making it suitable for high-performance applications.

Pros & Cons:

The primary advantage of titanium is its biocompatibility, making it ideal for dental applications. However, it is significantly more expensive than both stainless steel and aluminum, which may impact budget considerations for buyers.

Impact on Application:

Titanium’s compatibility with bodily fluids and resistance to corrosion make it an excellent choice for dental implants, ensuring long-term performance without degradation.

Considerations for International Buyers:

Buyers should ensure that titanium components meet standards like ASTM F136 and are aware of the higher costs associated with sourcing and manufacturing titanium products.

Composite Materials

Key Properties:

Composite materials often combine various elements to enhance performance characteristics, such as improved strength, reduced weight, and enhanced corrosion resistance. Their temperature ratings can vary widely based on the specific formulation.

Pros & Cons:

The versatility of composites allows for tailored properties to meet specific application needs. However, they can be more complex to manufacture and may require specialized processes, leading to increased costs.

Impact on Application:

Composites can be engineered for specific media compatibility, making them suitable for a variety of dental applications, though they may not be as universally applicable as metals.

Considerations for International Buyers:

Buyers should verify that composite materials comply with relevant standards, such as ISO 10993 for biocompatibility, especially in sensitive applications like dental implants.

Summary Table

| Material | Typical Use Case for w&h dental implant motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components of the motor | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight components | Lightweight and easy to handle | Less durable, shorter lifespan | Medium |

| Titanium | Critical load-bearing components | Exceptional strength and biocompatibility | High cost | High |

| Composite Materials | Specialized applications | Tailored properties for specific needs | Manufacturing complexity | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into the strategic material selection for w&h dental implant motors, ensuring informed decisions that align with performance requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for w&h dental implant motor

Manufacturing a dental implant motor, such as the w&h model, involves a series of intricate processes that ensure precision, durability, and performance. Understanding these manufacturing stages and quality assurance protocols is essential for B2B buyers looking to invest in reliable dental equipment.

Manufacturing Processes

1. Material Preparation

The manufacturing process begins with the selection of high-quality materials, primarily stainless steel and titanium, known for their strength and biocompatibility. Suppliers often undergo rigorous screening to ensure that raw materials meet international standards. B2B buyers should inquire about the source of these materials, emphasizing the importance of traceability and quality certifications.

2. Forming

Once the materials are prepared, they undergo forming processes, which may include forging, machining, and molding. Advanced CNC (Computer Numerical Control) machining is typically employed to create precise components with tight tolerances. This stage is critical as it lays the foundation for the motor’s performance and longevity. Buyers should evaluate the supplier’s machining capabilities and technology to ensure they can meet their specific requirements.

Illustrative Image (Source: Google Search)

3. Assembly

The assembly phase involves integrating various components, including the motor housing, gears, and electrical systems. This stage may utilize automated assembly lines to enhance efficiency and minimize human error. Skilled technicians often conduct manual assembly for intricate parts, ensuring that each motor meets the required specifications. Buyers should assess the assembly processes and worker qualifications to gauge the reliability of the final product.

4. Finishing

Finishing processes, such as polishing, coating, and sterilization, are crucial for enhancing the product’s aesthetic appeal and functional performance. Coatings can provide additional protection against corrosion and wear, which is particularly important in a dental environment. B2B buyers should inquire about the finishing techniques used and their impact on the product’s lifespan and usability.

Quality Assurance

Quality assurance is a cornerstone of manufacturing, particularly for medical devices like dental implant motors. Ensuring that products meet stringent quality standards is vital for both safety and compliance.

Relevant International Standards

- ISO 9001: This is a widely recognized standard for quality management systems (QMS). Suppliers should hold ISO 9001 certification to demonstrate their commitment to quality.

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For suppliers in the medical field, adherence to American Petroleum Institute (API) standards may be relevant, especially for components involving hydraulic systems.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified criteria before they enter the production process. Buyers can request IQC reports to verify compliance.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints monitor the production to catch defects early. This stage is essential for maintaining consistency.

- Final Quality Control (FQC): Before products are packaged and shipped, FQC ensures that each motor meets the final specifications. Buyers should ask for FQC documentation as part of their procurement process.

Common Testing Methods

- Performance Testing: Motors undergo various performance tests to ensure they meet operational specifications, including speed, torque, and noise levels.

- Durability Testing: This includes stress tests to simulate long-term use and ensure reliability under different conditions.

- Sterilization Testing: Confirming that the motor can withstand sterilization processes is crucial for dental applications.

Verifying Supplier Quality Control

B2B buyers should implement rigorous verification processes when selecting suppliers. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and adherence to standards. This firsthand observation is invaluable.

- Quality Reports: Request detailed quality reports that outline testing results, compliance with international standards, and any corrective actions taken during production.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased evaluations of the supplier’s quality processes and product reliability. This is particularly useful for buyers in Africa, South America, and the Middle East, where local regulations may vary.

Navigating QC and Certification Nuances

Understanding the nuances of quality control and certification is essential for international B2B buyers. Each region may have different regulatory requirements and expectations. Buyers from Europe, for instance, may prioritize CE marking, while those in Africa and South America might focus on local certifications that ensure safety and efficacy.

It is also crucial to consider the supply chain’s complexity. The ability to trace the origin of materials and components can significantly impact quality assurance. B2B buyers should establish clear communication with suppliers regarding their quality control measures and certifications to mitigate risks.

Conclusion

Investing in a w&h dental implant motor involves a thorough understanding of the manufacturing processes and quality assurance protocols. By focusing on material quality, precision engineering, and robust quality control measures, buyers can ensure they are selecting reliable products that meet their specific needs. Engaging in due diligence through audits, quality reports, and third-party inspections will further safeguard their investments and enhance operational efficiency.

Related Video: From Garage to Factory: 8 Micro-Manufacturing Setups You Need to See

Comprehensive Cost and Pricing Analysis for w&h dental implant motor Sourcing

Understanding the Cost Structure of w&h Dental Implant Motors

When sourcing w&h dental implant motors, it is crucial for international B2B buyers to grasp the comprehensive cost structure. This includes various components that influence the final pricing of the product. Key cost elements are:

-

Materials: High-quality components like titanium and specialized alloys are often used, which can significantly impact costs. Ensure to understand the types of materials employed in production, as they correlate directly with performance and durability.

-

Labor: The labor costs can vary based on the manufacturing location. Skilled labor in Europe may command higher wages compared to emerging markets in Africa or South America, affecting overall pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Buyers should inquire about the efficiency of the production process, as more efficient operations can lead to lower overhead costs.

-

Tooling: Custom tooling can be a substantial upfront investment, especially for bespoke motor designs. Understanding the tooling costs is essential, particularly when considering customization.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can add to the cost. Buyers should seek suppliers with strong QC measures, as this can prevent costly errors in the long run.

-

Logistics: Shipping costs vary significantly based on the origin and destination. Factors such as distance, transport mode, and any potential tariffs should be considered in the overall cost analysis.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins within the industry can provide leverage during negotiations.

Factors Influencing Pricing

Several factors can influence the pricing of w&h dental implant motors. Recognizing these can aid buyers in making informed decisions:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often yields better pricing. Suppliers may offer discounts for bulk purchases, making it vital to assess projected needs accurately.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the necessity of customization against budget constraints.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., ISO standards) can elevate costs but also enhance product reliability. Buyers should prioritize certifications that align with their regulatory requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium but often provide superior quality and service.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is essential as they determine who bears the shipping costs and risks, affecting the total cost.

Strategic Buyer Tips

To navigate the complexities of sourcing w&h dental implant motors effectively, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers to negotiate better terms. Consider leveraging volume discounts or long-term contracts for more favorable pricing.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Factor in maintenance, warranty, and potential downtime costs to assess the true value of the product.

-

Pricing Nuances: Be aware of regional pricing differences. For example, costs may vary significantly between suppliers in Europe and those in the Middle East or Africa due to varying labor costs and market conditions.

-

Market Research: Conduct thorough market research to benchmark prices across different suppliers. This can provide valuable insights into fair pricing and assist in negotiations.

-

Local Regulations: Familiarize yourself with import regulations and duties in your region. Understanding these aspects can help avoid unexpected costs that affect the overall budget.

Disclaimer

The prices and cost components discussed herein are indicative and can vary significantly based on specific supplier agreements, market conditions, and individual buyer circumstances. It is advisable to conduct detailed due diligence and obtain quotes from multiple suppliers for precise budgeting.

Essential Technical Properties and Trade Terminology for w&h dental implant motor

Key Technical Properties of w&h Dental Implant Motor

When considering the procurement of a w&h dental implant motor, understanding its technical specifications is crucial for ensuring compatibility and performance in clinical settings. Here are several key properties to evaluate:

-

Material Grade

– Definition: The material grade refers to the quality and composition of the materials used in the motor’s construction, such as stainless steel or titanium.

– Importance: High-grade materials enhance durability and resistance to corrosion, which is essential in a dental environment. Buyers should prioritize motors made from materials that meet international standards for medical devices. -

Torque Range

– Definition: Torque range indicates the maximum rotational force the motor can exert, typically measured in Newton-centimeters (Ncm).

– Importance: A wide torque range allows for versatility in various implant procedures, accommodating different types of implants and bone densities. Understanding the torque specifications ensures that the motor can handle the demands of specific dental applications. -

Speed Settings

– Definition: Speed settings refer to the operational speeds of the motor, often adjustable within a range (e.g., 20,000 to 40,000 RPM).

– Importance: Different procedures may require varying speeds for optimal results. B2B buyers should assess the speed capabilities to ensure they can meet diverse clinical needs, enhancing procedural efficiency. -

Ergonomics and Weight

– Definition: Ergonomics pertains to the design features that improve usability, while weight impacts the ease of handling.

– Importance: A lightweight, ergonomically designed motor reduces clinician fatigue during extended procedures. This aspect can influence purchasing decisions, as comfortable tools can lead to better performance and patient outcomes. -

Noise Level

– Definition: Noise level measures the sound produced by the motor during operation, usually expressed in decibels (dB).

– Importance: A quieter motor can enhance patient comfort and reduce anxiety during procedures. Buyers should consider noise specifications, especially in environments where patient experience is a priority.

Common Trade Terminology

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to the procurement of dental implant motors:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers often source motors directly from OEMs to ensure quality and compatibility with their existing systems. Understanding this term helps in identifying reliable suppliers. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is vital for budgeting and inventory management. Buyers from different regions should negotiate MOQs that align with their operational needs and sales forecasts. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing and terms for specific products.

– Relevance: Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms. This process is critical for informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Relevance: Familiarity with Incoterms is essential for international transactions to avoid misunderstandings and disputes. Buyers should specify these terms to ensure clarity in delivery responsibilities. -

Lead Time

– Definition: Lead time is the time taken from placing an order to the delivery of goods.

– Relevance: Understanding lead times helps buyers plan their inventory and operations effectively. B2B buyers should inquire about lead times to manage expectations and ensure timely availability of equipment.

By familiarizing themselves with these technical properties and industry terms, international B2B buyers can make more informed purchasing decisions when acquiring w&h dental implant motors, ultimately enhancing their operational efficiency and service delivery.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the w&h dental implant motor Sector

Market Overview & Key Trends

The w&h dental implant motor sector is experiencing robust growth driven by several global factors. Increasing demand for dental procedures, coupled with technological advancements in dental instruments, has made high-quality implant motors essential for dental practices worldwide. In emerging markets such as Africa and South America, the rise in disposable income and an expanding middle class are catalyzing greater investment in dental health, thereby enhancing demand for advanced dental technologies.

Key trends shaping the market include the integration of digital technologies, such as CAD/CAM systems, which streamline the workflow from diagnosis to restoration. Moreover, the trend towards minimally invasive procedures is pushing manufacturers to innovate and develop more compact, efficient, and user-friendly dental motors. International B2B buyers should pay attention to these technological advancements as they can significantly impact operational efficiency and patient outcomes.

For buyers in regions like the Middle East and Europe, especially in countries like Italy and Saudi Arabia, understanding local regulatory frameworks and compliance requirements is crucial. These regions are witnessing a surge in dental tourism, prompting local dental practitioners to upgrade their tools to meet international standards. Engaging with reliable suppliers who can offer not only quality products but also compliance support will be paramount for successful procurement strategies.

Sustainability & Ethical Sourcing in B2B

In the current market landscape, sustainability has emerged as a key consideration for B2B buyers. The environmental impact of dental manufacturing processes is under scrutiny, making it essential for companies to adopt sustainable practices. Buyers should prioritize suppliers that demonstrate a commitment to reducing their carbon footprint, utilizing renewable energy sources, and minimizing waste in their production processes.

Ethical sourcing is another critical factor. B2B buyers should ensure that their suppliers adhere to fair labor practices and provide transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can be indicators of a supplier’s commitment to sustainable and ethical practices. Additionally, opting for green materials, such as those certified by environmental standards, can enhance the overall sustainability profile of the dental practice.

By focusing on these aspects, buyers can not only align their procurement strategies with global sustainability goals but also appeal to an increasingly eco-conscious customer base.

Brief Evolution/History

The w&h dental implant motor sector has evolved significantly over the past few decades. Initially characterized by basic mechanical systems, the market has transitioned to highly sophisticated, electronically controlled motors that offer precision and reliability. This evolution has been driven by advancements in technology and a growing emphasis on patient comfort and treatment efficacy.

The introduction of digital solutions has further transformed the landscape, allowing for real-time feedback and integration with other dental technologies. As the sector continues to innovate, international B2B buyers must stay informed about the latest developments to make strategic sourcing decisions that reflect the current market dynamics.

Related Video: Trump Hints At ‘Very Big’ Trade Deal With India, Aims To ‘Open Up’ Trade Relations | India Today

Frequently Asked Questions (FAQs) for B2B Buyers of w&h dental implant motor

-

What should I consider when vetting suppliers for w&h dental implant motors?

When vetting suppliers, prioritize their industry reputation, certifications, and experience in the dental equipment sector. Check for ISO certifications or specific dental industry standards that ensure quality and safety. Request references from previous clients, particularly those in your region, to gauge reliability and after-sales support. Additionally, assess their communication responsiveness and willingness to provide product information, as these are crucial for establishing a long-term partnership. -

Can I customize the w&h dental implant motor to meet specific needs?

Many suppliers offer customization options for dental implant motors to cater to specific operational requirements. When inquiring, clearly outline your needs, including any specialized features or functionalities. Discuss with the supplier about design flexibility, potential costs associated with customization, and the impact on lead times. Ensure that they can provide prototypes or samples for evaluation before committing to a larger order. -

What are the typical minimum order quantities (MOQ) and lead times for w&h dental implant motors?

MOQs for dental equipment can vary significantly by supplier, often ranging from 5 to 50 units. It’s important to clarify this upfront to avoid unexpected costs. Lead times may also differ based on customization requests, stock availability, and shipping logistics. Generally, expect lead times between 4 to 12 weeks. Always confirm these details in your initial discussions to plan your inventory effectively. -

What payment methods are commonly accepted for international purchases?

Most suppliers accept various payment methods, including bank transfers, credit cards, and letters of credit. For international transactions, bank transfers are often preferred due to security and traceability. Discuss payment terms upfront, including any deposits required and payment schedules. Additionally, consider using escrow services for large orders to mitigate risks associated with international trade. -

What quality assurance processes should I expect from suppliers?

Reliable suppliers should have stringent quality assurance (QA) processes in place. Request documentation that outlines their QA protocols, including testing procedures for the dental implant motors. Inquire about the warranty period and return policies, as these reflect their confidence in the product quality. Also, ensure that products come with relevant certifications, such as CE marking in Europe, which indicates compliance with health and safety standards. -

How can I handle disputes with suppliers effectively?

To manage disputes, establish clear communication channels and a defined process for addressing issues early on. Ensure that your contracts outline dispute resolution mechanisms, such as mediation or arbitration, particularly for international agreements. Maintaining detailed records of all transactions and communications can provide essential evidence if disputes arise. Additionally, consider engaging a local legal expert familiar with international trade laws to navigate complex situations. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

When sourcing internationally, factor in shipping costs, customs duties, and potential delays in transit times. Collaborate with your supplier to determine the most efficient shipping methods, and consider using freight forwarders to streamline logistics. Ensure that you understand the import regulations in your country, as compliance is crucial for avoiding delays or additional charges. Also, verify that the supplier provides proper documentation for customs clearance. -

What are the risks associated with sourcing w&h dental implant motors internationally?

International sourcing carries risks such as fluctuating exchange rates, political instability, and differences in regulatory standards. To mitigate these risks, conduct thorough market research and consider diversifying your supplier base across different regions. Establishing strong relationships with suppliers can also help in navigating challenges. Additionally, consider purchasing insurance to protect your investment against potential loss during transit or in case of supplier default.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for w&h dental implant motor

In the evolving landscape of dental technology, the strategic sourcing of w&h dental implant motors presents a unique opportunity for international B2B buyers. By understanding key factors such as supplier reliability, cost-efficiency, and product quality, stakeholders can enhance their procurement strategies. Investing in high-quality dental equipment not only improves clinical outcomes but also reinforces a brand’s reputation among patients and professionals alike.

For buyers in regions like Africa, South America, the Middle East, and Europe, aligning with reputable suppliers is crucial. It ensures access to innovative technologies and compliance with international standards. Prioritizing partnerships with established manufacturers can facilitate smoother logistics, better after-sales support, and favorable pricing structures.

As the demand for dental implants continues to rise, the importance of effective sourcing strategies cannot be overstated. International buyers are encouraged to conduct thorough market research and leverage digital tools to identify potential suppliers. This proactive approach will not only streamline operations but also position businesses for long-term success in a competitive marketplace.

Embrace the future of dental care by making informed sourcing decisions today—your practice and patients will thank you.