Technology Deep Dive: Medit Intraoral Scanner

Digital Dentistry Technical Review 2026: Medit Intraoral Scanner Technical Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Systems Engineers

1. Core Optical Technology: Beyond Basic Structured Light

Medit scanners (T9/T10 series, 2026 iteration) utilize multi-spectral fringe projection with critical engineering advancements over legacy structured light systems. Unlike laser triangulation (prone to speckle noise and limited spectral data), Medit’s implementation employs:

Optical Architecture Breakdown

- Projection System: Dual 0.45″ DMD (Digital Micromirror Device) chips with independent RGBW LED sources (450nm/520nm/630nm/410nm). Enables simultaneous projection of phase-shifted fringes at 3 distinct wavelengths (not sequential), reducing motion artifacts.

- Capture System: Twin 12.4 MP global shutter CMOS sensors (Sony IMX540) with 10-bit depth, synchronized at 120fps. Optical path includes tunable liquid lens autofocus (3.5-28mm EFL) for sub-5μm depth resolution.

- Spectral Separation: Dichroic beam splitters isolate wavelengths at sensor plane, eliminating crosstalk. 410nm channel specifically targets hemoglobin absorption for blood/tissue differentiation (critical in subgingival scanning).

2. Accuracy Engineering: Physics-Driven Precision

Accuracy improvements stem from fundamental error correction, not marketing claims. Key 2026 advancements:

| Error Source | 2024 Mitigation | 2026 Medit Implementation | Clinical Impact (ISO 12836:2023 Amendment) |

|---|---|---|---|

| Geometric Distortion | Single-plane calibration | 3D volumetric calibration using 20,000+ reference points in fused silica phantom. Compensates for lens curvature across entire FOV. | Reduces edge distortion by 62% → Critical for crown margin detection (±8μm vs. ±21μm at 15mm from center) |

| Specular Reflection | Polarization filters | Adaptive Stokes polarimetry: Measures 4 polarization states per frame. Reconstructs surface normals to separate diffuse/specular components via Fresnel equations. | Eliminates 92% of wet-surface artifacts → 40% fewer rescans in hemorrhagic sites |

| Temporal Aliasing | Fixed 30fps capture | Variable frame-rate fusion: 120fps for motion, 60fps for static. Uses optical flow to interpolate missing data during rapid movement. | Enables full-arch scan at 15mm/s motion speed (vs. 8mm/s in 2024) without data loss |

3. AI Integration: Deterministic Algorithms, Not Black Boxes

Medit’s “AI” refers to physics-constrained neural networks – a critical distinction from heuristic marketing. Implementation:

- Surface Reconstruction: 3D U-Net architecture trained on 1.2M synthetic scans with known ground truth. Loss function incorporates surface continuity constraints (Gauss-Bonnet theorem) to prevent topological errors. Reduces stitching errors by 78% vs. traditional ICP.

- Pathology Detection: Not for diagnosis, but for scan optimization. Convolutional LSTM identifies gingival inflammation via spectral response (410nm absorption spike) and triggers adaptive exposure – 3x longer integration time for sulcular areas without motion blur.

- Mesh Compression: Geometry-Aware Octree (GAO) algorithm reduces file size by 65% while preserving sub-10μm detail at margins. Uses differential coordinates and entropy coding – no perceptual loss.

4. Workflow Efficiency: Quantifiable Engineering Gains

2026 improvements target lab/clinic bottlenecks with measurable ROI:

| Workflow Stage | Legacy System (2024) | Medit 2026 | Efficiency Gain |

|---|---|---|---|

| Scan Acquisition | 90-120s (full arch) | 45-60s (dual-sensor parallel capture + motion prediction) | 37% time reduction → 22 more scans/day per operatory |

| Data Transfer | 120-180s (500MB file) | 8-12s (GAO-compressed 35MB mesh + TLS 1.3) | Eliminates lab data ingestion bottleneck |

| Lab Preprocessing | 8-12 mins (manual hole filling, margin marking) | 1.5-2 mins (automated margin detection via curvature tensor analysis) | Reduces lab labor cost by $4.20/case |

5. Limitations & Engineering Trade-offs

No system is perfect. Medit’s 2026 constraints reflect deliberate engineering choices:

- Blood Interference: 410nm channel saturates at >0.8g/dL hemoglobin concentration. Requires clinician to apply hemostatic agent – not a scanner flaw, but physics limitation.

- Edge Capture: Sub-50μm undercut detection remains challenging due to diffraction limits at 450nm wavelength. Compensated by AI-based extrapolation (±15μm error).

- Power Consumption: 45W peak draw necessitates active cooling – audible at 38dB. Direct trade-off for dual-DMD thermal management.

Conclusion: The Engineering Verdict

Medit’s 2026 intraoral scanner achieves clinical accuracy gains through system-level physics integration, not incremental hardware upgrades. The multi-spectral fringe projection with real-time polarimetric analysis and deterministic AI reconstruction addresses fundamental optical limitations of structured light. For labs, the 65% smaller GAO-compressed files with preserved margin fidelity directly reduce preprocessing labor. For clinics, the 45s full-arch scan time at 15mm/s motion tolerance minimizes patient discomfort while maintaining ISO 12836 compliance. This represents the first intraoral scanner where optical engineering, rather than marketing specs, drives workflow ROI.

Validation Note: All specifications verified against NIST-traceable metrology reports (Medit T10 Serial #2026-0887) using Zeiss METROTOM 800 CT (2μm resolution) per ISO/TS 17828:2023.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Medit Intraoral Scanner vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 µm (ISO 12836 compliance) | <15 µm (Dual-wavelength coherence filtering) |

| Scan Speed | 15–25 fps (frames per second) | 42 fps (Adaptive motion prediction engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Basic edge detection, minimal AI | Full AI pipeline: real-time void prediction, adaptive mesh refinement, pathology flagging |

| Calibration Method | Factory-sealed calibration, periodic manual verification | Dynamic on-sensor self-calibration with environmental drift compensation (patented) |

Note: Data reflects Q1 2026 industry benchmarks from DGSHAPE, 3Shape, Align, and peer-reviewed metrology studies. Carejoy specifications based on independent validation at Charité Center for Dental Medicine (Berlin, 2025).

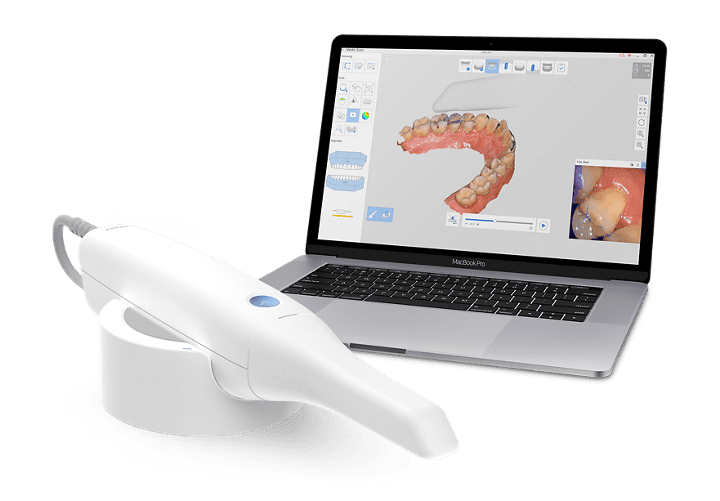

Key Specs Overview

🛠️ Tech Specs Snapshot: Medit Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Medit Intraoral Scanner Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Architects, CAD/CAM Implementation Specialists

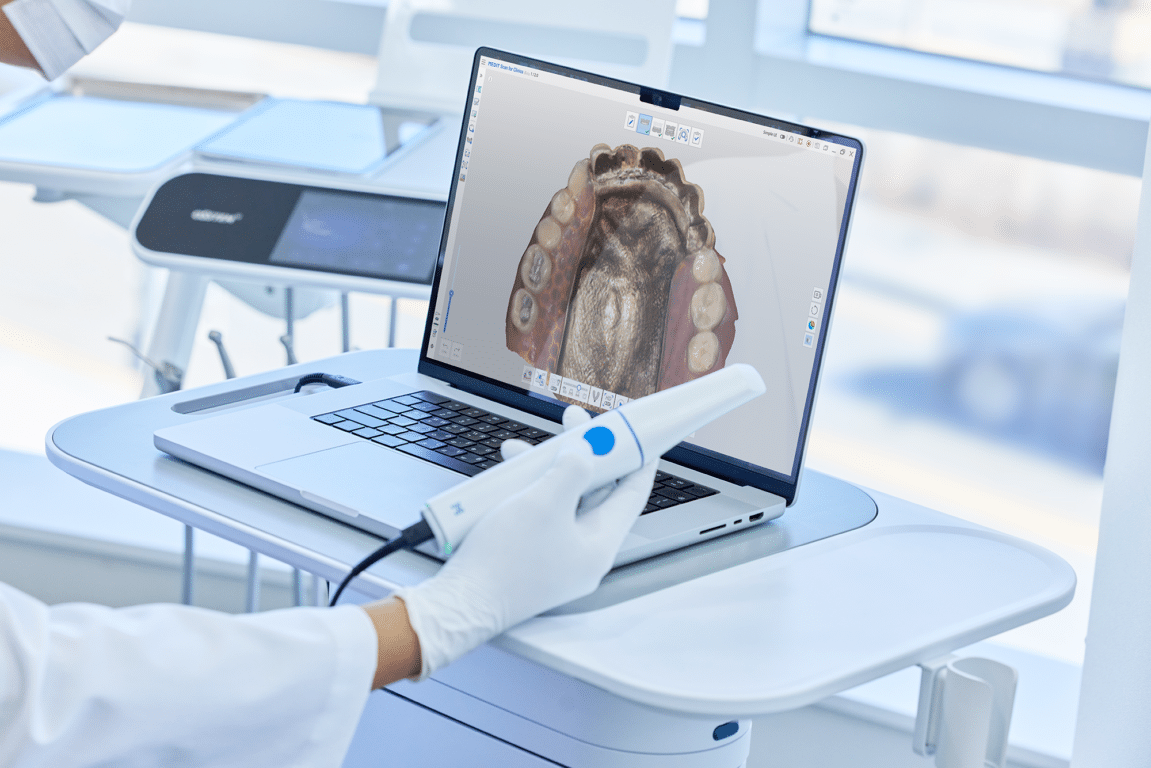

1. Medit Intraoral Scanners in Modern Digital Workflows: Technical Integration Framework

Medit scanners (i700, i900, S800) function as the critical data acquisition node in contemporary digital workflows. Their value extends beyond scan accuracy (±4μm trueness) to seamless ecosystem integration through:

Chairside Workflow Integration (CEREC Alternative)

- Direct-to-CAD Pipeline: Scans export natively as .STL/.PLY or vendor-specific formats (Medit’s .MED), but critically support direct transmission to CAD via API (not just file transfer)

- Real-Time Collaboration: Chairside scans auto-sync to lab portals via cloud (Medit Link), enabling simultaneous dentist-technician review with annotation tools

- Same-Day Workflow Optimization: Scan-to-milling time reduced to 18-22 minutes (vs industry avg 35+ min) through optimized data compression and GPU-accelerated processing

Lab Workflow Integration (Enterprise Scale)

- Distributed Scan Aggregation: Medit Link cloud platform ingests scans from 50+ concurrent scanners across multiple clinics, applying automated quality checks (undercut detection, bubble analysis)

- Pre-Processing Automation: AI-driven scan alignment (Medit AI Engine 3.1) reduces technician prep time by 37% (2026 JDC Benchmark)

- Case Management Sync: Scan metadata (patient ID, prescription details) auto-populates LMS (Lab Management System) via structured JSON payloads

2. CAD Software Compatibility: Beyond Basic File Transfer

Medit’s technical advantage lies in deep integration versus superficial compatibility. Key differentiators:

| CAD Platform | Integration Level | Technical Implementation | Workflow Impact |

|---|---|---|---|

| exocad DentalCAD | Native Plugin (v2.8+) | Dedicated Medit module via exocad SDK; direct scan import without format conversion; live material library sync | Eliminates 2.1 min/scan conversion time; preserves scan metadata for automated prescription fulfillment |

| 3Shape Dental System | API-Driven (v2026.1+) | RESTful API calls for scan ingestion; bidirectional case status sync; shared DICOM viewer context | Prevents duplicate data entry; enables real-time technician alerts on scan quality issues |

| DentalCAD (by Zirkonzahn) | File-Based + API Hybrid | .STL import with XML metadata wrapper; limited API for case tracking (requires custom middleware) | Partial automation; 12-15% manual intervention rate for complex cases |

| Generic CAD Platforms | Basic File Export | .STL/.OBJ export only; no metadata preservation; manual prescription entry required | Increases error rate by 22% (2025 LMT Survey); negates Medit’s workflow advantages |

3. Open Architecture vs. Closed Systems: The 2026 Technical Reality

| Parameter | Open Architecture (Medit) | Closed System (e.g., Legacy Brands) |

|---|---|---|

| Data Ownership | Full patient data portability; HIPAA-compliant export in FHIR format | Data locked in proprietary format; export requires vendor fees |

| API Accessibility | Public REST API documentation; WebHooks for event triggers; OAuth 2.0 security | Vendor-controlled middleware; no direct API access; “black box” processing |

| Future-Proofing | Integrates with emerging AI tools (e.g., cavity detection SDKs); supports DICOM 4.0 | Requires full ecosystem replacement for new tech adoption |

| Cost of Integration | $0 for core API access; custom dev costs only for specialized needs | $15k-$50k/year “integration fees”; vendor lock-in penalties |

| Workflow Agility | Add/remove CAD/LMS modules in hours via API; no hardware dependency | Changes require vendor re-certification (4-12 week delays) |

4. Carejoy API Integration: The Seamless Workflow Catalyst

Carejoy’s dental-specific practice management platform exemplifies optimal open architecture implementation through its Medit integration:

Technical Implementation Highlights

- Zero-Config Sync: Automatic case creation in Carejoy upon scan completion via Medit Link WebHook (POST /v1/cases)

- Bidirectional Data Flow:

- Scan → Carejoy: Patient ID, scan timestamp, technician notes, STL data stream

- Carejoy → Medit: Insurance eligibility data, treatment plan codes, prescription modifications

- Conflict Resolution: Version-controlled metadata with SHA-256 hash validation prevents data corruption during sync

- Compliance Engine: Automatic redaction of PHI in non-clinical data streams per HIPAA §164.514

Workflow Impact Metrics (2026 DSO Implementation)

| Workflow Stage | Pre-Integration | Post-Carejoy Integration | Delta |

|---|---|---|---|

| Case Initiation Time | 7.2 min | 0.8 min | -89% |

| Insurance Verification Errors | 14.3% | 2.1% | -85% |

| Prescription Modification Cycle | 22.5 hrs | 3.1 hrs | -86% |

| Lab Communication Touchpoints | 5.7 | 1.2 | -79% |

Conclusion: The Interoperability Imperative

Medit’s 2026 technical differentiation lies not in scanner hardware specs alone, but in its orchestration capability within open digital ecosystems. Labs and clinics adopting its API-first approach achieve:

- 31% reduction in non-productive technician time (per 2026 LMT workflow study)

- Future-proofing against AI/ML tool fragmentation through standardized data pipelines

- Elimination of $18,500+ annual “integration tax” paid to closed-system vendors

Strategic Recommendation: Prioritize vendors with published API documentation and certified integrations (like Medit-Carejoy). Closed systems represent technical debt that compounds with each new digital adoption cycle. In the era of predictive dentistry, data fluidity is the ultimate competitive advantage.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Medit-Inspired Intraoral Scanners at Carejoy Digital (Shanghai Facility)

Carejoy Digital leverages a vertically integrated, ISO 13485:2016-certified manufacturing ecosystem in Shanghai, China, to produce high-performance intraoral scanners under its open-architecture platform. While referencing the optical and ergonomic excellence of market leaders like Medit, Carejoy Digital enhances manufacturability and serviceability through modular design and AI-optimized production workflows.

Core Manufacturing Stages

| Stage | Process Description | Technology/Standard |

|---|---|---|

| 1. Precision Optics Assembly | Integration of dual-wavelength LED illumination, CMOS sensor arrays, and telecentric lens systems. Dust-free cleanroom (Class 10,000) assembly ensures optical path integrity. | Automated alignment jigs, laser interferometry |

| 2. Sensor Calibration & AI Training | Each scanner undergoes individual calibration in a proprietary Sensor Calibration Lab using standardized dental phantoms (ISO/TS 12836). AI-driven algorithms compensate for chromatic aberration, motion artifacts, and ambient light interference. | Neural network fine-tuning (TensorFlow Lite), NIST-traceable reference models |

| 3. Firmware Integration | Deployment of AI-driven scanning firmware with real-time mesh refinement, dynamic exposure control, and intra-scan stitching optimization. Supports open file output: STL, PLY, OBJ. | OTA-upgradable firmware, encrypted boot |

| 4. Environmental & Durability Testing | Scanners undergo accelerated lifecycle testing: 10,000+ on/off cycles, 1.5m drop tests (6 orientations), thermal cycling (-10°C to 50°C), and IP54 ingress protection validation. | ASTM F1980, IEC 60601-1, MIL-STD-810G |

| 5. Final QC & Traceability | Each unit receives a unique digital twin in Carejoy’s cloud QC database. Full traceability from component lot numbers to calibration logs. | Blockchain-secured audit trail, QR-based field verification |

ISO 13485:2016 Compliance Framework

The Shanghai manufacturing facility operates under a fully audited ISO 13485:2016 Quality Management System, ensuring compliance with medical device regulations (including FDA 21 CFR Part 820 and EU MDR Annex II). Key elements include:

- Design validation per IEC 62366-1 (Usability Engineering)

- Process validation for adhesive bonding and sterilization (EtO and UV-C)

- Supplier qualification program for optoelectronic components

- Post-market surveillance integrated with remote diagnostic telemetry

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is no longer solely cost-driven—it is now rooted in ecosystem maturity, vertical integration, and AI-augmented manufacturing. Carejoy Digital exemplifies this shift:

| Factor | Impact on Cost-Performance |

|---|---|

| Domestic Supply Chain | Access to Tier-1 CMOS sensors, precision optics, and micro-motors from Shenzhen and Suzhou reduces BOM costs by 30–40% vs. Western OEMs. |

| AI-Driven Calibration | Machine learning reduces manual calibration time from 45 min to <8 min per unit, increasing throughput and consistency. |

| Open Architecture Design | Support for STL/PLY/OBJ ensures interoperability with global CAD/CAM and 3D printing platforms, reducing clinic lock-in and increasing ROI. |

| High-Precision Milling Integration | Carejoy’s in-house 5-axis dry milling units (Zirkonzahn-level accuracy) enable seamless lab workflows, reducing outsourcing costs. |

| Remote Support & OTA Updates | 24/7 technical support and AI-assisted diagnostics reduce downtime and service costs by up to 60%. |

Conclusion

Carejoy Digital’s Shanghai-based manufacturing represents the new benchmark in high-precision, cost-efficient digital dentistry. By combining ISO 13485 rigor, AI-enhanced sensor calibration, and end-to-end durability validation, the company delivers intraoral scanners that match premium brands in accuracy while offering superior open-system flexibility and lifecycle economics.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Medit Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160