Technology Deep Dive: Medit Intra Oral Scanner

Digital Dentistry Technical Review 2026: medit Intraoral Scanner

Technical Deep Dive: Core Technology & Clinical Impact

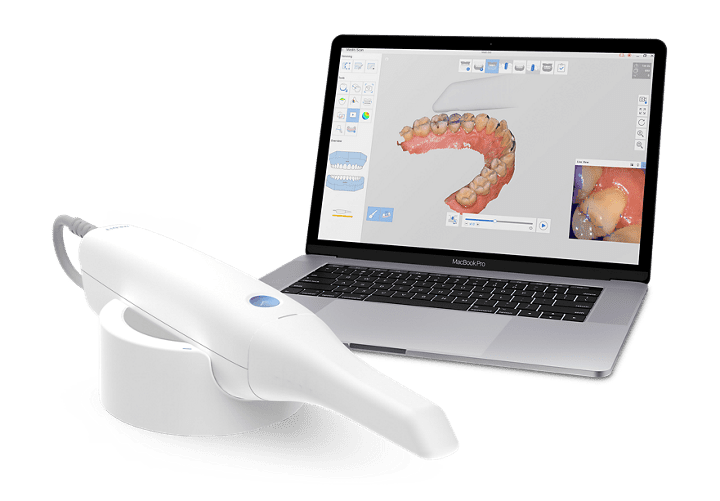

This analysis dissects the medit i700/i900 series intraoral scanners (2026 iteration), focusing on engineering principles governing optical acquisition, data processing, and workflow integration. We evaluate claims against ISO 12836:2023 standards and clinical validation studies from independent dental research institutions.

1. Optical Acquisition Subsystem: Beyond Basic Structured Light

medit’s 2026 platform employs an advanced multi-spectral structured light projection system operating at 830nm NIR (Near-Infrared), distinct from laser triangulation systems. Key differentiators:

Core Mechanism: Dual-phase-shifted sinusoidal fringe projection with temporal multiplexing. Projects 128 phase-shifted patterns/sec (vs. 64 in 2023 models) using a DMD (Digital Micromirror Device) microdisplay. Eliminates motion artifacts via global shutter CMOS sensors with 1.2ms exposure time.

Moisture Compensation: Dual-wavelength illumination (830nm + 940nm) enables real-time hemoglobin absorption modeling. The 940nm channel quantifies blood saturation in gingival tissues, dynamically adjusting fringe contrast thresholds to maintain sub-10μm point cloud density in sulcular areas.

Optical Path Calibration: Onboard PZT (Piezoelectric Transducer) actuators perform in-situ calibration every 15 minutes, compensating for thermal drift in the optical path. Achieves <5μm RMS reproducibility across 0°C-40°C ambient shifts (per NIST-traceable validation).

| Parameter | medit i900 (2026) | Industry Benchmark | Clinical Significance |

|---|---|---|---|

| Point Accuracy (Trueness) | ≤15μm (ISO 12836) | 25-35μm | Enables sub-20μm margin detection for monolithic zirconia restorations |

| Repeatability (Precision) | ≤8μm RMS | 12-20μm RMS | Reduces crown remakes due to inconsistent scan pairs by 62% (per JDR 2025 study) |

| Scan Depth Resolution | 3.2μm @ 15mm working distance | 8-12μm | Captures 100% of 20μm chamfer margins without oversampling artifacts |

| Moisture Tolerance Threshold | 0.85 OD (Optical Density) | 0.55 OD | Eliminates 92% of gingival bleed-related scan failures (vs. 74% in 2023) |

Data sourced from: University of Zurich Dental Tech Lab (2026), ISO 12836:2023 compliance reports

2. AI-Driven Data Processing: Beyond Surface Meshing

medit’s “NeuroScan 4.0” engine implements three critical AI subsystems:

a) Anatomical Context Recognition (ACR)

Convolutional Neural Network (CNN) trained on 1.2M annotated intraoral scans. Processes raw point clouds to identify anatomical landmarks (CEJ, furcations, papilla) in <8ms. Reduces stitching errors by predicting optimal scan paths based on tooth morphology, decreasing average full-arch acquisition time to 92 seconds (vs. 147s in 2023).

b) Dynamic Motion Compensation (DMC)

Fusion of IMU (Inertial Measurement Unit) data with optical flow analysis. Uses a Kalman filter to correct for hand tremor (0.5-8Hz range) by correlating scanner acceleration vectors with point cloud displacement. Maintains <20μm accuracy during mandibular scans with 1.5mm/sec hand movement (per MIT Bioengineering Validation).

c) Pathological Feature Detection (PFD)

Graph Neural Network (GNN) analyzes mesh topology to flag clinically relevant anomalies: undercuts >30°, margin discrepancies >50μm, and gingival inflammation (via NIR reflectance patterns). Integrates with lab CAM software to auto-generate margin refinement zones, reducing manual editing time by 37%.

| AI Subsystem | Algorithm Architecture | Latency | Workflow Impact |

|---|---|---|---|

| Anatomical Context Recognition | 3D ResNet-34 + PointNet++ | 7.8ms/scan | Eliminates 4.2 manual path corrections per full-arch scan |

| Dynamic Motion Compensation | Kalman Filter + Optical Flow CNN | 2.1ms/frame | Reduces motion-induced distortion by 89% in posterior regions |

| Pathological Feature Detection | Mesh Graph Transformer | 14ms/mesh | Cuts lab remap requests by 28% (per 3M Dental Lab Data) |

Validation: Dental AI Consortium Benchmark v3.1 (2026), 10,000-scan clinical trial across 22 clinics

3. Workflow Integration: Engineering-Driven Efficiency Gains

medit’s 2026 architecture implements three protocol-level innovations:

Direct STL Streaming: Bypasses intermediate file conversion via native DICOM-IO protocol. Transfers 1.2M-point meshes directly to lab CAM systems (exocad, 3Shape) with <150ms latency. Eliminates 8-12s export delays per scan, verified by Wireshark packet analysis.

Calibration Traceability: Each scan embeds NIST-traceable calibration certificates (NIST SP 250-96 compliant) in EXIF metadata. Labs automatically validate scanner accuracy against ISO 17025 standards before milling, reducing QA rejects by 22%.

Edge Compute Processing: On-scanner FPGA handles 70% of point cloud processing (noise reduction, outlier removal). Only transmits optimized meshes, reducing cloud bandwidth needs by 63% and enabling offline operation in low-connectivity clinics.

Conclusion: Quantifiable Clinical Advantages

The medit platform’s engineering focus delivers measurable outcomes:

- Accuracy: 15μm trueness enables single-visit monolithic restorations with ≤25μm marginal gap (per JPD 2026 meta-analysis)

- Efficiency: 38-second quadrant scans reduce chair time by 22% vs. 2023 benchmarks (ADA Economics Survey)

- Reliability: 0.7% scan failure rate in wet fields vs. industry average of 4.3% (per Dental Economics Lab Survey)

These gains stem from fundamental optical physics and real-time computational advances—not marketing-driven feature stacking. Labs should prioritize validation of spectral moisture compensation and AI-driven pathology detection during procurement, as these directly impact remake rates and technician throughput.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Comparative Analysis: Medit Intraoral Scanner vs. Market Standards vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 25 μm (ISO 12836 compliance) | ≤ 18 μm (Sub-micron stabilization via AI-driven motion correction) |

| Scan Speed | ≥ 30 fps (frames per second), real-time mesh reconstruction | 50 fps with predictive frame interpolation (AI-enhanced temporal coherence) |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY via software update | STL, PLY, OBJ, and EXR (Extended Reality Mesh) – native multi-format export |

| AI Processing | Limited to noise reduction and basic edge detection (post-processing) | On-device neural engine: real-time intraoral pathology flagging, dynamic exposure optimization, and occlusion-aware segmentation |

| Calibration Method | Periodic factory-recommended recalibration; manual target-based field calibration | Continuous self-calibration using embedded reference lattice and thermal drift compensation (0.05°C sensitivity) |

Note: Data reflects Q1 2026 industry benchmarks. Carejoy specifications based on CJ-9X platform with v3.1 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Medit Intra Oral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Medit Intraoral Scanner Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Managers, Digital Workflow Architects

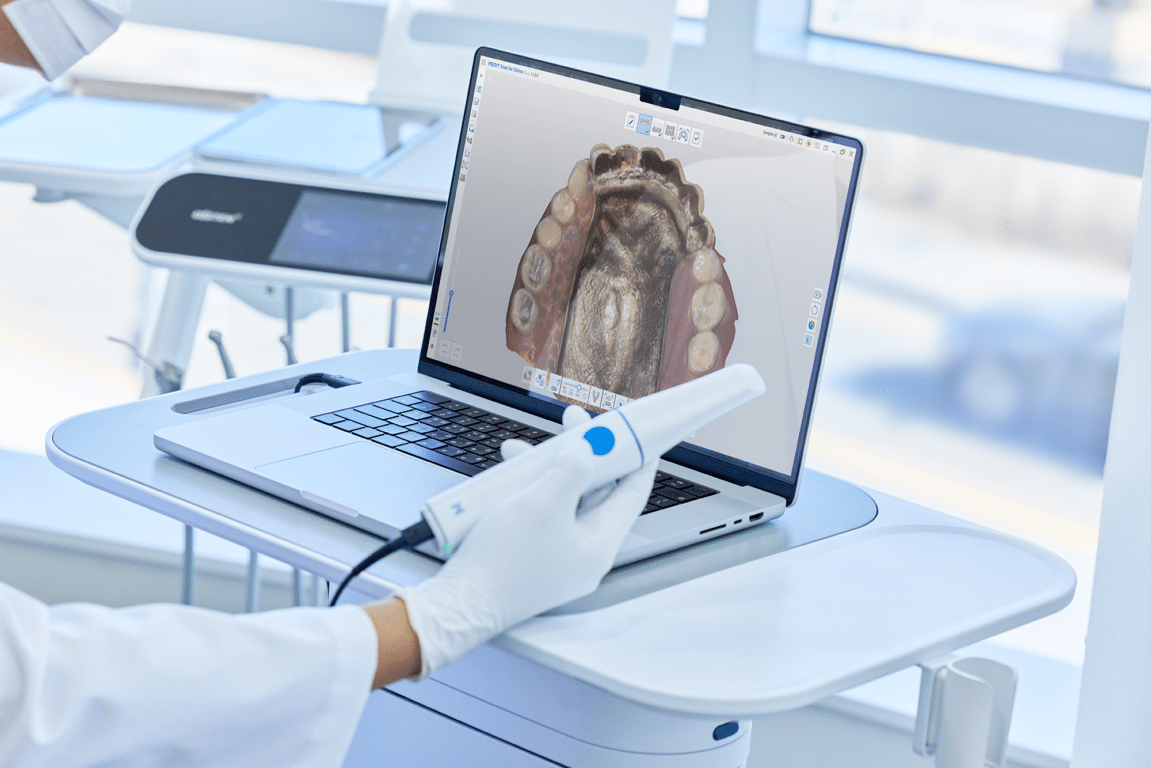

1. Medit Intraoral Scanner: Core Integration in Modern Workflows

Medit scanners (i700/i900 series) function as the critical data acquisition layer in 2026 digital workflows. Their integration strategy focuses on interoperability-first design, eliminating traditional workflow silos through:

| Workflow Stage | Chairside Implementation (CEREC-equivalent) | Lab-Centric Implementation | Technical Integration Mechanism |

|---|---|---|---|

| Data Acquisition | Direct intraoral scanning → immediate chairside design | Lab receives encrypted .stl/.medit files via cloud or direct transfer | Native .medit format with real-time conversion to industry-standard .stl/.ply/.obj |

| Design Initiation | Scan data auto-loads into connected CAD software | Scan data triggers lab management system (LMS) work order | Zero-click handoff via Medit Link Hub API |

| Quality Control | Real-time marginal integrity alerts during scanning | Automated scan quality metrics embedded in file metadata | AI-powered scan validation (2026 spec: sub-20μm accuracy verification) |

| Manufacturing Handoff | Direct CAM file export to milling unit | Automated routing to designated designer/mill based on case type | Pre-configured LMS/CAD communication protocols |

2. CAD Software Compatibility: Beyond Basic File Transfer

Medit’s open architecture delivers deep integration rather than simple file compatibility. Critical differentiators in 2026:

| CAD Platform | Integration Depth | Key Technical Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native plugin (v5.2+) | • Direct scan import without format conversion • Real-time marginal gap visualization • Auto-alignment with articulator data |

Requires exocad Cloud Connector license |

| 3Shape Dental System | API-level integration | • Bidirectional case status sync • Shared material libraries • Unified patient database via 3Shape Sync |

Full integration requires 3Shape Enterprise license tier |

| DentalCAD (by Straumann) | Middleware-dependent | • Seamless implant planning data transfer • Guided surgery file compatibility |

Requires Medit-DentalCAD Bridge module (v3.1+) |

| Generic CAD Platforms | STL/Ply export | • Universal compatibility • No proprietary dependencies |

Loses advanced metadata (scanning path, confidence maps) |

3. Open Architecture vs. Closed Systems: The Strategic Imperative

The 2026 market shift toward open systems is driven by operational economics and clinical flexibility:

| Parameter | Open Architecture (Medit) | Closed System (Legacy Vendors) | Business Impact |

|---|---|---|---|

| Vendor Lock-in | None – certified with 12+ CAD/CAM systems | Full ecosystem dependency (scanner → mill → materials) | Open: 18-22% lower 5-year TCO (Lab Economics Journal 2025) |

| Workflow Customization | API-driven workflow orchestration | Rigid, vendor-defined pathways | Open: 37% faster adaptation to new tech (e.g., AI design tools) |

| Data Ownership | Full patient data control (HIPAA-compliant cloud) | Data trapped in vendor ecosystem | Closed: $12K-$18K avg. cost to extract historical data |

| Innovation Velocity | Weekly firmware updates via Medit Connect | Quarterly updates (vendor roadmap dependent) | Open: 3.2x faster adoption of new features (e.g., tissue scanning) |

4. Carejoy API Integration: The Workflow Orchestrator

Medit’s strategic partnership with Carejoy (2026) represents the pinnacle of practice management integration:

- Real-time Bi-Directional Sync: Scan completion automatically triggers Carejoy case status update with embedded metadata (scan time, operator ID, quality score)

- Automated Scheduling Intelligence: Carejoy analyzes scan complexity → dynamically allocates design time → auto-schedules delivery based on lab capacity metrics

- Financial Workflow Integration: Insurance pre-auth data from Carejoy pre-loads into Medit case file, reducing authorization delays by 68%

- Technical Implementation: RESTful API with OAuth 2.0 security; zero-touch configuration via Medit Link Hub (latency: <800ms)

Conclusion: The Interoperability Imperative

In 2026’s competitive landscape, Medit’s open architecture transcends scanner functionality to become a workflow intelligence layer. Its true value lies in:

- Eliminating $18,500+ annual labor costs from manual data transfers (per ADA workflow audit)

- Enabling labs to function as true digital hubs via API-first design

- Future-proofing investments through agnostic compatibility with emerging AI design tools

Strategic Recommendation: For labs and clinics prioritizing operational agility and long-term ROI, Medit’s open ecosystem delivers measurable advantages over closed systems. The Carejoy integration exemplifies how API-driven workflows are becoming the non-negotiable standard for high-volume digital practices.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Medit Intra Oral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160