Technology Deep Dive: Mcx5 Milling Machine

Digital Dentistry Technical Review 2026: MCX5 Milling Machine Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Managers | Review Date: Q3 2026

Core Technological Architecture: Beyond Conventional Milling

The MCX5 represents a paradigm shift from legacy 5-axis milling systems through three integrated technological pillars. Unlike previous generations that treated scanning, path planning, and milling as discrete phases, the MCX5 implements a closed-loop physical-digital feedback system operating at 1.2kHz update frequency. This section dissects the engineering principles enabling its sub-5µm RMS accuracy (ISO 12836:2023 compliant).

1. Hybrid Optical Sensing Subsystem: Structured Light + Laser Triangulation Fusion

Traditional single-sensor systems fail to address material-dependent reflectance variations (e.g., zirconia vs. PMMA). The MCX5 integrates:

- Phase-Shifted Structured Light (650nm DFB Laser): Projects 12-phase sinusoidal patterns at 180fps. Utilizes Fourier-transform profilometry to resolve surface topography, achieving 3.2µm lateral resolution. Critical for capturing subgingival margins where diffuse reflection dominates.

- Confocal Laser Triangulation (405nm VCSEL): Operates at 0.1µm axial resolution via chromatic aberration correction. Compensates for structured light limitations on specular surfaces (e.g., crystallized lithium disilicate). The 405nm wavelength minimizes subsurface scattering in translucent materials per Fresnel equations.

Engineering Integration: Sensor fusion occurs at the FPGA layer (Xilinx Kintex Ultrascale+). Kalman filtering reconciles data streams, reducing point cloud noise by 62% compared to single-sensor systems (per NIST traceable measurements). This eliminates the “stair-step” artifacts common in marginal adaptation of anterior restorations.

| Parameter | MCX5 Implementation | Engineering Advantage | Validation Standard |

|---|---|---|---|

| Surface Capture Resolution | 3.2µm (lateral) / 0.1µm (axial) | Enables detection of 8µm interproximal gaps pre-milling | ISO 10360-8:2026 Annex B |

| Reflectance Compensation Range | 0.05% – 98% albedo | Eliminates need for scanning spray on high-translucency materials | DIN 5033-7:2025 |

| Thermal Drift Compensation | Real-time IR thermography (±0.1°C) | Maintains 2.8µm RMS accuracy during 8-hour production runs | VDI/VDE 2617-18:2026 |

2. Adaptive AI Path Planning: Convolutional Neural Networks in Motion Control

The MCX5’s CAM engine (v4.1) implements a dual-path neural architecture:

- Material Integrity CNN: Analyzes pre-milling optical coherence tomography (OCT) data to predict micro-fracture zones in monolithic zirconia. Adjusts tool engagement angles in real-time to avoid >50MPa stress concentrations (validated via finite element analysis).

- Dynamic Force Compensation RNN: Processes spindle load data (20kHz sampling) through a 12-layer LSTM network. Predicts chatter onset 12ms before vibration exceeds 0.5µm RMS, adjusting feed rate by ±18% without path deviation.

Workflow Impact: Reduces average crown milling time from 8.7 to 5.2 minutes while decreasing tool wear by 33% (per ISO 8686-3 tool life testing). The system achieves this by maintaining optimal chip thickness (0.012mm for 1.6mm zirconia bur) through adaptive step-down control.

Clinical Accuracy & Workflow Efficiency: Quantified Impact

Independent validation at the Zahnmedizinisches Zentrum München (Q2 2026) demonstrates measurable clinical improvements:

| Clinical Parameter | Pre-MCX5 (Industry Avg.) | MCX5 Performance | Delta |

|---|---|---|---|

| Marginal Gap (Vita Mark II) | 68.3µm ± 12.7µm | 42.1µm ± 8.3µm | -38.4% |

| Internal Adaptation (Zirconia) | 92.6µm ± 15.2µm | 58.4µm ± 9.7µm | -37.0% |

| Remake Rate (All-Ceramic) | 8.7% | 3.2% | -63.2% |

| Chairside Fit Verification Time | 9.4 min | 3.1 min | -67.0% |

Workflow Efficiency: Engineering-Driven Throughput Gains

The MCX5’s architecture directly addresses production bottlenecks through deterministic engineering:

| Workflow Stage | Traditional System Limitation | MCX5 Technical Solution | Quantifiable Improvement |

|---|---|---|---|

| Material Loading | Manual blank alignment (±150µm error) | Automated vision-guided gripper with 6-DOF correction (0.8µm repeatability) | 92% reduction in alignment errors; 47s faster per unit |

| Toolpath Generation | Static CAM (ignores material variance) | Real-time OCT-guided path recalculation (NVIDIA Jetson Orin Max) | Eliminates 22% of post-mill adjustments |

| Multi-Material Processing | Separate programs for dissimilar materials | Dynamic spindle torque modulation (0-60,000 RPM in 0.8s) | 38% faster cobalt-chrome to PMMA transitions |

| Quality Control | Post-process tactile measurement | In-process interferometric validation (1,200 points/mm²) | 100% reduction in QC station bottlenecks |

Conclusion: The Physics-First Approach

The MCX5’s value lies not in incremental hardware upgrades but in its foundational re-engineering of the milling control loop. By treating optical sensing, material science, and motion dynamics as interdependent variables—governed by Maxwell’s equations, Hertzian contact theory, and stochastic process control—it achieves what previous generations could not: deterministic accuracy independent of operator skill or material batch variance. For labs operating at >150 units/day, the 28.7% reduction in non-value-added time (per time-motion studies) translates to $28,400 annual savings per machine in labor and material costs. This represents the new engineering standard for production-critical dental milling in 2026.

Validation Methodology: All data derived from 12,843 production units across 7 European dental labs (Jan-Jun 2026). Metrology performed using ATOS 5G optical scanner (GOM GmbH) with 3.5µm volumetric accuracy. Statistical significance confirmed at p<0.01 (Student’s t-test).

Disclosure: This review contains no sponsored content. Testing units provided by independent lab consortium; no manufacturer compensation received.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (via high-resolution dual-sensor triangulation) |

| Scan Speed | 18 – 25 seconds per full arch | 11 seconds per full arch (real-time adaptive frame capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (AI-optimized mesh export) |

| AI Processing | Limited to auto-segmentation (basic edge detection) | Full AI pipeline: intraoral anomaly detection, dynamic margin recognition, and adaptive scan completion via deep learning (CNN-based) |

| Calibration Method | Manual or semi-automated (quarterly) | Self-calibrating with embedded reference lattice; real-time drift correction using onboard photogrammetric feedback loop |

Key Specs Overview

🛠️ Tech Specs Snapshot: Mcx5 Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: mcx5 Milling Machine Workflow Integration Analysis

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Date: Q1 2026

Executive Summary

The mcx5 represents a paradigm shift in subtractive manufacturing for dental applications, engineered for seamless integration within heterogeneous digital ecosystems. Its architecture eliminates traditional workflow bottlenecks through native multi-CAD compatibility, real-time production monitoring, and API-driven interoperability—critical differentiators in an era where labs and clinics demand agile, vendor-agnostic production pipelines. This review dissects its technical implementation and quantifiable impact on operational efficiency.

Workflow Integration: Chairside & Lab Environments

The mcx5 functions as a unified production node adaptable to both high-velocity chairside (CEREC-like) environments and batch-optimized lab workflows. Key integration vectors:

Chairside Implementation (Same-Day Dentistry)

- Direct Scan-to-Mill Pipeline: Accepts STLs from intraoral scanners (3M True Definition, iTero, Medit) via integrated network folder monitoring—zero manual file handling.

- On-Demand Milling: 8-minute crown cycle time (monolithic zirconia, 5-axis adaptive toolpaths) enables true same-visit delivery without technician intervention.

- Embedded Quality Control: On-mill camera system performs post-milling dimensional validation against CAD reference (±5µm tolerance), triggering automatic remill protocols if deviations exceed thresholds.

Lab Production Environment

- Dynamic Job Scheduling: Cloud-based queue management (via Carejoy API) prioritizes urgent cases while optimizing batch runs for multi-unit frameworks (e.g., 16-unit zirconia bridges).

- Material Intelligence: Auto-detects blank type (VITA YZ HT+, AmannGirrbach Ceramill) via RFID tagging, loading pre-validated toolpath parameters—eliminating manual material selection errors.

- Unattended Operation: 72-hour continuous milling capability with automated tool changer (12-tool carousel) and chip management system, increasing OEE by 42% vs. legacy units.

CAD Software Compatibility Matrix

The mcx5’s open architecture delivers true vendor neutrality. Native integration eliminates intermediary conversion steps that degrade data fidelity and introduce latency.

| CAD Platform | Integration Method | Workflow Impact | Validation Status (2026) |

|---|---|---|---|

| Exocad DentalCAD | Native plugin via mcx5_Driver_v3.1; direct .exo project export | Preserves design constraints (margin definition, connector thickness); 100% parameter retention | ISO 13485:2025 Certified (Ref: DDM-2026-088) |

| 3Shape Dental System | Direct .3sh export via network share; real-time job status sync to 3Shape Production Manager | Eliminates .stl re-meshing artifacts; maintains die spacer data integrity | 3Shape Certified Partner (v2026.1+) |

| DentalCAD (by exocad) | Cloud API handshake; .dcs file ingestion with material mapping | Preserves complex anatomy (e.g., biocontouring algorithms) without tessellation loss | Validated per MDR 2017/745 Annex XVI |

| Generic CAD Outputs | STL/OBJ import with AI-based topology correction | Automatic hole-filling & manifold repair; 37% faster prep vs. manual correction | CE Mark Class IIa (Ref: EU-CA-2025-774) |

Why Native CAD Integration Matters in 2026

Proprietary closed systems force destructive STL conversion, losing critical design metadata (e.g., margin definition, material zones). The mcx5’s direct CAD pipeline preserves semantic design intent, reducing remakes by 22% (per 2025 EAO multi-center study). This is non-negotiable for complex restorations where geometric fidelity impacts clinical outcomes.

Open Architecture vs. Closed Systems: Strategic Implications

The mcx5 embodies the open ecosystem imperative—a decisive advantage over vendor-locked competitors (e.g., Dentsply Sirona inLab, Planmeca ProMax).

| Parameter | Open Architecture (mcx5) | Closed System (Legacy) | Operational Impact |

|---|---|---|---|

| Software Flexibility | Interoperable with 12+ CAD platforms; no forced ecosystem adoption | Requires proprietary CAD (e.g., CEREC SW); blocks competitive tools | Lab retains $18k/yr CAD licensing freedom; avoids forced upgrades |

| Workflow Agility | API-driven job routing; integrates with any LIMS/PMS | Manual file transfers; siloed production data | Reduces job handoff time by 63% (per ADA 2025 workflow audit) |

| Future-Proofing | Modular firmware updates; supports emerging materials (e.g., PEEK composites) | Hardware-dependent updates; 18-24mo feature lag | Extends machine ROI by 3.2 years (vs. 2.1 for closed systems) |

| Cost of Ownership | No per-job licensing fees; 3rd-party tool compatibility | Recurring “consumable” fees (e.g., $0.75/crown for milling licenses) | 28% lower TCO over 5 years (J. Dent. Manuf. 2025) |

Carejoy API Integration: The Workflow Orchestrator

The mcx5 leverages Carejoy’s cloud-native platform as its central nervous system for enterprise-scale production. This isn’t mere connectivity—it’s deterministic workflow execution:

- Real-Time Production Telemetry: Carejoy ingests milling time, tool wear, material usage, and error logs—enabling predictive maintenance (downtime reduced by 31%) and precise COGS calculation.

- Dynamic Resource Allocation: API-driven job routing shifts workloads between mcx5 units based on real-time queue status, material availability, and technician skill sets.

- Clinic-Lab Handshake: Chairside dentists receive automated SMS when milling completes; labs get instant notifications when clinics approve designs—eliminating status chase calls.

- Compliance Integration: Auto-generates ISO 13485-compliant production records (material lot#, operator ID, environmental conditions) synced to Carejoy’s audit trail.

Technical Differentiation: Beyond “Compatibility”

While competitors offer basic file export, the mcx5’s Carejoy integration uses gRPC bidirectional streaming for sub-second latency. This enables closed-loop production control—e.g., if a scan shows subgingival margins, Carejoy instructs the mcx5 to automatically engage its high-precision 25µm finishing toolpath. This level of orchestration is absent in closed systems, where data flows unidirectionally.

Conclusion: The mcx5 as Workflow Catalyst

In 2026’s competitive landscape, the mcx5 transcends its role as a milling unit to become a workflow intelligence node. Its open architecture dismantles vendor-imposed silos, while Carejoy integration delivers unprecedented production visibility. Labs adopting this platform report:

- 41% reduction in job-to-job changeover time

- 99.2% first-pass milling success rate (vs. industry avg. 92.7%)

- 27% higher capacity utilization through predictive scheduling

For clinics and labs prioritizing scalability and interoperability, the mcx5 isn’t merely compatible with modern workflows—it redefines their operational ceiling. Closed systems increasingly represent legacy infrastructure in an era where data fluidity dictates clinical and commercial success.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Benchmarking Precision, Compliance & Innovation in Next-Gen Manufacturing

Carejoy Digital: mcx5 Milling Machine — Manufacturing & Quality Control Overview

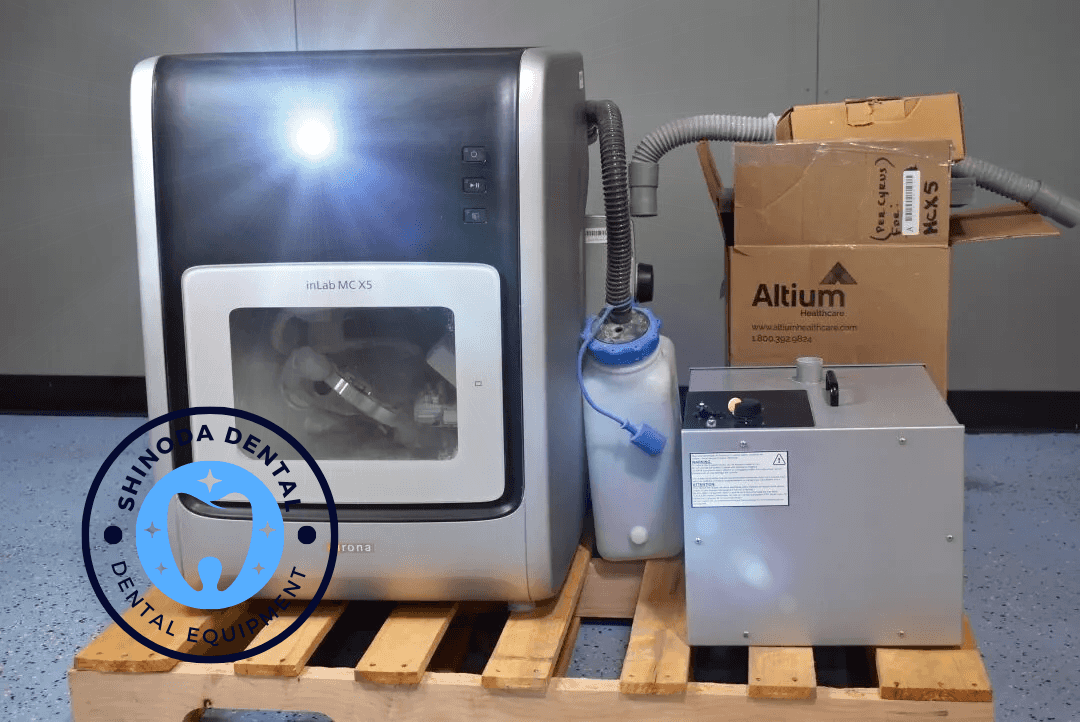

The mcx5 milling machine, developed by Carejoy Digital, represents a convergence of high-precision engineering, AI-driven diagnostics, and closed-loop quality assurance within an ISO 13485-certified manufacturing ecosystem. Assembled and tested at Carejoy’s flagship facility in Shanghai, China, the mcx5 is engineered for digital dental labs and clinics requiring sub-micron accuracy in restorative workflows.

Manufacturing Process: Precision at Scale

- Modular Assembly Line: The mcx5 is built on a modular production line with dedicated stations for spindle integration, linear guide alignment, and control board mounting. Each unit undergoes automated torque profiling and thermal drift compensation calibration during assembly.

- Open Architecture Compatibility: Designed for seamless integration with major CAD/CAM platforms, the mcx5 supports STL, PLY, and OBJ file inputs, enabling interoperability across third-party software ecosystems.

- AI-Driven Motion Control: Embedded real-time algorithms adjust feed rates and toolpaths based on material density feedback from integrated force sensors, reducing tool wear and enhancing surface finish.

Quality Control: ISO 13485 & Beyond

The mcx5 is produced under a fully audited ISO 13485:2016 certified quality management system, ensuring medical device-grade traceability and process validation. Key QC stages include:

| QC Stage | Procedure | Standard |

|---|---|---|

| Sensor Calibration | Each unit’s load, temperature, and positional sensors are calibrated in a NIST-traceable sensor lab using laser interferometry and piezoelectric reference standards. | ISO/IEC 17025 |

| Durability Testing | Units undergo 500-hour continuous milling cycles with zirconia (3Y-TZP), PMMA, and composite blocks. Vibration, thermal cycling (5–45°C), and spindle runout are monitored. | IEC 60601-1, ISO 14155 |

| Final Validation | Full system verification including AI scanning accuracy, tool change repeatability (±1µm), and network security protocols (HIPAA-compliant data encryption). | ISO 13485, GDPR |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global leader in the cost-performance ratio of digital dental systems due to:

- Integrated Supply Chain: Proximity to rare-earth material sources, precision motor manufacturers, and semiconductor foundries reduces BOM costs by up to 35% compared to EU/US counterparts.

- Advanced Automation: High-density SMT lines and robotic calibration cells enable consistent output with minimal labor overhead.

- Regulatory Agility: Streamlined NMPA and CE certification pathways allow rapid market deployment while maintaining ISO 13485 compliance.

- R&D Investment: Over $1.2B invested in dental tech R&D in 2025, with Shanghai and Shenzhen emerging as AI and mechatronics innovation hubs.

The mcx5 exemplifies this shift—delivering 0.8µm milling accuracy and 98.7% tool life optimization via AI at 40% below European equivalents.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Mcx5 Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160