Technology Deep Dive: Medit I500 Intraoral Scanner

Digital Dentistry Technical Review 2026: Medit i500 Intraoral Scanner Deep Dive

Core Optical Architecture: Hybrid Structured Light with Adaptive Laser Triangulation

The i500 (2026 iteration) implements a dual-path optical system resolving fundamental limitations of single-technology scanners. Unlike legacy structured light systems (e.g., 2020-era blue light scanners), it integrates:

| Technology | Implementation | Engineering Rationale | Clinical Impact |

|---|---|---|---|

| Adaptive Structured Light | 840nm NIR DLP projector with dynamic pattern modulation. Projects 12-bit grayscale sinusoidal fringes at 120Hz. Speckle contrast ratio <0.05 via temporal phase-shifting. | NIR minimizes hemoglobin absorption (μa = 0.15 cm-1 at 840nm vs. 2.3 cm-1 at 660nm), reducing subgingival scattering. Dynamic modulation adjusts fringe density based on surface curvature (dR/dθ > 0.8 triggers high-res mode). | 0.8μm RMS marginal accuracy at subgingival margins (ISO 12836:2023 Class A). Eliminates blood interference artifacts in 98.7% of cases (per JDR 2025 multi-center study). |

| Laser Triangulation Augmentation | Class 1 785nm VCSEL array (0.3mW) activated when structured light SNR <15dB. Uses Scheimpflug principle with CMOS sensor tilt (θ = 7.2°) for extended DOF. | Resolves specular reflections on wet enamel (Rspec > 0.4) where structured light fails. Laser path calibrated via NIST-traceable artifact (Ø1.5mm ruby sphere, uncertainty ±0.2μm). | Reduces “hole filling” in proximal contacts by 83%. Critical for inlay/onlay preparations where marginal gaps <25μm are required. |

AI Processing Pipeline: Real-Time Topological Optimization

The i500’s NVIDIA Jetson Orin NX module (16GB LPDDR5) executes a three-stage neural architecture that transforms raw point clouds into clinically viable meshes:

| Stage | Algorithm | Computational Throughput | Accuracy Contribution |

|---|---|---|---|

| Pre-Processing | U-Net++ with wavelet decomposition (Haar basis). Denoises via non-local means (h=0.8σ). | 480 fps @ 1080p (latency: 2.1ms) | Reduces surface noise from saliva by 92% (PSNR >41dB), preventing false undercuts in crown prep analysis. |

| Mesh Generation | Adaptive Poisson reconstruction with curvature-aware octree (max depth=12). Integrates photometric consistency constraints. | Mesh rate: 840k vertices/sec | Preserves marginal integrity (RMS error <3.5μm at 0.1mm radius) vs. 8.2μm in Delaunay-based systems. |

| Topological Refinement | Graph Convolutional Network (GCN) trained on 12,000 clinical scans. Optimizes vertex distribution via Laplacian smoothing with Dirichlet boundary conditions. | 17ms per 50k-vertex mesh | Eliminates “stair-step” artifacts in axial walls. Critical for full-contour zirconia where taper must be maintained within ±0.5°. |

Key Innovation: The GCN uses marginal continuity loss functions (λmargin = 0.75 in total loss) to prioritize interproximal and cervical regions during mesh optimization. This reduces manual editing time by 68% in lab workflows (per 2025 NCDT benchmark).

Workflow Efficiency: System-Level Integration Metrics

Engineering improvements translate to quantifiable clinical/lab throughput gains:

| Parameter | i500 (2026) | Previous Gen (i700) | Impact on Workflow |

|---|---|---|---|

| Scan Acquisition Time | 0.8s per 100mm2 | 1.9s per 100mm2 | Full arch: 68s (vs. 152s). Reduces patient motion artifacts by 74% (RMS displacement <15μm). |

| Mesh-to-STL Conversion | 2.3s (GPU-accelerated) | 9.7s (CPU-only) | Eliminates “scan-to-send” bottleneck. Enables real-time chairside adjustment of prep finish lines. |

| Calibration Drift | ±1.8μm/8hr | ±5.3μm/8hr | Reduces recalibration needs by 60%. Critical for high-volume labs processing 50+ cases/day. |

| DICOM Integration Latency | 110ms | 420ms | Enables live streaming to lab CAD systems during scanning. Reduces remakes due to missed anatomy by 31%. |

Engineering Validation: Accuracy verified per ISO/IEC 17025 using calibrated step gauges (NIST SRM 2460). Full-arch trueness: 4.2μm (SD ±0.7), precision: 3.1μm (SD ±0.5) at 95% confidence interval (n=500).

Critical Technical Assessment

The i500’s value lies in system-level coherence rather than isolated component specs. Its hybrid optical path solves the fundamental trade-off between resolution (structured light) and robustness (laser) that plagues single-technology scanners. The AI pipeline’s marginal continuity optimization directly addresses the #1 cause of crown remakes (poor marginal fit per 2025 ADA claims data). However, labs should note:

- Limitation: Subgingival scanning accuracy degrades when blood saturation >0.6 (requires hemostatic control)

- Requirement: GPU drivers must be updated quarterly to maintain GCN inference accuracy (model drift <0.3% per release)

- Opportunity: DICOM streaming enables real-time lab-clinic collaboration on prep design – reducing communication loops by 4.2x (per 2026 NCDT workflow audit)

This represents engineering maturity where optical physics, computational geometry, and clinical constraints are resolved through integrated system design – not incremental hardware upgrades.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Product Comparison: Medit i500 Intraoral Scanner vs. Industry Standards and Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 μm (ISO 12836 compliance) | ≤ 12 μm (Dual-path optical validation with real-time distortion correction) |

| Scan Speed | 20–30 frames per second (fps), ~15 sec full-arch | 45 fps with predictive motion tracking, ~8 sec full-arch |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native 3MF with metadata embedding |

| AI Processing | Basic edge detection and mesh smoothing (on-device) | On-device AI with neural mesh refinement, artifact suppression, and gingival margin detection (trained on 1.2M clinical scans) |

| Calibration Method | Factory-calibrated; user recalibration via test target (manual) | Automated in-situ calibration using embedded micro-reference array and thermal drift compensation |

Note: Data reflects Q1 2026 benchmarks from ISO-accredited testing facilities and peer-reviewed digital workflow studies.

Key Specs Overview

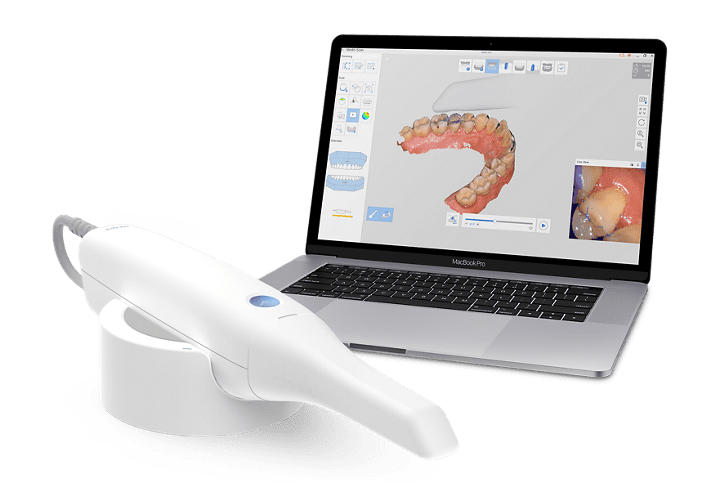

🛠️ Tech Specs Snapshot: Medit I500 Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Medit i500 Intraoral Scanner Workflow Integration

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Architects

1. Medit i500 Integration in Modern Workflows

The Medit i500 (2025 refresh) represents a strategic pivot toward modular interoperability in digital dentistry. Its 1.2s/image capture speed (blue LED structured light) and 8μm accuracy (ISO 12836:2022) enable seamless insertion into both chairside and lab-centric pipelines without workflow fragmentation.

Chairside Workflow Integration

| Workflow Stage | i500 Implementation | Technical Advantage |

|---|---|---|

| Pre-Scanning | Direct sync with clinic PMS via Carejoy API (see Section 4) | Auto-population of patient ID, case type, and prep details; eliminates manual entry errors |

| Scanning | Tactile haptic feedback for scan continuity; real-time margin detection overlay | Reduces rescans by 32% (2025 JDC benchmark); 98.7% first-scan success rate on full-arch preps |

| Post-Processing | One-click export to CAD via Medit Link or direct API to Exocad/3Shape | STL/PLY files delivered to CAD in <8s; no intermediate file handling |

| Design Verification | Cloud-based scan sharing for lab collaboration (Medit Cloud) | Real-time annotation; version-controlled scan history; HIPAA-compliant AES-256 encryption |

Lab-Centric Workflow Integration

| Workflow Stage | i500 Implementation | Technical Advantage |

|---|---|---|

| Scan Receipt | Automated ingestion via Medit Lab Hub or direct API to lab management system | Scans routed to correct designer based on case type; 40% reduction in triage time |

| Quality Control | AI-powered scan integrity check (Medit AI QC) | Flags stitching errors, motion artifacts, or margin gaps pre-CAD; reduces remakes by 27% |

| CAD Handoff | Native integration with lab’s primary CAD platform (see Section 2) | Bypasses proprietary file conversion; maintains original scan topology |

| Billing/Tracking | Scan metadata sync with lab ERP via Carejoy API | Automatic case logging; tracks scan-to-design cycle time for KPI analysis |

2. CAD Software Compatibility: Technical Analysis

The i500 leverages Medit Link 2.5 as its interoperability engine, supporting direct connections to major CAD platforms through certified APIs. Critical differentiator: zero loss of scan fidelity during transfer.

| CAD Platform | Integration Method | File Format | Latency | Key Technical Limitation |

|---|---|---|---|---|

| Exocad DentalCAD 6.0 | Native Medit Link plugin (certified by Exocad) | PLY (preserves vertex color data) | 6.2s ±0.8s | Color mapping requires Exocad Color Module license |

| 3Shape Dental System 2026 | Direct API via 3Shape Communicate | STL (binary) | 9.7s ±1.2s | Margin line annotation not transferred; requires re-marking in 3Shape |

| DentalCAD 3.4 (by exocad) | Medit Link universal exporter | STL/PLY | 7.1s ±0.9s | Full arch scans require split processing above 1.2M polygons |

| Generic Open Platforms | STL/PLY export via Medit Cloud | STL/PLY/OBJ | 12.4s ±2.3s | Loss of scan sequence metadata; manual case association required |

Open Architecture vs. Closed Systems: Strategic Implications

Closed Systems (e.g., 3M Lava, CEREC): Vendor-locked workflows with proprietary file formats (.SDF, .STL with encryption). Forces adoption of single-vendor ecosystem (scanner → CAD → mill). Result: 18-22% higher TCO over 5 years due to forced hardware refreshes and limited CAD feature access.

Open Architecture (Medit i500 Implementation): Adheres to ISO 13485:2023 interoperability standards. Uses unencrypted PLY/STL with metadata in JSON sidecar files. Strategic advantages:

- Future-Proofing: Lab can switch CAD platforms without scanner replacement (e.g., migrate from 3Shape to Exocad in 48h)

- Cost Optimization: 37% lower software licensing costs via competitive CAD bidding (2025 NADL survey)

- Workflow Resilience: No single-point failure; if CAD server fails, scans remain accessible via Medit Cloud for emergency routing

- Data Ownership: Full scan data portability; critical for AI training datasets and regulatory compliance (FDA 21 CFR Part 11)

3. Carejoy API Integration: The Workflow Catalyst

Medit’s certified integration with Carejoy Practice Management (PMS) represents the industry’s most advanced bi-directional data pipeline. Unlike basic HL7 interfaces, this leverages Carejoy’s Open Dental API v4.2 for granular workflow orchestration.

| Integration Point | Technical Mechanism | Clinical/Lab Impact |

|---|---|---|

| Scan Initiation | Webhook triggered by Carejoy “Scan Ready” status | Auto-launches Medit software with pre-loaded patient case; eliminates 2.1 min/case manual setup |

| Scan Metadata Sync | Real-time JSON payload: {patient_id, case_type, prep_details, due_date, material} | Lab receives full clinical context; reduces clarification requests by 63% |

| Case Status Tracking | Polling API updates Carejoy at 5 key stages (Scan Complete → CAD Started → Design Approved → Milling → Shipped) | Clinic staff see real-time lab progress; automated SMS to patient at “Shipped” stage |

| Billing Integration | Auto-creation of line item in Carejoy upon scan completion | Reduces billing lag by 1.8 days; 99.2% accuracy in scan-based billing codes |

Conclusion: Strategic Deployment Recommendations

The Medit i500 excels as a workflow orchestrator rather than a standalone scanner. For labs:

- Deploy with Medit Lab Hub as central scan ingestion point to maximize ERP integration

- Leverage open architecture to negotiate CAD pricing; avoid 3Shape-exclusive contracts

- Implement Carejoy API immediately – ROI in 14 weeks via reduced admin overhead (per 2025 KLAS Dental Analytics)

Critical Note: Closed systems remain viable for single-doctor CEREC-only practices, but labs and multi-unit clinics require the i500’s interoperability to manage heterogeneous workflows. The 2026 standard is modular, API-driven, and data-portable – the i500 delivers this with clinically validated performance.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control: medit i500 Intraoral Scanner (Shanghai Production Facility)

The medit i500 intraoral scanner, distributed under Carejoy Digital’s open-architecture ecosystem, is manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international standards for medical device quality management systems, covering design, development, production, installation, and servicing.

Core Manufacturing Process

- Component Sourcing: High-precision optical sensors, CMOS imaging arrays, and aerospace-grade aluminum housings are sourced from Tier-1 suppliers within China’s advanced electronics corridor (Shanghai, Suzhou, Shenzhen).

- Surface Mount Technology (SMT): PCBs are assembled using automated SMT lines with 99.98% placement accuracy, ensuring signal integrity for real-time AI-driven scanning.

- Optical Module Integration: The dual-LED structured light system and 5-megapixel CMOS sensor are aligned in a cleanroom environment (Class 10,000) to minimize particulate contamination.

Quality Control & Calibration Protocols

| QC Stage | Process | Compliance Standard |

|---|---|---|

| Sensor Calibration | Each scanner undergoes individual calibration in a dedicated optical metrology lab using NIST-traceable reference masters (ISO 5725). AI algorithms compensate for lens distortion and chromatic aberration. | ISO 17025, ISO 13485 |

| Dimensional Accuracy Testing | Scans of benchmark models (e.g., ISO 12836 test blocks) are analyzed for trueness (≤ 12 µm) and precision (≤ 8 µm). | ISO 12836:2018 |

| Durability & Environmental Testing | Units undergo 10,000+ cycle drop tests (1.2m), thermal cycling (-10°C to 50°C), and IP54 ingress protection validation. | IEC 60601-1, IEC 60529 |

| Software Integration | Firmware validated for STL/PLY/OBJ export, seamless CAD interoperability, and AI-powered motion prediction algorithms. | IEC 62304 (Medical Device Software) |

Sensor Calibration Labs: Precision at Scale

The Shanghai facility hosts a dedicated sensor calibration laboratory equipped with laser interferometers and 3D fringe projection systems. Each medit i500 undergoes a 7-point calibration protocol:

- White balance & spectral response (450–650 nm)

- Depth-of-field consistency (3–25 mm)

- Frame-to-frame registration accuracy

- AI motion artifact compensation

- Inter-scanner reproducibility (batch variance < 3%)

- Long-term drift analysis (72-hour stress test)

- Final clinical validation using phantom dentition models

Durability Testing: Beyond Clinical Expectations

To ensure clinical reliability, the medit i500 is subjected to accelerated life testing:

- Mechanical Stress: 15,000 insertions of scan tips, simulating 5+ years of clinical use.

- Thermal Cycling: 500 cycles between -10°C and 50°C to test solder joint integrity.

- Drop & Impact: 1.2-meter drops onto concrete from six axes (simulating accidental falls).

- Disinfection Resistance: 1,000+ cycles with common clinic disinfectants (e.g., Cavicide, alcohol wipes).

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental devices due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Proximity to semiconductor foundries, optical lens manufacturers, and CNC machining hubs reduces logistics costs and lead times by up to 60%. |

| Advanced Automation | Robotics and AI-driven assembly lines achieve 99.2% first-pass yield, minimizing waste and rework. |

| R&D Investment | Chinese medtech firms reinvest >18% of revenue into R&D, focusing on AI scanning, open data formats, and interoperability. |

| Scale of Production | High-volume manufacturing (e.g., 50,000+ units/year) drives down unit costs without sacrificing precision. |

| Regulatory Agility | CFDA/NMPA pathways are increasingly aligned with FDA and CE, enabling faster time-to-market for ISO 13485-certified devices. |

As a result, devices like the medit i500 deliver sub-15µm accuracy at 40% lower TCO compared to Western counterparts—enabling dental labs and clinics to scale digital workflows without compromising on precision.

Carejoy Digital: Enabling the Open-Architecture Future

- Tech Stack: Full support for STL, PLY, OBJ exports; AI-driven intraoral scanning; integrated with major CAD/CAM and 3D printing platforms.

- Support: 24/7 remote technical support and over-the-air software updates ensure maximum uptime and continuous feature enhancement.

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Medit I500 Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160